Datacom DM4380 User manual

DM4380

CARRIER ETHERNET SWITCH

INSTALLATION GUIDE

204.4336.00 –October/2019

DM4380 –Installation Guide

Legal Note

204.4336.00 - October/2019

2

LEGAL NOTE

In spite the fact that all the precautions were taken in development of the present

document, DATACOM shall not be held responsible for eventual errors or omissions as

well as no obligation is assumed due to damages resulting from the use of the

information included in this guide. The specifications provided in this guide shall be

subject to changes with no prior notification and are not acknowledged as any type of

contract.

© 2019 DATACOM - All rights reserved.

WARRANTY

DATACOM's products are covered by a warranty against manufacturing defects during a

minimum period of 12 (twelve) months including the legal term of 90 days, as from the

date of issue of the supply Nota Fiscal (Invoice).

Our warranty is standard counter warranty, this means, for exercise of the warranty,

the customer should send the product to DATACOM Authorized Technical Assistance

with paid freight. The return freight of the equipment will be DATACOM responsibility.

To obtain additional information, see our warranty policy in

www.datacom.com.br/en/home

Telephone Number: +55 51 3933-3094

DM4380 –Installation Guide

Contacts

204.4336.00 - October/2019

3

CONTACTS

TECHNICAL SUPPORT

Datacom has available a support portal - DmSupport, to help the customers in use and

config of our equipment.

Access to the DmSupport can be made through link:

https://supportcenter.datacom.com.br

In this site the following are available: firmwares, technical datasheets, config guide,

MIBs and manuals for download. In addition, it allows opening of calls for assistance

with our technical team.

Telephone Number: +55 51 3933-3122

We would like to highlight that our assistance through telephone support is available

from Monday through Friday from 08:00 AM through 05:30 PM.

Important: For support assistance 24x7, please request a quotation to our sales

department.

GENERAL INFORMATION

For any other additional information, please visit the www.datacom.com.br/en/home

or call:

DATACOM

Rua America, 1000

92990-000 –Eldorado do Sul –RS –Brazil

+55 51 3933-3000

DM4380 –Installation Guide

Product Documentation

204.4336.00 - October/2019

4

PRODUCT DOCUMENTATION

ABOUT THIS DOCUMENT

This document is part of a set of documents prepared to provide all necessary

information about DATACOM products.

SOFTWARE PLATFORM

QUICK CONFIGURATION GUIDE –Provides instructions on how to set

the functionalities in a quick manner in the equipment

TROUBLESHOOTING GUIDE –Provides instructions on how to analyze,

identify and solve problems with the product

COMMAND REFERENCE –Provides all the commands related to the

product

RELEASE NOTES –Provides instructions on the new functionalities,

identified defects and compatibilities between Software and Hardware

HARDWARE PLATFORM

DATASHEET –Provides the product technical characteristics

INSTALLATION GUIDE –Provides instructions on the procedures

covering product installation

The availability of some documents can vary depending on the type of product.

Access https://supportcenter.datacom.com.br/ to locate the related documents or

contact the Technical Support for additional information.

DM4380 –Installation Guide

Contents

204.4336.00 - October/2019

5

CONTENTS

LEGALNOTE...............................................................................................................................................................................2

WARRANTY.................................................................................................................................................................................2

CONTACTS..................................................................................................................................................................................3

TECHNICAL SUPPORT......................................................................................................................................................3

GENERAL INFORMATION................................................................................................................................................3

PRODUCT DOCUMENTATION................................................................................................................................................4

ABOUT THIS DOCUMENT ...............................................................................................................................................4

SOFTWARE PLATFORM ..................................................................................................................................................4

HARDWARE PLATFORM .................................................................................................................................................4

CONTENTS..................................................................................................................................................................................5

1INTRODUCING THE HARDWARE INSTALLATION GUIDE......................................................................................7

1.1 ABOUT THIS GUIDE ............................................................................................................................................7

1.2 INTENDED AUDIENCE ........................................................................................................................................7

1.3 CONVENTIONS ......................................................................................................................................................7

2GETTING STARTED..........................................................................................................................................................9

2.1 SAFETY WARNINGS............................................................................................................................................9

3HARDWARE DESCRIPTION......................................................................................................................................... 10

3.1 PRODUCT OVERVIEW ...................................................................................................................................... 10

3.2 MODEL DM4380 12XS+3CX................................................................................................................ 10

3.3 EQUIPMENT STATUS LEDS........................................................................................................................... 11

