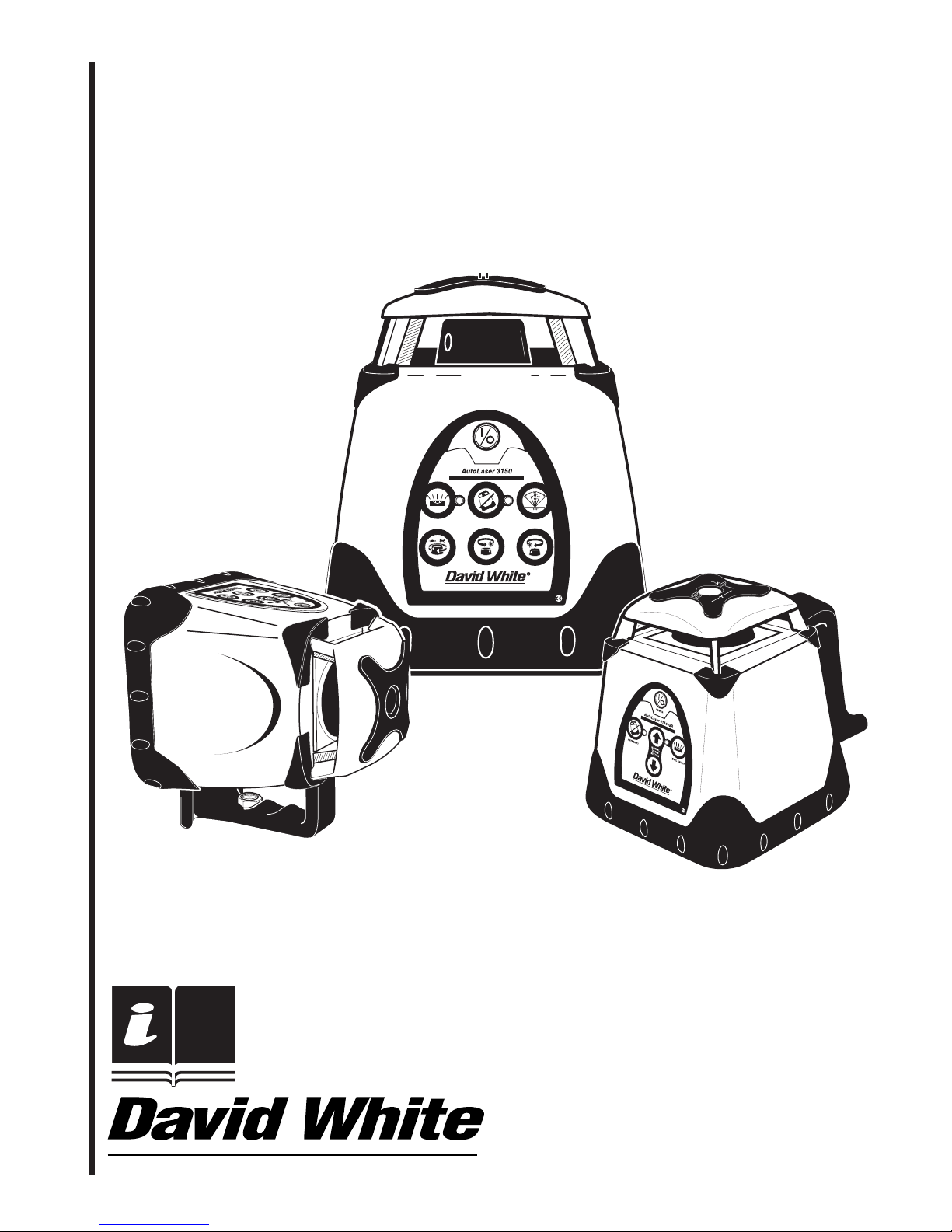

David White AutoLaser 3110-GR User manual

®

INSTRUCTION MANUAL

AutoLaser 3100 Series

Automatic Electronic Self-Leveling

Rotary Lasers

Models

47-3110-GR

47-3150

47-3175 IInnssttrruuccttiioonnMMaannuuaall

MMaannuuaallddeeIInnssttrruucccciioonneess

MMaannuueelldd’’IInnssttrruuccttiioonnss

MMaannuuaalleeddiiIIssttrruuzziioonnii

BBeeddiieennuunnggssaannl

leeiittuunngg

IInnssttrruuççõõeessddeeUUttiilliizzaaççããoo

2 • 3100 SERIES

3110-GR- Fig. 1

1

5

4

6

2

3

8

9 7

3100 SERIES • 3

3150- Fig. 2

3

4

1

2

5

9

7

8

4 • 3100 SERIES

10

1

4

7

8

9

11

12

3175- Fig. 3

3100 SERIES • 5

Fig. 4

Fig. 5 Fig. 6

PLUMB BEAM

VERTICAL LINE

Fig. 7

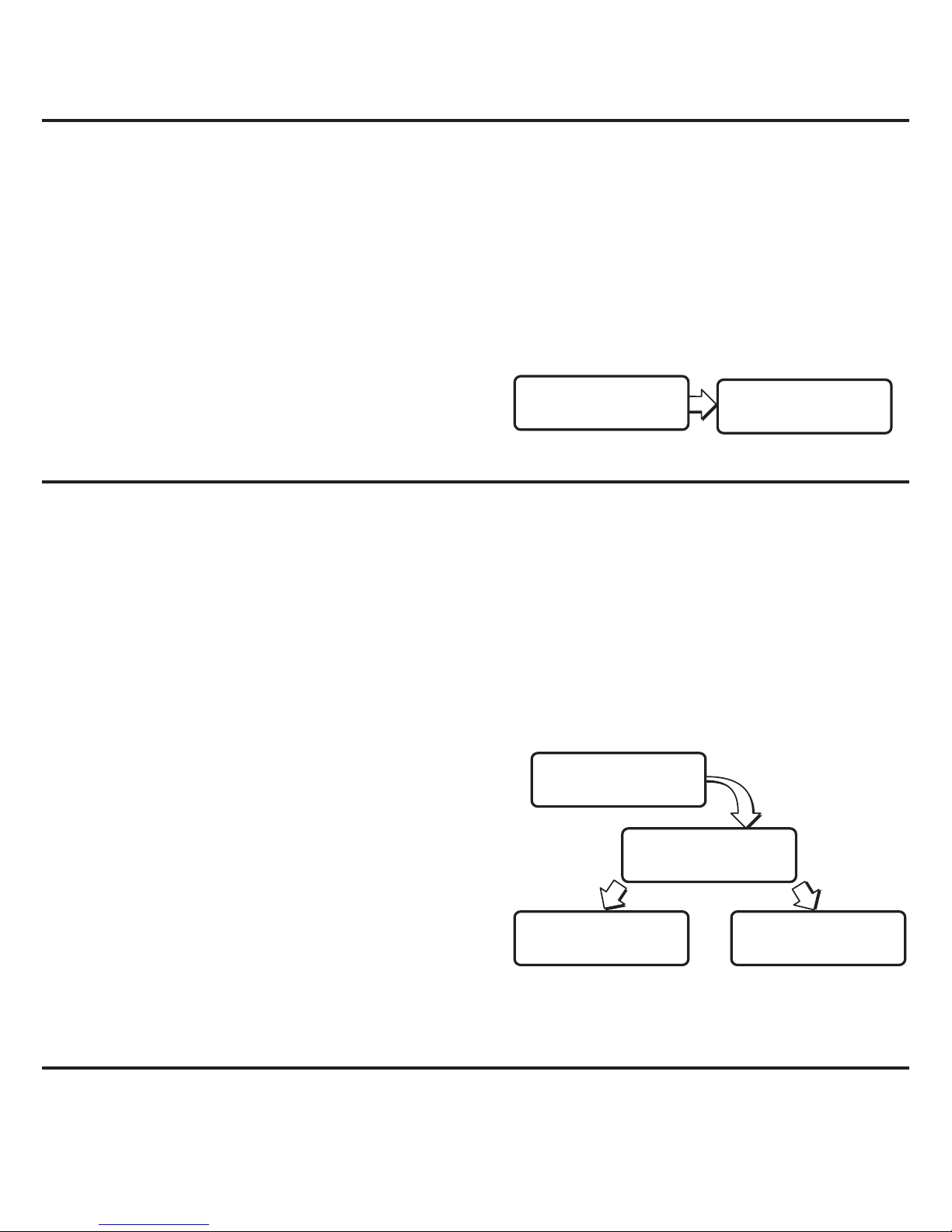

Y-Axis

Y

“MORE”

