5

General information

Introduction This section gives the general information about this service manual and about the unit.

Manual, part numberPart number of this service manual is 039131.

Target group The target group for this service manual is the technicians who install, maintain, and

exchange parts on the unit.

Copyright Copying of this service manual, or part of it, is forbidden without prior written

permission from Dantherm Air Handling A/S.

Reservations Dantherm Air Handling A/S reserves the right to make changes and improvements to

the product and the service manual at any time without prior notice or obligation.

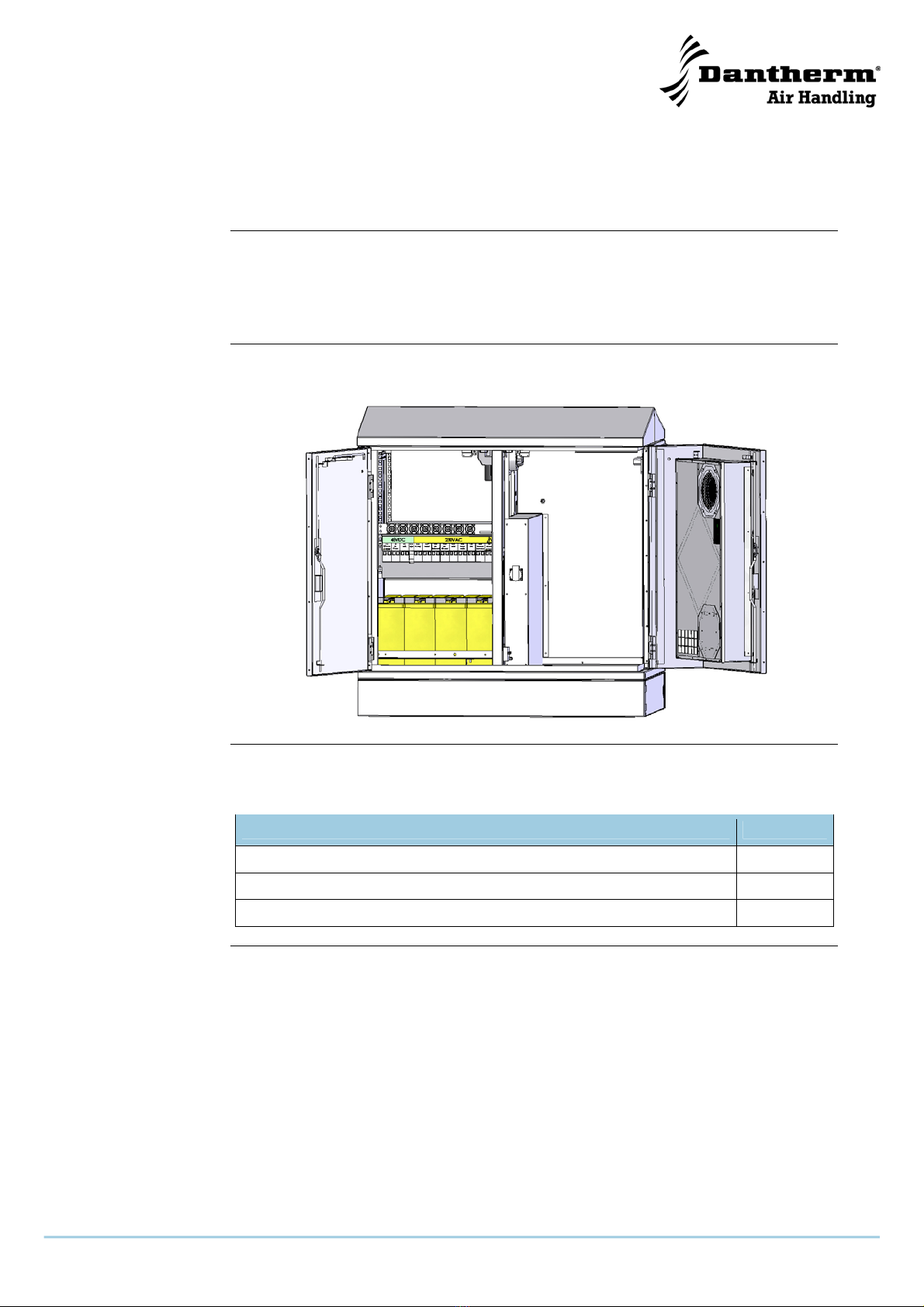

MTS2-outdoor

enclosure

Dantherm Air Handling A/S, Marienlystvej 65, DK-7800 Skive hereby declare that the

unit mentioned below:

MTS2 Outdoor solution, product no. 352890:

