Datex-Ohmeda M-NMT Use and care manual

Datex-Ohmeda

S/5TM NeuroMuscular Transmission Module, M-NMT (Rev. 02)

Technical Reference Manual Slot

All specifications are subject to change without notice.

Document No. 800 1018-1

June 2001

Datex-Ohmeda Inc.

3030 Ohmeda Drive

53707-7550 MADISON, WIS

USA

Tel. +1-608-221 1551, Fax +1-608-222 9147

www.us.datex-ohmeda.com

Datex-Ohmeda Division,

Instrumentarium Corp.

P.O. Box 900, FIN-00031

DATEX-OHMEDA, FINLAND

Tel. +358 10 394 11 Fax +358 9 146 3310

www.datex-ohmeda.com

Instrumentarium Corp. All rights reserved.

Table of contents

Document No. 800 1018-1

i

TABLE OF CONTENTS

NeuroMuscular Transmission Module, M-NMT

TABLE OF CONTENTS i

TABLE OF FIGURES ii

Introduction 1

1 Specifications 2

1.1 General specifications ..............................................................................................................................2

1.2 Technical specifications............................................................................................................................2

1.2.1 NMT.................................................................................................................................................2

1.2.2 Stimulator........................................................................................................................................2

1.2.3 Regional block mode........................................................................................................................2

2 Functional description 3

2.1 Measurement principle .............................................................................................................................3

2.1.1 Nerve stimulation .............................................................................................................................3

2.1.2 Response.........................................................................................................................................4

2.1.3 Regional block .................................................................................................................................4

2.2 Main components.....................................................................................................................................4

2.2.1 NMT board .......................................................................................................................................4

2.3 Connectors and signals.............................................................................................................................6

2.3.1 Module bus connector......................................................................................................................6

2.3.2 Front panel connector.......................................................................................................................7

3 Service procedures 8

3.1 General service information.......................................................................................................................8

3.2 Service check ...........................................................................................................................................9

3.2.1 Recommended tools ........................................................................................................................9

3.3 Disassembly and reassembly..................................................................................................................13

4 Troubleshooting 14

4.1 Troubleshooting chart .............................................................................................................................14

4.2 Troubleshooting flowchart .......................................................................................................................15

5ServiceMenu 16

5.1 NMT menu..............................................................................................................................................17

6 Spare parts 19

6.1 Spare part list.........................................................................................................................................19

6.1.1 NMT Module, M-NMT rev. 00...........................................................................................................19

6.1.2 NMT Module, M-NMT rev. 01...........................................................................................................19

6.1.3 NMT Module, M-NMT rev. 02...........................................................................................................19

6.1.4 Front panel stickers for AS/3 modules (square buttons) ...................................................................20

6.1.5 Front panel stickers for S/5 modules (round buttons).......................................................................20

