•

•

•

•

•

•

1 Introduction

1.1 Purpose of this Design Guide

This Design Guide is intended for qualified personnel, such as:

Project and systems engineers.

Design consultants.

Application and product specialists.

The Design Guide provides technical information to understand the capabilities of the VLT® Flow Drive FC 111 for integration into

motor control and monitoring systems. Its purpose is to provide design considerations and planning data for integration of the

drive into a system. It caters for selection of drives and options for a diversity of applications and installations. Reviewing the de-

tailed product information in the design stage enables developing a well-conceived system with optimal functionality and efficien-

cy.

This manual is targeted at a worldwide audience. Therefore, wherever occurring, both SI and imperial units are shown.

VLT®is a registered trademark for Danfoss A/S.

1.2 Additional Resources

1.2.1 Other Resources

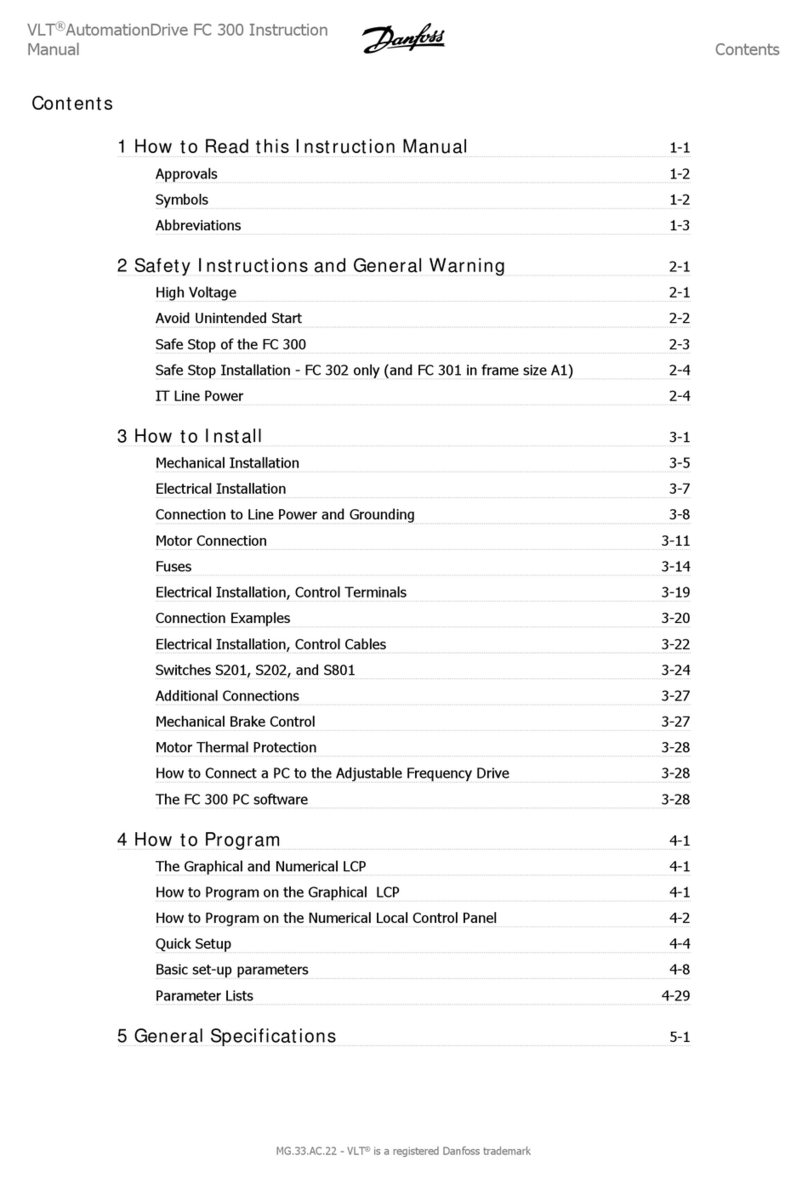

Other resources are available to understand advanced drive functions and programming.