Description: MTS 2 outdoor solution is an outdoor cabinet or enclosure equipped for

accommodating and servicing an MTS2 base station. The cabinet has multiple

configurations ranging from a standard configuration with only a basic power

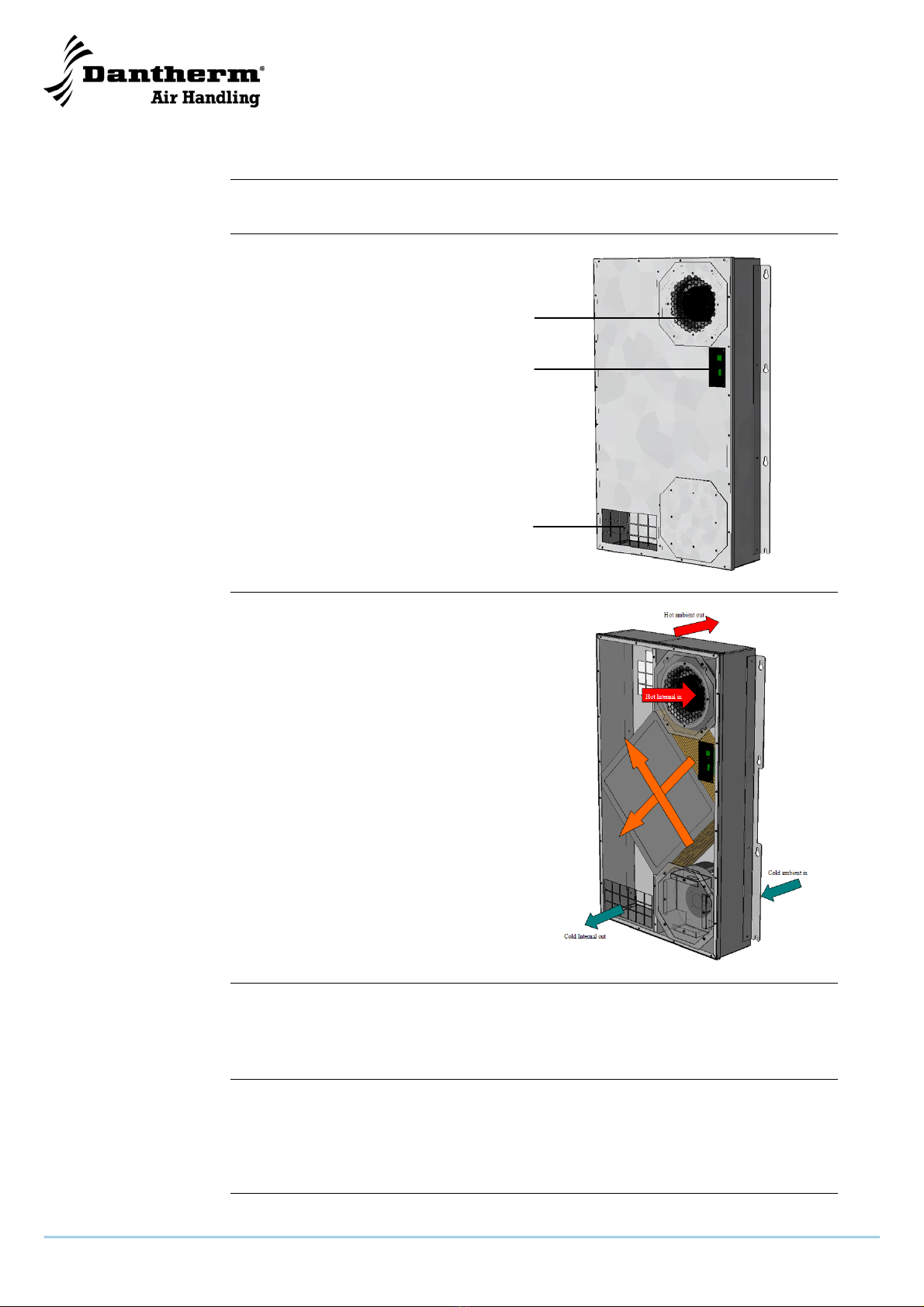

distribution panel (CE marked) and a heat-exchanger (CE marked) up to a full

integrated option list as defined in the service manual no 039131. Basis is equipped

with a door mounted heat exchanger (352735)(std.)a battery installation capable of

retaining 3 different VRLA size batteries (optional)a power distribution panel (CE-

marked) and internal cables routing, cabin lights, battery charger, surge arrestors etc.

Items not listed in the service manual are not covered by this declaration.

- is in conformity with the following directives covering the provisions of the normative

European Council Directives:

98/37/EEC Directive on the safety of machines

73/23/EEC Low Voltage Directive

89/336/EEC EMC Directive

- and Manufactured in conformity with the following harmonized standard:

EN60529:2001 IP55* (Degree of protection provided by enclosures)

kat.2 verified

EN 292 Machine safety

EN 60 950-1:2001+A11

Installation safety

EN50272-2 Battery installation

EN 61 000-2 Immunity

EN 61 000-3 Emission

EN 61 000-4 Immunity

EN 55022_Class B*)

Emission

*) MTS 2 Outdoor Solutions" integrated with Motorola MTS

2 Base Station Type No. FR914B, FR917A or FT917B

complies to EN 55022_Class A Emission

ETSI EN 300 019-2-1 T 1.2

Storage: not temperature controlled storage locations

039131 • 1.0 • 06.06.2007

Continued overleaf