7 Earlier revisions 21

APPENDIX A 23

Datex-Ohmeda S/5 monitors

Document No. 800 1018-1

ii

Service check form A-1

TABLE OF FIGURES

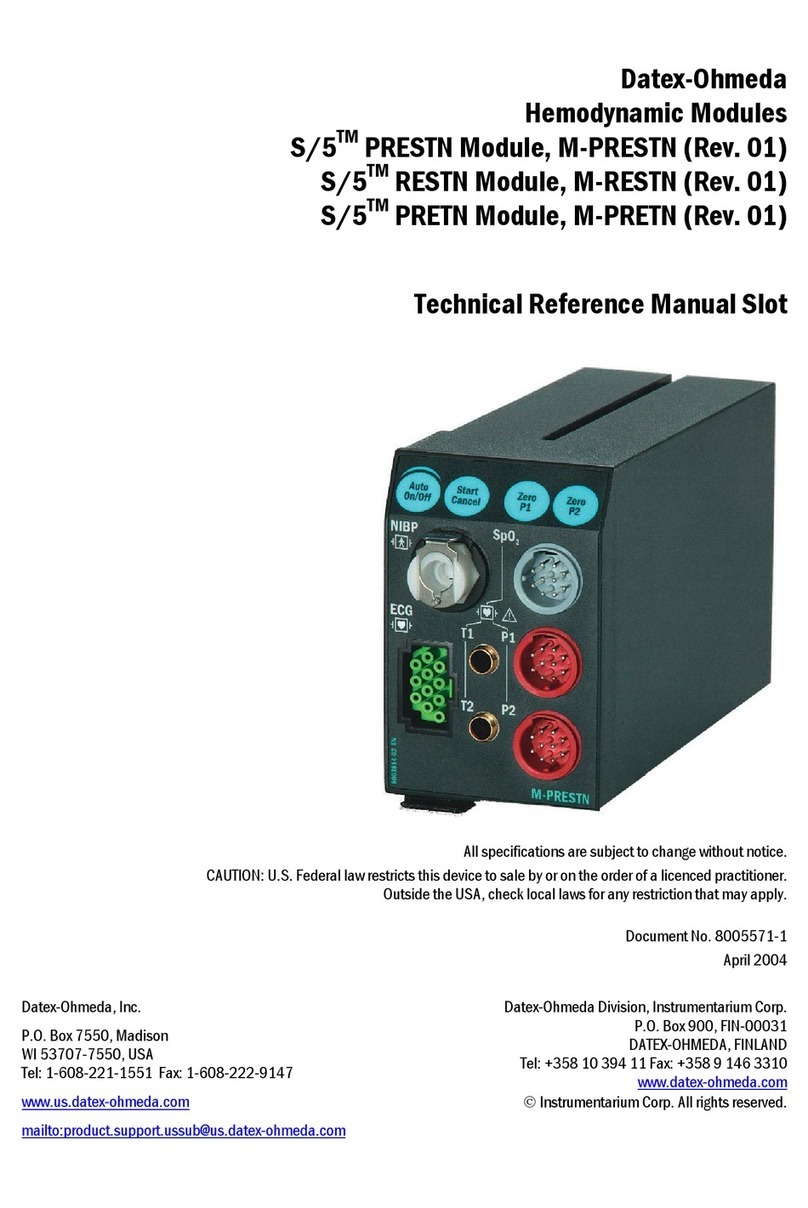

Figure 1 NeuroMuscular Transmission Module, M-NMT ....................................................................................... 1

Figure 2 Principle of response measurement ...................................................................................................... 4

Figure 3 Serial communication and opto isolation............................................................................................... 5

Figure 4 Stimulator block diagram...................................................................................................................... 5

Figure 5 Module troubleshooting flowchart .......................................................................................................15