X

“MORE”

“LESS” “LESS”

X—AXIS ERROR

Y—AXIS ERROR

SPINDLE ERROR

3150 / 3110-GR Errors

Fig. 8 Fig. 9

Fig. 10

Thank you for purchasing the AutoLaser 3100 Sereis Automatic Electronic Self-

Leveling Rotary Laser Level. Please read this manual thoroughly before operation

MODELS

48-3110-GR AutoLaser 3110-GR Visible Horizontal Beam Electronic Self-Leveling

Single Grade Rotary Laser

48-3150 AutoLaser 3150 Horizontal/Vertical Visible Split-Beam Electronic

Self-Leveling Rotary Laser. Dual grade with remote control

48-3175 AutoLaser 3175 Horizontal/Vertical Visible Split-Beam Electronic

Self-Leveling Laser with Dual Dial-in Grade.

Copyright© 2005 David White. All rights reserved

The information contained herein is proprietary information of David White, and is subject to

change without notice.

This document shall not be copied or otherwise reproduced without David White's written consent.

SAFETY AND CERTIFICATIONS

Working safely with this instrument is possible only when the operating and safety information are

read completely and the instructions contained therein are strictly followed.

The use of controls, adjustments, or the performance of procedures other than those specified

herein may result in hazardous radiation exposure.

Do not stare into the laser beams. Do not direct the laser beam at other persons. Do not

disassemble the instrument or attempt to perform any internal servicing. Laser class is indicated

on the instrument.

Repair and servicing of this laser are to be performed only by David White or authorized

service centers.

This laser complies with all applicable portions of title 21 of the Code of Federal Regulations set by:

the Dept. Of Health, Education, and Welfare; the Food and Drug Administration; the Center for

Devices; and the Bureau of Radiological Health.

The laser has also been tested and complies with the CE certification requirements set forth in the

EC regulations 89/336/EEC and EN 61000-6-1 (EN50082-1), EN 61000-6-3 (EN50081-1) and IEC 60-825-1.

6 • 3100 SERIES

EN

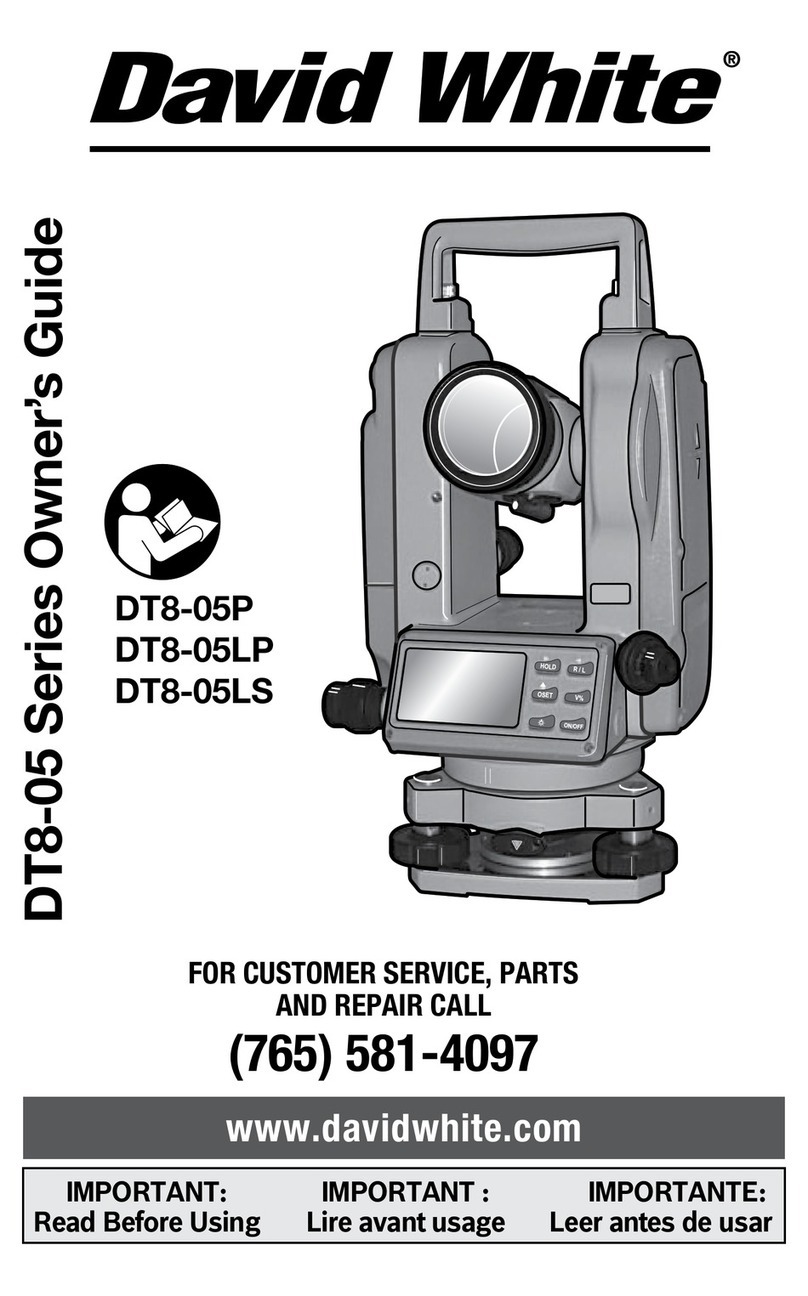

1. Self-Leveling (+/-5º) Rotating

Laser Head. ( With vertical visible

split-beam 3150, 3175 only)

2. Battery Level LED Indicator Lights

When ALL lights illuminate,

instrument has full power. When

indicator lights reach Yellow it is time

to change/recharge batteries.

(3110-GR, 3150 only)

3. Anti-Drift System LED Indicator

(3110-GR, 3150 only)

4. Power ON/OFF button

5. Manual Mode LED Indicator

(3110-GR, 3150 only)

6. Manual Grade Adjustment Buttons

(3110-GR only)

7. 5/8” x 11 Tripod Mounting Threads (for

level work)

8. Gun Sight with “X” and “Y” Identifiers

9. Heavy-Duty Handle-(Built in Trivet for

Laydown and Vertical Applications

with 5/8” x 11 Thread 3150, 3175 only)

10. Select/Adjustment Buttons (3175 only)

11. LCD Display Panel (3175 only)

12. Mode Selection Button (3175 only)

3100 SERIES • 7

APPLICATIONS

Use your 3100 Series Self-Leveling Laser for these and many other projects:

Outdoor General Construction Applications & Site Preparation, Grading & Excavating, Batterboards

and Foundations, Masonry Work, Setting Concrete Forms, Machinery Installation, Marking

Elevation, Septic Work, Paving Roads, Driveways, Checking Depth of Trenches.