3.4 SERIAL CONSOLE INTERFACE (RS-232).............................................................................................. 11

3.5 USB INTERFACE CONSOLE ......................................................................................................................... 12

3.6 USB INTERFACE HOST.................................................................................................................................. 12

3.7 INTERFACE MANAGEMENT ETHERNET (MGMT) ............................................................................. 12

3.8 DATA INTERFACE.............................................................................................................................................. 13

3.9 ALARM INPUT AND OUTPUT ........................................................................................................................ 16

3.10 PSUS AND POWER INPUTS......................................................................................................................... 16

3.11 PROTECTIVE GROUNDING ............................................................................................................................ 21

4DM4380 INSTALLATION.............................................................................................................................................. 22

4.1 DM4380 PACKAGE CONTENT .................................................................................................................. 22

4.2 IDENTIFYING THE PRODUCT ........................................................................................................................ 22

4.3 PREPARING THE INSTALLATION SITE...................................................................................................... 22

4.4 19-INCH RACK INSTALLATION ................................................................................................................... 23

DM4380 –Installation Guide

Contents

204.4336.00 - October/2019

6

4.5 CONNECTING THE PROTECTIVE GROUNDING ...................................................................................... 24

4.6 VENTILATION...................................................................................................................................................... 24

4.7 POWERING THE EQUIPMENT....................................................................................................................... 25

4.8 CHECKING THE PRODUCT’S OPERATION............................................................................................... 25

5INSTALLING AND REMOVING QSFP28/QSFP+/SFP/SFP+ MODULES............................................................. 27

5.1 INSTALLING THE SFP+/SFP MODULES .............................................................................................. 27

5.2 REMOVING SFP+/SFP MODULES.......................................................................................................... 29

5.3 INSTALLING THE QSFP28/QSFP+ MODULES ................................................................................ 29

5.4 REMOVING QSFP28/QSFP+ MODULES............................................................................................ 30

6LOGGING IN FOR FIRST TIME..................................................................................................................................... 32

6.1 MANAGEMENT USING CONSOLE INTERFACE ....................................................................................... 32

6.2 MANAGEMENT USING ETHERNET INTERFACE ..................................................................................... 32

6.3 CONFIGURING USERS..................................................................................................................................... 33

6.4 CHANGING DEFAULT ADMINISTRATOR ACCOUNT PASSWORD ................................................ 34

7TECHNICAL SPECIFICATION....................................................................................................................................... 35

7.1 INTERFACES ........................................................................................................................................................ 35

7.2 POWER SUPPLY AND CONSUMPTION .................................................................................................... 35

7.3 PHYSICAL SPECIFICATIONS......................................................................................................................... 35

7.4 ENVIRONMENT INFORMATION ................................................................................................................... 36

8STANDARDS AND REGULATIONS............................................................................................................................ 37

DM4380 –Installation Guide

Introducing the Hardware Installation Guide

204.4336.00 - October/2019

7

1INTRODUCING THE HARDWARE INSTALLATION GUIDE

1.1 ABOUT THIS GUIDE

This guide provides information about hardware specification and installation

procedures from DM4380 carrier ethernet switch family. This document also covers

initial configuration, those normally needed after hardware installation.

It is assumed that the individual or individuals managing any aspect of this product

have basic understanding of Ethernet and Telecommunications networks.

1.2 INTENDED AUDIENCE

The DM4380 Installation Guide is intended for Network Administrators, technicians and

other qualified service personnel responsible for installing, configuring, planning and

maintaining the DM4380 switch.

1.3 CONVENTIONS

In order to improve the agreement, the following conventions are made throughout this

guide:

1.3.1 Icons Convention

Icon

Type

Description

Note

Notes give an explanation about some topic in the foregoing

paragraph.

Caution

This symbol means that this text is very important and, if

the orientations were not correct followed, it may cause

damage or hazard.

Warning

This symbols means that, case the procedure was not

correctly followed, may exist electrical shock risk.

Warning

Represents LASER radiation. It is necessary to avoid eye and

skin exposure.

Caution

Indicates that equipment, or a part is ESDS (Electrostatic

Discharge Sensitive). It should not be handled without

grounding antistatic wrist strap or equivalent.

Warning

Non-ionizing radiation emission.