NeuroMuscular Transmission Module, M-NMT

Document No. 800 1018-1

1

INTRODUCTION

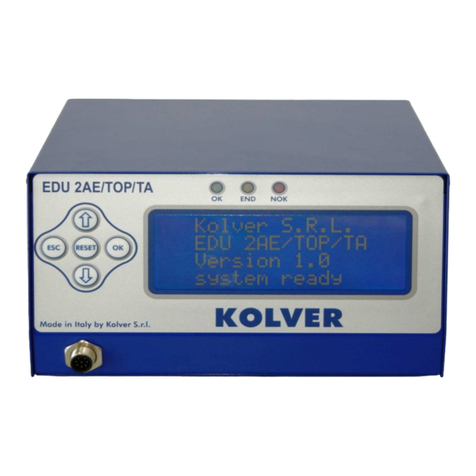

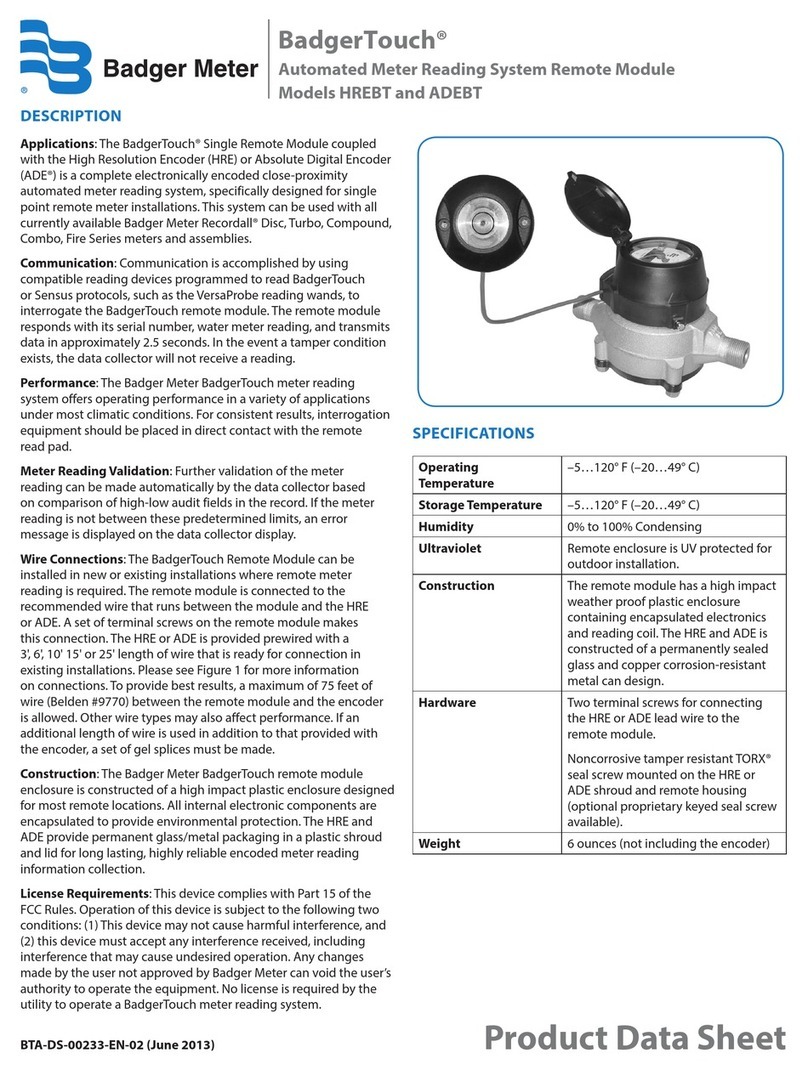

This section provides information for the maintenance and service of the NeuroMuscular

Transmission Module, M-NMT. The M-NMT module is a single width plug-in module designed for

use with the S/5 Anesthesia and Compact Anesthesia Monitors. The module contains peripheral

nerve stimulation and response measurement which supports electromyography EMG. The module

can also be used as a nerve locator for regional nerve blocking with a regional block cable.

However, in this case there is no response measurement.

Figure 1 NeuroMuscular Transmission Module, M-NMT

Datex-Ohmeda S/5 monitors

Document No. 800 1018-1

2

1SPECIFICATIONS

1.1 General specifications

Module size, W ×D ×H 37 ×180 ×112 mm / 1.5 ×7.1 ×4.4 in

Module weight 0.37 kg /0.8 lbs

Power consumption 3.3 W

1.2 Technical specifications

1.2.1 NMT

Stimulation modes Train of four (TOF)

Double burst (3.3) (DBS)

Single twitch (ST)

50 Hz tetanus + post tetanic count (PTC)

Measurement intervals for TOF and DBS

Manual; 10 s, 12 s, 15 s, 20 s, 1 min, 5 min, 15 min

Measurement intervals for ST Manual; 1 s, 10 s, 20 s

1.2.2 Stimulator

Stimulus pulse Square wave, constant current

Pulse width 100, 200 or 300 µs

Stimulus current range 10...70 mA with 5 mA steps

Stimulus current accuracy 10 % or ±3 mA whichever is the greater

Max. load 3 kΩ

Max. voltage 300 V

1.2.3 Regional block mode

Stimulation modes Single twitch

Intervals 1 s, 2 s, 3 s

Stimulus pulse Square wave, constant current

Pulse width 40 µs

Stimulus current range 0...5.0 mA with 0.1 mA steps

Stimulus current accuracy 20 % or 0.3 mA whichever is the greater

NeuroMuscular Transmission Module, M-NMT

Document No. 800 1018-1

3

2FUNCTIONAL DESCRIPTION

2.1 Measurement principle

2.1.1 Nerve stimulation

There are three stimulus modes in the NeuroMuscular Transmission Module: Train of Four (TOF),

Double Burst 3,3 (DBS) and Single Twitch (ST).

In the Train of Four stimulus mode, four stimulation pulses are generated at 0.5 second intervals.

The response is measured after each stimulus and the ratio of the fourth and first response of the

TOF sequence is calculated (TOF%).

NOTE: If the first response does not exceed a certain signal level, TOF% is not calculated due to

poor accuracy.

Double burst (3,3) stimulation includes two bursts with a 750 ms interval. Both bursts consist of

three pulses separated by 20 ms intervals. The responses of both bursts are measured, and the

ratio of the second and first response is calculated (DBS%). EMG responses are measured

immediately after the first stimulus pulse of both bursts.

In Single Twitch stimulation, one stimulation pulse is generated. The response is measured after

the stimulus. In order to prevent decurarization of the stimulated area, the measurement is

automatically stopped after 5 minutes stimulation in 1 sec cycle time.

Tetanic/PTC

Tetanic/PTC (Post Tetanic Count) can measure deeper relaxation than TOF. The tetanic stimulation

is produced when Start is chosen under Tetanic/PTC. The length of stimulation is 5 seconds. The

stimulation generates pulses with a frequency of 50 Hz and with a selected pulse width and

current. After tetanic stimulation and a three second delay, Single Twitch stimulation is produced

to detect the post tetanic count (PTC). PTC describes the number of responses detected after

tetanic stimulation. If there is no response, the measurement will be stopped. If responses will not

fade away, a maximum of 20 responses will be calculated. If more can be detected, the PTC value

is displayed only as '> 20' and measurement will be stopped. If the TOF, DBS or ST measurement

cycle was on when tetanic stimulation started, the cycle will continue after the PTC. After

completing the PTC measurement during 1 minute TOF, DBS or another PTC measurement is not

possible. This is to avoid erroneous readings due to post tetanic potentiation.

