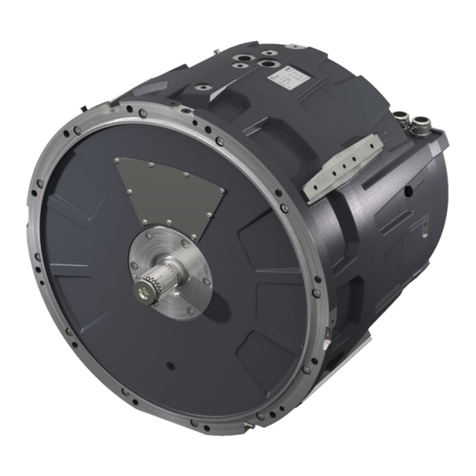

This manual is the installation, operation and maintenance manual for the EM-PMI540-

T2000

electric machine.

Copyright

Danfoss Oy. All rights reserved.

No parts of this manual may be reproduced or transmitted in any form or by any means, electrical

or mechanical including photocopying, recording or by an information storage or retrieval system,

without permission in writing from the publisher.

All specications and contents of this manual are subject to change without notice.

Intended use of the manual

This manual contains instructions necessary to safely and properly handle, install, operate and

maintain the electric machine. They should be brought to the attention of anyone who installs,

operates or maintains the machine or associated equipment.

All of the safety warnings and instructions in this book must be followed to prevent injury to

personnel or damage to property . Only qualied and authorized personnel, familiar with health

and safety requirements and national legislation, shall be permitted to handle, install, operate and

maintain the device.

This manual must be kept for future reference during installation, operation and maintenance.

This manual uses illustrations as examples only. Illustrations in this manual may not necessarily

reect all system features.

Product naming convention

In this user guide, EM-PMI

family permanent magnet motors and generators are referred to as the

electric machine.

Frame model indicates dimensions and electrical characteristics of the electric machine. The

following naming convention is used to refer to the electric machine frame model:

EM-PMI540-T2000-XXXX+XX

Table 1. The naming

codes of the electric machine

Part of

the

name Meaning

EM Electric Machine

PMIXXX

or

PMEXXX

Permanent Magnet Internal and a number relative to the

diameter

of the electric machine, or

Permanent Magnet External and a number relative to

diameter of the electric machine

TXXXX Average continuous torque of the motor range, relative to the lenght of the machine

XXXX Rated rotation speed

+XX Options, see option table

below.

The power input of the machine may require one or several three phase power systems. This is

indicated by a power connection option marking, for example:

DUAL or QUAD in the machine

model code. One three phases power system can include one or three connection boxes in the

machine. The most usual case is when an electric machine has a single connection box, but this is

not shown in the machine model

code.

Example: EM-PMI540-T2000-1300-DUAL