DM4380 –Installation Guide

Introducing the Hardware Installation Guide

204.4336.00 - October/2019

8

Note

WEEE Directive Symbol (Applicable in the European Union

and other European countries with separate collection

systems).This symbol on the product or its packaging

indicates that this product must not be disposed of with

other waste. Instead, it is your responsibility to dispose of

your waste equipment by handing it over to a designated

collection point for the recycling of waste electrical and

electronic equipment. The separate collection and recycling

of your waste equipment at the time of disposal will help

conserve natural resources and ensure that it is recycled in

a manner that protects human health and the environment.

For more information about where you can drop off your

consumer waste equipment for recycling, please contact

your local city recycling office or the dealer from whom you

originally purchased the product.

A caution type notice calls attention to conditions that, if not avoided,

may damage or destroy hardware or software.

A warning type notice calls attention to conditions that, if not avoided,

could result in death or serious injury.

DM4380 –Installation Guide

Getting Started

204.4336.00 - October/2019

9

2GETTING STARTED

2.1 SAFETY WARNINGS

Before to continue, read carefully the following safety warnings:

Prior to installation carefully read the whole guide.

Pay attention to the safety instructions during installation, operation or

maintenance of this product. Installation, adjustments or maintenance

must be performed only by qualified, trained and authorized personnel.

To prevent the risk of electrical shocks, before turning the equipment on

or connecting an interface card or cable, install the protective grounding

system.

Before connecting any cable to the equipment, make sure that the

grounding system is functional.

Optical Transceivers used in DM4380 have invisible LASER emitting.

Although all DATACOM homologated transceivers and most of the market

transceivers comply with LASER safety standards, avoid direct contact

and exposure to eyes and skin.

The optical modules use invisible radiation laser transmitters. Although

most SFP/SFP+/QSFP+/QSFP28 on the market meet LASER safety

specifications, never look directly at the terminals of a module or an

optical cord. Exposure to laser emissions may cause partial or total loss

of vision.

DM4380 –Installation Guide

Hardware DESCRIPTION

204.4336.00 - October/2019

10

3HARDWARE DESCRIPTION

This chapter describes the DM4380 line hardware features.

3.1 PRODUCT OVERVIEW

The DM4380 line has the product version shown below.