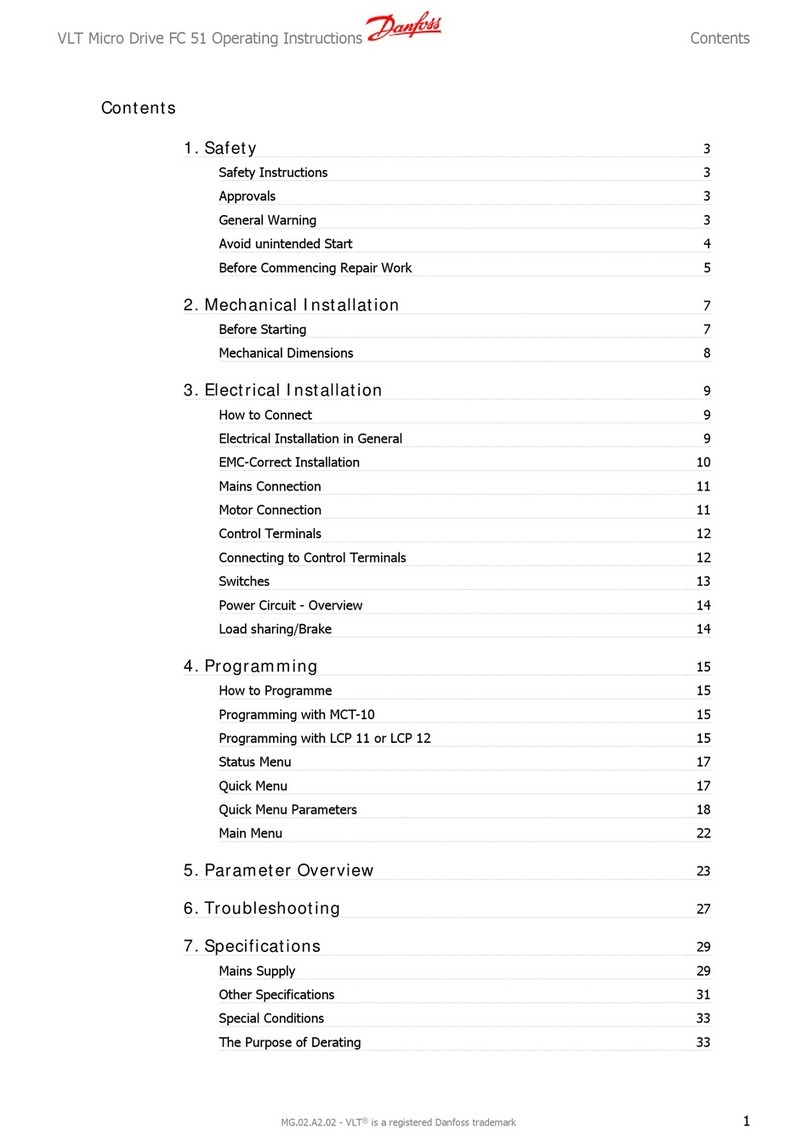

VLT® Flow Drive FC 111 Operating Guide provides basic information on mechanical dimensions, installation, and programming.

VLT® Flow Drive FC 111 Programming Guide provides information on how to program, and includes complete parameter de-

scriptions.

Danfoss VLT® Energy Box software. Select PC Software Download at www.danfoss.com.

VLT® Energy Box software allows energy consumption comparisons of HVAC fans and pumps driven by Danfoss drives and alterna-

tive methods of flow control. Use this tool to accurately project the costs, savings, and payback of using Danfoss drives on HVAC

fans, pumps, and cooling towers.

Supplementary publications and manuals are available from Danfoss website www.danfoss.com.

1.2.2 MCT 10 Set-up Software Support

Download the software from the service and support section on www.danfoss.com.

During the installation process of the software, enter access code 81462700 to activate the VLT® Flow Drive FC 111 functionality. A

license key is not required for using the VLT® Flow Drive FC 111 functionality.

The latest software does not always contain the latest updates for drives. Contact the local sales office for the latest drive updates (in

the form of *.OSS files).

1.3 Document and Software Version

This guide is regularly reviewed and updated. All suggestions for improvement are welcome.

The original language of this manual is English.

Table 1: Document and Software Version

AJ363928382091, version 0101

1.4 Regulatory Compliance

1.4.1 Introduction

AC drives are designed in compliance with the directives described in this section.

1.4.2 CE Mark

The CE mark (Communauté Européenne) indicates that the product manufacturer conforms to all applicable EU directives. The EU

directives applicable to the design and manufacture of drives are listed in the following table.

AJ363928382091en-000101 / 130R098310 | Danfoss A/S © 2021.04

Introduction

VLT® Flow Drive FC 111

Design Guide