PAGE 8 44202-0898<90-00004>

INSTALLATION

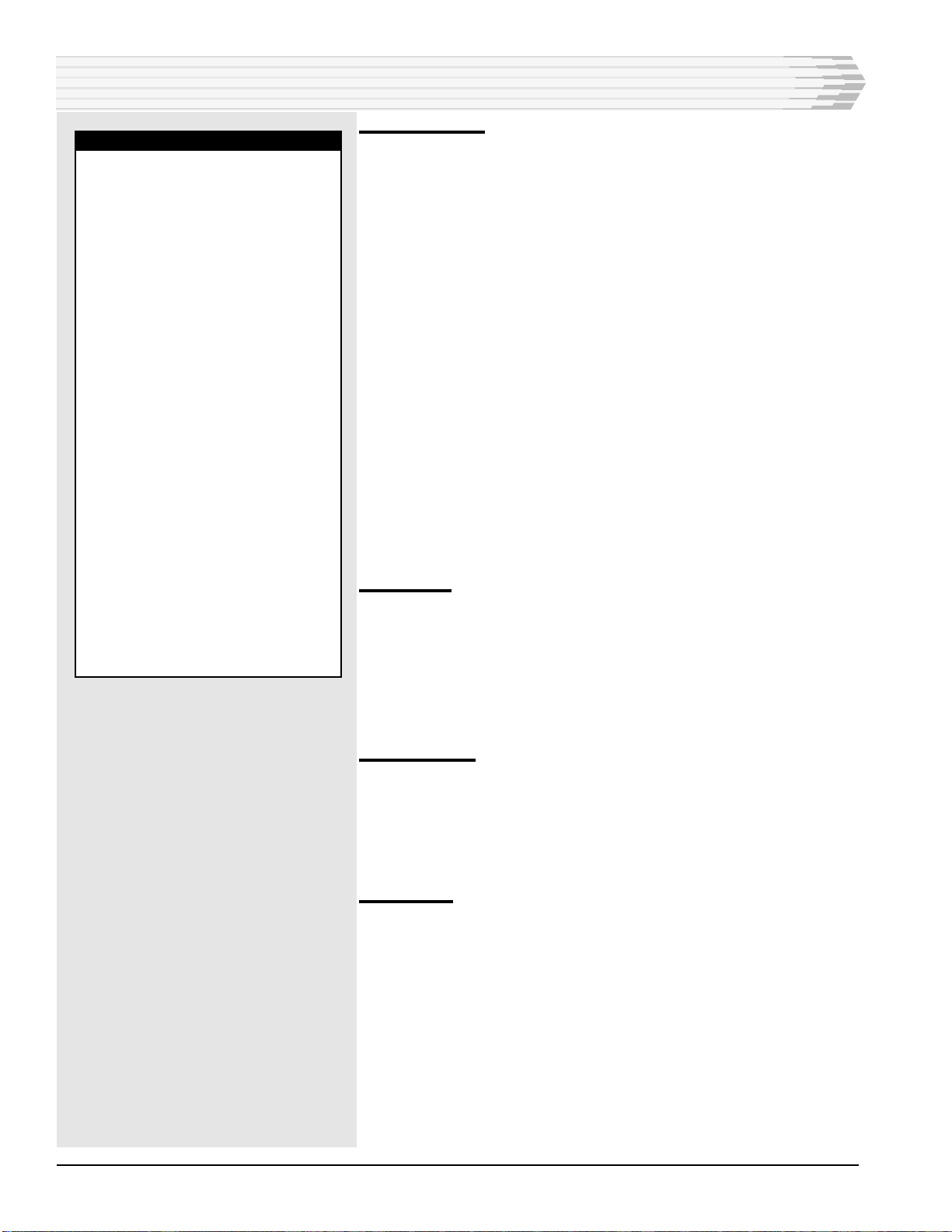

SWITCH

2W/4W

RTS TEST

POSITION

2W

4W

UP

DOWN

DESCRIPTION

Selects 2-wire operation

Selects 4-wire operation

Turns on RTS and DTR. Carrier is transmitted. (Switch on front panel)

Disables TEST functions.

NOTE: When RTS TEST switch is ON, RTS and DTR LEDs on front panel are ON.

SWITCH

DLB

ALB

POSITION

UP

DOWN

UP

DOWN

DESCRIPTION

Enables digital loopback (DLB) functions.

Disables DLB functions.

Enables analog loopback (ALB) functions.

Disables ALB functions.