Figure 1 - DM4380 12XS+3CX

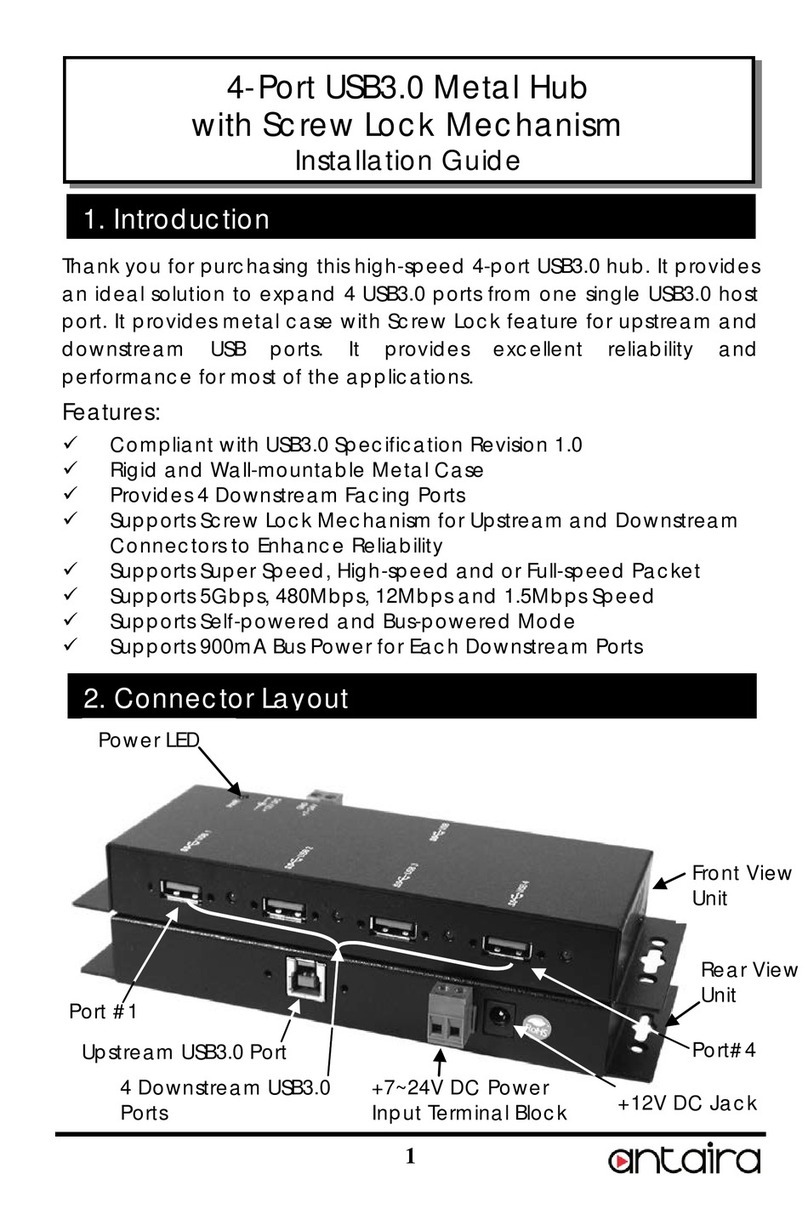

3.2 MODEL DM438012XS+3CX

Figure 2 - DM4380 12CX+3CX Views

Description

1

10GE Ethernet ports

2

40/100GE Ethernet ports

3

10GE Ethernet port LEDs

4

40/100GE Ethernet LED ports

5

Alarm interface (2 inputs and 1 output)

6

RS-232 Console Port

DM4380 –Installation Guide

Hardware DESCRIPTION

204.4336.00 - October/2019

11

7

Ethernet Management Port

8

PSU Slots

9

PSU 125 DC Power Input

10

Power Supply cooling inlets

11

System ALARM/FAIL LED

12

PSU 125 DC Status LEDs

13

PSU 125 DC Status LEDs

14

Auxiliary Safety Grounding

15

Host USB Port

16

USB Port Console

17

PSU 125 AC Power Input

18

Equipment cooling outlets

Table 1 –DM4380 12XS+3CX Interface Description

3.3 EQUIPMENT STATUS LEDS

The DM4380 Switch has two statuses indicating LEDs in the front panel, the LED

ALARM/FAIL located in the Mainboard and the LED PWR located in each PSU. The table

below describes the behavior of the status LEDs of the equipment.

LED PWR

ON GREEN: Indicates that the power supply is running and that

the equipment is powered or on standby ready to take over the

load.

OFF: Power supply with problems or not powered.

LED

ALARM/FAIL

OFF: Equipment operating normally, without detected failures

or alarms.

ON RED: Indicates that the equipment is in a state of internal

failure.

ON BLINKING RED (slow): Indicates that the equipment is in a

lower gravity alarm state.

ON BLINKING RED (fast): Indicates that the equipment is in a

lower gravity alarm state.

When the power is connected to the equipment, this LED will turn

red for a short time, and then will turn off.

Table 2 - Status LED behavior

3.4 SERIAL CONSOLE INTERFACE (RS-232)

The DM4380 equipment line has a console port for local management. The console port

uses an RJ45 connector. A cable with a male RJ45 connector and a female DB9

connector must be used for the connection to a computer or laptop.

The serial console cable is an accessory included in the DM4380. Additional cables can

be purchased separately via code 710.0137.xx or assembled as described in the

DM4380 –Installation Guide

Hardware DESCRIPTION

204.4336.00 - October/2019

12

following figures. The pin assignment of the RJ45 connector and its match with the DB9

connector is described in table 4.

Figure 3 –Console Cable

Figure 4 - Console interface connector pin assignment

RJ45 Male

DB9

Female

Function

DM4380 Input/output

1

-

Reserved

-

2

-

Reserved

-

3

2

RS232_TX

Output

4

5

DGND

Ground

5

5

DGND

Ground

6

3

RS232_RX

Input

7

-

Reserved

-

8

-

Reserved

-

Table 3 - Console interface connector pin assignment

3.5 USB INTERFACE CONSOLE

For management via USB, the DM4380 has a USB console port accessible via Mini-USB

cable (not included) on rear panel.

The driver for use of this interface in Windows can be found in

http://www.datacom.com.br/support.

3.6 USB INTERFACE HOST

The product provides a type A USB interface host on the rear panel that can operate

according to specification 2.0. There is no need to use this interface during the switch’s

installation process. Contact Technical Support for more information on using this

interface.

3.7 INTERFACE MANAGEMENT ETHERNET (MGMT)

The DM4380 has a Gigabit Ethernet interface used for local or remote management of

the switch. For details on how to use it, see the chapter Logging in for First Time. This

interface has two status LEDs whose behavior is described in TABLE 4.

