Daytona B917 User manual

1

B917 WHEEL BALANCER

READ THIS ENTIRE MANUAL BEFORE OPERATION BEGINS

Serial No. __________

Model No. ___B 917___

2

Warning

⚫This manual is a necessary part of the product. Please read carefully.

⚫Keep the manual for later use when maintaining the machine.

⚫This machine can only be used for the designated purposes. Never use it for any other purpose.

⚫The manufacturer is not responsible for the damage incurred by improper use or use other than the intended

purpose.

Precaution

⚫The equipment can only be operated by qualified personnel with special training. Modification to any

components or parts, or use the machine for other purpose without either obtaining the agreement from the producer,

or observing the requirement of the instructions may lead to direct or indirect damage to the equipment.

★ The equipment should be installed on the stable ground, not wooden pallet, otherwise not accurate.

⚫Keep the back panel 0.6M away from the wall for good ventilation. Enough room should be left on both

sides for convenient operation.

⚫Do not put the equipment a place with high temperature or moisture, or near the heating system, water tap,

air-humidifier or chimney.

⚫Avoid lots of dust, ammonia, alcohol, thinner or spraying binder.

⚫People who are no operating the machines should be kept away when it is used.

⚫Use appropriate equipment and tools, protective and safety equipment, including eyeglasses, earplugs and

working boots.

⚫Pay special attention to the marks on the machine.

⚫Do not touch or approach the moving parts by hand during operating.

⚫Do not remove the safety device or keep it from working properly.

3

Contents

1. General-----------------------------------------------------------------------------------------------------------------1

2. Machine assembly----------------------------------------------------------------------------------------------------1

3. Controls and components--------------------------------------------------------------------------------------------3

4. Indication and use of wheel balancer------------------------------------------------------------------------------6

5. Self-calibration of wheel balancer -----------------------------------------------------------------------------10

6. Errors------------------------------------------------------------------------------------------------------------------11

7. Self- diagnoses-------------------------------------------------------------------------------------------------------12

8. Setting machine------------------------------------------------------------------------------------------------------12

9. OPT function --------------------------------------------------------------------------------------------------------13

10. Spare parts list and Exploded drawings-------------------------------------------------------------------------15

4

1. General

1.1. Technical data:

⚫Max wheel weight:65kg

⚫Power:0.2kw;0.37kw

⚫Power supply: 220v;230v;240v;110v;50hz;60hz

⚫Balancing accuracy:

1g

⚫8balancing modes: DYN, ALU1, ALU2, ALU3, ALU4, ALU5, ALUS, ST

⚫Balancing speed:200r/min

⚫Cycle time:8s

⚫Rim diameter:10〃~24〃(256mm~610mm)