Drop Ceiling Installation, Floors, Cabinets & Shelves, Carpentry, Pools, Decks & Patios, Flagpoles,

Aligning 90° Joints & Edges, Landscaping, Tile Work, Septic Work, Plumbing, Batterboards,

Fencing, Walls & Partitions, Remodeling, Siding Installation, Doors & Windows.

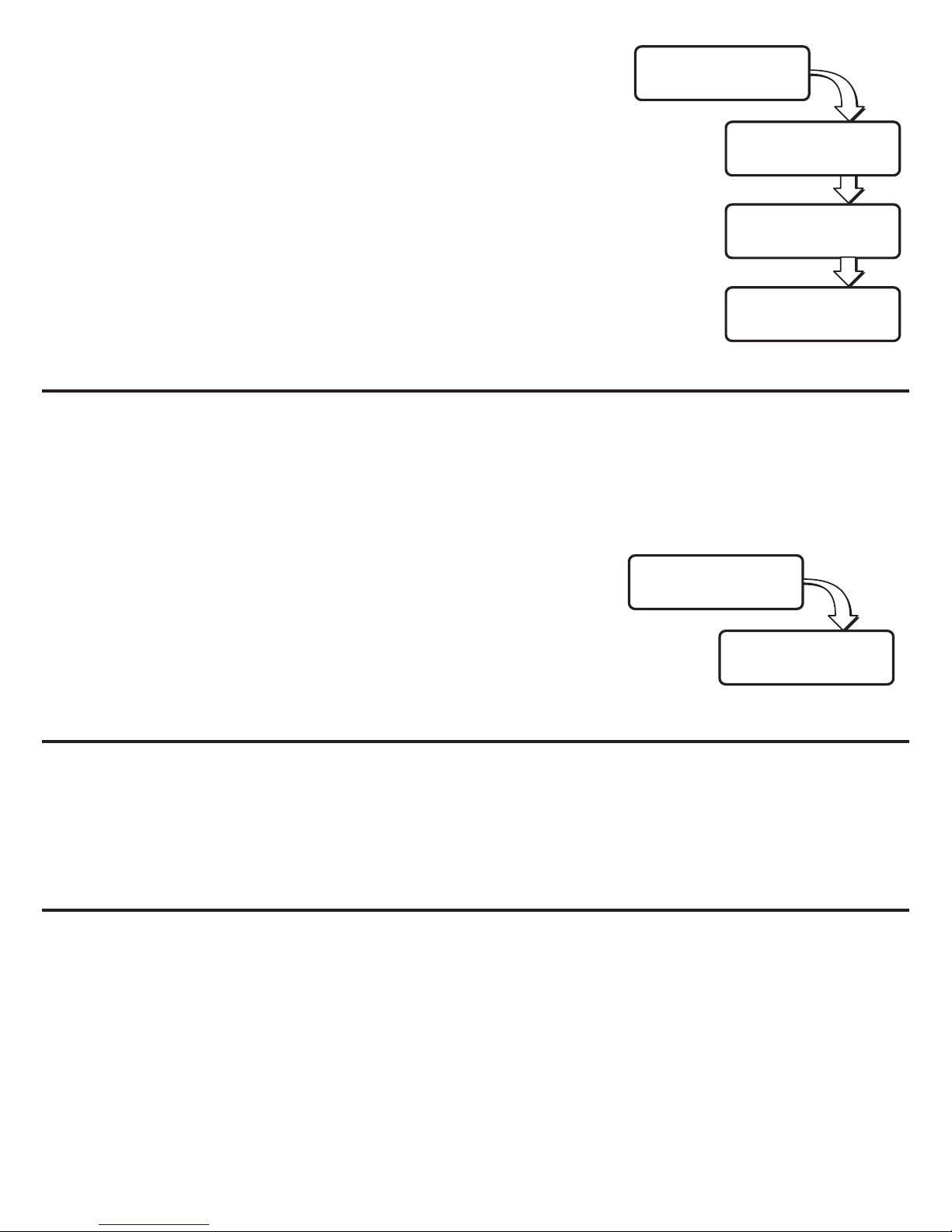

Power Button (Allow 60

seconds for unit to self-level)

ADS Button– Anti-Drift System

ON | OFF (3110-GR, 3150 only)

Manual Mode/Automatic Level

Button (3110-GR, 3150 only)

Scanning Feature – 4 Preset

Angles ( 3150 only)

Variable Speed Rotation Button

– 4 Speed Selection (3150 only)

CW and CCW Button

Clockwise andCounter- Clock-

wise Head Positioning (Press

and Hold Button Moves the

Rotation More Quickly)

(3150 only)

Manual Grade Adjustment

Buttons (3110GR only)

