Data Aire DAP III User manual

Data Aire DAPTM III

BACnet Integration Instructions

Data Aire, Inc.

230 West BlueRidge Avenue

Orange, California 92865

800-347-2473

714-921-6000

www.dataaire.com

Engineering Document Number 600-000-460

April 2009

Revision 2.0

Data Aire, Inc. DAPTM III BACnet Integration Instructions

Engineering Document - 600-000-460 Page 2 of 13

Table of Contents

1Overview.....................................................................................................3

2Hardware Requirements and Installation............................................3

2.1 Required Network Card........................................................................3

2.1.1 The BACnet MS/TP protocol interface . ...................................................3

2.1.2 The BACnet IP protocol interface............................................................3

2.2 Network Card Installation ....................................................................4

2.2.1 For BACnet MS/TP interface ..................................................................4

2.2.2 For BACnet/IP interface .........................................................................5

2.3 Network Wiring .....................................................................................5

2.3.1 For RS-485 Multidrop network connection ...............................................5

2.3.2 For the Ethernet connection ...................................................................6

3Communication Port Setting...................................................................6

3.1 The RS-485 communication Port............................................................6

3.2 For BACnet/IP communication UDP port................................................6

4BACnet Object Definitions......................................................................7

4.1 Binary Value Objects............................................................................7

4.1.1 Readable fields................................................................................7

4.1.2 Object List .......................................................................................7

4.2 Analog Input Objects..........................................................................10

4.2.1 Readable fields..............................................................................10

4.2.2 Object List .....................................................................................10

4.3 Analog Value Objects.........................................................................10

4.3.1 Readable fields..............................................................................10

4.3.2 Object List .....................................................................................11

4.4 Multi-State Value Objects...................................................................13

4.4.1 Readable fields..............................................................................13

4.4.2 Object List .....................................................................................13

4.5 References..........................................................................................13

Data Aire, Inc. DAPTM III BACnet Integration Instructions

Engineering Document - 600-000-460 Page 3 of 13

1 Overview

The DAP III control panel supports a BACnet communication with a BMS for the system

monitoring and control. This document describes all the requirements and configuration

steps to implement the interface with a DAP III panel using the BACnet MS/TP and

Bacnet IP protocol.

2 Hardware Requirements and Installation

2.1 Required Network Card

2.1.1 The BACnet MS/TP protocol interface requires a Data Aire RS-485 Multidrop

communication network card to be installed into the DAP III Display board.

The RS-485 Multidrop card part number is 160-400-383.

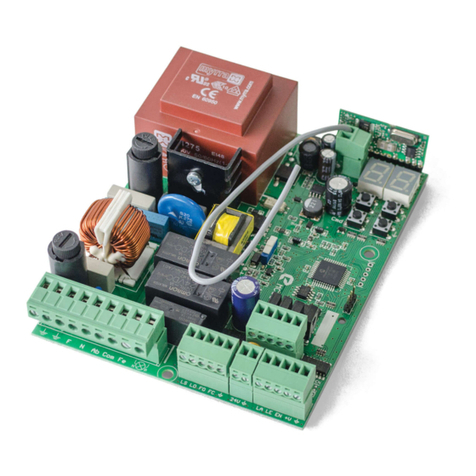

Figure 1: Data Aire RS-485 Multidrop Communications Network card

2.1.2 The BACnet IP protocol interface requires a Data Aire Ethernet network card to

be installed into the DAP III Display board. The Ethernet card part number is

160-400-385. This card is compliant with IEEE 802.3/802.3u 100BaseTX

Ethernet standard and auto-negotiation at 10Mbps/ 100 Mbps.

Figure 2: Data Aire Ethernet Communications Network card

BOARD CONNECTOR

RJ-45 CONNECTOR

END JUMPERTEST JUMPER

BOARD CONNECTOR

Data Aire, Inc. DAPTM III BACnet Integration Instructions

Engineering Document - 600-000-460 Page 4 of 13

2.2 Network Card Installation

IMPORTANT NOTE: The DAP III panel supports one network connection at a

time therefore only one type of the network card can be

installed.

2.2.1 For BACnet MS/TP interface, plug an RS-485 Multidrop communication network

card to the Communication Header J1 of the DAP III Display board. Make sure

the End jumper is on “T” (Terminate) position if the installed unit is the last unit in

the communication loop. In some case, the End jumper may not be required,

check with the BMS manufacturer for the requirement of this End jumper. See

Figure 3 below for the DAP III Display board with an RS-485 Multidrop card

installed.

