Datum DTR80R User manual

ROTARY LASER

DIAL-IN DUAL GRADE

MODEL NO.: DTR80R DTR80G

OPERATING

INSTRUCTIONS

TO PREVENT SERIOUS INJURY, READ

AND UNDERSTAND ALLWARNINGS

AND INSTRUCTIONS BEFORE USE.

2ROTARY LASER LEVEL

TABLE OF CONTENT

SPECIFICATIONS ........................................................................................................3

HAZARD SIGNAL WORD DEFINITIONS .................................................................3

GENERAL SAFETY RULES FOR OPERATION .........................................................4

CONTENT CHECKLIST ...............................................................................................5

COMPONENT OVERVIEW .........................................................................................6

LASER CONTROL DESCRIPTION .............................................................................7

DETECTOR CONTROL DESCRIPTION ....................................................................8

PREOPERATION SET UP ..........................................................................................9

OPERATION LASER INSTRUMENT........................................................................10

USING REMOTE FOR DIAL IN GRADE ....................................................................12

OPERATION LASER DETECTOR.............................................................................12

CALIBRATION CHECK................................................................................................13

MAINTENANCE AND SERVICE.................................................................................13

TROUBLESHOOTING .................................................................................................14

PRODUCT LABELS......................................................................................................14

OPTIONAL ACCESSORIES ........................................................................................15

WARRANTY INFORMATION .....................................................................................16

3OPERATING MANUAL

ABOUT YOUR LASER LEVEL

Thank you for purchasing this DATUM Dual Grade Rotary Laser. Your instrument features extra

bright laser technology, motorised self-levelling, manual grade, dial-in grade on both X and Y

axis and much more.

Please read and understand the content of this instruction manual before using this product.

Save this manual for future reference.

SPECIFICATIONS

MODEL DTR80R DTR80G

BEAM COLOUR Red Green

LASER CLASS Class 3R Class 3R

LASER WAVELENGTH 635nm 520nm

ACCURACY ±1 mm at 30m

OPERATING RANGE (WITH DETECTOR) Ø800m

AUTO LEVELLING RANGE ±5°

BATTERY LIFE (CONTI. OPERATION) 20 Hours 15 Hours

POWER SUPPLY 4 x C-cell 1.5V batteries

4 x Ni-MH 1.2V 4000 mAh rechargeable batteries

Ni-MH BATTERY CHARGER (INDOOR) Input:100-240V~, 50/60Hz Output: 5.6V, 900mA

LINE PATTERN 360° Rotating Line

PLUMB DOTS Up and Down (Red) Up (Green) and Down (Red)

IP RATING IP65

TRIPOD THREADS 5/8” on side and base for horizontal and vertical operations

REMOTE CONTROL DT100RM

DETECTOR DT05REC DT06REC

DATUM is constantly improving its products. All information in this manual is based on the latest product information available at the time of

printing. The specications outlined herein are subject to change without prior notice or obligation.

HAZARD SIGNAL WORD DEFINITIONS

!Indicates an imminently hazardous situation which, if not avoided, will result

in death or serious injury. Obey all safety messages that follow this symbol to

avoid possible injury or death.

DANGER Indicates an imminently hazardous situation which, if not avoided, will result

in death or serious injury.

WARNING Indicates a potentially hazardous situation which, if not avoided, could result

in death or serious injury.

CAUTION Indicates a potentially hazardous situation which, if not avoided, may result

in minor or moderate injury.

CAUTION Used without the safety alert symbol indicates a potentially hazardous

situation which, if not avoided, may result in property damage.

!

!

!

4ROTARY LASER LEVEL

GENERAL SAFETY RULES FOR OPERATION

WARNING

Read all safety warnings, instructions, illustrations and specications

provided with this instrument. Failure to follow all instructions listed below

may result in personal injury.

Save all warnings and instructions for future reference.

•Do not stare into beam regardless of distance.

•Do not use the laser intensive glasses as safety goggles, sunglasses or when driving.

•Do not point laser in the direction of other people or animals.

•Do not point laser in the direction of mirrors or other reective surfaces.

•Store in a secure location with the tool case provided when not in use.

•This is a quality precision measuring device and is 100% factory adjusted within the stated

tolerance.

•Laser should not be used as a toy or by children.