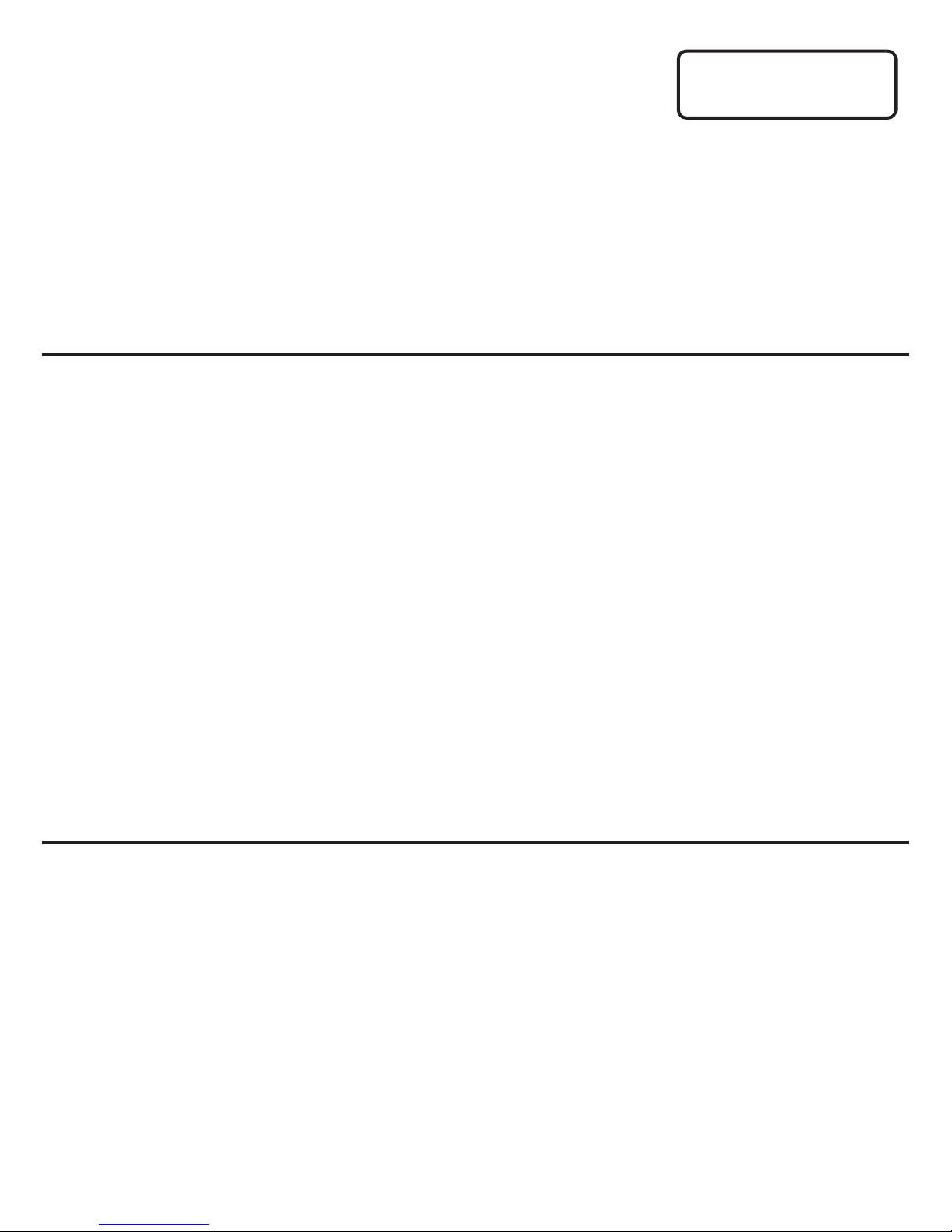

ICONS

Reference in

the text

AA

BB

CC

DD

EE

FF

GG

HH

II

FEATURES - Fig. 1 , 2 & 3

8 • 3100 SERIES

Operating Instructions for General Construction Applications

NOTE: A level plane of laser light is created by the rotating beam of the laser. The laser light can be

used to reference elevations with the use of a laser detector. (Fig. 4)

1. Place the instrument on a flat, level surface such as a tripod. Setup the instrument in an

area where it can not be obstructed and is set at a convenient height.

2: Press the (A) button. Allow the instrument to self-level.

3. Setup a "Benchmark" .

4. 3150 and 3175 Only – Set the Variable Speed Rotation (page 10 ) to the desired rotation

speed of the laser head. Ideal speed for use with laser detector is 600 RPM.

5. Take elevation readings using the plane of laser light as a reference.Follow the Detector

Operation Procedures in this manual.

Ceiling Grid Applications

1. Attach the laser to the optional wallmount bracket. Be sure the control buttons are facing

outward. Tightening the locking screw will secure the instrument to the bracket.

2. After installing the first piece of ceiling trim, attach the wallmount to it. Be sure the

wallmount is secure to the trim.

3. Press the (A) button. Allow the instrument to self-level.

4. Adjust the distance of the instrument from the grid, typically 1.5-inch (38mm) below the grid.

Loosen the adjustment screw and slide the instrument up/down on the wall mount. When

the desired height has been reached, tighten the adjustment screw to secure the instrument.

NOTE: Setup a Benchmark

During the work day, periodically check your initial set-up to ensure that the laser reference

has not moved.

Establish, at a suitable distance (furthest possible), a benchmark (reference) on a stable surface

(ie. tree, building). Periodically during the work day, check the benchmark to ensure that your

setup has not moved.

5. Setup a "Benchmark" (page 8).

6. Install the ceiling grid. Attach the magnetic laser target to the ceiling trim being installed.

Adjust the height of the trim until the laser beam strikes the target.(Fig. 5)

Laydown Applications (3150, 3175)

1. Place the instrument in the laydown position on a flat, level surface.

2. Press the (A) button. Allow the instrument to self-level.(Fig. 6)

3. Setup a "Benchmark" (page 8).

OPERATION

Remove the laser from its carrying case. The instrument is shipped with a battery current

protection insert, which must be removed before operation.

NOTE: All 3100 Series instruments are shipped with ADS on as the default setting. This setting can

be changed by the user (see Anti-Drift System - ADS, page 12).

Note: 3175 instruments will default to Grade Mode when the instrument is turned on. The Mode

button is used for both selecting between the X-axis and Y-axis for setting grade and exiting the

Grade Mode (see Grade Mode — Dual or Single Axis Grade). Press and release the Mode button

to select between the X-axis and Y-axis when setting grade. To exit the Grade Mode, press and

hold the Mode button for 4 to 5 seconds, then release. This will bring up the Mode Select Menu.

The user can now toggle to other menu options. Pressing the Mode button for 4 to 5 seconds and

releasing is only required to exit the Grade Mode.

Leveling

1: The instrument can stand alone on a level, sturdy surface or preferably secured to a 5⁄8" x 11

surveyor’s tripod.

2: Press the (A) button once, and allow time (up to 60 seconds) for the instrument to self-level.

NOTE: The laser head may begin to rotate before leveling is complete. The self-leveling speed is

approximately 1° per 4 seconds.

3: After self-leveling, the instrument will begin operating in Rotation Mode. Note: The 3150 will

return to last mode of operation (i.e. sweep, spot, or rotation speed); however, does

not retain grade information.

NOTE: After self-leveling, the instrument will begin operating in Rotation Mode for 3110-GR, last

selected mode of operation (i.e. Sweep, Spot, Rotation Mode) for 3150, and Grade Mode for 3175.

Plumbing / Lay-Down (Models 3150 and 3175)

1. On a flat surface, place the instrument on its back using the built-in trivet (control panel

facing upward). (Fig. 7)

2. Press the (A) button once, and allow time for the instrument to self-level.

3100 SERIES • 9

Note: For fine adjustment of the vertical laser plane or of the 90° beam, please refer to “Line Position”

Variable Rotation Mode (Models 3150 and 3175)

The rotation mode will give you the option of increasing or decreasing the speed of the rotating

laser. This feature can be used to create a room-wide, 360° height reference or vertical plumb line

for general alignment, drop ceiling installation, and more.

model 3150

Pressing the (E) button, will adjust the speed from 600, 300, 150, and 0 RPM.

model 3175

Using the SELECT buttons, adjust the rotation speed in increments of 50 RPM; lowest possible

speed is 100 RPM and the highest is 1000 RPM.

Sweep or Scanning Mode (Models

3150 and 3175)

Instead of creating a room-wide reference line, the Sweep (Scanning) Mode creates a shorter,

brighter laser “chalk line” that can be used for leveling or plumbing doors, windows, fixtures, and

more. You may also use this feature to keep the instrument from interfering with other lasers and

detectors on site.

model 3150

Pressing the (D) button, will lengthen or shorten the sweep of the laser beam. Preset angles of 10º,

45º, 90º,180º and spot can be set. Position the sweep area by using the (F) or (G) buttons.

model 3175

Using the MODE button to enter the "POSition"

option, and use the SELECT buttons to position the

sweep clockwise or ccw. Press the MODE button to

return to SWEEP SETUP. Use the right SELECT button

to enter the “LENGTH” option and use the

corresponding SELECT buttons to lengthen or

shorten the sweep of the laser beam to the

appropriate length for your application. The sweep

can be as long as 359° or as short as 3°. The last

sweep setup entered remains in memory and will be recalled.

Point-to-Point Mode (Model 3175)

Similar to the Sweep Setup mode, the Point-To-Point Mode allows you to create a laser “chalk

line”, sweeping between any two positionsyou specify.

