VLT

®

AutomationDrive EtherNet/IP

MG.90.J1.02 – VLT is a registered Danfoss trademark

1

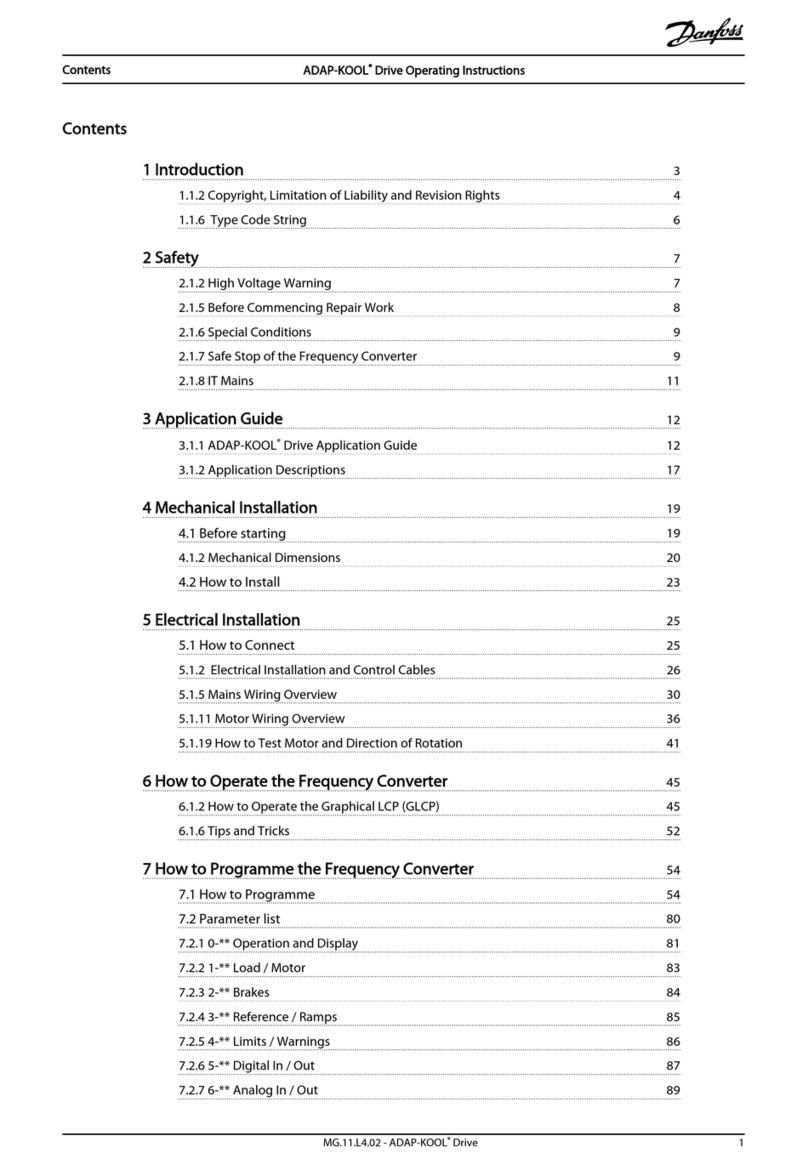

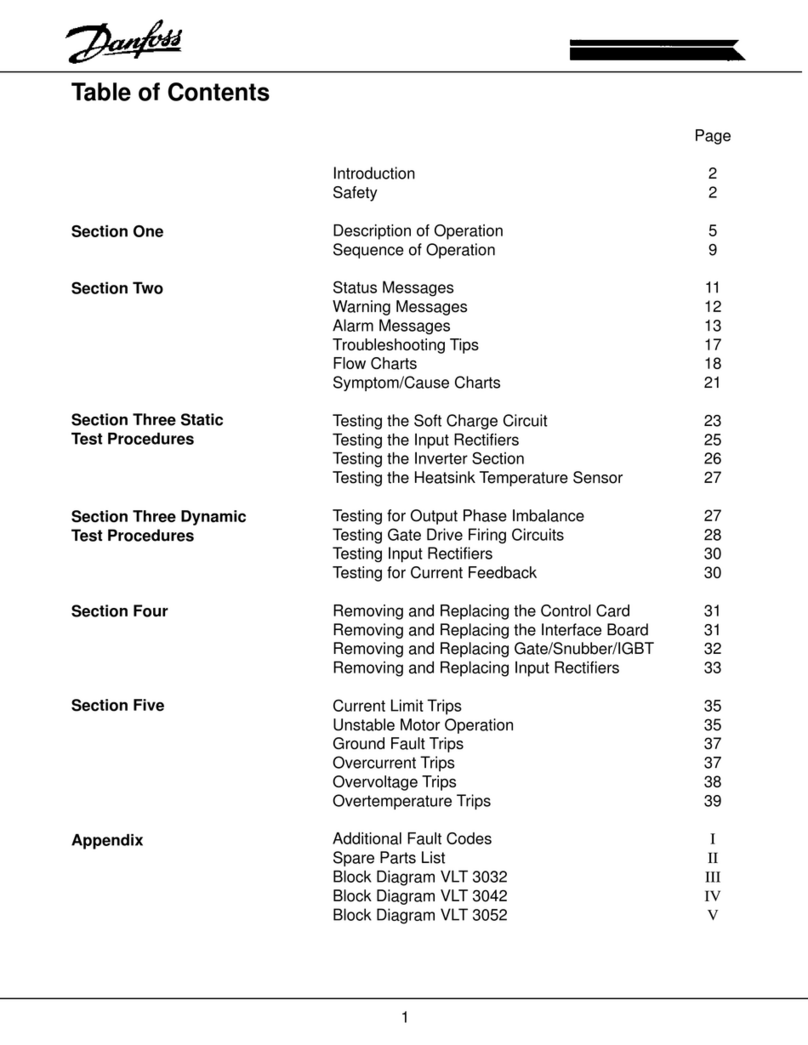

Contents

Safety Note ................................................................................................................... 3