•Do not view beam through optical instruments such as theodolites, binoculars, cameras or

magnifying lenses.

•Avoid using laser in darkened areas. Ensure sucient light levels to avoid damage to eyes.

•Set up the instrument to ensure laser beam path is above or below eye level.

•Ensure the instrument is securely set up to avoid accidental movement.

•Always ensure the laser beam is aimed at a sturdy work piece without reective surface.

Bright shiny reective sheet steel or the like is not suitable for laser use as the reective

surface could direct the beam back at the operator.

•Do not break up or throw the battery into re, please recycle the battery after use.

•Turn the instrument o when it is not in use. Leaving the laser on increases the risk of

staring into the laser beam.

•Do not use or store the instrument in locations where the temperature may reach or

exceed 40°C.

•Never use supplied charger to charge alkaline batteries. It’s only designed for charging

the Ni-MH battery pack supplied with the unit.

•Never set laser level on a surface with heavy vibrations or in territories where heavy

apparatus is being worked.

•High mechanical stress, high ambient temperatures or immersion into uids can cause

leakage, re or explosions of the batteries.

•Do not disassemble the instrument or attempt to perform any internal servicing as this will

void your warranty. Not user serviceable parts included. Only approved and authorised

service technicians can carry out warranty repairs.

•Avoid direct eye exposure. Consult your laser safety ocer or IEC 60825.14:2011 Part 14 for

best operating practice.

CAUTION Class 3R laser product according to IEC 60825-1:2014.

Avoid direct eye exposure. Do not direct it towards other people.

!

!