Use the left SELECT button to enter the “PTP: SET PT A” option, and use the SELECT buttons to

10 • 3100 SERIES

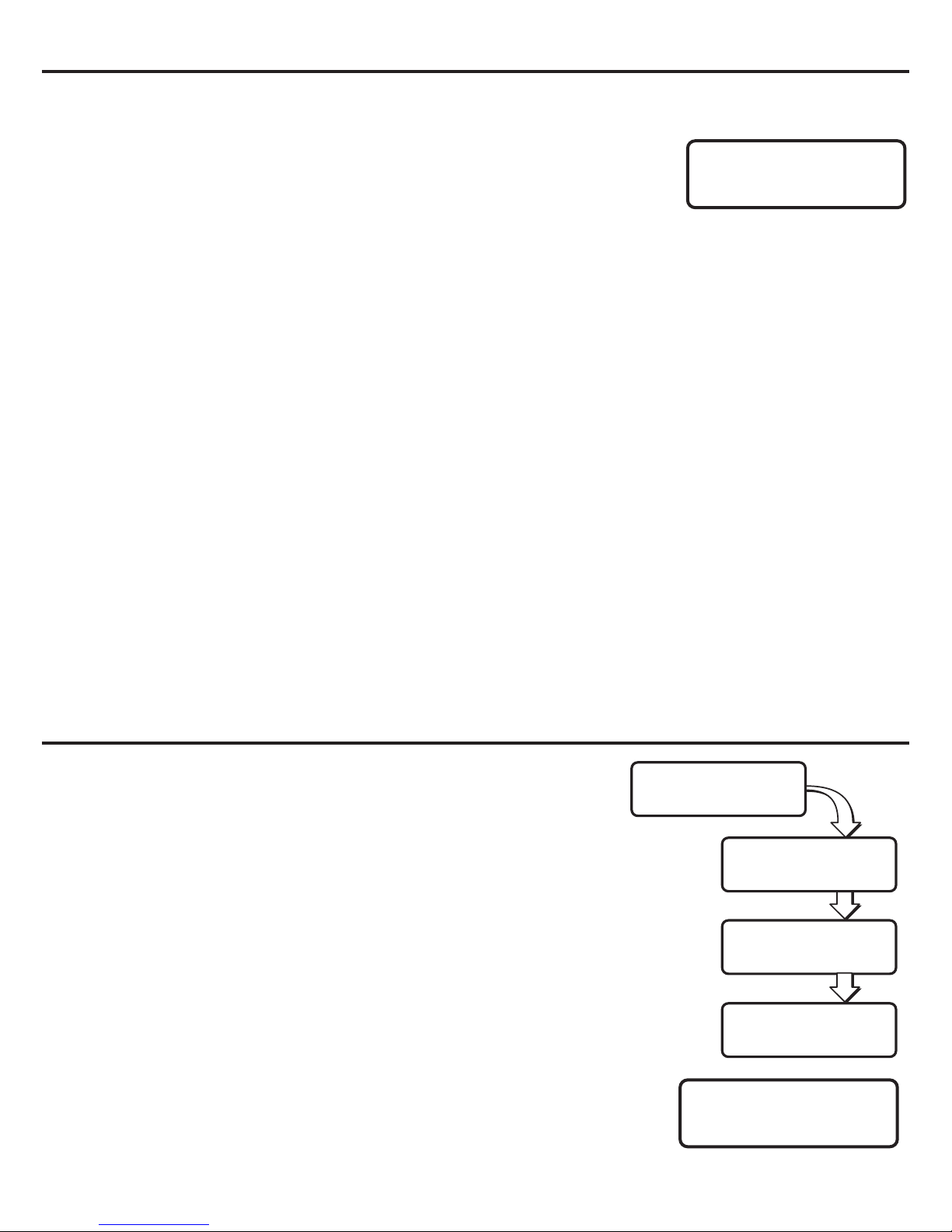

FAST SLOW

ROTATE 300

SELECT

ROTATION

SELECT

SWEEP SETUP

POS LENGTH

SWEEP SETUP

CCW CW

SWEEP POS

LONG SHORT

SWEEP LENGTH

rotate the position of the start point clockwise or

counterclockwise. Press the MODE button to enter the “PTP: SET

PT B” option, and use the SELECT buttons to rotate the position of

the end point clockwise or counterclockwise. Press the MODE

button to begin the sweeping action between the two points. You

may use the SELECT buttons to readjust the position of each point

if needed.

NNoottee: In Sweep or Point-to-Point Mode, the selected sweep area

will not be exact. The laser will vary slightly from the

selected points.

Spot Mode (Models 3150 and 3175)

Spot Mode creates a motionless laser dot for reference, allowing the instrument to be used as a

straight-line laser.

model 3150

Press the (E) button untill the laser is in Spot Mode. Press the (F) or ( G) to rotate the laser head

clockwise or counter-clockwise. Pressing and holding the (G) or

(F) button moves the rotating beam more quickly.

model 3175

Use the SELECT buttons to rotate the position of the dot

clockwise or counterclockwise.

Re-Leveling (Models 3110-GR and 3150)

If the instrument is bumped or moved, the instrument will automatically attempt to re-level itself.

On a job site, it may be necessary to prevent re-leveling in order to prevent inaccurate

measurements by the operator. The Anti-Drift System (ADS) is used for this purpose (see Anti-Drift

System - ADS). The instrument can also be placed in Manual Mode to allow the instrument to

continue operating when out of level.

Axis Drive Error (Models 3110-GR and 3150)

If the laser is set up or tipped beyond its self-leveling range of ±5°, the laser head will initially

attempt to level; however, when the self-leveling limit is reached, an error will indicate an axis

error (Fig. 8).

Turn the instrument OFF, move the instrument to a more level position, then turn the instrument

on again.

Model 3175

The display shows “X TOO STEEP or Y TOO STEEP” Turn the instrument OFF, move the instrument

to a more level position, then turn the instrument on again.

If the instrument continues to poduce errors, contact David White®-Customer Service.

3100 SERIES • 11

SELECT

PT TO PT

CCW CW

PTP: SET PT A

CCW CW

PTP: SET PT B

PT A PT B

PTP: SWEEPING

SELECT

SPOT

CCW CW

SPOT

Spindle Motor Error

Models 3110-GR and 3150

If the laser spindle motor fails to rotate or rotates outside of the set speed, an error indicator will

indicate a spindle motor error (Fig. 8). If this occurs, see “Troubleshooting”.

Model 3175

The display shows “Spindle Motor Error”.

If the instrument continues to produce errors, contact David White®-Customer Service.

Auto Level Mode (Model 3175)

The Auto Level Mode allows you to control how the instrument

reacts when moved out of level.

Auto Level Mode can be ON, OFF, or ADS. If Auto Level Mode is

set to ON, the instrument will

re-level if the instrument is moved out of level.

If Auto Level Mode is set to OFF, the laser will NOT re-level if the

instrument is moved out of level, and will continue to operate; use

this option when using an adapter or mount that allows you to tilt

the instrument to create a diagonal laser line. Use the left SELECT

button to turn the Auto Level option ON or OFF. You may also put

the level into ADS Mode ( see Anti-Drift System- ADS).

Anti-Drift System – ADS (Models 3110-GR

3150, and 3175)

The Anti-Drift System, when ON, will signal to the operator that the instrument has been moved out

of level.The laser head will stop rotating, and the beam and ADS LED will blink in the models

3110GR and 3150; in the model 3175 the display will show “CONT UNIT UNLEVEL”.

Models 3150, 3110-GR

The default setting for ADS is user selectable. The default setting may be set to ADS ON or ADS

OFF. When the instrument is OFF, press and hold the “I” button (3110-GR) or the “G” button (3150)

and then press the “A” button. Once the instrument is on, turn the instrument off for 15 sec and

then back on. If ADS was ON (OFF), it will now be OFF (ON).

To activate ADS, turn off the Manual Mode (if it is ON), by pressing “C” and then press the ADS

(“B”) button. If after 1 minute, the instrument is disturbed and the ADS light is flashing it is

necessary to check any bench marks that have been made and ensure the proper "HI" (Height of

Instrument). After the flashing ADS has been reset, by pressing the button one time, you will have

an additional minute to set and check your measurements.

