Fixez les œillets au saute-vent. La manœuvre est plus facile à

partir de l'arrière.

Prévoir de l’espace pour travailler. Retirer les vis Torx T30 qui maintiennent le montage du phare au Té

inférieur et retirer le phare. Le déposer sur le garde boue en utilisant un chiffon pour le protéger.

Retirer le rangement de câble de l’avant du tube avant.

Retirer les 4 vis T25 qui maintiennent le support plastique d’instruments au Té supérieur. La vis de gauche

possède un autre rangement de câble. Cela ne sera pas nécessaire, le mettre de côté avec l’autre.

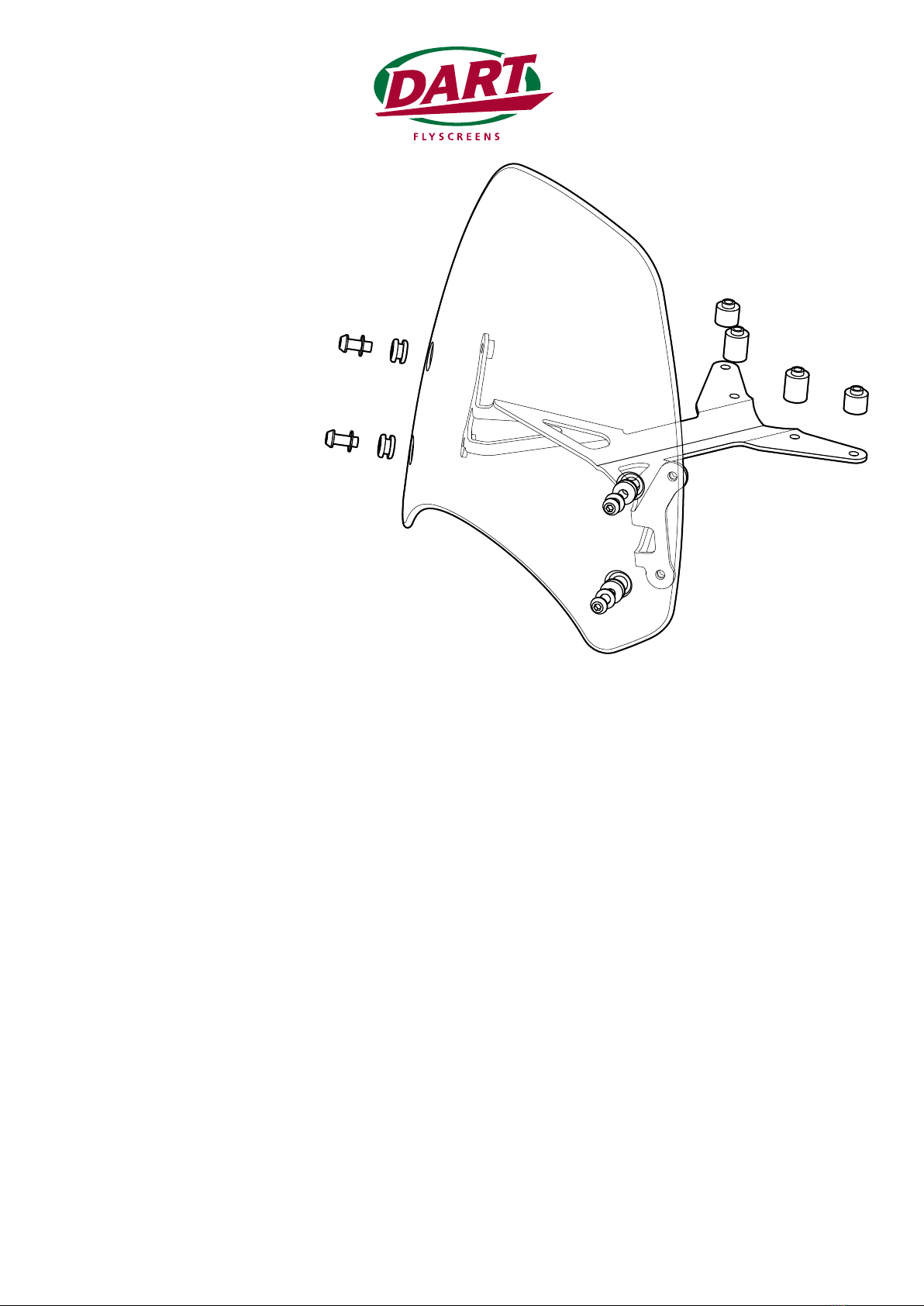

Insérer les 4 douilles dans la partie inférieure du support d’instruments. Les anneaux étagés doivent

s'enclencher dans les trous du support plastique. Les deux douilles plus longues doivent être dans les trous

centraux avec les deux douilles plus courtes à l'extérieur.

