Apressure gauge is used to verify pressure readings.

Astop watch is used to “clock” the meter RPM for

calculating gas flow rate.

CAUTION: When the meter is on line pressure, follow applica-

ble safety rules and wear appropriate protective apparatus.

1. Install the pressure differential indicating device into

the meter inlet and outlet differential taps. Install a

pressure gauge or other pressure standard on the inlet

side of the meter if not a component of the test

equipment.

2. Adjust the meter bypass and the meter inlet valves

until the meter is operating at a predetermined or

selected flow rate in the lower capacity range, or

approximately 25 percent of meter rated capacity.

Let the flow rate stabilize.

3. Time or “clock” the passage of a predetermined volume

of gas as registered on the odometer or instrument to

determine the Index or Flow Rate in Actual Cubic Feet

per Hour (or m3/h):

Index Rate = Cubic Feet x 3600

Test Time (sec)

Convertthe calculated flow rate to a percentage of meter

rated capacity:

%Meter Capacity = Index Rate

Meter Base Rating

4. Recordthe pressuredifferential, line pressure, and gas

specific gravity. Repeat the test to obtain an accurate

average reading.

NOTE: At the time of meter start-up in a new installation,

repeat Steps 2-3 at a minimum of three different flow

rates, each between 25% and 100% of meter capacity.

The original base line curve should be drawn using

data at a constant pressure for all three tests.

5. Remove the differential test equipment and pressure

standard.

6. If the pressuredifferential is within acceptable limits,

return the meter to full service. If the pressure

differential is higher than recommended, remove the

meter for inspection and service. For Factoryassistance

regarding meter inspection and/or repair, please call the

Product Services Department, your Customer Service

Representative, local Sales Representative, or Distributor

and request a Return Material Authorization (RMA).