To turn ADS off press the “B” button once. This will put the instrument into normal Auto

Self-Leveling mode.

12 • 3100 SERIES

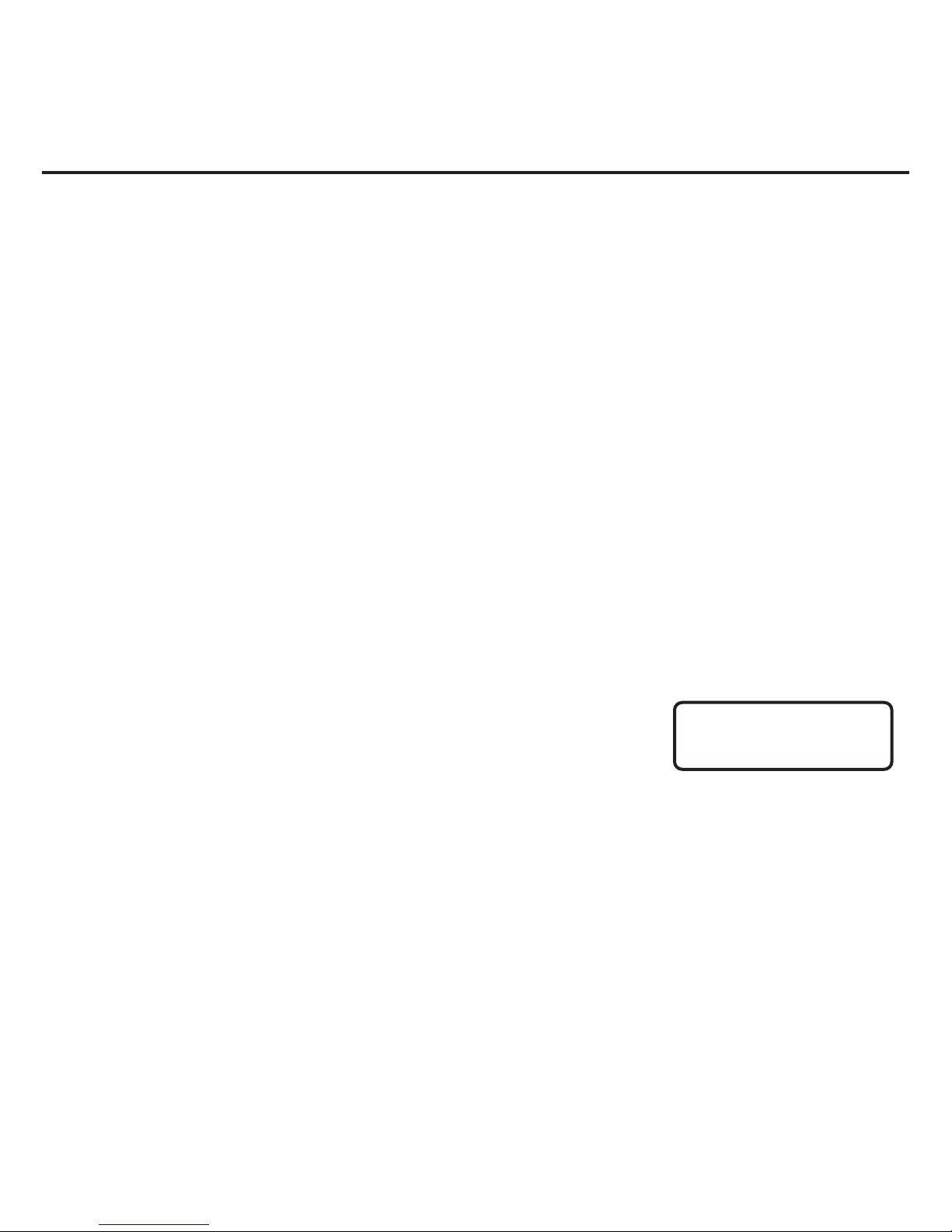

SELECT

AUTOLEVEL

ON

AUTOLEVEL

OFF

AUTOLEVEL

ADS

AUTOLEVEL

Model 3175

This function is prompted through the Auto Level Mode; it clearly

signals the user when the instrument is moved out of level. Turn ADS

on by selecting it in Auto Level Mode and using the MODE button to

return to your desired mode. If ADS is turned on, when the instrument

is moved out of level, the laser head will stop rotating and the beam will blink. The operator must

use the right SELECT button to select the “CONTinue” option.

The default setting for ADS is user selectable. When the instrument is OFF, press and hold the right

SELECT button and then press the ON/OFF button. Once the instrument is on, turn the instrument

off for 15 sec and then back on. This will toggle the default setting for Auto Level Mode between

ADS and on.

Grade Mode – Single Axis Grade (Models 3110-GR)

The single grade function is ideal for general site grading, checking excavations, landscaping and

drainage, and more. (Fig. 9)

The selected grade can be as much as a positive or negative 10%, and set in reference to the Y

axis of the instrument, noted by the embossed printing on the case.

Model 3110-GR

Manual grade mode can be activated by placing the automatic leveling sensor in the OFF position.

NOTE: The ADS must be deactivated to use the Manual Select button.

Pressing the “C” button will deactivate the level sensor. Using the “H” ("MORE") and “I” ("LESS")

arrow buttons, adjust to your desired grade. Rotating head tilts on the Y axis.

NOTE: If the instrument is bumped or moved while in Manual Grade mode, the instrument will not

re-level itself.

The laser will react to “MORE” and “LESS” input. Allow the instrument ample time to react to the

input provided, between grade setups or changes. (Fig. 10)

Manual Grade Mode (Models 3150, 3110-GR and 3175)

Manual mode disengages the leveling feature, allowing the instrument to be placed in any position

to grade.

To activate the Manual Mode, Turn off the ADS (if it is on) and then press the “C” button. (Note:

The instrument should be level and rotating before entering manual mode to eliminate the

possibility of error.) Once the button has been pressed the Manual Mode Indicator Light will blink.

Press the “C” button again to return to normal operation.

Note: When returning to normal operation the instrument must be within its leveling range. Re-set

the instrument to a level position before pressing the “C” button to the off position.

NOTE: (Model 3150) Once the instrument is in manual mode, the remote can be used to set a slope

in the Y-axis by pressign the UP or DOWN button, or X-axis by pressing the remote LEFT or RIGHT

Arrow Button.

3100 SERIES • 13

CONT

UNIT UNLEVEL

Grade Mode – Dual or Single Axis Grade (Model 3175)

The dual grade function allows more specialized site preparations such as road grading, airport

jobs (grading & paving), irrigation, trenching, landfills, slopes and

embankments, and pipelaying. (Fig.11)

The Dual Grade Mode screen is the default screen when the instrument

is turned on. Use the MODE button to choose either the X axis or Y axis.

An > on the display will indicate the selected axis. Press the left SELECT

button to increase slope, press the right SELECT button to decrease slope. Ideally for single axis

grade, use the Y axis in order to use the top mounted sight to orient the instrument to your target,

as well as locate the high and low positionswithin the arc. While grade on both axes is set to zero,

the instrument will continue to self-level. Percentage of grade can be selected at any time while in

this mode. However, the instrument will not go to the desired grade until the instrument has

leveled.

Allow the instrument ample time to react to the input provided. Refer to examples in (Fig. 12) to

predict your results.

To exit Grade Mode, press and hold the MODE button for 4 to 5 seconds. When the button is

released, the MODE select menu is available. (it is not necessary to press and hold the MODE

button to exit any other mode).