Datex-Ohmeda S/5 monitors

Document No. 800 1018-1

4

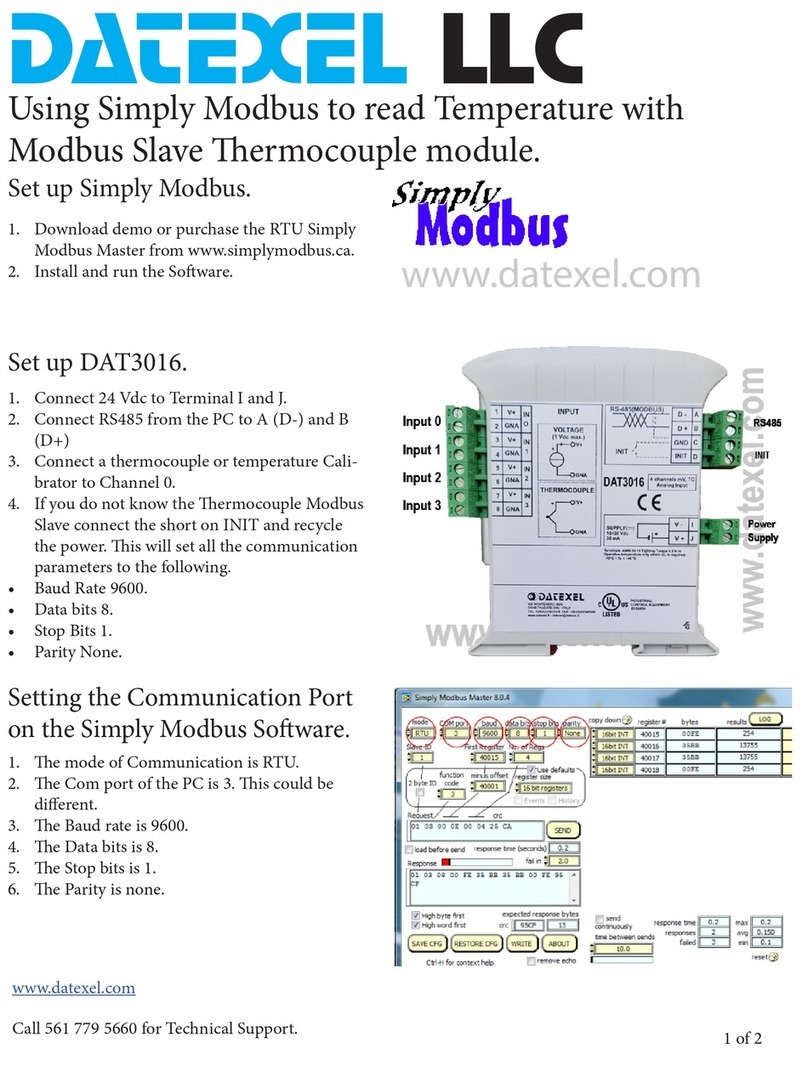

2.1.2 Response

Before each stimulation, the sequence offset, noise and threshold for the response detection is

measured. Offset is a baseline of the noise measurement. Noise is calculated by the same

algorithm as the response signal itself. The response detection threshold is calculated based on

the noise, and if the response is not greater than the threshold then it is interpreted as no response.

EMG

Mechano

Sensor

Measurement

EMG leads off

Timing control

A

/D & P

µ

Figure 2 Principle of response measurement

EMG measurement

The EMG response is measured as integrated muscle activity. The EMG measurement starts 3 ms

after the stimulation and lasts 15 ms. The 3 ms delay helps to prevent the effect of stimulation

artifact.

Mechano sensor measurement

Response is measured as movement of the thumb, which is the area of positive signal.

2.1.3 Regional block

A regional block cable can be used as a nerve locator in local anesthesia. A maximum current of

5.0 mA is given every, every other or every 3rd second. The response measurement is ocular.

2.2 Main components

2.2.1 NMT board

The NMT Circuit Board consists of the following functional sections:

•constant current stimulator

•measuring electronics for the EMG signals

NeuroMuscular Transmission Module, M-NMT

Document No. 800 1018-1

5

•microprocessor for the stimulation and measuring control, and for counting the measuring