After installing the network card, go to Menu 6-1 – Unit & Network ID in Group

Menu 6 – Network to set the unit network ID number. Go to Menu 6-2 –Network

Protocol to configure or verify the network protocol. Menu 6-2 to 6-7 are locked

menus, refer to the DAP III Operation Manual for the procedure of how to unlock

these menus before enter values. It is recommended to reset the DAP III panel

after changing the network protocol or the unit ID number.

+

_

Figure 3: DAP III Display Board With an RS-485 Multidrop Network Card

Communication Header J1Tx and Rx LED

Shield RS-485 Communication Wirin

g

RS-485 Multidro

p

Communication

Data Aire, Inc. DAPTM III BACnet Integration Instructions

Engineering Document - 600-000-460 Page 5 of 13

2.2.2 For BACnet IP interface, connect an Ethernet Communications network card to

the Communication Header J1 of the DAP III Display board. See Figure 4 for the

DAP III Display board with an Ethernet card installed.

After installing the network card, go to menu 6-1 – Unit and Network ID in Group

menu 6 to set the unit network ID and to menu 6-2 –Network protocol to

configure the network protocol. Menu 6-2 to 6-7 are locked menus, refer to the

DAP III Operation Manual for the procedure of how to unlock these menus before

entering IP address. It is recommended to reset the DAP III panel after changing

the network protocol or the unit ID number.

Figure 4: DAP III Display Board With an Ethernet Communications Network Card

2.3 Network Wiring

2.3.1 For RS-485 Multidrop network connection, the 18 AWG or 22 AWG shielded,

twisted pair cable is recommended. The network wiring should be wired in the

multidrop fashion: The RS-485 devices are wired in parallel. The wiring should

start from the RS-485 port of the BMS Gateway module. See Figure 3 above for

the DAP III RS-485 network wiring terminations.

Communication Header

J1

RJ-45 Connector with Link

and Activity LED Ethernet Communication Card

Gateway

DAP III Display board of unit

#1 with RS-485 Multidrop card

(Supplied by Data Aire.)

DAP III Display Board of unit

#2 with RS-485 Multidrop card

(Supplied by Data Aire)

RS-485 Modbus Gateway

module (Supplied by BMS

Twisted-pair Multidrop connection to Gateway module Wiring to

next unit

BMS Computer

Data Aire, Inc. DAPTM III BACnet Integration Instructions

Engineering Document - 600-000-460 Page 6 of 13

2.3.2 For the Ethernet connection, use the CAT-5 Ethernet cable. The DAP III panel

should be connected to the same network with the BMS by a network switch or a

network hub. Each unit requires having a dedicated IP address. Consult with

the building IT personnel or building network administrator on IP addressing.

3 Communication Port Setting

3.1 The RS-485 communication Port for BACnet MS/TP protocol is configured as

follow:

3.2 For BACnet IP communication UDP port setting, refer to the DAP III Operation

Manual for the procedure to enter an IP address and port setting to the DAP III.

The BACnet/IP UDP port (Listen port) in the DAP III is default to 47808.

Baud Rate 9600 (adjustable)

Word Length 8

Parity None

Stop Bits 1

Network switch or

hub (Supplied by

others)

DAP III Display board of unit

#1 with Ethernet card

(Supplied by Data Aire.)

DAP III Display board of unit

#2 with Ethernet card

(Supplied by Data Aire.)