⚫Sound pressure level during work cycle:<70db

1.2. Features:

⚫ALU balancing mode may choose 9 o’clock or 12 o’clock position to add weight

⚫Statistic and dynamic balancing, ALU-programs for alloy rims or special shaped

⚫Self diagnoses, easy to find the problem

⚫Apply to steel and aluminum alloy rim

1.3. Working environment:

⚫Temperature:5~50℃

⚫Height:≤4000m

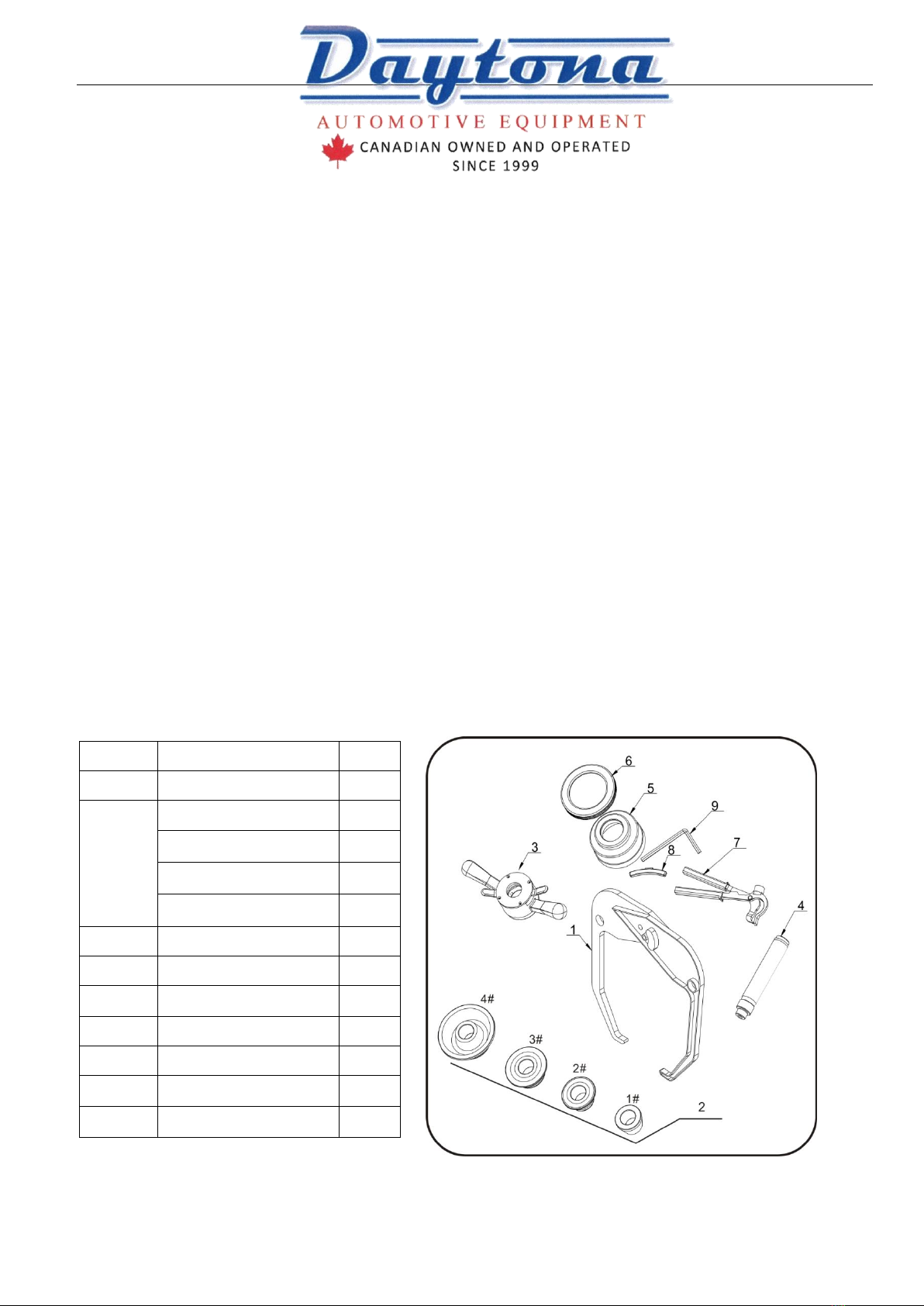

2.Machine assembly

2.1. Unpack

Unpack the carton, check if missing any spare parts.

No.

Item

Qty

1

Width gauge

1

2

Conic No.1

1

Conic No.2

1

Conic No.3

1

Conic No.4

1

3

Quick relase nut

1

4

Thread hub

1

5

Bowl for quick nut

1

6

Pad for bowl

1

7

Balancing hammer

1

8

100g weight

1

9

Allen wrench

1

5

2.2. Install

⚫The equipment should be installed on the stable ground, not wooden pallet, otherwise not accurate.

⚫Keep the back panel 0.6M away from the wall for good ventilation. Enough room should be left on both

sides for convenient operation.

2.3. Fix balancer to floor with screws on the bottom.

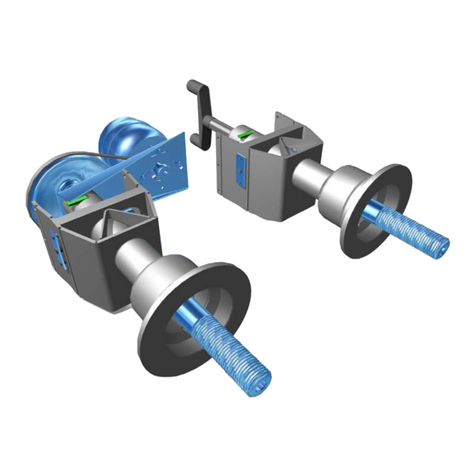

2.4. Install adaptor

The wheel balancer is supplied complete with cone type adaptor for fastening wheel with central bore. (see below

picture)

2.5. Install wheel

Clean wheel, take off counterweights, check pressure of wheel.

Choose the way of installation according to the type of wheel.

Main shaft-wheel— Main shaft-suitable cone(big head towards inside)

suitable cone( small head towards inside)—quick handle nut —wheel—quick handle nut

Attention:May add a wheel, and hold the wheel to help install the thread hub. When installing or taking off wheel,

do not let wheel move on the shaft, to avoid scratching shaft.

3.Controls and components

No.

Item

Standard/Optiona

l

6

A

Switch

S

B

Head with

tool tray

S

C

Gauge head

S

D

Main shaft

S

E

Pedal

breaker

O

F

Safe guard

S

G

Key board

S

Six balancing modes

Icon

Balancing

mode

Operation

Add weights

Standard/Default

Turn on machine

Input a,b,d value

Start spin, after spin stop

Clip on weights on

both sides of rim edge

ALU2

1. Turn on machine

2. Input a,b,d value

3. Press ALU button, indicator lit up

4. Start spin, after spin stop

Add adhesive weights

on the rim shoulder

both sides

(Button Colors May vary)

7

ALU3

1. Turn on machine

2. Input a,b,d value

3. Press ALU button, indicator lit up

4. Start spin, after spin stop

Clip on weight on

inside rim edge, add

adhesive weight on

outside rim shoulder

ALU1

1. Turn on machine

2.Input a,b,d value

3.Press ALU button, indicator lit up

4.Start spin, after spin stop

Add adhesive weights

on the rim shoulder

both sides

ALUS

1. Turn on machine

2. Press ALU button, indicator lit up

3. Input aI,aE,d value

4. Start spin, after spin stop

Add adhesive weights

on the two positions

gauge head touch

Static mode, for

motorcycle

wheels

1. Turn on machine

2. Input a,b,d value

3. Press ALU button

Start spin, after spin stop

Add adhesive weight

Key board (H)

Icon

Function

Icon

Function

Set distance

Optimization of unbalance

Set rim width

Selection of “ALU” modes

Set rim diameter

Static mode, for motorcycle wheels

“ST” Will show in right display

Recalculation

Unbalance display pitch and threshold

Start

Stop/Cancel

8

4. Indication and use of wheel balancer

4.1.DYN (Standard/Default) mode

4.1.1. Clean wheel, take off counterweights, check pressure of wheel.Choose the way of installation according to the type

of wheel.

Main shaft-wheel— Main shaft-suitable cone(big head towards inside)

suitable cone( small head towards inside)—quick handle nut —wheel—quick handle nut

Attention:May add a wheel, and hold the wheel to help install the thread hub. When installing or taking off wheel,

do not let wheel move on the shaft, to avoid scratching shaft.

