www.danfoss.com DKCD 5/2002

Temperature setting

Set room temperature on the thermostat dial. On

the right-hand side of the thermostat is a func-

tion switch with 3 possible settings:

Sun

:The room temperature will be as set on the

thermostat.

Clock

: Used only if the zone regulator is en-

gaged.The temperature will be as set on the

room thermostat, but in accordance with the

consumption pattern entered.

The consumption pattern in the zone regulator

can be overridden by moving the switch to sun or

moon.

Moon

:The room temperature will be as set on

the thermostat - minus 5°C.

Limitation of the setting range

Behind the button for temperature setting are two

lock-pins.These can be placed in the setting

knob as shown in fig. 4 if the thermostat setting

range is to be narrowed.

Putting into operation

Each room thermostat has a unique ID number

preventing conflicts with other thermostats.

A single room thermostat is capable of regulating

several heating outputs, provided these outputs

are assigned to the thermostat.

Assigning thermostats to output(s)

-The installation cable between room thermostat

and CFM (fig. 2) must be connected in assigning

each thermostat to the respective output(s).

-IntheLED array the firstavailable output will

flash. The LED in the CFR will also flash. Out-

puts already assigned will not be lit (fig. 2). By

pressing OK the thermostat will be assigned to

that output. If the room thermostat is to be as-

signed under another lit output, scroll to the out-

put bymeans of the +/- keys,then press OK.

-When the installation cable is removed, the red

LED behind the front panel (fig. 4) will flash for at

least 4 minutes.See “Test of room thermostat”

Removal of assigned thermostat

-It is not necessary to have the installation

cable in place when removing an assigned ther-

mostat. Once a thermostat has been removed, it

may be reassigned to another output.

-Removal of room thermostat is done by pressing

OK for 5 seconds, then the entire LED array will

be lit. Scroll to the specific room thermostat to

be removed with the +/- button,and press OK for

5 seconds. The thermostat has now been re-

moved.

Test of room thermostat

If a defect in a room thermostat is suspected, the

following test may be carried out:

- Set the thermostat to the highest temperature.

- Move the function switch on the side of the

room thermostat to a new position.

- If the LED behind the front panel (fig. 4)

flashes quickly for 4 minutes, the room thermo-

stat is OK.

Battery change

If the battery is getting low, the LED will flash 6

times every 6 seconds. See fig. 4.