results

•serial communication

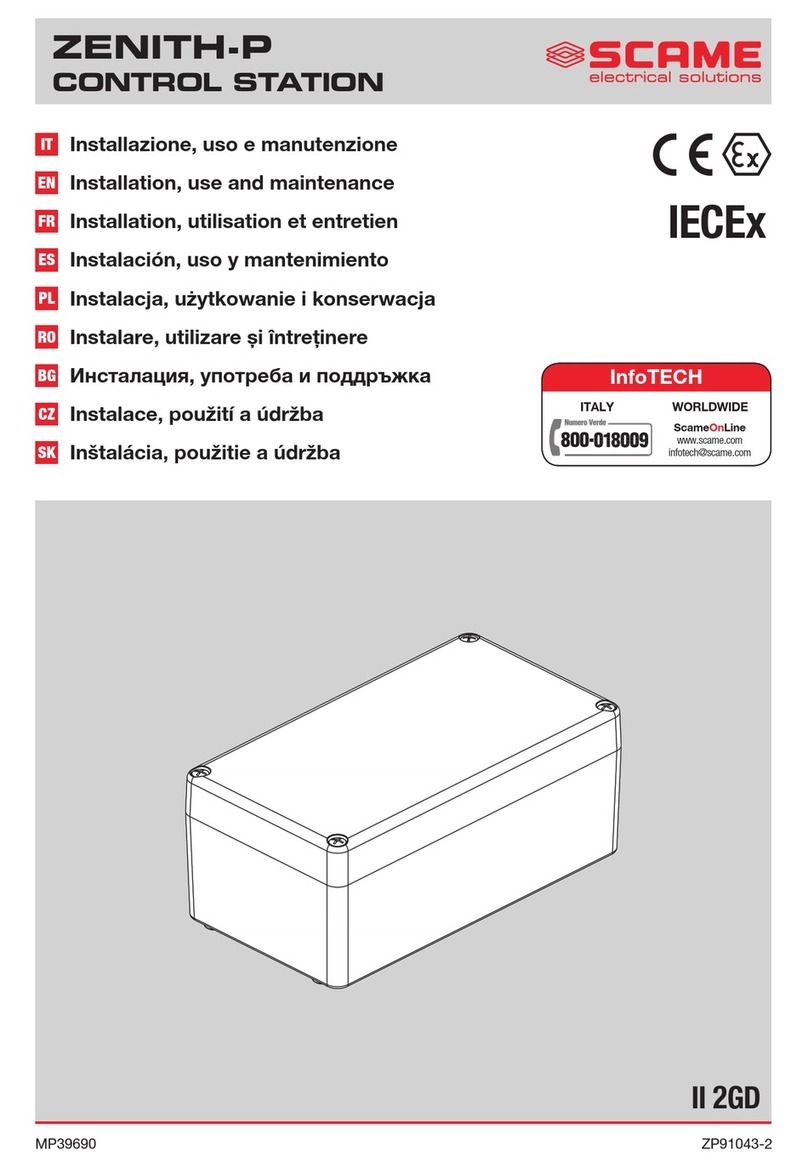

The serial bus speed is 500 kbps and the bus itself is half duplex, i.e. data can be transferred in

both directions but only one way at a time.

Serial communication

Figure 3 Serial communication and opto isolation

Stimulator

The constant current stimulator generates pulses whose amplitude is independent of the load. The

main components of the stimulator are a transformer, a capacitor and a transistor. The transformer

produces a high voltage which charges the capacitor and the transistor adjusts the pulse width and

amplitude of the current.

Patient Constant current

generator

Power supply

Current

adjustment

Current

control

Continuous

stimulation

congestion

80C196KD

PWM

HSO

Figure 4 Stimulator block diagram

Datex-Ohmeda S/5 monitors

Document No. 800 1018-1

6

2.3 Connectors and signals

2.3.1 Module bus connector

13

1

14

25

Table 1 Module bus connector (X1)

Pin No. I/O Signal

1 I RESET_RS485

2 I -15 VDC

3 I +15 VDIRTY

4 I +15 VDC

5 I/O -DATA_RS485

6 I/O DATA_RS485

7 - Ground & Shield

8 I -RESET_RS485

9 I CTSB

10 O RTSB

11 I RXDB

12 O TXDB

13 - Ground & Shield

14 I +32 VDIRTY

15 I GroundDIRTY

16 I CTSC

17 O RTSC

18 I RXDC

19 O TXDC

20 - ON/STANDBY

21 - PWM_ECG

22 - RXDD_RS232

23 - TXDD_RS232

24 I +5 VDC

25 I +5 VDC

NeuroMuscular Transmission Module, M-NMT

Document No. 800 1018-1

7

2.3.2 Front panel connector

NMT connector (NMT)

Pin No. Signal

6

8

9

0

1

2

4

5

7

3

1

2

3

4

5

6

7

8

9

10

EMG Signal +

EMG Signal -

Not Used

Stimulus +

Stimulus -

Ground

Not Connected

Sensor Identification

+5 V

Mechanical Signal

Datex-Ohmeda S/5 monitors

Document No. 800 1018-1

8

3SERVICE PROCEDURES

3.1 General service information

Field service of the NeuroMuscular Transmission Module, M-NMT, is limited to replacing faulty

circuit boards or mechanical parts. Faulty circuit boards should be returned to Datex-Ohmeda for

repair.