DM4380 –Installation Guide

Hardware DESCRIPTION

204.4336.00 - October/2019

13

Figure 5 - MGMT LEDs (DM4380 12XS+3CX)

Indicator

Color

Status

Description

LINK/ACT

GREEN

Off

Link Down (inactive port)

On

Link Up (active port)

Blinking

Data sending and/or receiving activity

SPEED

YELLOW

Off

Port operating in 1000Base-T mode

On

Port operating in 10Base-T or 100Base-TX

Table 4 –MGMT Interface LEDs

3.8 DATA INTERFACE

3.8.1 10 Gigabit SFP+ Optical Ethernet Interfaces (10GBase-X)

The DM4380 12XS+3CX has 12 10 Gigabit Optical Ethernet interfaces using SFP+

connectors. The status indicating LED contains the LINK/ACT/SPEED information on the

same bicolor LED.

DM4380 –Installation Guide

Hardware DESCRIPTION

204.4336.00 - October/2019

14

Figure 6 - 10GE SFP+ Port LEDs

3.8.1.1 10 Gigabit Optical Ethernet Interface LED indicators

The convention to indicate the operation and mode of operation of the 10GE SFP+

interfaces is described in the table below:

Indicator

Color

Status

Description

LINK/ACT

/SPEED

GREEN

On

Link Up (active port) operating in

10GBase-X mode.

YELLOW

On

Link Up (active port) operating at a rate

lower than 10GE.

GREEN or

YELLOW

Blinking

Data sending and/or receiving activity

-

Off

Link Down (active port)

Table 5 - 10GE SFP+ Interface LED indicators

3.8.1.2 40 and 100 Gigabit Optical Ethernet Interfaces

The DM4380 12XS+3CX has 3 high-speed interfaces using QSFP28 connectors.

DM4380 –Installation Guide

Hardware DESCRIPTION

204.4336.00 - October/2019

15

Figure 7 –40/100GE Ports

3.8.1.3 40 and 100 Gigabit Optical Ethernet Interface LED indicators

The 40GE/100GE ports have LEDs that indicate the operation of the ports on the left

front part of the equipment, as shown in figure 8. The convention to indicate the

operation and the 40GE and 100GE interface operating mode is described in Table 6.

Figure 8 –40/100GE port LEDs

Indicator

Color

Status

Description

LINK/ACT/

SPEED

GREEN

On

Link Up (active port) operating in 100GBase-X

mode.

YELLOW

On

Link Up (active port) operating at a rate lower

than 100GE.

GREEN or

YELLOW

Blinking

Data sending and/or receiving activity

DM4380 –Installation Guide

Hardware DESCRIPTION

204.4336.00 - October/2019

16

-

Off

Link Down (inactive port)

Table 6 –40/100GE Interface LED indicators

3.9 ALARM INPUT AND OUTPUT

The DM4380 has two alarm inputs and one alarm output in an RJ45 connector. Alarm 1

and 2 inputs are isolated via optocoupler. External alarm detection occurs when the

voltage difference between IN+ and IN- reaches 12V. The Table 7 presents the voltages

and status for alarm 1 and 2 inputs.

Signal IN-

Signal IN+

Description

0V (Reference)

0V to 3V

No alarm

0V (Reference)

12V to 60V

Alarm

Table 7 –Conditions for alarm detection

For alarm output, the equipment uses a relay. In an alarm situation

1

or when the switch

is off, pin 7 (common) is short circuited with pin 8 (NF). When operating without alarms,

pin 7 (common) will be short circuited with pin 6 (NA), while pin 8 (NF) will be isolated.

The table below describes the pin settings used in connector RJ45 of the alarm

interface.

RJ45 Male

Signal

1

Input 1 –IN+

2

Input 1 –IN-

3

Input 2 –IN+

4

Input 2 –IN-

5

Not connected

6

Output –NA (Alarm Off)

7

Output –Common

8

Output –NF (Alarm On)

Table 8 - Alarm pin connector

3.10 PSUS AND POWER INPUTS

The equipment of the DM4380 line has two slots for the PSU 125 power supply

(supplied separately).

The DM4380 family has support for two PSU models, the PSU 125 DC operates with -48

/ -60Vdc and PSU 125 AC operates with 100/240Vac (50/60Hz).

The PSU 125 DC has TERMINAL BLOCK power terminals located in front panel of the

PSU.

1

Roadmap feature, contact Technical Support if you have any questions.

DM4380 –Installation Guide

Hardware DESCRIPTION

204.4336.00 - October/2019

17

The PSU 125 AC has three-pin IEC 320/C14 plug power terminals located in rear panel

of the equipment.