4.1.2. Turn on machine

4.1.3. Input a b d value

ab

d

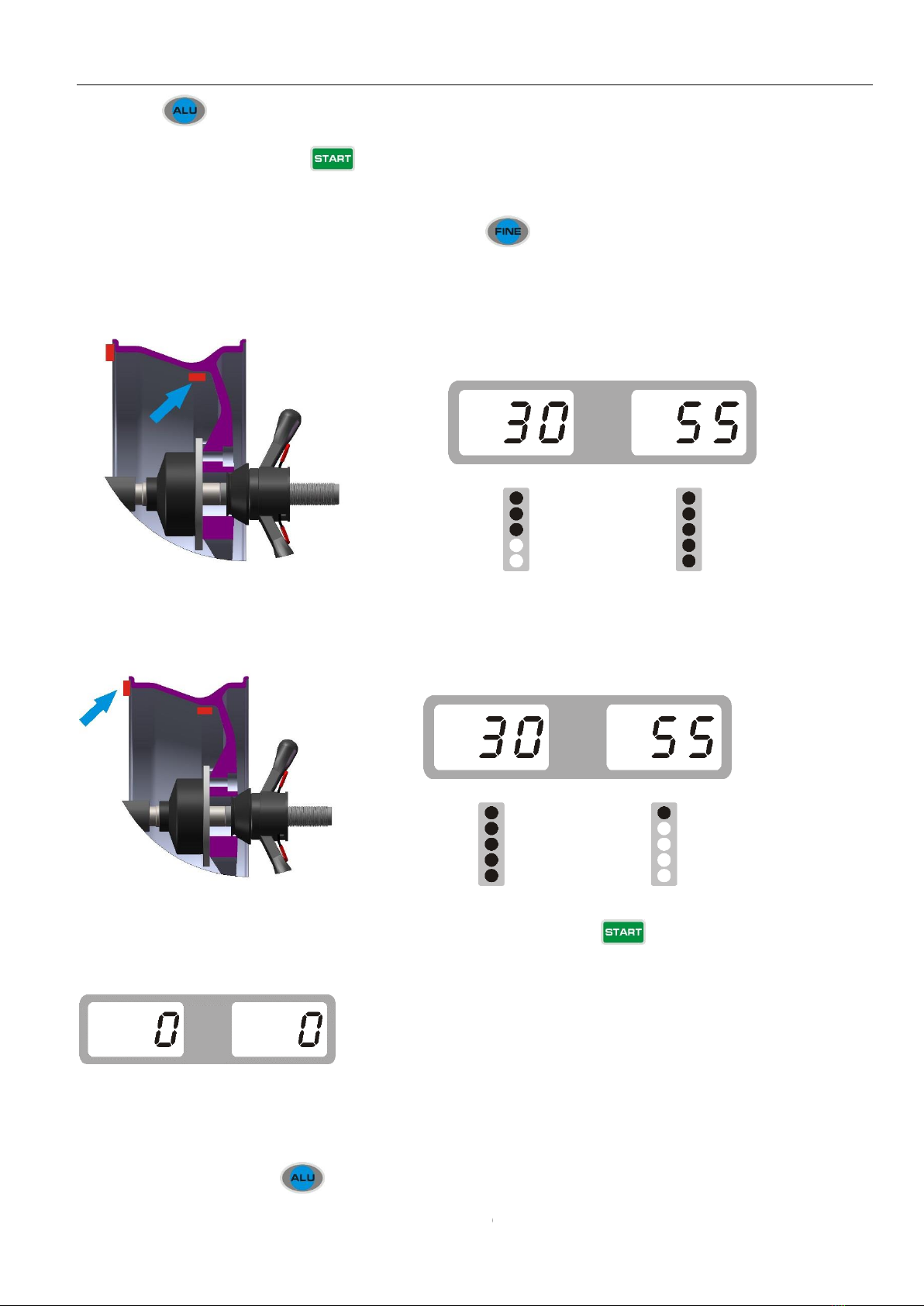

◼Move gauge to touch edge of rim (Fig.1), read the value of distance, press and to change,set “a”

value.

◼Use width gauge to read the value of width (Fig. 2), press and to change, set “b” value.

◼Read the value of diameter (marked on the wheel), press and set “d” value.

Fig.1 Fig.2

9

4.1.4. Put down the guard and; press to perform a measuring spin.

4.1.5. In a few seconds the wheel is brought to operating speed and begin measuring unbalance, the unbalance values

remain on instruments 1 and 3 when the wheel stopped. Press may check the real unbalance value under threshold.

4.1.6. Anticlockwise moving wheel slowly, the displays with right LED’s lit up full indicate the correct angular position

where to mount the counterweights (12 o’clock position) outside, as Fig.3, clip the counterweight.

Fig. 3

4.1.7.Anticlockwise moving wheel slowly, the displays with left LED’s lit up full indicate the correct angular position

where to mount the counterweights (12 o’clock position) inside, as Fig.4, clip the counterweight.

Fig. 4

4.1.8. After finishing cliping the counterweights, put down the guard or press ,to perform balancing spin

again, if comes out 00 00,means balancing succeed. (Fig.5)

Fig. 5

4.2.ALU-2 mode (ALU-1, ALU3 same operation, only the position to add weights

different)