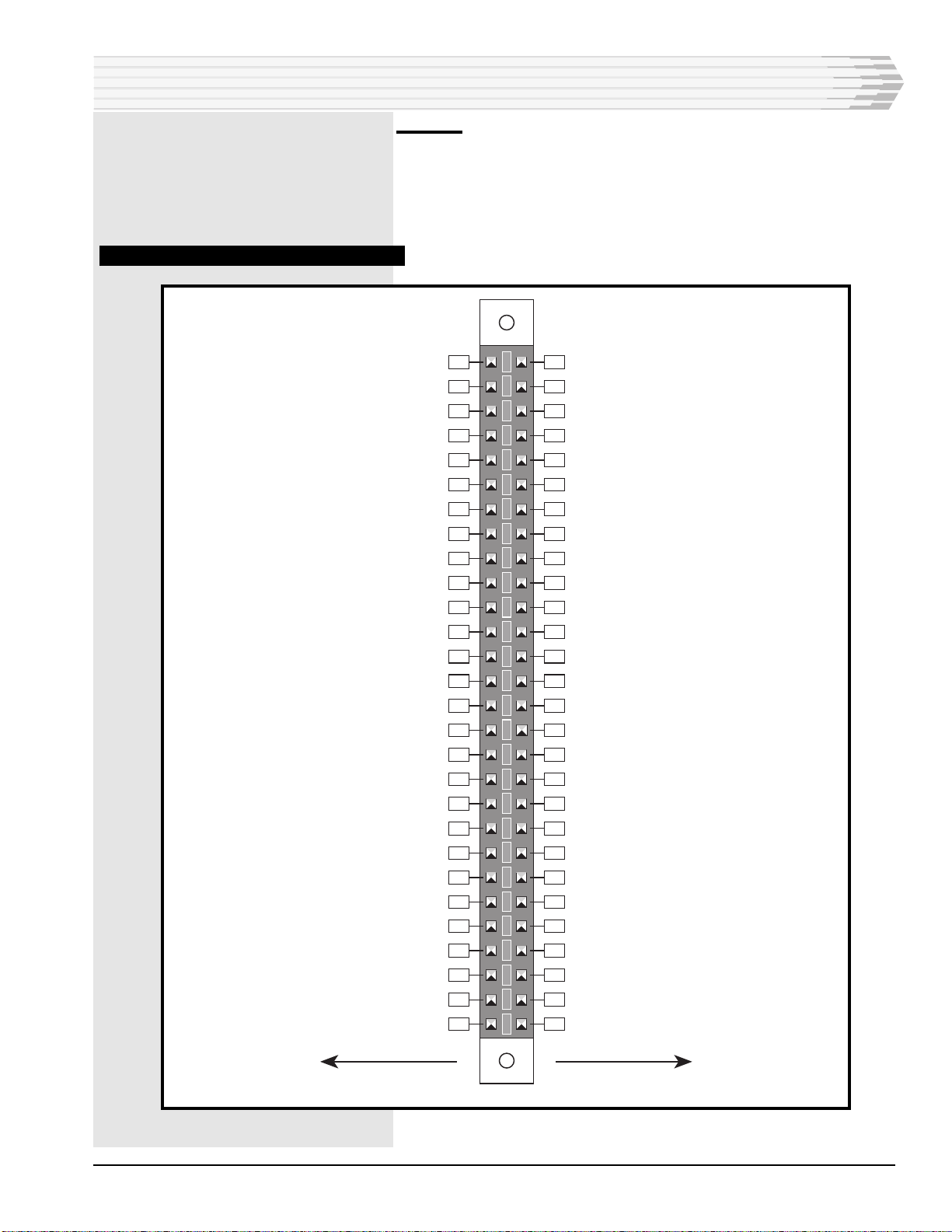

SWITCH S5 (5-POSITION MINI DIP)

S5-1

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

S5-2

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

S5-3

ON

ON

ON

ON

OFF

OFF

OFF

OFF

ON

ON

ON

OFF

OFF

OFF

OFF

ON

ON

ON

ON

OFF

OFF

OFF

OFF

ON

ON

ON

S5-4

ON

ON

ON

ON

ON

ON

ON

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

ON

ON

ON

ON

ON

ON

ON

OFF

OFF

OFF

S5-5

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

DESCRIPTION

Bell 103 Originate, 300 bps, Full Duplex

Bell 103 Answer, 300 bps, Full Duplex

Bell 202, 1200 bps, Half Duplex

Bell 202, 1200 bps, w/Amplitude Equalizer

CCITT V.21, Originate, 300 bps, Full Duplex

CCITT V.21, Answer, 300 bps, Full Duplex

CCITT V.23, Mode 2, 1200 bps, Half Duplex

CCITT V.23, Mode 2, 1200 bps, Half Duplex, w/Amplitude

Equalizer

CCITT V.23, Mode 1, 600 bps, Half Duplex

Bell 202, 1200 bps

Bell 202, 1200 baud, w/ Amplitude Equalizer

CCITT V.23, Mode 1, 600 bps, w/Soft Turn-Off

Reserved

CCITT V.23, Mode 2, 1200 bps, w/Soft Turn-1

CCITT V.23, Mode 2, 1200 bps, w/Amplitude Equalizer and

Soft Turn-Off

Bell 103, Originate Loopback

Bell 103, Answer Loopback

Bell 202, Main Loopback *

Bell 202, w/Amplitude Equalizer Loopback

CCITT V.21, Originate Loopback

CCITT V.21, Answer Loopback

CCITT V.23, Mode 2, Main Loopback

CCITT V.23, Mode 2, w/Amplitude Equalizer Loopback

CCITT V.23, Mode 1, Main Loopback

CCITT V.23, Back Loopback

Bell 202

TABLE B - SWITCH SETTINGS, 44202 MODEM

* NOTE: Normal setting is for Bell 202, Main Loopback.