Davco BC604 SS User manual

March 2010

March 6, 2009

B

BE

EF

FO

OR

RE

E

O

OP

PE

ER

RA

AT

TI

IN

NG

G

T

TH

HE

E

D

DA

AV

VC

CO

O

®

B

BR

RU

US

SH

H

C

CU

UT

TT

TE

ER

R

A

AC

CC

CO

OM

MP

PA

AN

NY

YI

IN

NG

G

T

TH

HI

IS

S

M

MA

AN

NU

UA

AL

L,

,

P

PL

LE

EA

AS

SE

E

I

IN

NS

ST

TA

AL

LL

L

T

TH

HE

E

I

IN

NC

CL

LU

UD

DE

ED

D

C

CA

AU

UT

TI

IO

ON

N

D

DE

EC

CA

AL

LS

S

IN THE CAB OF THE BRUSH CUTTER

CARRIER IN A HIGHLY VISIBLE AREA

March 2010

March 6, 2009

W

WE

EL

LC

CO

OM

ME

E

Congratulations on your purchase of a DAVCO ®

Manufacturing BC604SS Brush Cutter. The DAVCO® Brush

Cutter, when combined withan approved carrier, will provide

you with unmatched durability, productivity and versatility. As

an Owner or Operator, it is your responsibility to learn the

capabilities and limitations of the DAVCO®BC604SS Brush

Cutter to maximize both safety and performance. Before

operating this DAVCO®product, make sure you read and

understand this owner’s manual as well as your carrier’s

operations manual. If you have any questions or comments

regarding this or other DAVCO® products, don’t hesitate to

contact us by phone @ (780) 532-0097, by fax @ (780) 532-7101

or by e-mail: mulchers@telus.net.

March 2010

March 6, 2009

P

Pe

er

rs

so

on

na

al

l

&

&

P

Pr

ro

op

pe

er

rt

ty

y

S

Sa

af

fe

et

ty

y

•Brush cutting, mowing, or other operations that can cause flying

debris, can be a fire hazard in the carrier. With the engine off and

cool, regularly inspect and clean the engine compartment and other

areas where there may be hot or rotating parts. This should be

performed as often as needed to prevent the combustion of this

debris. Failure to do so could result in a fire, causing severe

machine damage, injury or death.

•DO NOT operate DAVCO ®Brush Cutters within 200 yards of

living things or items susceptible to damage from flying debris or

falling trees.

•DO NOT operate without safety approved shielding (door).

Proper Personal Protective Equipment (i.e. Safety glasses, hard

hat, dust mask, etc.) is highly recommended. Failure to do so

could result in damage, injury or death.

•When the disc is rotating, DO NOT tilt the DAVCO® Brush

Cutter so the knives are in line with the operator.

•Before servicing or leaving the cab: be sure the hydraulics are

disengaged, the engine is shut off, and the discs have come to a

complete stop. (Note: to prevent run-on, try to stall the disc into

the ground or brush and disengage the hydraulics.)

•To remove debris from the brush cutter, the brush cutter must

remain flat on the ground. Any other method may result in

damage, injury or death.

•DO NOT straighten bent cutting knives. Straightening bent

knives may cause cracking. Bent knives should be replaced with

new DAVCO ®replacement knives.

March 2010

March 6, 2009

S

SP

PE

EC

CI

IF

FI

IC

CA

AT

TI

IO

ON

NS

S:

:

Attachment type: Industrial Brush Cutter

Model Number: BC604 SS

Attachment Weight: 1500 lbs.

Required Hydraulic Flow: 22-30gpm

Required Hydraulic Pressure: 3000 psi

P

PL

LE

EA

AS

SE

E

N

NO

OT

TE

E:

:

•It is the responsibility of the owner/operator to inspect and maintain parts and

equipment for the utmost reliability and safety.

•Periodically check all nuts and bolts for proper tightness and excessive wear.

•For the owner/operator’s convenience, DAVCO

®

Manufacturing has provided

a parts list in this operator’s manual for replacement parts

. Factory

Replacement parts are to be used to maintain warranty.