5OPERATING MANUAL

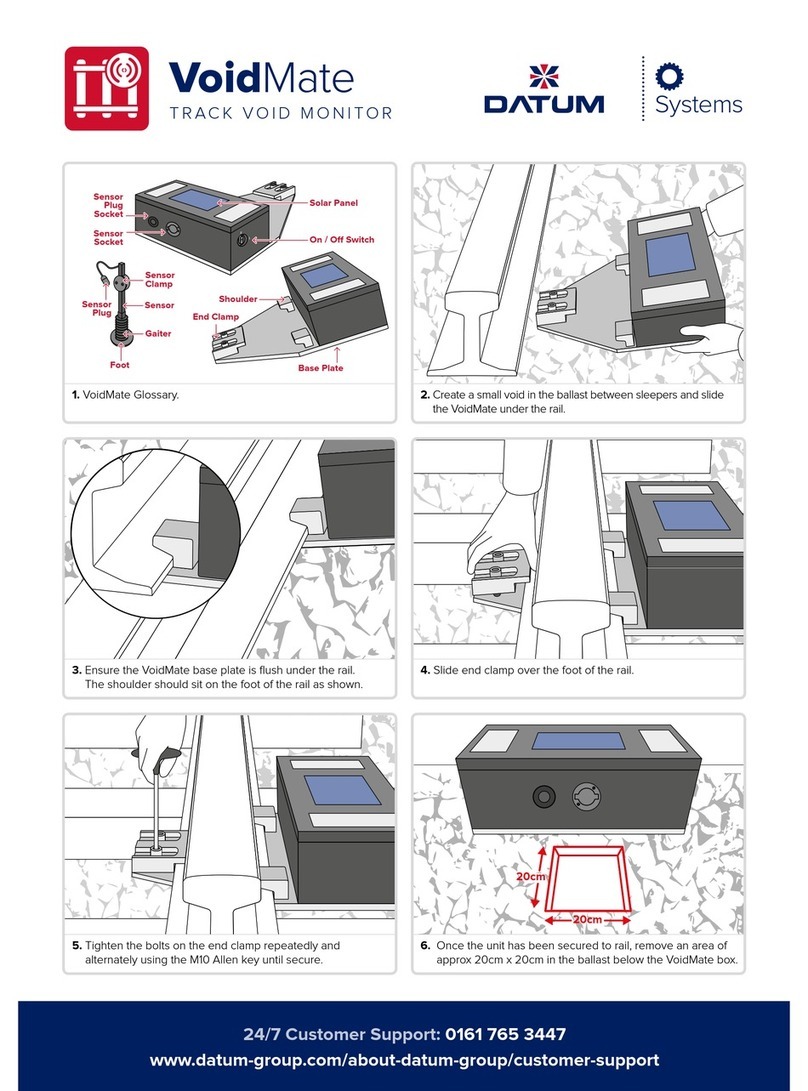

CONTENT CHECKLIST

1

2 3 4

5

6

107 8 9

1. Heavy duty tool case with EVA foam

2. 100m Remote control with LCD screen

3. Millimetre laser detector

4. Dual grade rotary laser

5. Ni-MH battery charger (indoor only)

6. Alkaline battery pack

7. Sta mounting bracket for detector

8. Laser glasses

9. Laser target

10. Ni-MH battery pack

6ROTARY LASER LEVEL

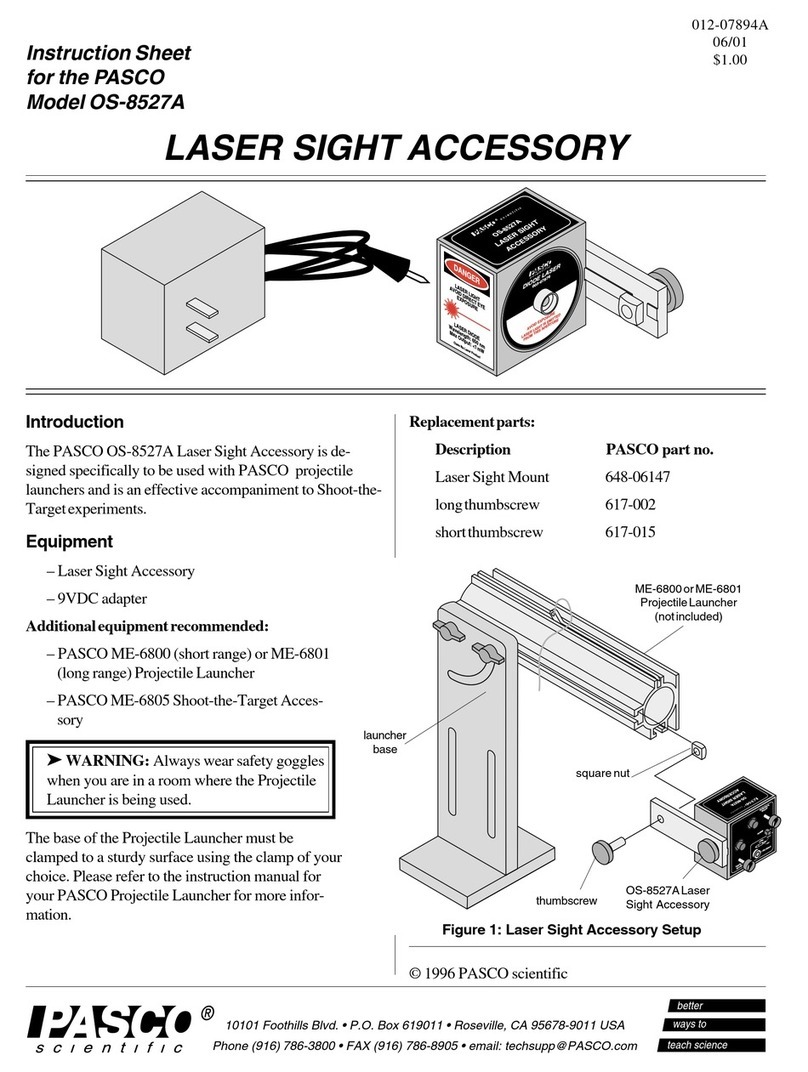

COMPONENT OVERVIEW

1. Metal Lighthouse

2. Rotating laser module

3. Laser control panel

4. Up plumb dot output window

5. Rubber feet - for vertical operation

without tripod

6. 5/8” Tripod thread - for vertical operation

7. Battery compartment

21

3

78

9

5

8. Battery charging jack

(for Ni-MH battery only)