Introduction ........................................................................................................................... 4

About this Manual........................................................................................................... 4

Technical Overview ......................................................................................................... 5

Assumptions.................................................................................................................. 5

Hardware ...................................................................................................................... 5

Background Knowledge.................................................................................................... 5

FC 300-related Literature ................................................................................................. 5

ODVA Conformance......................................................................................................... 5

Abbreviations................................................................................................................. 6

How to Install......................................................................................................................... 7

The EtherNet/IP Option.................................................................................................... 7

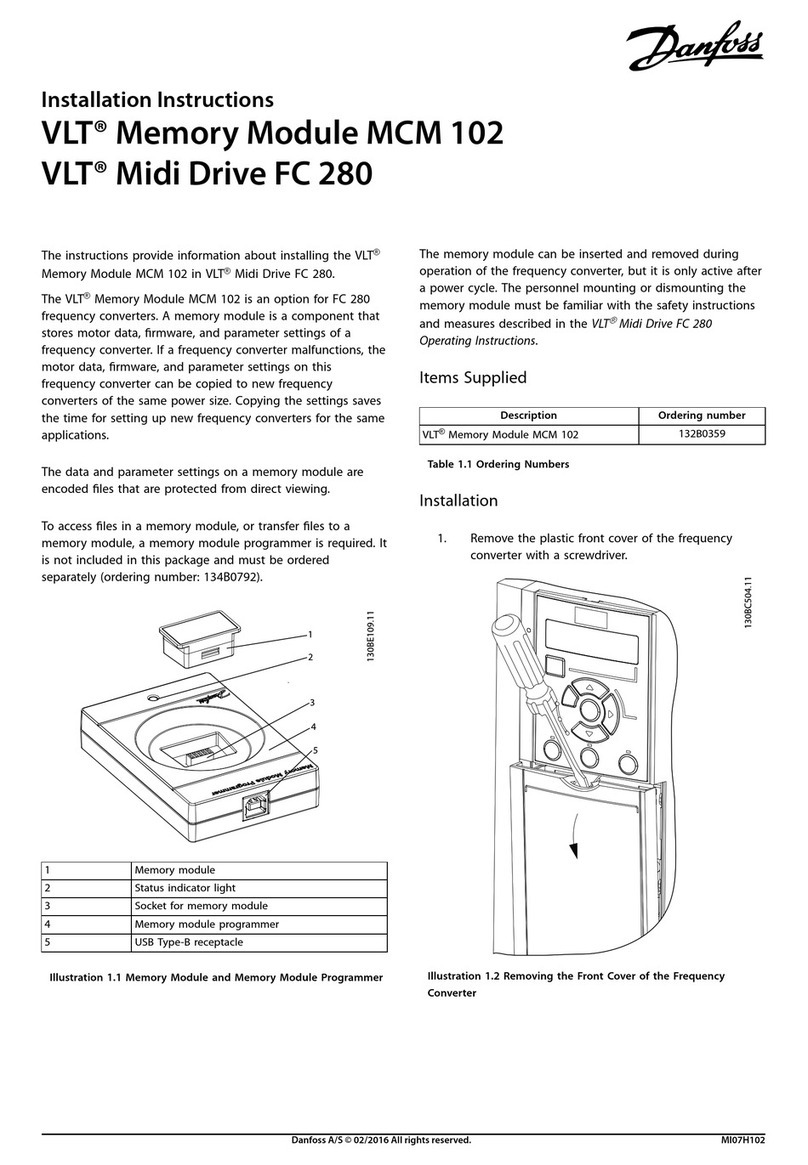

How to Install Option in Frequency Converter....................................................................... 8

LED Behaviour ............................................................................................................... 9

Topology..................................................................................................................... 10

Network...................................................................................................................... 11

Recommended Design Rules ........................................................................................... 12

EMC Precautions........................................................................................................... 13

How to Configure the System............................................................................................... 14

IP Settings .................................................................................................................. 14

Ethernet Link Parameters ............................................................................................... 16

Configuring the Scanner................................................................................................. 17

IP traffic......................................................................................................................19

How to Control the FC 300 ................................................................................................... 20

I/O Assembly Instances ................................................................................................. 20

EtherNet/IP connections................................................................................................. 21

Control Word Profile ...................................................................................................... 23

Change of State, COS.................................................................................................... 23

Danfoss FC Control Profile .............................................................................................. 24

ODVA Control Profile ..................................................................................................... 28

Reference Handling ....................................................................................................... 30

Parameters........................................................................................................................... 32

Parameter List.............................................................................................................. 43

Data Types Supported by FC 300..................................................................................... 44

Troubleshooting ................................................................................................................... 45

Step-by-step troubleshooting.......................................................................................... 45

Alarm Word and Warning Word ....................................................................................... 46

Appendix .............................................................................................................................. 51

Supported CIP Objects................................................................................................... 51

Index.................................................................................................................................... 60