•Before shutting off the hydraulic motor, gradually throttle down to idle before

disengaging the hydraulic valve. This helps to prevent cavitation in the

hydraulic motor, and to help slow the cutting disc down; it can be stalled into

the ground or brush after being disengaged.

•Route Hoses properly & watch your hoses, pinched hoses are not warrantable

March 2010

March 6, 2009

3. General Operations

Fig. 3-1

*The BC-604SS model DAVCO® Brush Cutter is rated for cutting

vegetation and trees up to 4 inches in diameter.

Fig. 3-2

For optimal performance, the DAVCO® Brush Cutter should be kept level with

the ground during operation (see Fig. 3-2). Caution-to prevent damage to your DAVCO®Brush Cutter take

care to avoid hidden obstacles such as rocks, underground wires and other buried objects.

Fig. 3-3

Figure 3-3 shows a common position for the DAVCO® Brush Cutter during

operation. This cutting position is also a very effective method of mulching debris into finer pieces. Note:

excessive tilting of the Davco®Brush Cutter is not recommended, although slight tilting of the deck into

the direction of travel can increase cutting efficiency.

Fig. 3-4

*Figures 3-4 demonstrates a method of brush cutting that is not recommended.

Cutting in this manner throws debris outward and increases the likelihood of bending the cutting blades.

March 2010

March 6, 2009

Fig. 3-5

Never expose the underside of the DAVCO® Brush Cutter to the operator’s cab (Fig.

3-5) or to personnel within sight of the machine. Flying debris can cause equipment damage, serious injury

or death. Never exit cab while loader arms are raised.

4. Knife change

Fig. 4-1

Remove the disc inspection cover (1) in Fig. 4-1 to gain access to the top of the disc.

Rotate the disc by hand until the first set of knife bolts are visible in the hole.

Fig. 4-2

To remove the knives, set the DAVCO® Brush Cutter on the stand or blocks, undo

the nuts (as illustrated on Fig 4-2), drop the bolts, and then remove the knives and the pucks horizontally.

To install the knives, reverse the procedure, and torque the bolts to 250 ft/lb for Course thread or 300 ft

lbs for fine thread bolts. Note- Remember to re-torque the bolts after the first 8 hours of operation

following a knife replacement

5. Identification

Fig 5-1

Fig. 5-1 shows the identification of the DAVCO® Brush Cutter that includes the

serial numbers and the model (B). Please refer to these numbers when calling for technical support, or

replacement parts.

Fig 6-1

Spindle bolts (Item A in Figure 6-1) must be torqued to 300 ft/lb. Inspect

periodically.

March 2010

March 6, 2009

Maintenance & Tips

•Grease Daily: Four or five pumps of quality grease from a hand pump grease gun, which meet the

NLGI GC/LB requirements to each bearing’s grease nipple once a day minimum.

•Cutting Knives are to be inspected daily for sharpness, excessive wear or bending (If used while

bent, damage to the bolts, pucks and discs may occur). DAVCO® knives can be sharpened, or

turned over. DO NOT straighten bent cutting knives.

•Pucks are to be inspected periodically and with every knife change for excessive wear. Rotate the

pucks 1/3 of a turn with each new knife and replaced if necessary. For maximum Puck life put a

coating of assembly grease around the outside of the puck.

•Knife bolts to be inspected with every knife change for excessive wear or bending. Bolts have to

be changed if any damage is found. Torque the knife bolts to 250 ft/lbs. for Course thread or 300

ft lbs for fine thread bolts. Re-torque the knife bolts after the first 8 hours of use, and as

required thereafter.

•Stover nuts to be inspected and changed with every third knife change because they may lose

their self-locking ability(When using Course thread bolts).

•Discs need to be inspected at regular intervals. After excessive use cracks may appear, if this is the

case the disc assemblies must be changed.

•Housing Bearings: With the disc rotating at a low RPM, listen for rumbling or grinding sounds in

the housing, which could be a sign of possible bearing failure.

•Spindle Nut (item #3, on Fig. 7-1) torque must not exceed 200 in/lb. Excessive preload on

bearings will cause premature failure. Check pre-load every 200hrs.

•Maintain a constant RPM on the DAVCO® Brush Cutter, using the travel speed of the carrier to

determine the thoroughness of the cut. The slower that the carrier travels, the more complete the

cut that the DAVCO® Brush Cutter will make, and the finer the mulch.