Ethernet connection to BMS

BMS

computer

Data Aire, Inc. DAPTM III BACnet Integration Instructions

Engineering Document - 600-000-460 Page 7 of 13

4 BACnet Object Definitions

4.1 Binary Value Objects

4.1.1 Readable fields

Object-identifier Status-flags

Object-name Event-state

Object-type Out-of-service

Present-value

4.1.2 Object List

Object Name Instance

No. BV Object Description Present-

Value

Writeable

Dehumidification 1 Unit is dehumidifying

No

Humidification 2 Unit is humidifying

No

Energy Saver 3 Energy Saver function is active

No

Cooling Held 4 Cooling is inhibited

No

Heating Held 5 Heating is inhibited

No

Humidification Held 6 Humidification is inhibited

No

Dehumidification Held 7 Dehumidification is inhibited

No

Reheat During Dehumidification 8 Reheat on during dehumidification

No

Water Under Floor 9 Water Under Floor detection alarm

No

No Air Flow 10 Loss of the air flow alarm

No

Dirty Filter 11 Filter clogged alarm

No

Humidifier Problem 12 Loss of the humidifier make-up water

pressure alarm No

Low Voltage Warning 13 DC power of the DAP III boards drops

below the required level No

Fire-Stat Trip 14 The return air temperature rises above

the Firestat temperature setting limit No

Compressor Short Cycle Warning 15 Compressor short cycle warning is active

No

Power Problem 16 Power reset or unit restart notification

No

Humidity Sensor Problem 17 Faulty Humidity sensor detected

No

Data Aire, Inc. DAPTM III BACnet Integration Instructions

Engineering Document - 600-000-460 Page 8 of 13

Object Name Instance

No. BV Object Description Present-

Value

Writeable

Temperature Sensor Problem 18 Faulty Return Air temperature sensor

detected No

Maintenance Due 19 The blower runtime has elapsed the

scheduled maintenance hours No

High Pressure / Internal

Overload: Compressor 1 20 Compressor #1 high pressure switch or

compressor internal overload relay trips No

Low Pressure C1 21 Compressor #1 low pressure switch

opens No

High Pressure C2/ Internal

Overload: Compressor 2 22 Compressor #2 high pressure switch or

compressor internal overload relay trips No

Low Pressure C2 23 Compressor #2 low pressure switch

opens No

Smoke Detector

(Optional) 24 Smoke Detected, unit shutdown. An

optional smoke detector required No

No Water Flow

(Optional) 25 Loss of water on calling for cooling, An

optional Water Flow switch required. No

Discharge Air Sensor Problem

(Optional) 26 Faulty Discharge Air temperature sensor

detected. An optional temperature

required

No

High Temperature Warning 27 The Return Air temperature rises above

the high temperature alarm limit setting No

Low Temperature Warning 28 The Return Air temperature drops below

the low temperature alarm limit setting No

High Humidity Warning 29 The Relative humidity rises above the

high humidity alarm limit setting No

Low Humidity Warning 30 The Relative humidity drops below the

low humidity alarm limit setting No

Fan Motor Overload

(Optional) 31 The optional fan motor overload trips. No

Local Alarm 1 (Optional) 32 The optional alarm input 1 is

programmed to Local alarm #1: See tag

inside door and the alarm signal is active

No

Local Alarm 2 (Optional) 33 The optional alarm input 2 is

programmed to Local alarm #2: See tag

inside door and the alarm signal is active

No

Local Alarm 3 (Optional) 34 The optional alarm input 3 is

programmed to Local alarm #3: See tag

inside door and the alarm signal is active

No

Local Alarm 4 (Optional) 35 The optional alarm input 4 is

programmed to Local alarm #4: See tag

inside door and the alarm signal is active

No

Standby Pump On

(Optional) 36 The optional alarm input is programmed

to Standby pump on: Check primary

pump and the alarm signal is active

No

UPS Power On

(Optional) 37 The optional alarm input is programmed

to UPS power on: Check main power

supply and the alarm signal is active

No

Custom Alarm 1

(Optional) 38 The optional alarm input 1 is

programmed to Custom alarm #1 and the

alarm signal is active

No

Data Aire, Inc. DAPTM III BACnet Integration Instructions

Engineering Document - 600-000-460 Page 9 of 13

Object Name Instance

No. BV Object Description Present-

Value

Writeable

Custom Alarm 2

(Optional) 39 The optional alarm input 2 is

programmed to Custom alarm #2 and the

alarm signal is active

No

Custom Alarm 3

(Optional) 40 The optional alarm input 3 is

programmed to Custom alarm #3 and the

alarm signal is active

No

Custom Alarm 4

(Optional) 41 The optional alarm input 4 is

programmed to Custom alarm #4 and the

alarm signal is active

No

Humidification Inhibited

(optional) 42 The optional inputs are programmed to

Humidification inhibited and the input

signal is active

No

Reheat Inhibited

(Optional) 43 The optional inputs are programmed to

Reheat inhibited and the input signal is

active

No

Reheat And Humid. Inhibited

(Optional) 44 The optional inputs are programmed to

Reheat and Humidification inhibited and

the input signal is active

No

Low Discharge Air Temperature

Alarm

(Optional)

45 The Discharge Air temperature drops

below the low discharge temperature

setting limit. An optional Discharge Air

temperature sensor required

No

Manual Override 46 Manual override switches are on; unit

operates in the manual control mode. No

High Condensate water level

(Optional) 47 High condensate water level switch of

the optional condensate pump closes.

This is a standard alarm on ceiling units.

No

Unit In Standby, All Functions

Held Off Alarm (Optional) 48 The optional alarm input 1 is

programmed to Unit in standby, all

functions held off and the alarm signal is

active. Unit is put to standby mode.