4.2.1. Set “a” “d” “b” values

10

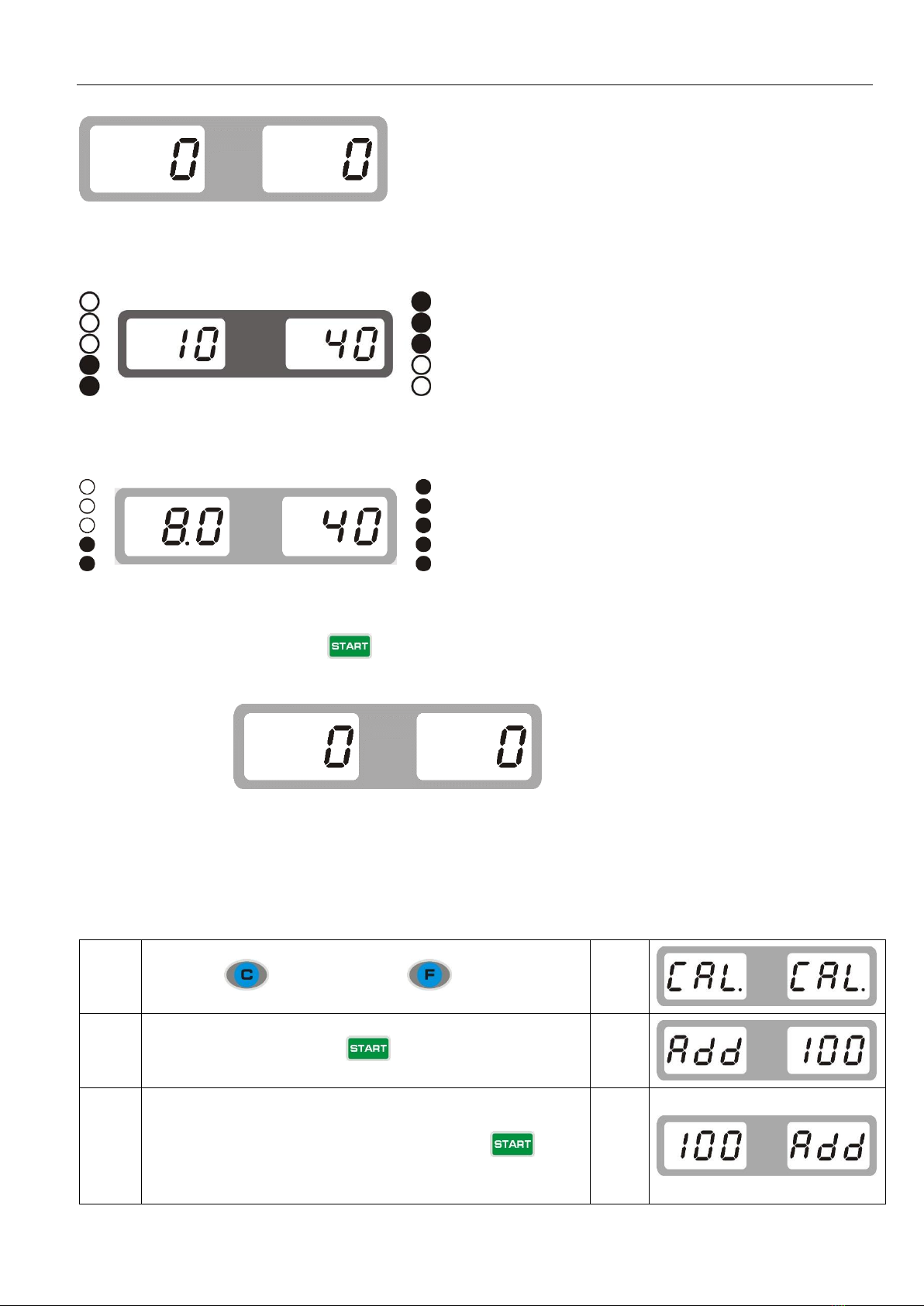

4.2.2. Press until ALU2 indicator lit up

4.2.3. Put down the guard or press to perform a measuring spin.

4.2.4. In a few seconds the wheel is brought to operating speed and begin measuring unbalance, the unbalance values

remain on instruments 1 and 3 when the wheel stopped. Press may check the real unbalance value under threshold.

4.2.5. Anticlockwise moving wheel slowly, the displays with right LED’s lit up full indicate the correct angular position

where to mount the counterweights, 12 o’clock position (9H=Off) or 9 o’clock (9H=On) position outside, as Fig.6, add

the counterweight.

Fig. 6

4.2.6. Anticlockwise moving wheel slowly, the displays with left LED’s lit up full indicate the correct angular position

where to mount the counterweights, 12 o’clock position (9H=Off) or 9 o’clock (9H=On) position inside, as Fig.7, add the

counterweight.

Fig. 7

4.2.7. After finishing mounting the counterweights, put down the guard or press ,to perform balancing spin again,

if comes out 00 00,means balancing succeed. (Fig.8)

Fig. 8

4.3.ALU-S mode

This mode is used for special rim, if ALU1/ALU2/ALU3 can not be used, you should choose ALUS mode.

4.3.1. Turn on machine, press until the indicator of ALUS lit up.

11

4.3.2. Set aI, aE, d Value

⚫Set aI value: Pull gauge out, first to touch position of FI to measure aI value, press or to input

aI value.

⚫Set aE value :Then touch position of FE to measure aE value, press or to input aE value.

⚫Set d value: Then press and to input d value. = Inside Diameter of rim

Fig. 9

4.3.3. Put down the guard and press to perform a measuring spin. 4.3.1. 12 o’clock position to add weight

Set SLC as OFF according to 8.1

Anticlockwise moving wheel slowly, until the right LED lit up full, add weight on 12 o’clock position (Fig.10)

Fig. 10

Anticlockwise moving wheel slowly, until the left LED lit up full, add weight on 12 o’clock position (Fig.11)

Fig. 11

After finishing mounting the counterweights, put down the guard and press ,to perform balancing spin again, if

12

comes out 00 00,means balancing succeed. (Fig.12)

Fig. 12

4.3.2. Use gauge head to add weight

Set SLC as ON according to 8.1

Fig. 13

Anticlockwise moving wheel slowly, until the right LED lit up full(The inside show is the distance from the outside)

(Fig.14)

Fig. 14

Then turn down safe guard and press to start spin, comes Fig. 22 means the wheel is balanced.