Datex-Ohmeda is always available for service advice. Please provide the unit serial number, full

type designation, and a detailed description of the fault.

The Datex-Ohmeda NMT Stimulator (order code 871251) is recommended for functional checks.

CAUTION Only trained personnel with appropriate equipment should perform the tests and repairs outlined in

this section. Unauthorized service may void warranty of the unit.

NeuroMuscular Transmission Module, M-NMT

Document No. 800 1018-1

9

3.2 Service check

These instructions include complete procedures for a service check. The service check is

recommended to be performed after any service repair. However, the service check procedures can

also be used for determining possible failures.

The procedures should be performed in ascending order.

The instructions include a check form (Appendix A) which should be filled in when performing the

procedures.

The mark ?in the instructions means that the check form should be signed after performing

the procedure.

The procedures are designed for monitors with S/5 monitor software of revision 01. However, most

of the procedures also apply to monitors, which contain some other monitor software

type/revision.

3.2.1 Recommended tools

Tool Order No. Notes

NMT simulator 871251

M-NMT ElectroSensor

M-NMT MechanoSensor

M-NMT Sensor Cable

3 kΩresistor

Screwdriver

•Detach the module box by removing the two screws from the back of the module. Be careful

with the loose latch and spring locking pin.

1. Check internal parts:

−screws are tightened properly

−cables are connected properly

−the EMC cover is attached properly

−there are no loose objects inside the module

?

2. Check external parts:

−the front cover and the front panel sticker are intact

−connectors are intact and are attached properly

−the module box, latch and spring locking pin are intact

?

•Refit the module box and check that the latch moves properly.

Datex-Ohmeda S/5 monitors

Document No. 800 1018-1

10

•Turn the monitor on and wait until the normal monitoring screen appears.

•Configure the monitor screen so that information regarding the NMT measurement is shown,

for example:

Monitor Setup - Screen 1 Setup - Digit Fields - Field 4 - Nmt

•Preset the NMT measurement settings:

Others - NMT - Stimulus Mode - TOF

Set Cycle Time - 10 sec

NMT Setup - Current - S(70 mA)

Pulse Width - 200

µ

µµ

µ

S

Stim. Beep Volume - 2

3. Plug in the module. Check that it goes in smoothly and locks up properly

?

4. Check that the module is recognized, i.e. the NMT header with related information appear in

the chosen digit field.

?

5. Enter the service menu:

Monitor Setup - Install/Service (password 16-4-34) - Service (password 26-23-8)

Take down the information regarding NMT software by selecting SCROLL VERS and turning

the ComWheel.

?

6. Enter the NMT module service menu:

Parameters - NMT

Check that the “Timeouts”, “Bad checksums” and “Bad c-s by mod” values are not increasing

faster than by 50 per second. Check that the module’s memories have passed the internal

memory test, i.e. “RAM”, “ROM” and “EEPROM” all state OK.

?

7. Check the front panel START-UP and STOP/CONTINUE membrane keys.

Press each key for at least one second and check that the key being pressed is identified,

i.e. the color under the corresponding text on the menu turns blue.

?

NeuroMuscular Transmission Module, M-NMT

Document No. 800 1018-1

11

8. Check that the message “Cable off” is shown in the digit field and that “Cable” in the service

menu states OFF.

Plug the M-NMT Sensor Cable with the M-NMT ElectroSensor into front panel connector

NMT. Check that the message in the digit field changes to “Measurement OFF” and “Cable”

on the service menu states EMG and ELECTR. OFF.

?

9. Perform the stimulus current test.

Connect a 3 kΩresistor between the ElectroSensor’s stimulus electrode leads (brown and

white).

Start the test by highlighting START CURR. TEST on the service menu and pressing the

ComWheel. Check that the test was successful with all three test currents, i.e. the “Current

test (mA):” on the menu states 30 OK, 50 OK and 70 OK.

?

•Connect the M-NMT ElectroSensor leads to the NMT simulator. Set the switch on the

simulator to “Fade off” and turn the knob to “max”. Check “Cable” on the service menu now

states only EMG.

10. Start NMT measurement (TOF) by pressing the START-UP key on the module.

When the message “Supramax search” changes to “Setting reference” in the digit field,

check that the supramaximal current detected is less than 70 mA, i.e. the “Current set”

value on the service menu is less than 700.

?

11. Check that the module gives four successive stimulus pulses with 10 second intervals. A

small asterisk (✼) should be shown in the digit field during each of the stimulus pulses and

simultaneous sound signals should be heard from the loudspeaker.

Check that on the service menu the values for “T1%”, “T2%”, “T3%”, “T4%” and “Ratio%”

are all within 950-1059.

Check also that in the digit field the “TOF%” value is within 95-105, “Count” is 4 and “T1%”

is within 95-105.