No

Cooling Inhibit 1001 The Cooling stages will be inhibited

when this point is on. Yes-

Enumerated

(0,1)

Heating Inhibit 1002 The Heating stages will be inhibited

when this point is on Yes-

Enumerated

(0,1)

Humidification Inhibit 1003 The Humidification function will be

inhibited if this point is on Yes-

Enumerated

(0,1)

Dehumidification Inhibit 1004 The dehumidification function will be

inhibited if this point is on. Yes-

Enumerated

(0,1)

Blower Inhibit 1005 The blower(s) will stop if this point is

on. In a normal circumstance, this point

should be off at all time

Yes-

Enumerated

(0,1)

Data Aire, Inc. DAPTM III BACnet Integration Instructions

Engineering Document - 600-000-460 Page 10 of 13

4.2 Analog Input Objects

4.2.1 Readable fields

Object-identifier Status-flags

Object-name Event-state

Object-type Out-of-service

Present-value Units

4.2.2 Object List

Object Name Instance

No. AI Object Name Present-

Value

Writeable

Return Air Temperature 1 Current Return Air temperature

No

Relative Humidity 2 Current Relative humidity

No

Discharge Air Temperature 3 Current Discharge Air temperature. This

temperature is only available when an

optional Discharge Air sensor is installed

No

Chilled Water Temperature

(Optional) 4 Chilled Water temperature. This

temperature is only available when an

optional Chilled water sensor is installed.

No

Analog Input 1 Sensor

(Optional) 5 An optional analog sensors such as

temperature transmitter must be installed

and programmed into analog module

input 1

No

Analog Input 2 Sensor

(Optional) 6 An optional analog sensor such as

temperature transmitter must be installed

and programmed into analog module

input 2.

No

Analog Input 3 Sensor

(Optional) 7 An optional analog sensors such as

temperature transmitter must be installed

and programmed into analog module

input 3

No

Analog Input 4 Sensor

(Optional) 8 An optional analog sensors such as

temperature transmitter must be installed

and programmed into analog module

input 4

No

4.3 Analog Value Objects

4.3.1 Readable fields

Object-identifier Status-flags

Object-name Event-state

Object-type Out-of-service

Present-value Units

Data Aire, Inc. DAPTM III BACnet Integration Instructions

Engineering Document - 600-000-460 Page 11 of 13

4.3.2 Object List

Object Name Instance

No. AV Object Description Present-

Value

Writeable

Cooling Stages On 1 Cooling stages are currently on (0-5).

This point only applies to DX unit No

Heating Stages On 2 Heating stages are currently on (0-4)

No

Chilled Water Valve Open

Percentage 3 Chilled Water valve open percentage

(0-100%). This point only applies to

chilled water unit.

No

Humidifier Valve

(Optional) 4 Humidifier valve open percentage (0-

100). This point only applies to unit

that has an optional modulating

humidifier

No

High Temperature In The Last

24Hrs. 5 Maximum value of the Return Air

temperature in the last 24 hours No

Low Temperature In The last 24Hrs. 6 Minimum value of the Return Air

temperature in the last 24 hours No

High Humidity In The last 24Hrs. 7 Maximum value of the Relative

humidity in the last 24 hours No

Low Humidity In The Last 24Hrs. 8 Minimum value of the Relative

humidity in the last 24 hours No

Cooling Utilization 9 Cooling Utilization of the last hour

(0-100 percent). This applies to DX

unit only

No

Heating Utilization 10 Heating utilization of the last hour

(0-100 percent) No

Chilled Water Utilization 11 Chilled Water valve utilization of the

last hour (0-100 percent). This

applies to unit with Chilled water

unit only

No

Humidifier Utilization 12 Humidifier utilization of the last hour

(0-100 percent) No

Compressor 1 Runtime 13 The total runtime of the compressor

#1 (Hour) No

Compressor 2 Runtime 14 The total runtime of the compressor

#2 (Hour) No

Compressor 3 Runtime 15 The total runtime of the compressor

#3 (Hour) No

Compressor 4 Runtime 16 The total runtime of the compressor

#4 (Hour) No

Heat Stage 1 Runtime 17 The total runtime of the heating stage

#1 (Hour) No

Heat Stage 2 Runtime 18 The total runtime of the heating stage

#2 (Hour) No

Heat Stage 3 Runtime 19 The total runtime of the heating stage

#3 (Hour) No

Humidifier Runtime 20 The total runtime of the humidifier

(Hour) No

Data Aire, Inc. DAPTM III BACnet Integration Instructions

Engineering Document - 600-000-460 Page 12 of 13

Object Name Instance

No. AV Object Description Present-

Value

Writeable

Blower Runtime 21 The total runtime of the blower

motor(s) (Hour) No

Condenser Runtime 22 The total runtime of the condenser.