Proving Operations

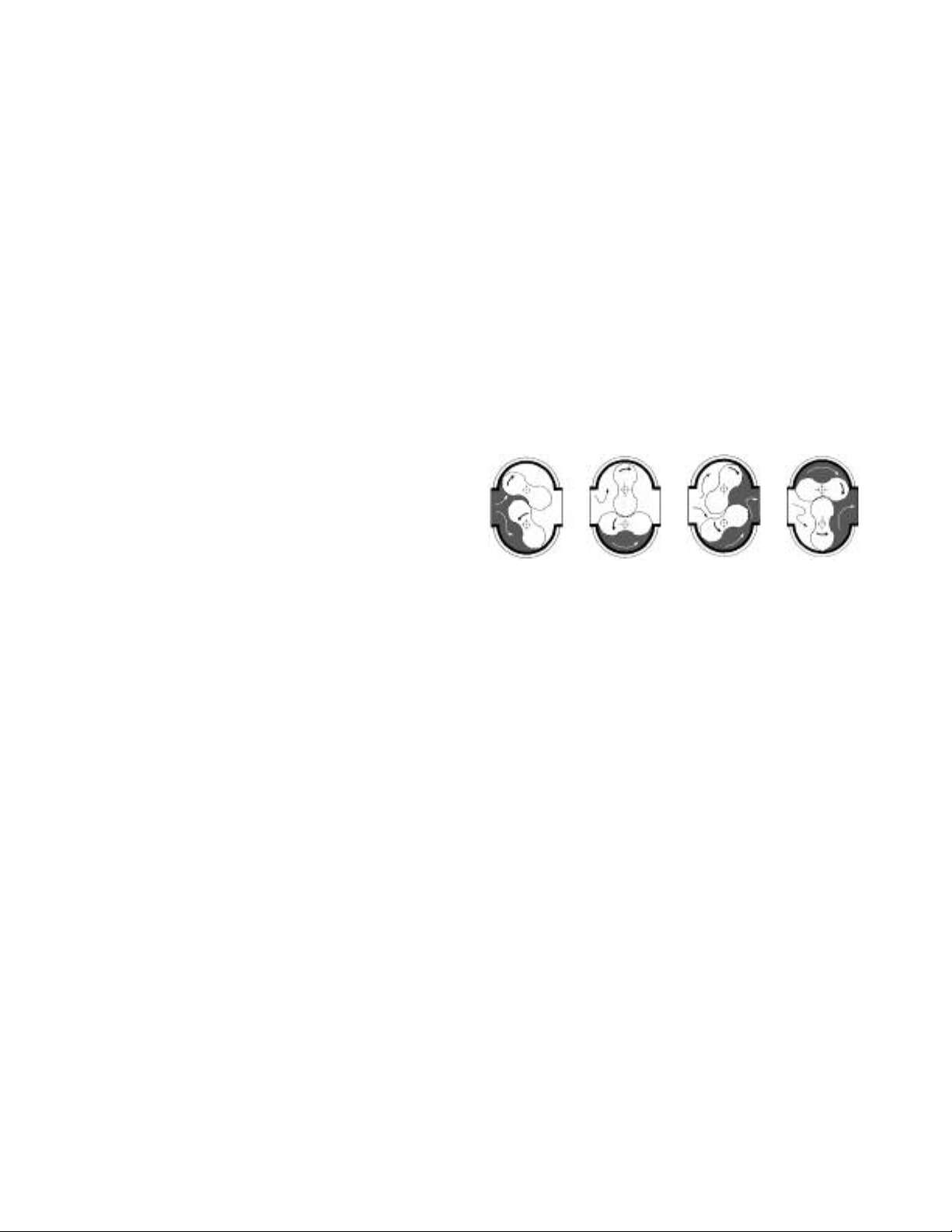

Conventional scanning methods may be used with the 5C15

and 8C15 index in meter proving. The standard index for

these meters is a circular (dial) index similar to that found

on residential diaphragm meters. The preferred method is to

focus a photocell or scanner on the “Half Foot” test hand.

Each revolution represents 1/2 cubic foot of volume.

Adifferential pressure test consists of a series of

differential pressure readings taken across the meter at

several gas flow rates within the meter’s capacity range.

Ideally, testing should be performed when the meter is

first installed and under the actual conditions of gas line

pressure and specific gravity that will exist in service.

Multiple curves may be necessary for meters under varying

pressure conditions.

When less than 15 PSIG (100kPa Gauge), the meter

differential can, for all practical purposes, be compared

directly with Factory curves or specific meter test results.

The factory Test Data Sheet lists actual meter test results

of accuracy and differential obtained from a bell or piston

prover test on air at atmospheric pressure. Published data

is representative of typical product production.

Establishing Base Line Curves -Developing an original

differential or baseline curve is recommended at the time

of meter initial installation. At least three (3) test points

are required at gas flow rates from 25% to 100% of meter

capacity.Plot the points on a graph and then connect the

points to form a curve. This provides an accurate baseline

for comparison to later tests.

The gas line pressure, specific gravity of the gas, and line

temperature should also be recorded. If the application is

under varying pressure conditions, plot multiple curves for

various pressure ranges (i.e. 5,10 and 15 psig). An increase

in flow rate, line pressure or specific gravity will cause an

increase in the differential.

After developing a base-line curve, meter condition and

performance can be checked periodically by running a

similar differential rate test at a single selected point.

This does not give the overall characteristics for the

meter, but does provide a quick reference check.

Differentials taken at varying flow rates are needed to

give an overall picture.

If the differential pressure increases by more than

50 percent of the original value, inspect the meter for

causes of increased resistance. Principal causes are

binding of impellers, wornbearings, contaminates such

as dirt or valve grease in the meter chamber.

Test Procedure - the test is performed using a ROOTS®

Smart manometer, or other differential pressure test

equipment with an indicating scale range of about 0.9”

(150mm) of water column. The testing device should have

inlet, outlet, and bypass valving, and must be pressure

rated for the maximum metering pressure for the test.

Pressure lines should be connected to the 1/4’ meter inlet

and outlet pressure taps located on the meter

body just above and below the meter nameplate.

(Test plugs can be permanently installed in the pressure

taps to facilitate testing.)

6