9. Down plumb dot output window

with 5/8” tripod thread - for horizontal

operation

10. Signal output window

11. Digital screen for dial-in grade

12. Remote control panel

4

6

10

11

12

7OPERATING MANUAL

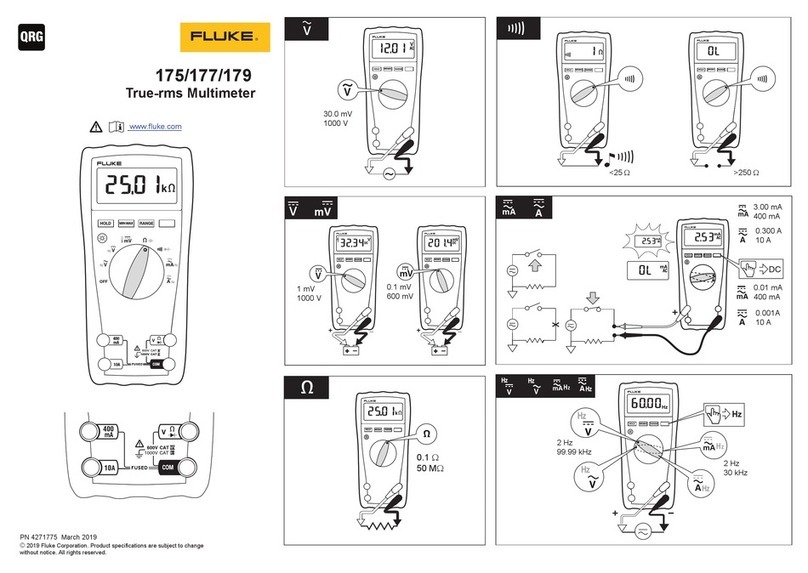

LASER CONTROL DESCRIPTION

BUTTON DIRECTION OF USE

A - Counter-clockwise

Rotation Control

In scanning mode, press this button to move the scanning beam in a

counter-clockwise motion.

B - Clockwise Rotation

Control

In scanning mode, press this button to move the scanning beam in a

clockwise motion.

C - RPM Speed Control When a slower speed is required for visibility, adjust the speed by pressing

RPM button. There are 5 rotation speeds to choose from: 0 - 60 - 120 - 300

- 600

D - Scan Mode The scan mode allows the laser beam to emit only in a restricted radius

forming a horizontal line. There are 5 width of scanning motions choose

from: 0° - 10° - 45° - 90° - 180°

To move the line, press Rotation Control button (A and B).

To exit the scan mode, press the RPM button (C).

E - Tilt Alarm/Wind Mode Press once to activate Tilt Alarm mode.

Press again to switch to Wind Mode.

F - Manual/Auto Control When the power is on, the laser starts with Automatic Mode. Switch to

Manual Mode for grading slopes. The LED indicator light is on when Manual

Mode is active.

G - Grade Adjustment In Manual Mode, these two buttons allow you to adjust grade on X axis.

H - Grade Adjustment In Manual Mode, these two buttons allow you to adjust grade on Y axis.

Laser Power Button Press the On/O button to turn on the laser.

The instrument always starts up in Automatic mode and begins self-

levelling if it’s set up within 5° range (horizontal or vertical). Switch to

Manual mode by pressing button (F).

A

C

E

B

D

F

G

H

G

I

8ROTARY LASER LEVEL

DETECTOR CONTROL DESCRIPTION

BUTTON DIRECTION OF USE

I - On/O Detector On/O button.

J - Volume Control O-Medium-High

K - Units Selection/Screen

Backlight

Unit Selection - Press the button to switch dierent unit for readings:

cm, mm, in and ft.

Screen Backlight - Press and hold this button for 3 seconds to activate the

backlight for extra visibility.

L - Accuracy Setting Change detection accuracy.

LED INDICATOR DESCRIPTION

ORANGE Indicates the laser beam is above the leveled line

GREEN Indicates the laser beam is on grade with the levelled line

RED Indicates the laser beam is under the levelled line

3

4

1

5

2

I

1. Speaker

2. LED indicator lights

3. Bubble level

4. Laser sensor panel

5. LCD screen

6. Sta mounting

bracket

6

J

K

L

9OPERATING MANUAL

PRE-OPERATION SET UP

POWER SUPPLY

Alkaline Battery Pack

•Your instrument requires 4 C-cell batteries. Use only new, high-quality battery for best

results.

•Locate battery compartment at the bottom of the laser. Insert batteries into the carrier

according to the symbols and polarity then place it into the battery compartment.

•When the battery voltage is low, the power indicator light will start ashing in which the

batteries must be replaced.

•Once the voltage is below 3.9V, the unit will shut o automatically due to low battery.