March 2010

March 6, 2009

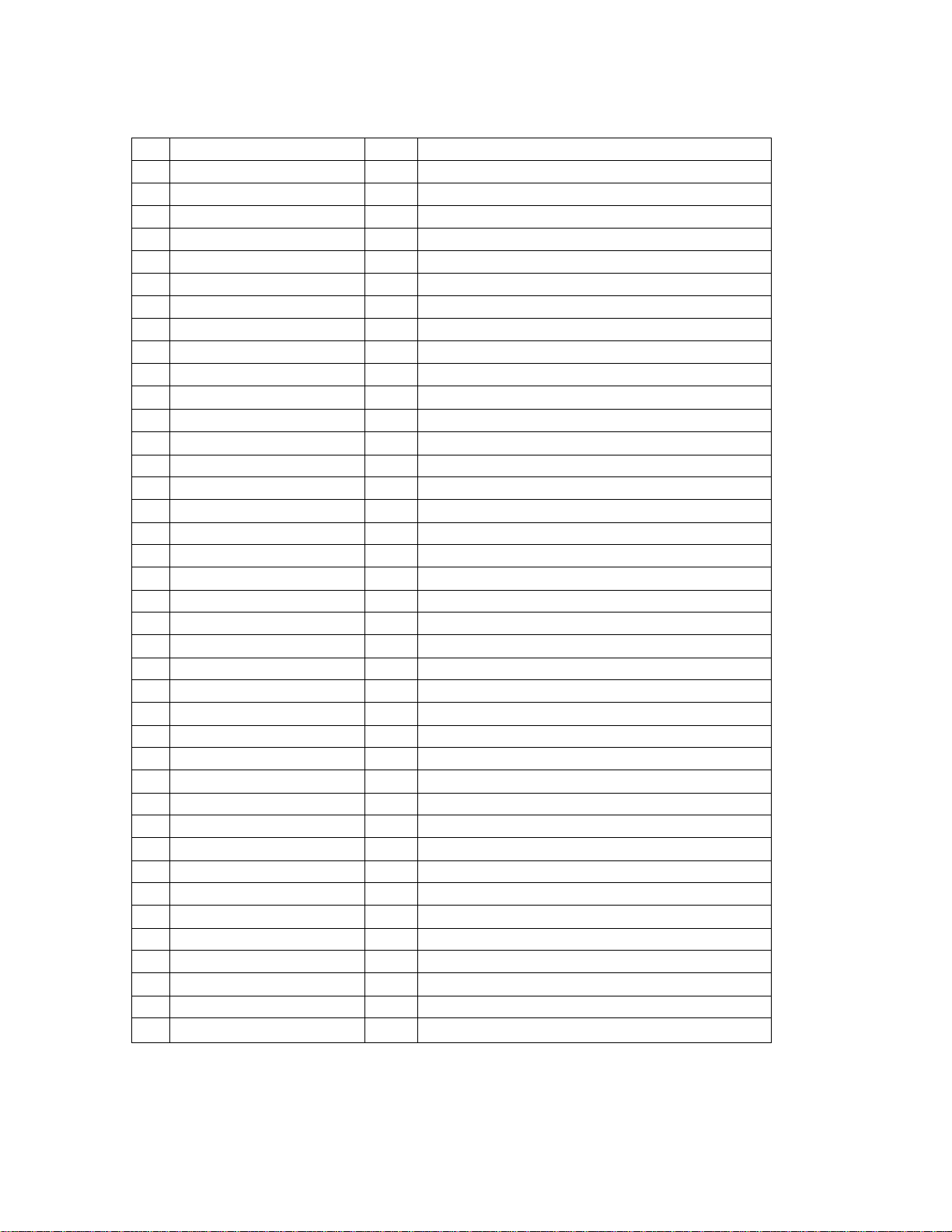

8. Parts List (BC 604 SS). Refers to Figs. 7-1, 7-2 & 7-3

1

0166-063

1

Spindle Nut Lock Plate

2

0166-062

1

Spindle Housing

3

0402-097

1

Spindle Nut

4

0166-038

1

Spindle

5 0402-089 1 Bearing & Seal Kit

6

0166-061

1

Top Disc

7

0402-088

4

Puck

8

0402-091

4

Cutting Knife

9

750

1

Knife Bolt Kit (supersedes 0402-092)