The PSU 125 power supplies operate in a 1:1 redundancy manner, with only one being

sufficient to maintain full operation of the equipment. The combination of AC and DC

power supplies in the same equipment is allowed. The insertion/removal of power

cables and the PSU 125s can be hot-swapped, allowing the uninterrupted operation of

the equipment, if one of the two power supplies is turned off or presents failures. The

PSU 125 has a PWR LED on its front panel that, when GREEN, indicates that it is

correctly powered and operational.

Figure 9 - PSU 125 DC front panel

Figure 10 - PSU 125 AC front panel

The equipment is de-energized through its power cable (s). The power

outlet must be nearby and easily accessible.

The electrical installation of the site should be protected by devices

against short circuits.

On the PSU 125 DC, fuses F1 and F2 support currents up to 15A. They

are 86V Fast Acting. If necessary, only replace it with one of the same

specifications. The F3 output fuse supports currents up to 15A. It is also

86V Fast Acting. If necessary, also replace it with another one with the

same specifications.

DM4380 –Installation Guide

Hardware DESCRIPTION

204.4336.00 - October/2019

18

In the PSU 125 AC, fuse F1 supports currents of up to 5A. They are of

Fast Acting type, 250V. If necessary, only replace it with one of the same

specifications. The F1000 output fuse supports up to 15A. It is a Fast

Acting type, 86V. If necessary, also replace it with another one with the

same specifications.

In the situation in which both PSUs are present and the power inputs are

energized and operating with voltages within the specified range, the AC

power inputs will take precedence over the DC power input, regardless of

the connected slot.

In the situation in which both DC PSUs are present and the power inputs

are energized and operating with voltages within the specified range,

PSU 1 will be supplying power to the equipment and PSU 2 will be on

standby.

3.10.1 Pinout and Polarity

3.10.1.1 PSU 125 AC

The figure below presents the IEC 320/C14 connector pinout for the equipment’s power

supply.

Figure 11 –AC Power Connector Pinout

According to the NBR 14136 standard, the grounding pin of the product

must be connected to the grounding installations of the installation site,

since the power pins have no polarity indication.

DM4380 –Installation Guide

Hardware DESCRIPTION

204.4336.00 - October/2019

19

3.10.1.2 PSU 125 DC

The figure below shows the pin settings of the TERMINAL BLOCK connector to power the

switch.

Figure 12 - DC Power Connector Pinout Settings

3.10.2 Power Cables

3.10.2.1 PSU 125 AC

The PSU 125 AC includes a 3-meter power cord in the standard female IEC 320/C14 for

the NBR 14136 plug.

3.10.2.2 PSU 125 DC

The PSU 125 DC includes a 3.5 meter DC power cable in the PP 1 mm2gauge standard

with both ends open and the TERMINAL BLOCK standard male connector (normally

shipped screwed to the PSU 125 DC) for the installation of the cable.

Follow the information below to install the cable to the Terminal Block connector:

Step 1

Remove the TERMINAL BLOCK connector from the PSU 125 DC by

unscrewing the two side screws of the connector using a 1/8"

screwdriver (number 0) as shown below:

DM4380 –Installation Guide

Hardware DESCRIPTION

204.4336.00 - October/2019

20

Figure 13 –Removing the TERMINAL BLOCK from the PSU 125 DC

Step 2

Locate the power cord shipped with the PSU 125 DC, and cut it to

the desired preferred length. If the cable needs to be replaced, it is

important that it have a gauge of 1mm2or higher, and that the

conductor colors follow the specifications of the country where it is

installed.

Step 3

Using the same 1/8" screwdriver (number 0) used above, as shown

below:

Figure 14 –Installing the cable mounted to the TERMINAL BLOCK

Step 4

Before the cable is powered, screw the connector with the cable

installed on the PSU 125 DC, using the same 1/8" screwdriver

(number 0) used above, as shown below:

Figure 15 –Installing the cable mounted to the TERMINAL BLOCK on the PSU

125 DC

Table 9 –Installing the PSU 125 DC power supply

Table of contents

Other Datacom Switch manuals

Popular Switch manuals by other brands

Marshall Electronics

Marshall Electronics VMV-402-SH user manual

Accton Technology

Accton Technology USB204A Quick installation guide

SpeakerCraft

SpeakerCraft LL-One owner's manual

netvox

netvox ZigBee Z802 user manual

ATEN

ATEN ALTUSEN KH2508a user manual

Brocade Communications Systems

Brocade Communications Systems 7800 Hardware reference manual