?

12. Check that the “Noise” value on the service menu stays under 50.

?

13. Change the stimulus pulse width to 100 µs through the NMT service menu:

NMT Setup - Pulse Width - 100

µ

µµ

µ

S

Datex-Ohmeda S/5 monitors

Document No. 800 1018-1

12

Check that the “TOF%” value is still within 95-105, “Count” is 4 and “T1%” is within 95-105

in the digit field.

Check the same parameters with a stimulus pulse width of 300 µs.

?

14. Turn the knob on the NMT simulator to “0”.

Check that on the service menu the values for “T1%”, “T2%”, “T3%”, “T4%” turn to 0 and the

“Ratio%” states - - -. In the digit field “TOF%” should also state - - - , and “Count” and “T1%”

should show 0.

Turn the NMT simulator knob back to “max”.

?

15. Change the stimulus mode to Double Burst Stimulation (DBS) through the service menu:

NMT Setup - Stimulus Mode - DBS

Check that the module now gives only two stimulus pulses with a 10 seconds interval.

Check that on the service menu the values for “T1%”, “T2%”, and “Ratio%” are still within

950-1059. In the digit field the “DBS%” value should be within 95-105, “Count” is 2 and

“T1%” is within 95-105.

?

16. Change the stimulus mode to Single Twitch Stimulation (ST):

NMT Setup - Stimulus Mode - ST

Check that the module starts to give only one stimulus pulse with a 1 second interval. Note

the time when the ST stimulation started.

Check that on the service menu the value for “T1%” is within 950-1059. In the digit field the

“Count” value should be 1 and “T1%” within 95-105.

Let the monitor continue to give single twitch stimulation.

?

17. Check that the NMT measurement stops and the message “Measurement OFF” appears in

the digit field for NMT five minutes after the start of the ST stimulation.

?

18. Replace the M-NMT ElectroSensor with the M-NMT MechanoSensor and check that “Cable”

on the service menu states PIEZO.

?

NeuroMuscular Transmission Module, M-NMT

Document No. 800 1018-1

13

19. Perform an electrical safety check and a leakage current test.

?

20. Check that the module functions normally after performing the electrical safety check.

?

21. Clean the module with suitable detergent.

?

•Fill in all necessary documents.

3.3 Disassembly and reassembly

Disassemble the NeuroMuscular Transmission Module, M-NMT, in the following way. See the

exploded view of the module.

1. Remove the two screws from the back of the module.

2. Pull the module box slowly rearward and detach it from main body. Be careful with the loose

latch and spring locking pin.

3. Detach the NMT board by removing the two screws located near the front panel frame,

disconnect the cables and pull out the front panel frame.

To reassemble the module, reverse the order of the disassembly steps.

CAUTION When reassembling the module, make sure that the cables are reconnected

properly.

Datex-Ohmeda S/5 monitors

Document No. 800 1018-1

14

4TROUBLESHOOTING

4.1 Troubleshooting chart

Trouble Cause Treatment

Check the stimulus electrodes.

EMG electrode off.

Loose electrodes or loose stimulus

clip.

Change or attach the electrodes or

clip.

Supramax. not found. Loose electrodes or loose stimulus

clip.

Stimulus electrodes attached to

wrong place.

Patient is relaxated.

Change or attach the electrodes or

clip.

Change the place of the stimulus

electrode.

Response too weak. Loose stimulus electrodes.

Measuring electrodes attached to

wrong place.

Patient is relaxated.

Change or attach the electrodes.

Change the place of the meas.

electrodes.

Ref. not stable. Patient is relaxated.

Movement artifact.