Fig. 22

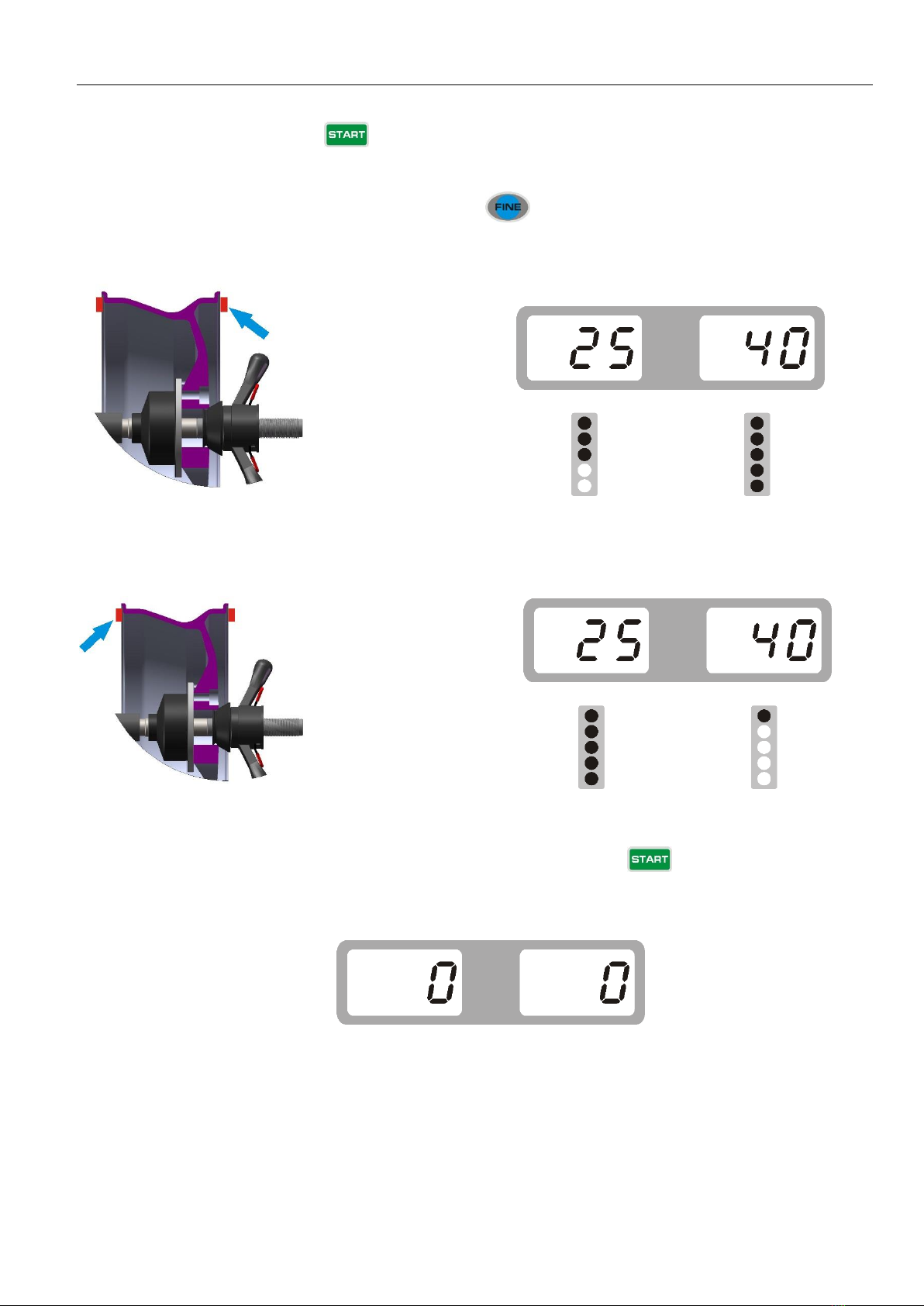

Self-calibration of wheel balancer

Do the self-calibration whenever you think the balancer is not accurate. The 100g weight must be accurate.

Turn on balancer, install a medium size wheel (13″-15″)which can use clip-on weight, set “a b d” value, then

Step 1

Press and hold, then press

comes

Step 2

Put down safe guard or press start spin, after spin stop

comes

Step 3

Open the safe guard and clip a 100 gram weight on the outside

12 o’clock position, put down safe guard and press to

start spin, after spin stop

comes

13

Step 4

Open the safe guard and clip a 100 gram weight on the inside 12

o’clock position, put down safe guard and press to start

spin, after spin stop

comes

self-calibration finished

Errors

Various abnormal conditions can arise during machined operation by the microprocessor, if comes the errors, must stop

operation, find the reason and the solution according, if the error persists, consult the supplier.

No.