Ni-MH Battery Pack

•Your laser is supplied with a rechargeable Ni-MH battery pack and a battery charger.

•Place Ni-MH battery pack into the battery compartment. Charge the battery via charging

port (one on base and one on the side) with the supplied charger (indoor use only).

•Battery indicator light on charger is in red while charging. Once the battery is charged in

full, the indicator light will turn into green.

•Remove the charger once the battery is full.

•When the battery is running low, all LED indicator lights on the control panel will start

ashing in which the battery pack must be recharged.

WARNING

Only use charger supplied by DATUM to charge the Ni-MH batteries. Using a

battery charger not recommended by DATUM can destroy the batteries.

The charger supplied is indoor use only. Do not charge alkaline batteries.

LOCATION

•Keep the location clear of possible obstructions that could block or reect the laser beam.

•Place the instrument on stable ground. Ground vibration and extremely windy conditions

can aect the operation.

SETTING UP ON TRIPOD

•Attach the instrument securely to a tripod or wall mount on a stable level surface.

See “Optional Accessories”for recommendations.

•Be sure to secure the tripod or wall mount to avoid windy conditions.

LASER PLACEMENT

•HORIZONTAL OPERATION - set up the instrument up right on a stable at surface, tripod or

wall mount. Ensure the instrument is set up within ±5°.

•VERTICAL OPERATION - lay the instrument on its back on a stable at surface, tripod or wall

mount. Ensure the instrument is set up within ±5°. This can be used for vertical alignment

of form work, pipelines and etc.

!

10 ROTARY LASER LEVEL

OPERATION - LASER INSTRUMENT

ON/OFF

Press the power button to turn on the instrument. Once it’s on:

•The instrument always starts up in Automatic Mode and begins self-levelling if it’s set up

within 5° range (horizontal or vertical). During self-levelling, laser beam ashes before it

starts spinning.

•Once it’s self-levelled, laser head will start to spin, emitting a rotating laser beam pattern.

•If the instrument is bumped or senses interference, the laser head will stop spinning

and re-level. Once unit has re-levelled, the laser head will begin to spin again, emitting a

rotating laser beam pattern.

•If the instrument is outside of the 5° range, it will not level causing the laser beam to ash

continuously. Reposition your instrument within the range until the instrument can re-

level.

Note: If the unit has been bumped or moved and the laser recommences spinning the instrument may not

be at the original level position. Please recheck your RL/datum point.

RPM SPEED CONTROL

Rotation speed can be controlled by pressing RPM button on the instrument. In automatic

mode, laser rotation speed starts at 600rpm. Adjust the speed from 600rpm - 0rpm - 60rpm -

120rpm- 300rpm - 600rpm.

SCAN MODE

The scanning mode allows the laser beam to emit only in a restricted radius forming a horizontal line within

180°. There are 5 levels to choose from: 0° - 10° - 45° - 90° - 180°.

•Turn on the instrument and allow self level.

•Press the SCAN button to active scan mode. Laser starts with 0° when entering scan mode.

•Adjust the scan width by pressing scan button.

•To move the scan line, utilise the rotation control buttons.

•To exit the scan mode, press RPM button and the laser will begin to self-level and rotate

again.

ROTATION CONTROL

In scan mode:

•Press the counter-clockwise rotation button to move the laser line to the left.

•Press the clockwise rotation button to move the laser line to the right.

11OPERATING MANUAL

MANUAL MODE GRADE SLOPE MODE

Your rotary laser has an incorporated grade slope function to manually set grades/slope up

to 8% on X and Y axis.

•Turn on the instrument and allow self level. Then press AUTO/MAN button the instrument

active manual mode.

•Manual mode indicator light is on when it’s activated.

•In manual mode, the self-levelling will be deactivated for grading slope.

•Press AUTO/MAN button again to turn o manual mode and return to automatic self-

levelling mode.

HOW TO USE MANUAL MODE

Once laser is levelled and spinning, press the AUTO/MAN button to activate manual mode.

•Use the left and right arrows to adjust the slope of the laser along the X axis

•Use the top and down arrows to adjust the slope of the laser along the Y axis

•To return to the auto-level mode, press the AUTO/MAN button again.

Note: When in manual mode, the laser will not self level.

TILT ALARM

Once the instrument is automatically levelled. Tilt Alarm can be activated by pressing the tilt

alarm button (E). This function becomes active and monitors the movement of the laser

30 seconds after it’s completely levelled and starts rotating.