NOTE: The total percent grade possible is from a perfectly level base position. If the instrument is

mounted on a tripod head which is not perfectly level, then the grade percentage range capability

would be reduced by the slope of the base, as this affects the tilt range of the laser head. For

maximum grade range, ensure a level tripod head using a spirit level before mounting

your instrument.

FOR ALL GRADE LASERS: For greater accuracy in grade applications, precisely level the laser

level before entering into GRADE MODE.

FOR 3175: If the instrument can’t achieve desired grade it will give an error message “GRADE TOO STEEP”

Anti-Drift in Grade Mode (Models 3175)

The Auto Level Mode can be set to ADS while instrument is in

Grade Mode. ADS will protect against accidental bumps or

settling of the instrument that could cause errors. If the

instrument has been setup to default to Auto Level ADS at startup,

the Grade Mode ADS is already on. If the instrument has not been

set up to default to Auto Level ADS at startup, enter the Auto

Level Mode and selecting ADS. Return to Grade Mode after

selecting ADS. ADS will only be active as long as one axis is set

to zero percent grade (Single Axis Grade). ADS will not be active

while in Dual Axis Grade. ADS is automatically disabled for 30

seconds whenever a new set point is entered for the grade axis.

In Grade Mode, when the instrument is moved out of grade level,

the laser head will stop rotation and the beam will blink to indicate to

the operator that the HI of the instrument may have changed. To

continue, the operator must acknowledge by pressing the right

SELECT button to select the “CONTinue” option.

14 • 3100 SERIES

SELECT

AUTOLEVEL

ON LEVEL

AUTOLEVEL

OFF LEVEL

AUTOLEVEL

ADS LEVEL

AUTOLEVEL

CONT

UNIT UNLEVEL

+ >X 0.00% –

>Y 0.00% –

NOTE: If movement occurs in only the grade axis, ADS may not indicate movement since the

movement is being detected by the non-grade (level) axis. However, in a real world application,

both the grade and level axis will likely move.

Line Position Mode (Model 3150 and 3175)

In this mode, the instrument allows you to fine-tune the location of your vertical (plumb) laser line.

For example, if you’ve established a plumb line and find that the line is slightly off to the left or right

of your target, use Line Position to jog the line into place without moving the entire instrument

(useful for floor and wall tile installation, walls or partitions, etc.). The laser will now remain aligned

to your target even if you enter other modes (Rotation, Spot, Point-to-Point)

model 3150

Line Position mode is available when the instrument is placed in the plumbing position (control

panel facing upward). While the instrument is in the plumbing position, it can be used in Rotation,

Sweep or Spot mode. To enter the Line Position mode and position the laser reference point the

instrument must be rotating. Use the “F” or “G” buttons to position the laser reference point while

the instrument is rotating ( Fig. 13). If the instrument is in Spot or Sweeping mode the “F” and “G”

buttons are used to move the spot or sweep clockwise and counterclockwise, as they do when

the laser is in the upright position.

NOTE: The LEFT and RIGHT buttons of the RC700 Remote can be used to position the reference line

regardless of the instrument being in Rotation, Spot, or Sweep Mode.

If in manual mode , the LEFT and RIGHT buttons will position the reference line and the UP and

DOWN buttons will move the vertical line up and down

model 3175

Line Position mode is available when your instrument is placed in the

plumbing position (control panel facing upward). While the instrument

is in the pluming position, it can be used in Rotation, Spot, or Point-to-

Point mode. To enter Line Position mode, use the Mode button to go to

the Line Position option and press select. The instrument will rotate at

the last rotation speed selected. Press the SELECT buttons to move the position of the laser

reference point clockwise (right) or counterclockwise (left) into perfect alignment with your target.

(Fig.14)

REPLACING BATTERY

For models 3110-GR and 3150, if the battery is low, the red light (only) is illuminating on the front of

the instrument.

For model 3175, if the battery is low, the LCD will display “ERROR BATTERY LOW”.

If the instrument operates erratically, try replacing the batteries. (Fig.15)

1. Remove the battery tray by unscrewing the plastic nut around the mounting thread

on the bottom of the instrument.

2. Remove the old batteries and replace with 4 new “D” cell Alkaline batteries.

3100 SERIES • 15

CCW CW

LINE POS

3. Replace the battery tray. Make sure the battery contacts between the battery pack

and the instrument compartment are aligned.

NOTE: Do not mix old and new batteries. Replace all batteries at the same time with new batteries.

Remove batteries before storage of the instrument.

Rechargeable Battery Pack

If you are using a rechargeable battery pack (Cat #57-NB700), your instrument will provide

approximately 14 hours of intermittent use with each full charge. The batteries will begin to

perform optimally after five full charges and discharges. You may charge the battery pack within

the instrument.

Ensure the power is off, and connect the charging plug to the appropriate charging jack on the

bottom of the battery pack. Then plug the charger into the appropriate 120/230V AC outlet. Charge

time is typically around 8 hours . The instrument can be charged and used at the same time, but

only a minimal charge will be applied to the battery pack.

CALIBRATION

Your 3100 Series Self-Leveling Laser is a sealed instrument and is calibrated to precise accuracies

at the factory. However, a calibration check is recommended before the initial use of your laser,

and then periodically from that point forward. Be sure to allow time (up to 60 seconds) for the

instrument to completely self-level before each check.

Upright Position Peg Test – X axis (All models)

1. To test the X axis, mount the laser on a tripod or a level, sturdy surface and place

100 feet (30m) away from a wall. Face the “X+” side of the instrument to the wall (Fig. 16).

2. Press the “A” button and allow the instrument to self-level. Using the laser detector, locate

and mark the position of the laser line on the wall Position “A”).

3. Loosen the instrument from the tripod and rotate the instrument 180°. Ensure that the height

of the tripod does not change, as this will affect your results. Secure and re-level

the instrument.

4. Again, using the laser detector, locate and mark the position of the laser on the

wall (Position “B”).

5. Mark the centerline between Position A and Position B (Position C). Callibration is necessary

if the vertical difference between Position A and Position C or Position B and Position C is

greater than the specified accuracy.

Repeat the above steps to ensure a correct reading. If the distance is greater than specified

accuracy, you will need to calibrate the X axis.

NOTE: For 3150 and 3175 Spot Mode can be used without detector if designed

16 • 3100 SERIES

Upright Position Calibration– X axis

model 3110-GR (Fig.16)

1. Power On the instrument with the “A” button while holding the “C” button down, then

release the “A” button. You will know if Calibration Mode is activated when the Manual

Mode and Anti-Drift LEDs flash alternately. Then, the Manual Mode LED will remain lit; this

indicates that the instrument is calibrating within the X axis.(Fig. 17)

2. The “H”and “I” buttons change the axis increments. The ”H” button will produce a

positive (+) increment.

NOTE: for 3110-GR Pressing the “C” button will toggle between Xand Y axis for calibration. Manual

LED on indicates X- axis is selected.

3. You must raise or lower the beam to center between positions A and B (position C) on the

target. The instrument will react to “+” and “–” input within the X+ quadrant. The instrument

DOES NOT react to adjustments until the instrument is forced to re-level (i.e. rotate

and re-check point A).

If B is below A, increase the increment (+).

If B is above A, decrease the increment (-).

4. The adjustments are automatically saved.

You must now repeat the peg test to insure you have made the correct calibration. A peg test can

be done in Calibration Mode.

model 3150

1. Power On the instrument while holding the “C” button. You will know if Calibration Mode is

activated when the Manual Mode and Anti-Drift LEDs flash alternately.