Errors

Reasons

Solution

1

1.No spin

2.Shaft spin

1.If no spin, check or change power

board

2.If spin, check or change position pick

up board and computer board

3. Adjust position pick up board support

2

1.No wheel or wheel not locked

tightly

2.Position pick up board

problem

1.Lock tightly

2. check or change position pick up board

3

1.No enough pressure in wheel

2.Wheel distortion

1.Add proper pressure in wheel

2.Check wheel

4

1.Position pick up board

problem

2. Computer board problem

1.Check or change position pick up board

2.Check or change computer board

5

1. Micro switch problem

2. Computer board problem

1.Check or change Micro switch

2.Check or change computer board

6

1. Power board problem

2. Computer board problem

1.Check or change power board

2.Check or change computer board

7

1. Program lost

2. Computer board problem

1.Self calibration

2. Check or change computer board

8

1. No add 100g weight during

self calibration

2.Computer board problem

3.Power board problem

1. Add 100g weight

2.Check or change computer board

3.Check or change power board

14

9

1.Micro switch problem

2. Computer board problem

1.Check or change micro switch

2.Check or change computer board

10

1.Computer board problem

2.Power board problem

1.Check or change computer board

2.Check or change Power board

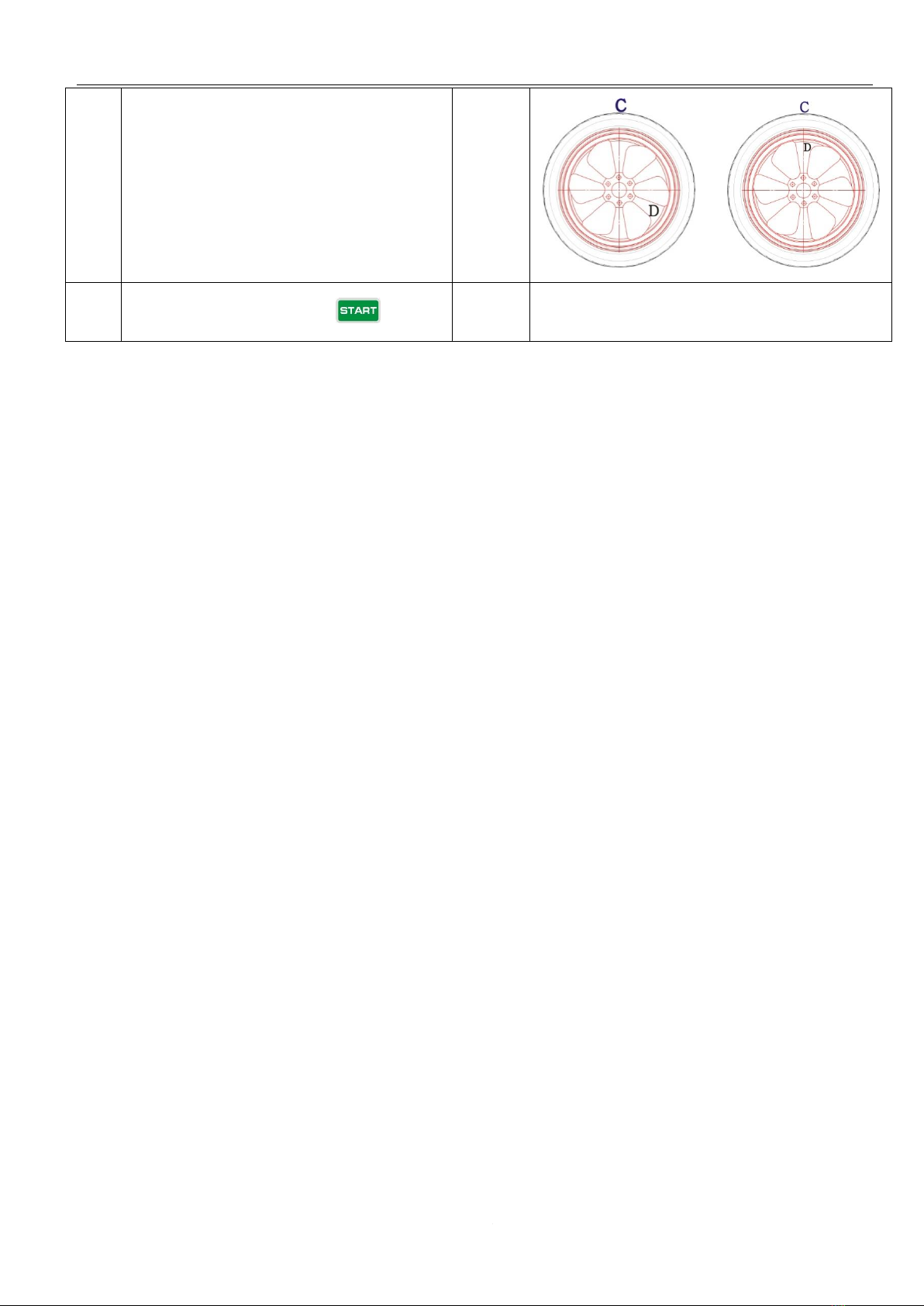

9.OPT function

Note: When unbalance value is too much, choose OPT, and operator must be experienced.

Install wheel, input a b d value

1

Press

comes>

2

Put down safe guard and press

comes>

3

With the help of tire changer, change the rim and

rubber 180 degree

reference

>

>>

4

Then put down safe guard and press

comes>

5

Rotate wheel until four indicators lit up (two on

both sides, the dark spot in the right side picture),

mark the positon C with chalk on rubber

reference

>

6

Rotate wheel until two indicators lit up (one on

both sides, the dark spot in the right side picture),

mark the positon D with chalk on rim

reference

>

15

7

With the help of tire changer, change the rim and

rubber to make C and D match

reference

>

>>

8

Put down safe guard and press

comes>

If unbalance is less than before, OPT succeed

IDENTIFYING MECHANICAL MOUNTING REPEATABILITY ERRORS ON WHEEL BALANCERS

Chasing weights, changing weight angles, changing weight amounts, and changes in run out and force variation may all be produced by

incorrect mounting or worn/damaged adaptors. Balancers cannot identify mechanical mounting errors caused by incorrect mounting

methods or worn/damaged mounting adaptors. Correct mounting MUST be verified by the technician, including identifying the on-vehicle

mounting method. Adaptors must be inspected for excessive wear and should be cleaned regularly to prevent dirt from affecting the

balancer results.

If mechanical mounting errors do not seem to be evident calibration can be performed – refer to procedures in manual.

TO TEST ELECTRONIC AND HARDWARE REPEATABILITY:

✓Mount an assembly on the spindle shaft

✓Input the weight location dimensions using standard clip-on weight locations

✓Measure and record the non-rounded amount of imbalance on each weight plane

✓Repeat this procedure four times without removing the wheel to verify the balancer can repeat measurements within 0.05

ounce (per plane). If it does not repeat the measurements, check the wheel for debris or water in the tire

TO TEST MECHANICAL MOUNTING REPEATABILITY:

✓With the assembly mounted on the spindle shaft, perform a balance spin

✓Record the non-rounded weight amounts for the inner and outer planes. (Do not apply weights)

✓When the data is recorded, loosen the wing nut and using the foot pedal to lock the spindle in position, rotate the wheel 90

degrees clockwise. Perform another balance spin. Record the non-rounded weight amounts for the inner and outer planes

✓Repeat the above steps twice more so measurements are taken at 0, 90, 180, and 270 degrees. The weight amount from

the highest to lowest recorded number should not vary by more than 0.25 ounce for smaller passenger car wheels (per plane), 0.50

ounce for SUV wheels (per plane), and 1.0 ounce for larger truck wheels (per plane). If recorded readings change by more than

this, repeat the measurements at 0, 90, 180, and 270 degrees again

DATA ANALYSIS:

Note: Larger rim/tire assemblies may experience more variation in data than smaller assemblies. This should be considered when

16

comparing data.