This is used to prevent incorrect work or readings caused by movement.

•When activated, tilt alarm indicator light ashes continuously.

•If the instrument is knocked or interfered with while the alarm is activated, the laser will

stop rotating and start ashing. In this case, check and adjust the instrument set up. It’s

also recommended to check DATUM point when the unit re-levels.

•Reset the instrument by turning it o then back on. Or press TILT/WIND button twice to

deactivate the alarm.

WIND MODE

Your instrument comes with a built in Wind Mode feature to assist with levelling in high wind

conditions. When Wind Mode is activated, the laser will continue to self-level without cutting

out when interfered by high wind, vibration or slight movement.

•To active wind mode, press TILT/WIND button twice. When activated, the indicator light

right next to WIND will light up.

•To turn o wind mode, press the button again to deactivate this function and return to

self-levelling mode.

Note: Tilt Alarm and Wind Mode cannot be used simultaneously as they function in the

opposite way.

12 ROTARY LASER LEVEL

USING REMOTE FOR DIAL IN GRADE

Your instrument comes with an digital wireless remote which allows you to set up dial-in grade

at a distance up to 100m.

Turn on the instrument and allow self-level. Turn on the remote and

allow them to sync.

To create a dial-in grade with the remote:

•Press“GRADE” button on the remote control to activate dial-in

grade. The remote screen will show the dial-in function for X and

Y axis with X axis selected.

•Setting desired grade by pressing button “+” and “-” on the

remote control. It’s designed to grade with increment of 0.1%.

•To grade Y axis, press “X/Y” once to switch to Y axis and adjust by

pressing “+” and “-” on the remote control.

•Once your desired grade is set up, press “GRADE” again. The laser

head will stop spinning for a few seconds and adjust its slope to

the grade then start spinning.

•Exit Grade Mode by pressing“GRADE” button again. The instrument will switch back to

Automatic Mode and begin self-levelling. Levelling icon on remote will start blinking while

it’s self-levelling.

For other operation controls such as RPM speed control, scanning mode and rotation control,

refer to previous section for details.

OPERATION - LASER DETECTOR

Your detector uses 4 x AA 1.5V batteries. Locate battery compartment at the back of the

detector and insert batteries according to the symbols and polarity.

Mounting the sta clamp to the detector via the 1/4” thread on the back.

•Switch the detector on by pressing the power button.

•The LCD screen will display the battery level, accuracy setting and speaker mode.

•Press button (L) to change between dierent accuracy settings.

•Move the detector into the path of the laser beam.

•Hold the detector upright for horizontal beams or rotate the detector 90° for vertical

beams.

•The direction arrows or level line on the LCD screen will indicate the position of the laser

beam. The detector will emit a constant beep once the level position has been located.

WARNING

If the product is used with accessories, for example masts, staves, poles, you

may increase the risk of being struck by lightning.

Do not operate the product in a thunderstorm.

!

13OPERATING MANUAL

CALIBRATION CHECK

It’s possible for you to check the calibration of the laser. It’s recommended to check the

calibration of the laser before performing any levelling task. Calibration by yourself is only

approximate and the accuracy of the calibration will depend on the care with which you

proceed.

•Place the instrument on a at, level surface or a tripod 30m away from a wall or sta with a

detector.

•Align the rst axis so that it’s square to the wall or sta. Allow the laser to self level

completely.

•Mark the position of the beam on wall or note the position of the beam from sta (P1).

•Rotate the instrument 180° and allow the instrument to self level again.

•Mark or note the position of the beam (P2).

•Rotate the instrument 90° and align the second axis so that it’s square to the wall and

allow the laser to self level completely.

•Mark the position of the beam on wall or note the position of the beam from sta (P3).

•Rotate the instrument 180° and allow the instrument to self level again.

•Mark or note the position of the beam (P4).

•The instrument is within its accuracy specication if the 4 parts are within ±1 mm from the

centre.

MAINTENANCE AND SERVICE

•The instrument is a precision measuring device and should always be handled with care.

•Do not attempt to open the device. To ensure product SAFETY and RELIABILITY, repairs,

maintenance and adjustment should be performed by authorized service centres.

Contact your dealer for more details.