2. The “C” and “E” button change the X-axis increments. The “C” button will produce a

positive (+) increment (the “D” and “F” will change the Y-axis. And the “D” button will

produce a positive (+) for Y). (Fig.17)

3. You must raise or lower the beam to center between positions A and B on the target. The

instrument will react to “+” and “–” input within the X+ quadrant. The instrument DOES NOT

react to adjustments until the instrument is forced to re-level (i.e. rotate and re-check point A).

If B is below A, increase the increment (+).

If B is above A, decrease the increment (-).

4. The adjustments are automatically saved.

You must now repeat the peg test to insure you have made the correct calibration. A peg test can

be done in Calibration Mode.

3100 SERIES • 17

model 3175

1. Power ON the instrument while holding the MODE button down.

2. Release both buttons at the same time and wait for calibration instructions to appear on

screen. You will have to select the direction of calibration change.

3. Use the right SELECT button, following the chart, to access the X axis for calibration .

Please record the three-digit number that appears in the LCD the first time you enter the axis

calibration menu; this number is the factory setting (i.e. 510), to which you can return if

necessary (this number may vary anywhere between 430 and 590).

You must raise or lower the beam to center between positions A and B(Position C) on the wall. The

instrument will react to “+” and “–” input within the X+ quadrant.

If B is below A, increase the number (”+”).

If B is above A, decrease the number (“–”).

4. Press the MODE Button to exit the X axis calibration menu, and save any changes to the

calibration settings by turning off the instrument (“QUIT”).

You must now repeat the peg test to insure you have made the correct calibration. A peg test can

be done in Calibration Mode.

Upright Position Peg Test and Calibration – Y axis (All models)

To test the Y axis, mount the instrument on a tripod and place approximately 100 feet (30m) away

from the target, with the control side (Y+ quadrant) facing the target (Fig. 18); follow steps 2 thru 4

of "Upright Position Peg Test – X axis". Calibrate as in "Upright Position Calibration – X axis",

choosing the Y axis to calibrate and adjusting “+” and “–” input as necessary within

the Y+ quadrant.

Note: In the model 3110-GR, in order to calibrate the Y axis, when the Manual and ADS LED’s flash

to indicate that you entered the Calibration Mode, press the Manual button in order to turn off the

corresponding LED.

If you are unable to calibrate the instrument, or if the difference between positions A and B is too

great to calibrate within the numerical range of 430 to 590, please contact David White or an

authorized service center for assistance.

Laydown Position Peg Test – Z axis (3150, 3175 only)

1. To test the Z axis, place the instrument on its back using the built-in trivet (control panel

facing upward), 100 feet (30m) from a wall on a flat, level surface.

2. Hang a plumb line down the wall at least 8 feet long (2,5 m).

18 • 3100 SERIES

LANG CAL

QUIT

X Y Z

BACK

CAL POS

BACK

X Y

BACK

SPOT ROTATE

QUIT

X Y

Z QUIT

CCW CW

BACK

+ Y AXIS -

BACK 510

+ X AXIS -

BACK 510

+ Z AXIS -

BACK 510

3. Press the “A” button (“POWER” in the 3175) and allow the instrument to self-level. If

necessary, adjust the rotation speed to easily view the laser beam on the wall. Orient the

instrument parallel to the wall and attempt to align with your plumb line. (Fig.19)

If the laser line does not align with the plumb line, then calibration is necessary.

Laydown Position Calibration – Z axis (3150 and 3175 only)

Keep the instrument in its current position. Power OFF the instrument.

model 3150

1. Power ON the instrument while holding the “C” button down. You will know if Calibration

Mode is activated when the Manual Mode and Anti-Drift LEDs flash alternately.

2. The “D” and “F” button change the axis increments. The “D” button will produce a

positive (+) increment.

3. Select the “D” button to rotate the laser beam counterclockwise, or the “F” button to rotate

the laser beam clockwise into alignment with your plumb line.(Fig. 19) For example, the beam

must rotate counterclockwise to align with the plumb line, so you must select the “D” button.

4. The adjustments are automatically saved.

model 3175

1. Power ON the instrument while holding the MODE button down.

2. Release the two buttons at the same time and wait until calibration instructions appear on

screen. Use the right SELECT button, following the chart You find in “Calibration of the X

axis”. To access the Z axis press MODE. Please record the three-digit number that appears

in the LCD the first time you enter the axis calibration menu; this number is the factory

setting (i.e. 510), to which you can return if necessary (this number may vary anywhere

between 430 and 590).

3. Select “+” to rotate the laser beam counterclockwise, or “–” to rotate the laser beam

clockwise into alignment with your plumb line. For example, the beam must rotate

counterclockwise to align with the plumb line, so you must select “+”.

4. Press the MODE Button to exit the Z axis calibration menu, and save any changes to the

calibration settings by turning off the instrument (“QUIT”).

You must now repeat the peg test to insure you have made the correct calibration. A peg test can

be done in Calibration Mode.

MAINTENANCE AND CARE

Always clean the instrument after use. Use a soft, dry cloth to remove any dirt or moisture from the

instrument. Do not use benzene, paint thinner, or other solvents to clean the instrument. Store the

instrument in its case when not in use. Batteries should be removed before long-term storage.

ENVIRONMENTAL PROTECTION

Recycle raw materials instead of disposing as waste. The machine, accessories and

packaging should be sorted for environmental-friendly recycling. Do not throw used

batteries into waste, fire or water but dispose of in an environmentally friendly manner

according to the applicable legal regulations.

3100 SERIES • 19

SPECIFICATIONS

TROUBLESHOOTING

The following information lists basic tests that can be performed to check the 3100 Series in the

event of poor performance.

Check Your Batteries: One of the most common causes of performance failures is due to defective

or incorrectly installed batteries. Check to see if any batteries are installed backwards and correct

if necessary.

20 • 3100 SERIES

Weight

Laser Only

Beam Type

class II/IIIa

Operating Range

with Laser Detector

Leveling Type

Horizontal Leveling

Vertical Leveling

Grade Capability

Manual

Up to 2000-feet (610m) Diameter with Laser Detector

Electronic Self-Leveling

Leveling Accuracy

Vertical Accuracy

±1/16-inch@100’ ±1/8-inch@100’ ±1/16-inch@100’

8" Height x 6-1/4" Width x 6-3/8" Depth

(203mm H x 159mm W x 162mm D)

75± Hours Intermittent Use with Alkaline Batteries

14+ Hours Used with Fully Charged Ni-Cad Battery Pack

650 nm

3110-GR 3150 3175

635 nm

"hi-powered" 635 nm

"hi-powered"

Dimensions

Yes Yes Yes

No Yes Yes

Single Axis

Up to ±10%

Single Axis

Up to ±10%

w/Remote

Dual Axis

Up to ±10%

Visible Split-Beam No Yes Yes

Self-Leveling Range ±5º ±5º ±5º

Grade Accuracy ±0.1% Grade

––––

––

Rotation Speed

600 0, 150, 300, 600 0 - 1000

RPM

Battery Power

5.5 ± lbs. (2.5kg) with Batteries

Scanning Feature No Yes Yes

Operating Temperature -4º F to 120ºF

(-20ºC to 49ºC)

Environment IP54 - Water Resistant

VariableFixed

with

"ADS"

(±1.5mm at 30m) (±1.5mm at 30m)(±3mm at 30m)

±1/8-inch@100’

(±3mm at 30m)

±1/8-inch@100’

(±3mm at 30m)

Other manuals for AutoLaser 3110-GR

1

This manual suits for next models

2

Table of contents

Languages:

Other David White Measuring Instrument manuals