Do not check repeatability using ALU mode because it is “hyper-sensitive” in comparison to clip-on weight placement. In ALU mode

the diameters are smaller and the planes are closer together compared to standard clip weight balance, therefore any change in re-centering

will be amplified compared to when clip-on weight planes are dialed-in.

For example, a wheel that needs 0.25 or 0.50 oz. weights in ALU mode may show zeroes in clip-on weight mode. You can also get cases

where dynamic imbalance on standard is small, such as 1 oz., and it jumps to 4 or more oz. in ALU if the planes are close enough together.

All balancers will do this….and that’s why most balancers have such a hard time hitting zero on the first spin.

If the imbalance amounts change and the readings from the first sample data and the second sample data are NOT the same for 0, 90,

180, and 270 degrees, the assembly is not being mounted correctly. Refer to “Mounting the Wheel on the Spindle Shaft” for proper

mounting techniques.

If ALL readings change, BUT the readings from the first sample data and the second sample data are the same for 0, 90, 180, and 270

degrees, the hub/shaft assembly is out of position. Use a dial indicator to check for run out on the hub face and on the shaft. Run out on

the hub face should not exceed 0.0015”. Run out on the shaft should not exceed 0.0015”. If run out exceeds these limits, remove the

threaded hub/shaft assembly and inspect for any debris or nicks on the tapered mounting surfaces only, spindle and hub assembly must be

replaced.

BALANCER MOUNTING METHODS

MOUNTING THE WHEEL ON THE VEHICLE

Since today’s vehicles are more sensitive to road feel, it is critical to be aware of how the wheel mounts on the vehicle. Acceptable ride

quality depends on accurately mounting the wheel on the vehicle hub. Step torqueing lug nuts in a star pattern should be followed on every

installation.

If the wheel is not placed on the vehicle using the same centerline that was used on the balancer, the wheel balance, run out, and force

variation will not be duplicated.

Improper wheel centering is a huge problem when the hub bore of the wheel does not ‘slip fit’ onto the hub of the vehicle. Extra

caution should be used when mounting these types of wheels after servicing on the balancer. This is especially prevalent on lower cost

aftermarket wheels. In many cases, a tire and/or wheel is blamed for creating unacceptable vibration when in fact it was merely mounted

on the vehicle improperly.

MOUNTING THE WHEEL ON THE SPINDLE SHAFT

Since today’s vehicle designs are lighter and more sensitive to road feel, it is critical to achieve the best balance. Proper balance requires

that the tire/wheel assembly be centered on the balancer. Most balancers will balance the tire/wheel assembly to zero, even with the

tire/wheel assembly mounted off center. The main objective of the balancer operator is to center the wheel on the balancer using the best

available method. Mounting the wheel off-centre on the balancer creates incorrect measurements of imbalance and run out conditions.