NeuroMuscular Transmission Module, M-NMT

Document No. 800 1018-1

15

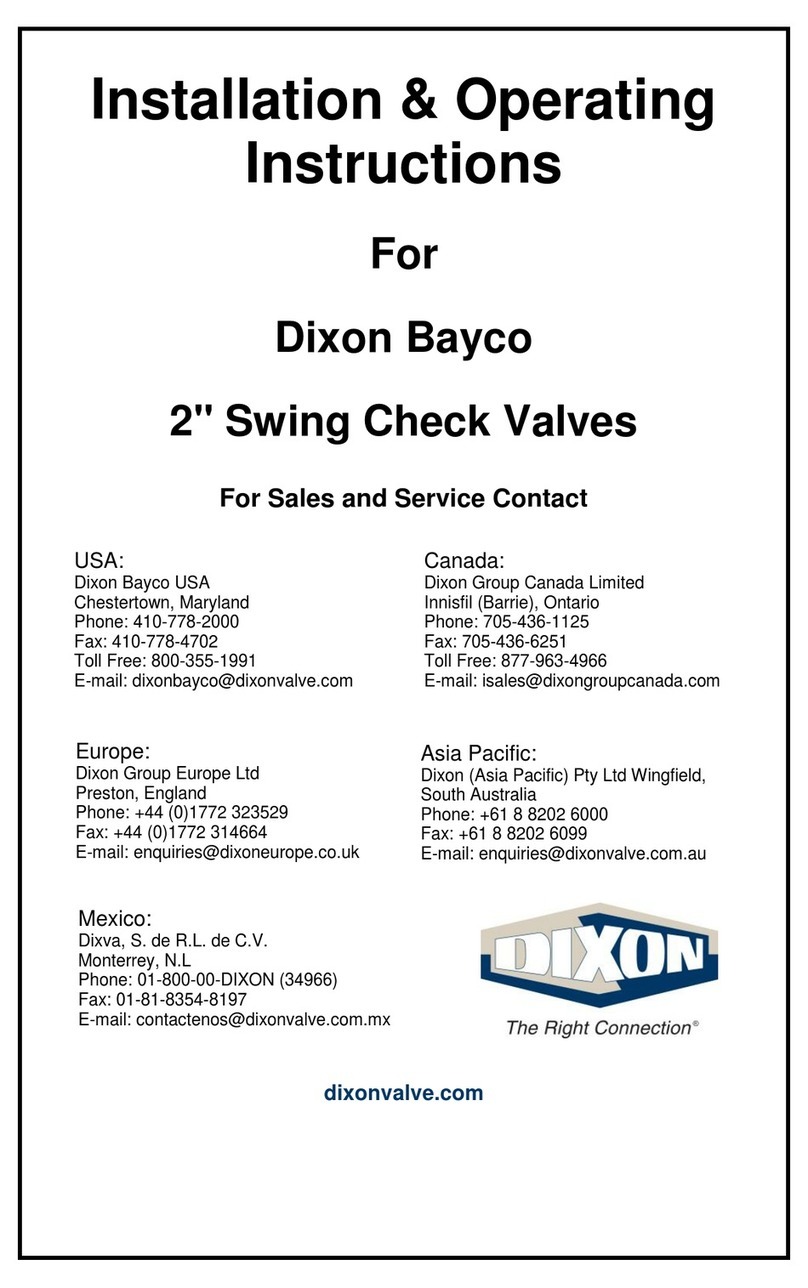

4.2 Troubleshooting flowchart

no

Possible fault in NMT module

Open NMT Service Menu

Check Timeouts, Bad checksums,

Bad c-s by mod

Check RAM,ROM,EEPROM

Check that sensor is identified

Connect ElectroSensor to NMT

stimulator and start measurement

Check front panel key functions

Fault not in NMT module

Replace the original sensor Connect the connector Replace the original

NMT input board

Replace the original sensor

Replace the original NMT input

board

Replace the original sensor

Replace the original NMT sensor

cable

Replace the original NMT input

board

Replace the original keypad

Connect the keypad

Replace the original NMT sensor

cable

Replace the original

NMT sensor cable

Does another module

work in the same slot?

Does the test pass with

another sensor?

Does the test pass with

another NMT sensor

cable?

Are the NMT input board

wires connected?

Does the test pass

with another NMT

input board?

Does the test pass with

another sensor?

Does the test pass with

another NMT sensor

cable?

Does the test pass with

another sensor?

Does the test pass with

another NMT input

board?

Does the test pass with

another NMT sensor

cable

Does the test pass with

another NMT input

board?

Is the keypad

connected?

Does the test pass with

another keypad?

Test stimulus current

OK? Replace NMT board

no

yes

yes

OK?

OK?

yes

yes

yes yes no yes

no

OK?

Responses OK?

OK?

yes

yes

yes

yes

yes

yes

yes

no

yes

no

no

no

no

yes

no

no

no

no

no

yes

no

no yesno

no

no

Replace NMT board

Replace NMT board

Replace NMT board

Replace NMT board

Replace NMT board

Figure 5 Module troubleshooting flowchart

Datex-Ohmeda S/5 monitors

Document No. 800 1018-1

16

5SERVICE MENU

1. Press the Monitor Setup key.

2. Select Install/Service (password 16-4-34).

3. Select Service (password 26-23-8).

4. Select Parameters.

5. Select NMT.

Table of contents

Other Datex-Ohmeda Control Unit manuals

Popular Control Unit manuals by other brands

Acromag

Acromag VPX6860 user manual

Dixon Bayco

Dixon Bayco 3020 Series Installation & operating instructions

Quantum Rehab

Quantum Rehab Network Adapter Dynamic DX Basic operation instructions

MFB

MFB SYNTH LITE II Operator's manual

Badger Meter

Badger Meter BadgerTouch HREBT manual

Automationdirect.com

Automationdirect.com Productivity 1000 P1-08TD2 manual