10

0166-011

1

Spindle Bolt Kit

11

0166-047

1

Bottom Disc Assy

631

1 set

Bolt head Guard *

12

0166-021

1

Spindle Bolt Guard

13

208A

4

Bolt

14

0166-037

1

Disc Spacer

15

0402-087

1

Motor Pilot Ring

16

0402-095

1

Anti-Cavitation Housing

17

0402-086

4

Motor Washer

18

209

4

Bolt

19

0402-093

1

Hydraulic Motor

20

0402-094

1

Anti Cavitation Cartridge

21

210

10

Bolt

22

213

1

Grease Nipple*

23

204

1

Grease Nipple*

24

205A

4

Allen Head Cap Screw

25

206

1

M-ORB Hex Head Plug

26

214

2

O-Ring

27

Depends On Carrier

2

Quick Coupler

28

Depends On Carrier

2

Hose

29

0166-008

1

Safety Bar

30

0166-003

2

Rod End Kit

32

121

1

Inspection cover (See Figure 4-1)

* Not Shown

March 2010

March 6, 2009

Fig. 7-2

March 2010

March 6, 2009

D

DA

AV

VC

CO

O

®

B

BR

RU

US

SH

H

C

CU

UT

TT

TE

ER

R

O

On

ne

e

(

(1

1)

)

Y

Ye

ea

ar

r

W

WA

AR

RR

RA

AN

NT

TY

Y

The warranty herein set forth applies solely to the DAVCO ®Brush cutter:

SERIAL NUMBER .

Manufactured by DAVCO ®Manufacturing Ltd. and is in lieu of all other warranties,

expressed or implied. No person, agent, or dealer is authorized or empowered to give any

other warranty or to assume any other liability on behalf of DAVCO ®Manufacturing

Ltd. The warranty is limited to the original purchaser only; no warranty is transferable to

any subsequent owner.

DAVCO ®Manufacturing Ltd. warrants the DAVCO ®Brush Cutter against defects in

material and workmanship under normal use and service for a period of one year with

unlimited hours from the date of delivery, and will repair or replace at DAVCO ®

Manufacturing Ltd.'s discretion, free of charge to the original purchaser, any part that our

examination reveals to be defective in material or workmanship. The warranty includes

labor based on a flat rate, but does not include transportation costs, diagnosing time,

clean up, or consequential damages. (Motor damage due to carrier hydraulic system

contamination is not covered.)

1. Only Original Equipment parts are covered by this warranty.

2. Wear items are not covered against normal use.

DAVCO ®Manufacturing Ltd. reserves the right to inspect components and or parts

prior to any decision involving a warranty claim. In no case shall DAVCO

®Manufacturing Ltd. grant a remedy that exceeds the purchase price of the component or

part, and or the time to remove and or replace the component or part.

DAVCO ®Manufacturing Ltd. reserves the right to make design changes without

incurring any obligation to make such changes to previously manufactured equipment.

This warranty does NOT apply to damage caused by misuse, abuse, neglect (lack of

lubrication), or improper adjustment, accident, or improper application. Any repairs or

alterations made to the equipment without written authorization from DAVCO ®

Manufacturing Ltd. will void this warranty.

NO OTHER WARRANTY OR GUARANTEE OF ANY KIND IS MADE BY DAVCO®

MANUFACTURING LTD. EXPRESSED OR IMPLIED, STATUTORY, BY

OPERATION OR LAW, OR OTHERWISE, INCLUDING MERCHANTABILITY

AND FITNESS FOR ANY PARTICULAR PURPOSE. DAVCO MANUFACTURING

LTD. DISCLAIMS LIABILITY FOR DIRECT, INDIRECT, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES OF ANY KIND.

WARRANTY LIMITATIONS:

Modifications: The limited warranty covers the DAVCO®Brush cutter as built by

DAVCO ®Manufacturing Ltd.

Carriers: Most skid steers with adequate hydraulic flows.

Table of contents