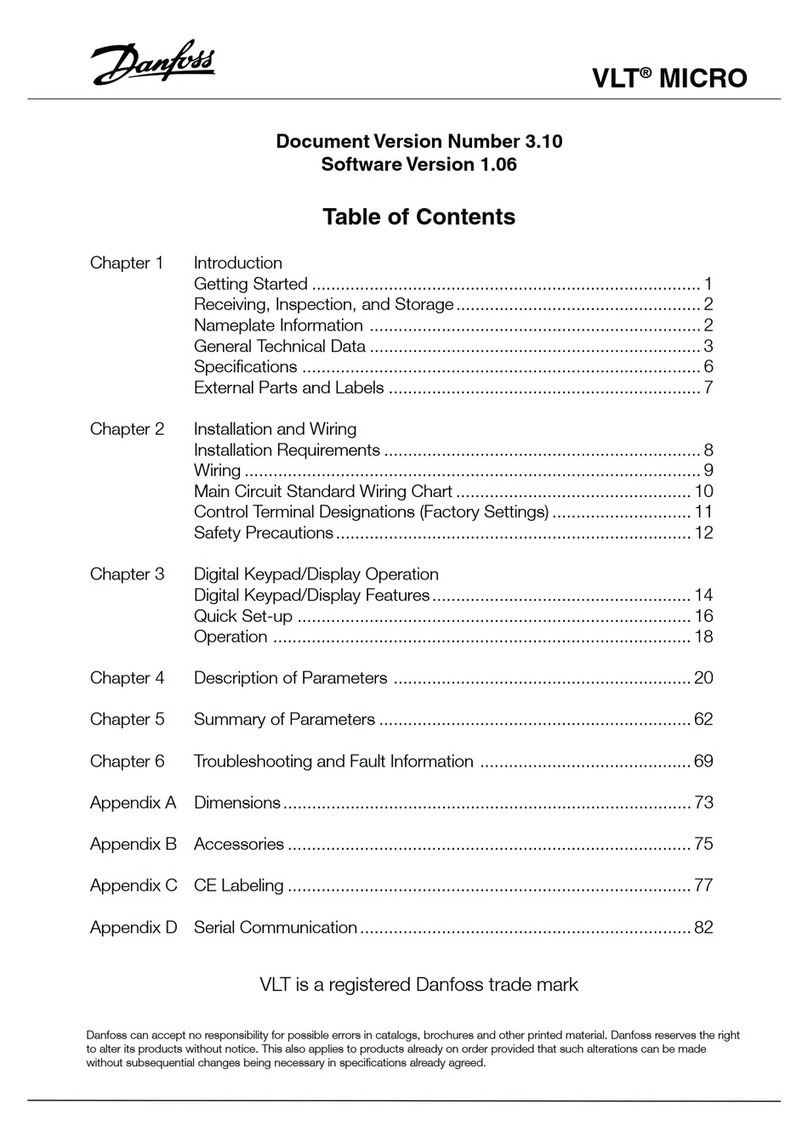

Master regulator CFM

This regulator governs the individual heat cir-

cuits via wireless communication with the asso-

ciated room thermostats. Connection of 8 heat

circuits is enabled.

If more heat circuits are required, connect one

or max. two slave regulators CFS, each with

connection for 8 circuits.This allows max.24

heat circuits to be governed.

The master/slave is to be fitted immediately

above the distributor pipe on the wall or in a dis-

tribution cabinet. Easy access to plugs and ter-

minals should be ensured.See instruction draw-

ing on the opposite page.

If two slave regulators are connected, move the

jumper in “slave 2” to position 2.See instruction

drawing.

The connection cable for the slave regulator is 1

m.Cable lengths of up to 100 m are enabled

(available from your electrical items wholesaler)

Alarm

There are 2 options with respect to alarms given

by the master regulator:

-Integral acoustic signal can be selected by

moving the jumper marked “buzzer” from OFF

to ON.See installation drawing.

-External alarm generator can be connected to

the output marked .

Technical data

Max.ambient temperature 60°C.

Enclosure IP40

Zone regulator CFZ

The zone regulator governs a maximum of 6

heat zones.For each heat zone, individual tim-

ing programmes can be connected.For reading

and operating convenience, it is recommended

to place the regulator at eye height.

The connection cable is 5 m.Cable lengths up

to 100 m are permitted (available from your

electrical items supplier).

Troubleshooting

Appearance Problem Reason/cause Solution Comments

CFM controller out-

put array blinks

specifically from a

row and column(s)

Alarm symbol in

zone controller,

CFZ flashes

Acoustic alarm

buzzes (provided

jumper is set to

“ON”)

Master or slave

controller row(s)

and entire columns

lit on master output

array

Constant light in

LED array

LED on back of

room thermostat

does not blink dur-

ing test mode

All output LEDs are

unresponsive

CFM controller out-

put array blinks rap-

idly 3 times specifi-

cally from a row

and column(s)

Lack or ex-

cessive heat

to floor heat-

ing system

Room tem-

perature is

below 6oC

(43oF)

No heat

No heat

Lack or ex-

cessive heat

to floor heat-

ing system

No heat

None

Distance between room and

master is too far.

Degradation of signal due to

reinforced concrete or foil

faced insulation between

floors.

External antenna mounted

close to metal parts or wires.

Master control is placed in

metal enclosure.

Interference from electronic

equipment using the same

frequency, 433.92Mhz (i.e.

baby monitors, portable or

wireless headphones)

Low battery

Problem in heating system

or signal to thermostat

Blown fuse in master/slave

Loose wire connection be-

tween master and slave con-

troller

Defective zone actuator

Lack of heated fluid to sys-

tem

Faulty battery

Bad contacts between bat-

tery and thermostat

Defective room thermostat

Improper wiring

Master controller is defective

Normal operation during test

of room thermostat

Reposition thermostat in

room until signal is clear.

Reposition external an-

tenna, however if signal is

still unclear move external

antenna to the

same floor as

thermostat(s)

Reposition room thermo-

stat and run test mode

Mount external antenna if

not already installed.

Eliminate interfering elec-

tronic equipment

Replace battery and test

thermostat

Check heating supply to

the system and the circu-

lator pump

Check master control,

CFM, is properly wired.

First check actuators for

proper wiring then re-

place fuse in

master/slave controller,

1.25A

Check wire and connec-

tion between master and

slave

Replace zone actuator

Check heating supply to

the system and the circu-

lator pump

Replace battery/

Adjust connection in ther-

mostat to ensure better

contact to battery

Replace room thermostat

Check wiring of power to

CFM

Replace master control-

ler.

If signal is

continuosly

poor contact

Danfoss

Max. load for

CFM 6W,

max. Load

for CFS 3W

Installation and operation Wireless floorheating controller and room thermostat, type CF