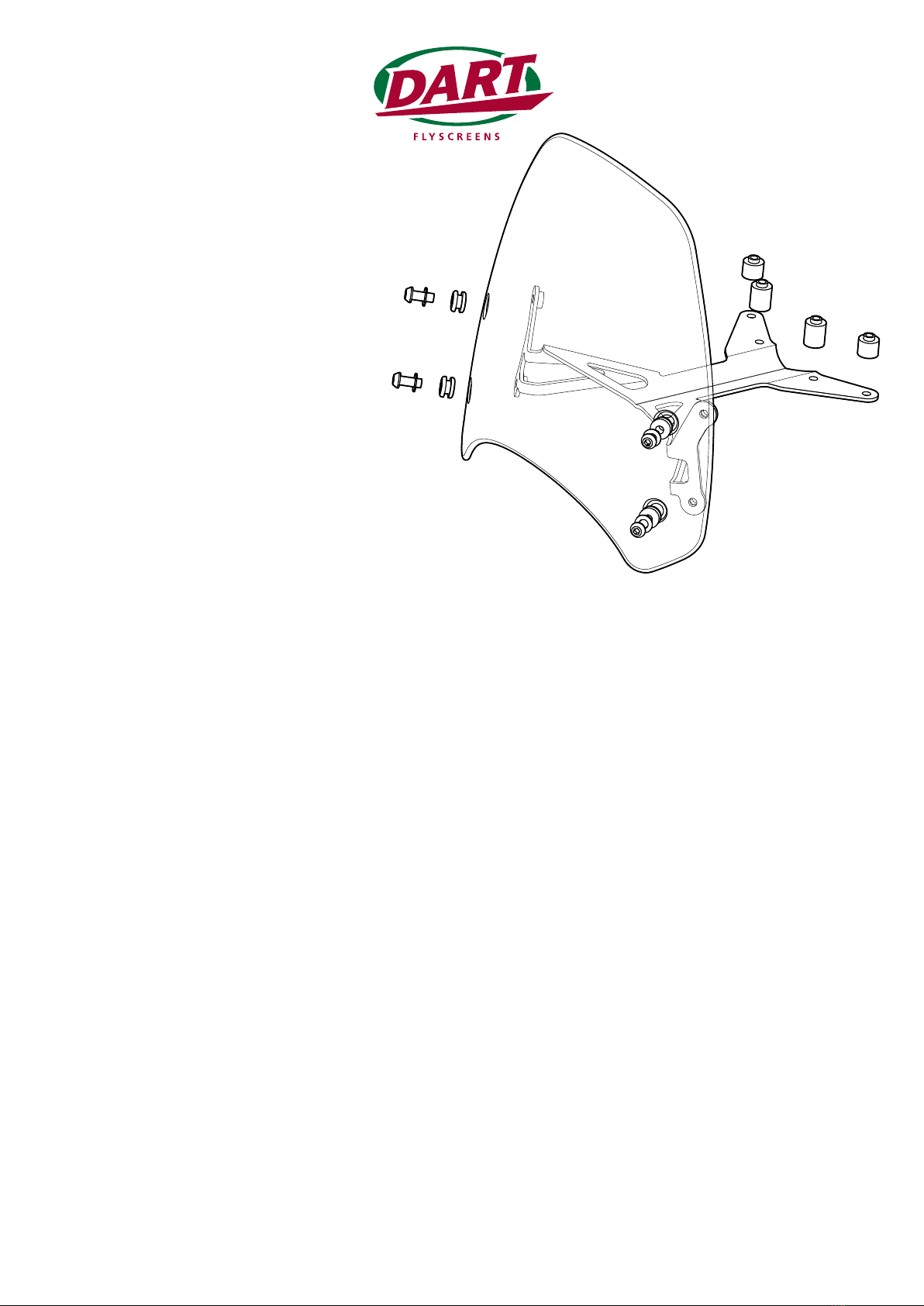

Positionner le support de saute-vent au dessous du support d’instruments et les maintenir ensemble comme

un sandwich. Guider l’assemblage en position sous le Té supérieur.

Tout en maintenant le montage en position, insérer l’une des paires centrales de vis M5x30mm par dessous le

support et visser dans le té du haut. Insérer ensuite la seconde vis.

Vérifier que tout est en position et insérer les deux autres vis. Les visser à la main de manière homogène puis

les serrer graduellement à l’aide d’une clé Allen de 3mm.

La partie la plus difficile étant terminée, remettre le phare.

Insérer les œillets dans les perçages du saute-vent. Le plus efficace est de la faire par l’arrière du saute-vent.

Maintenir le saute-vent en position et insérer les 2 vis à tête hexagonales avec leurs rondelles en s’assurant

qu’elles sont engagées dans les écrous captifs des supports. Ne pas les resserrer.

Vérifier à nouveau que toutes les vis et boulons sont suffisamment serrés. Le montage est maintenant terminé.

11. Fit the top two machine screws. Once everything is in position, gradually tighten all the screws

evenly until they are seated on the brackets.

12. Double check that everything is sufficiently tight and if so, fitting is now complete!

MAINTENANCE: No special maintenance is required. Do not use solvents to clean - just warm soapy water.

Many proprietary glass cleaners are suitable for polycarbonate - check the label before trying.

IMPORTANT NOTICE: Whilst the screen provides a good level of impact protection, it is not warranted

unbreakable. It is NOT a substitute for eye protection, which should be worn at all times while riding.

Designed and produced by Dart Flyscreens Ltd, Unit 10, Blackheath Business Centre, London SE10 8BA

e-mail: steve@dartflyscreens.com

INSTRUCTIONS D’INSTALLATION DU

SAUTE-VENT - BMW RnineT

Merci d'avoir choisi le saute-vent Dart. Il a été

soigneusement conçu afin de convenir à un

modèle spécifique de moto. Si vous suivez ce

mode d'emploi, le montage ne devrait pas

présenter de problèmes. Liste des articles

contenus dans la boîte :

1 x saute-vent polycarbonate Makrolon®

4 x oeillets en caoutchouc EPDM

1 x patte de fixation gauche pour le saute-vent

1 x patte de fixation droite pour le saute-vent

2 x manchons en Aluminium (15mm)

2 x manchons en Aluminium(12mm)

4 x vis hexagonale inoxydable M5 x 30mm

4 x vis hexagonale inoxydable à métaux

4 x rondelles

8

9

10

11

12

REMARQUE IMPORTANTE : le saute-vent fournit un bon niveau de protection mais n'est cependant pas incassable. Il

ne remplace PAS une protection pour les yeux, qui doit être portée en permanence pendant la conduite.

Conçu et fabriqué par Dart Flyscreens Ltd, 59 Boyne Road, London SE13 5AN