•Do not drop, knock or shake the laser level as this will aect precision.

•Remove batteries when the instrument is not in use.

•Keep the instrument clean at all times. Use a soft lint-free cloth for the body and lens tissue

for glass windows. Do not use abrasive cleaners or solvents.

•Do not store the instrument in the hot areas, hot temperatures can short the life of

electronic device, damage battery, and warp or melt certain plastics.

•Do not store the laser level in the cold areas. When the unit warms up to its normal

operating temperature, moisture can form inside where it may damage circuit board.

•Avoid shock, vibrations, extreme heat and humidity.

•Do not immerse the instrument in water.

•Always turn the instrument OFF when storing, transporting or moving around the job site.

•Calibration is recommended at least once a year or as needed.

•When transporting the instrument, always make sure that it’s carried in its original tool

case. Never carry the product loose in a road vehicle.

14 ROTARY LASER LEVEL

TROUBLESHOOTING

ISSUE POSSIBLE CAUSE AND SOLUTIONS

Laser does not turn on

Check batteries. Make sure batteries are installed according to the

correct polarity.

The batteries may be low or depleted. Make sure the batteries are in

proper working condition. If in doubt, try installing new batteries.

If the laser has been stored in extremely hot temperatures, allow it to

cool.

Laser does not level

Instrument may be outside it’s levelling range. Position the

instrument, tripod or the base surface.

Instrument may have impact damage. Contact service centre for

repair and calibration.

Instrument may be outside its self-levelling range. Adjust the position

within the self-levelling range.

Instrument may be in Manual Mode. The laser must be in Automatic

Mode to self level.

Laser beam distance is reduced Dirt and dusty condition can reduce the visibility of the laser beam.

Clean the laser output window.

Laser head does not rotate Instrument may be levelling or in Wind Mode. Refer to“Direction of

U s e ”.

Laser detector is not working

properly

The detector may be low in battery. Replace batteries and install

according to the correct polarity.

The detector may be out of usable range. Move the detector closer to

the instrument.

PRODUCT LABELS

DTR80R DTR80G

15OPERATING MANUAL

OPTIONAL ACCESSORIES

DATUM oers a range of accessories that are compatible with our laser levels. They can be

purchased separately and add more exibility to get your job done.

HEAVY DUTY WALL BRACKET (DT05AC)

DOME HEAD LASER TRIPOD (DT1730D) FLAT HEAD LASER TRIPOD (DT1730F)

5M E-FACE STAFF (DT5ME) 5MM-FACE 5 SECTION STAFF (DT5MCM)

Maximum height:

1730mm

Minimum Height:

1010mm

Maximum height:

1730mm

Minimum Height:

1010mm

July 12, 2019 11:57 am

WARRANTY INFORMATION

This warranty is provided by DATUM of 20 Thackray Road, Port Melbourne VIC 3207.

Phone: 1800 868 258.

Express Warranty

Subject to the exclusions set out below, we warrant that this product will be free from defects

in materials or workmanship for 3 years (90 days for accessories, batteries and chargers) from

the date of purchase.

The benets conferred by this warranty are in addition to all rights and remedies which you

may be entitled to under the Australian Consumer Law, and any other statutory rights you may

have under other applicable laws. This warranty does not exclude, restrict or modify any such

rights or remedies.

Warranty exclusions

This express warranty does not apply where a defect or other issue with the product is caused

by normal wear and tear, misuse or abuse of the product.

Consumer guarantees

Our goods come with guarantees that cannot be excluded under the Australian Consumer Law.

You are entitled to a replacement or refund for a major failure and for compensation for any

other reasonably foreseeable loss or damage.

You are also entitled to have the goods repaired or replaced if the goods fail to be of acceptable

quality and the failure does not amount to a major failure.

Warranty claims

To make a claim under this warranty, you must bring the product along with the proof of

purchase and any other documentary evidence which you think is relevant to the your place of

purchase where the claim will be handled on our behalf during the warranty period specied

above. Any cost incurred by you in bringing the product to the place of purchase will be borne

by you.

Calibration and repair service

Datum recommends to check instrument calibration at least once a year or on as needed

basis. For calibration or repair service (not covered under warranty), please visit your place of

purchase.

This manual suits for next models

1

Table of contents

Other Datum Measuring Instrument manuals