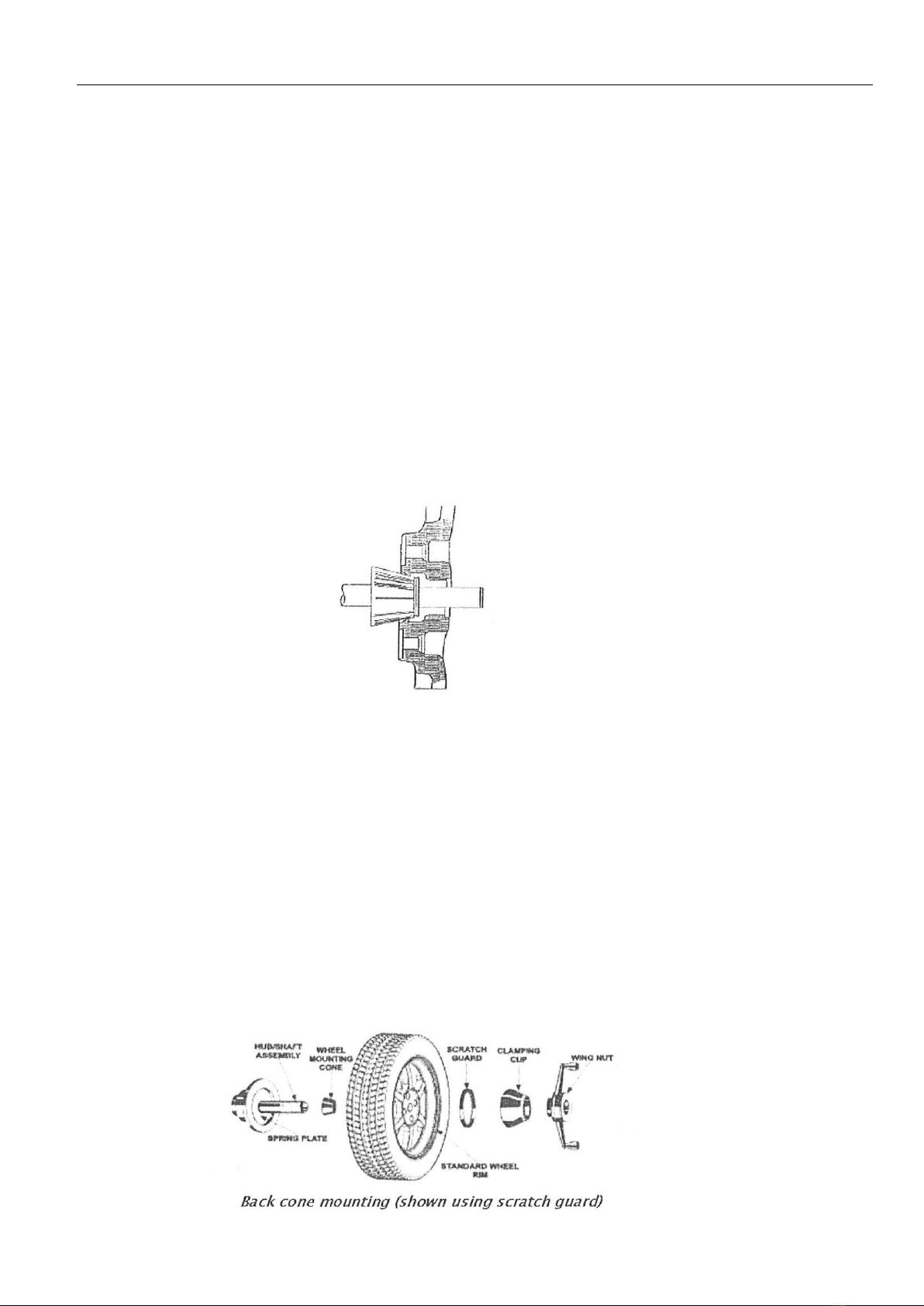

MOUNTING WHEELS WITH CONES

The majority of wheels are mounted with a cone to center them on the balancer’s shaft. Cones are manufactured with different tapers.

17

The taper and the fit of the cone make a significant difference in accurate centering. Cones having a low taper fit the hub bore and guide

the wheel for better centering during the mounting process.

Most wheels benefit with the cone mounted from the backside. This method is referred to as back cone mounting.

CHECK FOR:

✓Correct mounting cone/adaptor for this wheel design

✓Wheel defect such as metal burr interfering with the cone/adaptor

✓Dirt or debris interfering with the cone/adaptor

BACK CONE MOUNTING PROCEDURE

Select the proper wheel-mounting cone by placing it in the center bore of the wheel to be balanced.

Select the cone that contacts the wheel nearest the center of the cone.

Place the wheel-mounting cone on the spindle against the spring plate. Mount the wheel with the inner rim facing the balancer and

centered on the cone.

Install the clamping cup and wing nut on the spindle shaft against the wheel and secure the entire assembly by firmly tightening the

wing nut. Depress the foot pedal to hold the spindle in place (if available). Slowly roll the wheel toward you during the initial tightening

of the wing nut. This helps the wheel to roll up the taper of the cone as opposed to forcing it to slide up the cone.

18

The scratch guard may be installed on the clamping cup to protect aluminum rims from being marred, but should not be used on steel

wheels.

FRONT CONE MOUNTING PROCEDURE

This procedure utilized a tapered cone inserted from the front side of the wheel instead of the backside as previously described.

Select the proper wheel-mounting cone by placing it in the center bore of the wheel to be balanced. Choose the cone that contacts

the wheel nearest the center of the cone.

Mount the wheel with the inner rim facing the balancer. Place the wheel-mounting cone on the spindle with the small end of the cone

facing the front of the wheel.

Install the wing nut and pressure ring assembly onto the spindle shaft against the wheel and secure the entire assembly by firmly

tightening the wing nut.

Heavy wheel centering may benefit by pulling the tire away from the hub face at top dead center while tightening the wing nut. This

helps the wheel to overcome gravity against the hub or spacer.

PRESSURE RING

The pressure ring should be used to prevent the wing nut from directly contacting an adaptor or a cone.

It may also be used in place of a pressure cup if space is limited between the wheel and the end of the spindle.

TIRE TECH INFORMATION/GENERAL TIRE INFORMATION

19

1. The definition of balance is the uniform distribution of mass about an axis of rotation, where the center of gravity is in the

same location as the center of rotation.

2. One of the limitations of balancing tire and wheel assemblies off a vehicle is that repeatability can be an issue. In other

words, you may not get the same results when you attempt to rebalance a wheel that has already been balanced. What has

changed? It is not the tire or rim. What has changed is the geometry of the tire and wheel on the balancer.

3. Weights on the wheel have an inherent problem due to the tire/rim geometry. Since the imbalance is normally out at the

tire tread surface, and has more effect on balance than an equal weight located at the rim radius.

4. Wheel balancers operate at a smaller radius than a wheel, making it progressively less effective as the tire diameter increase

for a given wheel diameter.

5. Match mounting tires on wheels is also a process where a tire’s installed position on the wheel is specifically selected to

help minimize the final combination’s force variation and/or imbalance.

6. Tires used off-road are notoriously hard to balance and keep balanced. They are big, they have large tread blocks (subject

to “chunking”).

7. “Lug-centric” wheels are notoriously hard to balance on common “hub-centric” balancers and are found with many different

rim manufacturers. Toyota also locates the wheel on the hub, via the rim studs. (i.e. lug-centric) and a special lug centric adaptor

should be used to properly balance the wheel.

8. According to Tru-Balance, wheel-centering products bypass the hub pilot and actually center the wheel to the wheel studs

using the 12, 4, and 8 o’clock positions, resulting in less weight value change during reposition of wheel to hub mounting on wheel

balancing machines.

9. The way that a wheel is mounted on a balancer will not only affect the accuracy of the balance job itself but also the

repeatability of the balancing results.

10. You can select different methods of wheel mounting according to practice to have wheel spin straight as possible.

POSITIVE positioning is featured with simple quick operation with suitable cone and nut on the outside of rim, commonly used

with steel rims and aluminum alloy rims with small deformation.

NEGATIVE positioning is used when deformation is noticed with the spin of the wheel. Adopt this method of positioning to

guarantee the accurate positioning of the rim inner hole and main shaft. Especially the thick ALU. Negative positioning is with

the suitable cone on the inside of the rim and the bowl and nut on the outside.

Table of contents

Popular Wheel Balancer manuals by other brands

Hofmann

Hofmann geodyna 4500-2 Operation manual

MANATEC

MANATEC JUMBO HCV operating manual

M&B Engineering

M&B Engineering WB 355 Original instruction manual

Atlas

Atlas WBT-210 quick start guide

CAR-MON

CAR-MON LFT Series quick start guide

HENNESSY INDUSTRIES

HENNESSY INDUSTRIES coats ProRide Diagnostic manual