This will be available when the

optional Relay module is installed

No

Dehumidification Runtime 23 The total runtime of dehumidification

No

Energy Saver Runtime

(Optional) 24 The total runtime of the energy saver

chilled water valve. This applies to

the DX unit with energy saver

cooling only.

No

Chilled Water Runtime 25 The total runtime of the chilled water

valve. This point applies to chilled

water unit only

No

Analog Output 1

(Optional) 37 Optional analog output 1 Value No

Analog Output 2

(Optional) 38 Optional analog output 2 Value No

Fire stat Temperature Limit 1001 Fire stat temperature limit setting

(100-150F) – Default 100 F Yes-Real

value

High Humidity Limit 1002 High humidity alarm Limit setting

(10-90%). Default: 60 % Yes- Real

value

High Temperature Limit 1003 High temperature alarm Limit setting

(50-90F). Default: 80 F Yes- Real

value

Humidity Deadband 1004 Humidity deadband (0-15%).

Default: 3% Yes- Real

value

Low Discharge Air Temperature

Limit (optional) 1005 Low Discharge Air temperature

alarm Limit setting (45-61F). This

requires an optional Discharge Air

temperature sensor. Default: 52 F

Yes- Real

value

Low Humidity Limit 1006 Low humidity alarm limit setting

(10-90%). Default: 40% Yes- Real

value

Low Temperature Limit 1007 Low Return Air temperature alarm

Limit setting (50-90F). Default: 60F Yes- Real

value

Chilled Water Available Limit

(Optional) 1008 Chilled Water available setpoint (40-

60F). Default: 50 F. This applies to

unit that has an energy saver or

auxiliary chilled water coil.

Yes- Real

value

Humidity Setpoint 1009 Humidity setpoint (30-70%).

Default: 50% Yes- Real

value

Unit Start Delay 1010 Unit start time delay setting (5-600

seconds). Default: 5 seconds Yes- Real

value

Temperature Deadband 1011 Temperature deadband (1-5F).

Default: 2F Yes- Real

value

Temperature Setpoint 1012 Temperature setpoint (65-85F).

Default: 72F Yes-Real

value

Fan Speed Control

(Optional) 1013 Optional fan speed control setting

(85-100%). Default: 100%. This

option requires an Analog module.

Yes- Real

value

Data Aire, Inc. DAPTM III BACnet Integration Instructions

Engineering Document - 600-000-460 Page 13 of 13

4.4 Multi-State Value Objects

4.4.1 Readable fields

Object-identifier Status-flags

Object-name Event-state

Object-type Out-of-service

Present-value Number-of-states

4.4.2 Object List

Object Name Instance

# MSV Object Description Present-

value

Writeable

Person To Contact

(Optional) 13 Information of the person to contact

on the alarm event. This requires a

factory-preprogrammed message.

No

Reset Mode Warning 14 Loss of power or Unit restart warning

message No

Water Under Floor Alarm Action 17 Water under floor alarm action

setting, menu 4-9 of the DAP III

panel. This can be set to unit

shutdown or compressor lock-out

No

No Water Flow Alarm Action

(optional) 18 No water flow alarm action setting,

menu 4-10 of the DAP III panel. This

can be set to compressor lock-out or

none. This requires an optional water

flow sensor.

No

Energy saver Lockout Time

(optional) 19 Energy saver lockout time delay once

the DX cooling comes on. This is set

on menu 3-8 of the DAP III panel.

Energy saver option required

No

Auto flush Timer

(Optional) 1001 Auto flush Timer setting. This setting

only applies when an optional

Infrared humidifier is used.

Yes-

Unsigned

value

Unit on/off Control 1002 This point controls the unit on/off.

The default setting value is 1; unit is

ON. Changing the setting value to 2

will turn the unit OFF. Default =1

(ON).

Yes-

Unsigned

value

4.5 References

ANSI/ASHRAE Standard 135-2001, BACnet - A Data Communication Protocol

for Building Automation and Control Networks

Other manuals for DAP III

2

Table of contents

Other Data Aire Control Panel manuals

Popular Control Panel manuals by other brands

Motorline professional

Motorline professional MC50 User& installer's manual

Aritech

Aritech 1X-F Series Quick installation guide

JCM Technologies

JCM Technologies INTEGRA user manual

Eminent

Eminent e-Domotica e-Centre 2 manual

Johnson Controls

Johnson Controls S1-TTSCC01 User's information manual

OERTLI

OERTLI OEtroCom-2 technical information