Contents

1About this document........................................................................................... 7

1.1 Target groups................................................................................................7

1.2 Storage.........................................................................................................8

1.3 Name plate ...................................................................................................9

1.4Abbreviations................................................................................................9

2Safety instructions............................................................................................ 10

2.1 Presentation of warnings ............................................................................10

2.2 Intended use...............................................................................................10

2.3 Product-specific risks..................................................................................12

2.3.1 Risks imposed by mechanical equipment........................................ 12

2.3.2 Risks imposed by hydraulic equipment............................................ 12

2.3.3 Risks imposed by substances .........................................................13

2.3.4 Risks imposed by noise...................................................................13

2.3.5 Risks in case of fire..........................................................................13

2.4 Safety..........................................................................................................14

2.4.1 Working area...................................................................................14

2.4.2 Protection equipment.......................................................................14

2.4.3 Warning signs on the machine ........................................................ 16

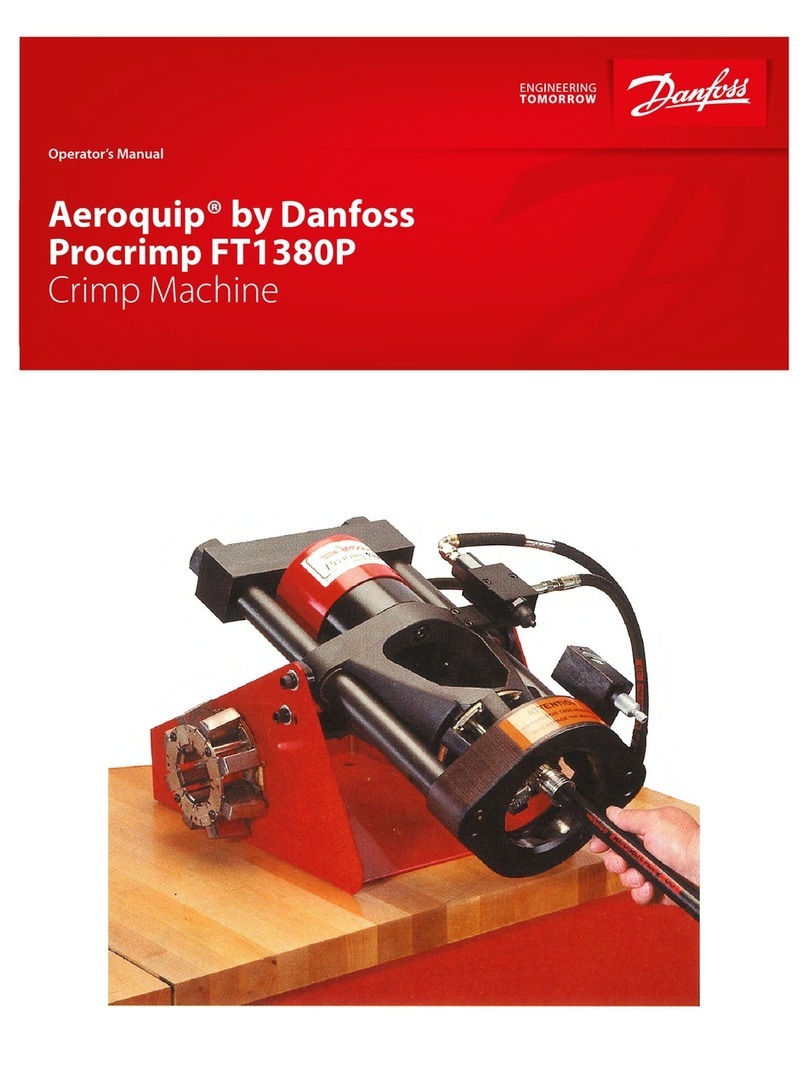

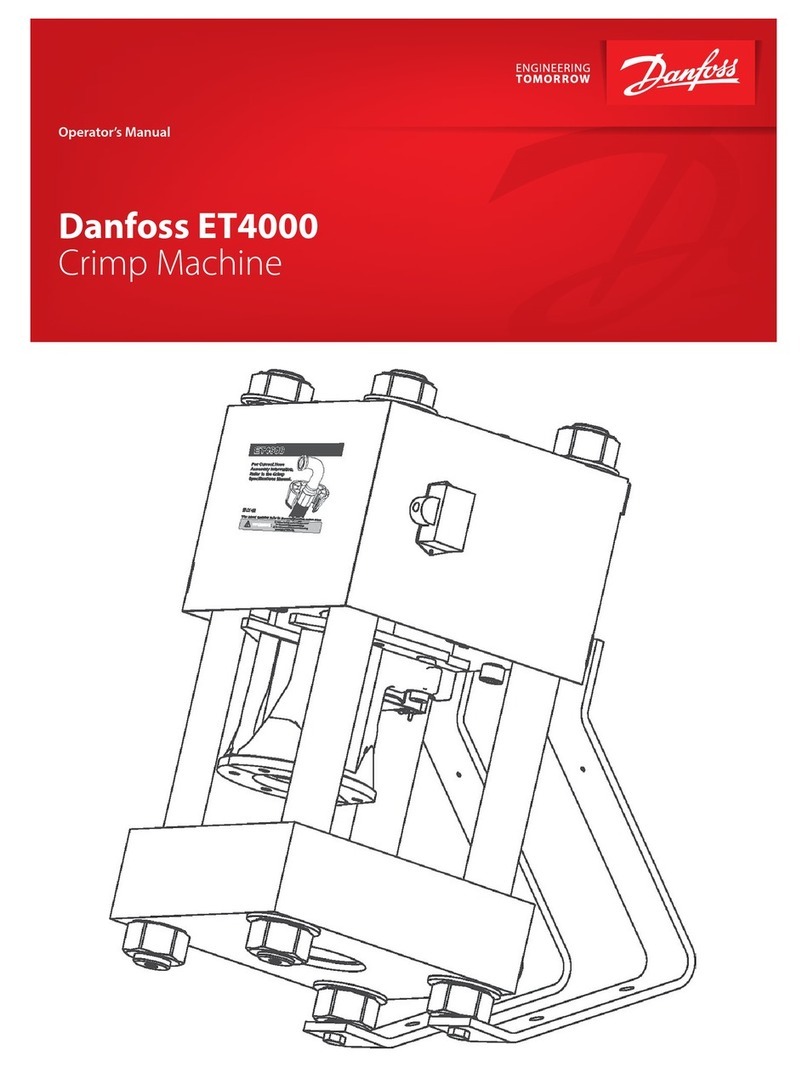

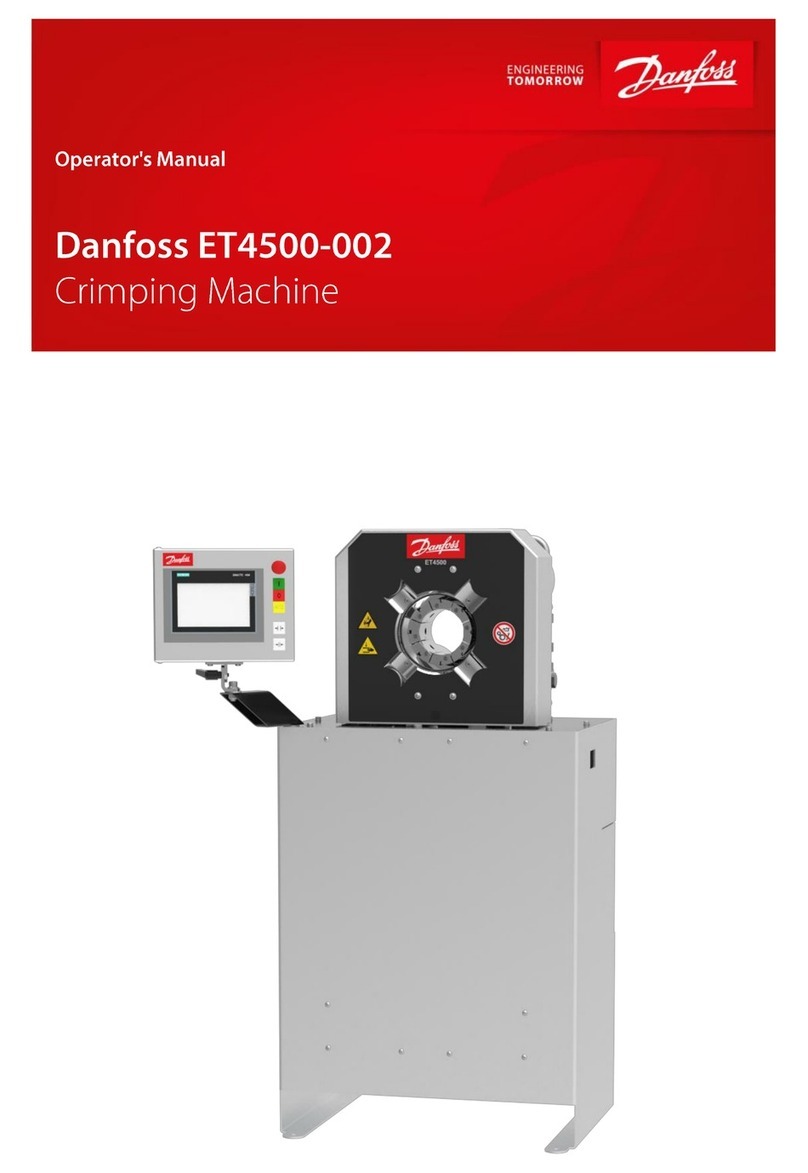

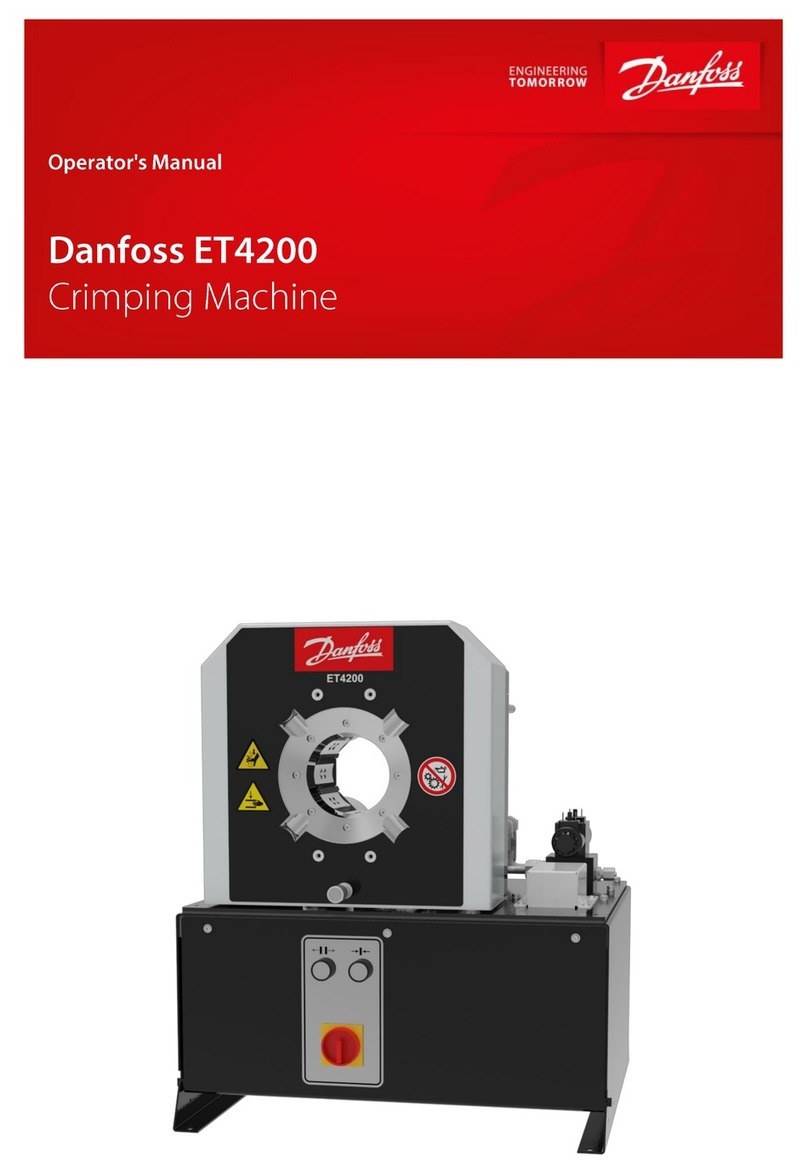

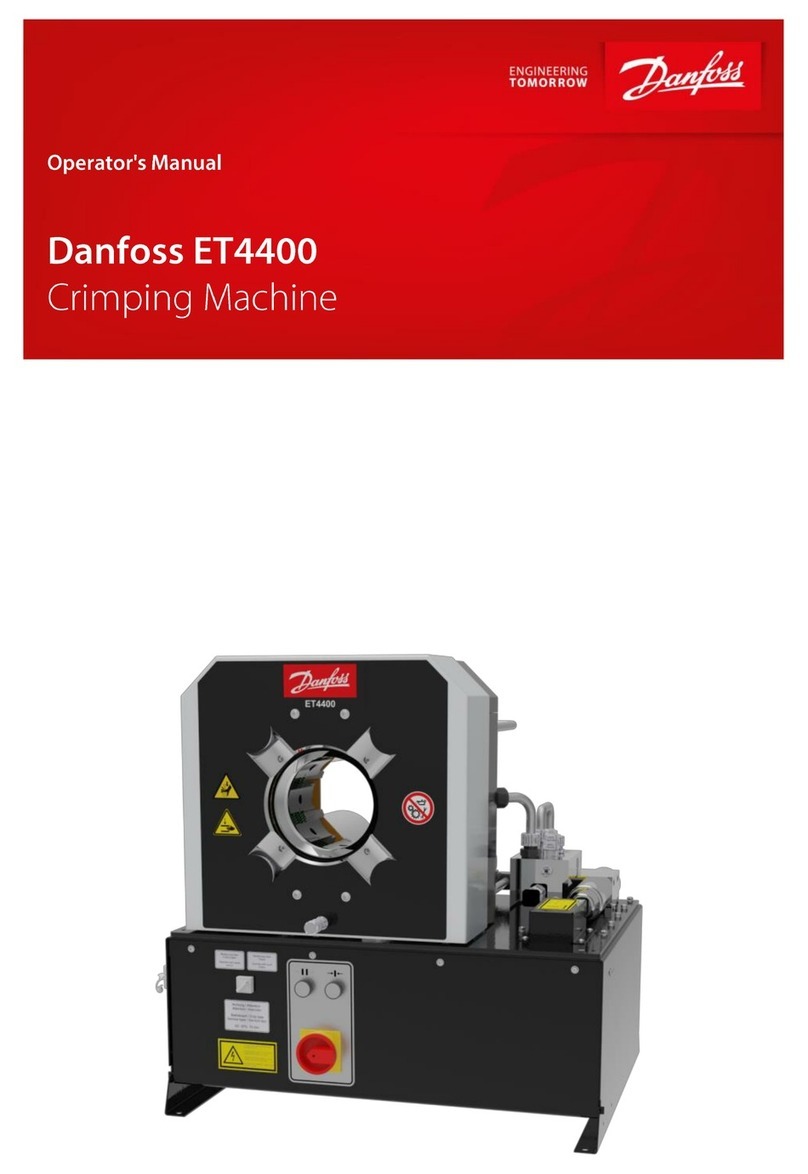

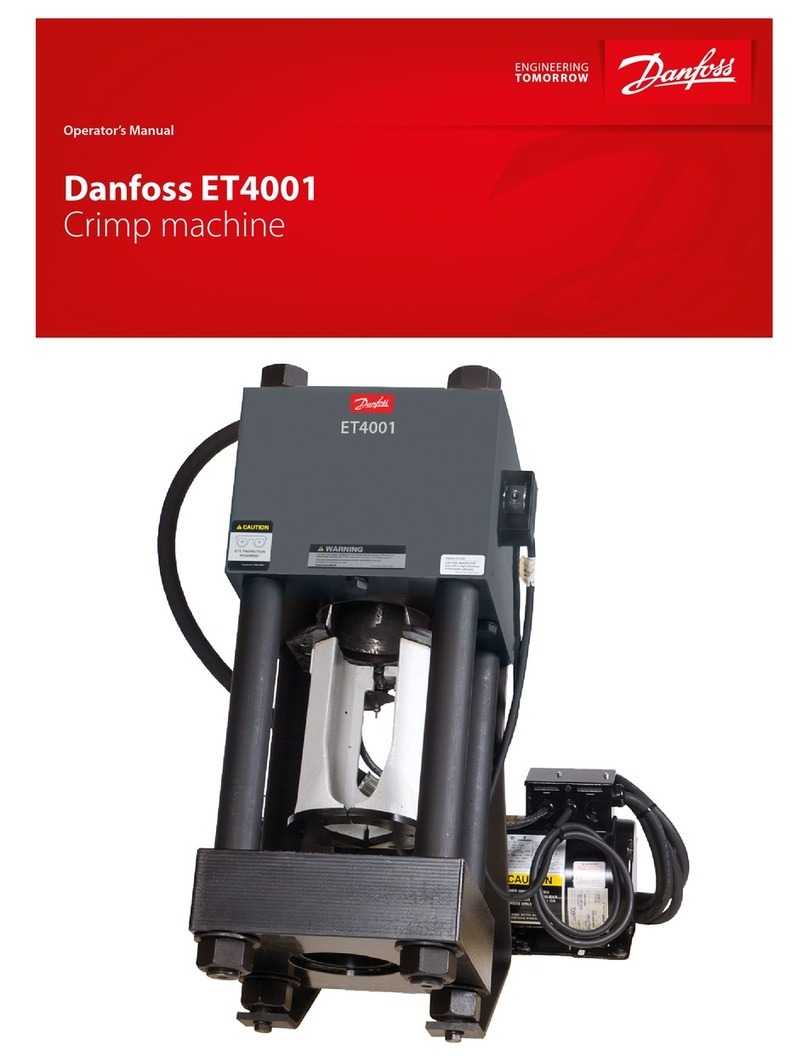

3Machine description.......................................................................................... 17

3.1 Design and function.................................................................................... 17

3.2 Forming process.........................................................................................18

3.3 Technical data............................................................................................. 20

4Transport and commissioning......................................................................... 23

4.1 Transport ....................................................................................................23

4.2 Intermediate storage of machine/unit.......................................................... 24

4.3 Commissioning ...........................................................................................24

4.4 Mounting the telescopic handle ..................................................................25

4.4.1 Filling hydraulic oil ...........................................................................26

5Operation ........................................................................................................... 28

5.1 What you have to observe..........................................................................28

5.2 Forming the workpiece................................................................................28

5.2.1 Prerequisites....................................................................................28

5.2.2 Hand pump operation mode............................................................29