7. OPERATION 41

7.1. DEFECTS / MALFUNCTIONS 41

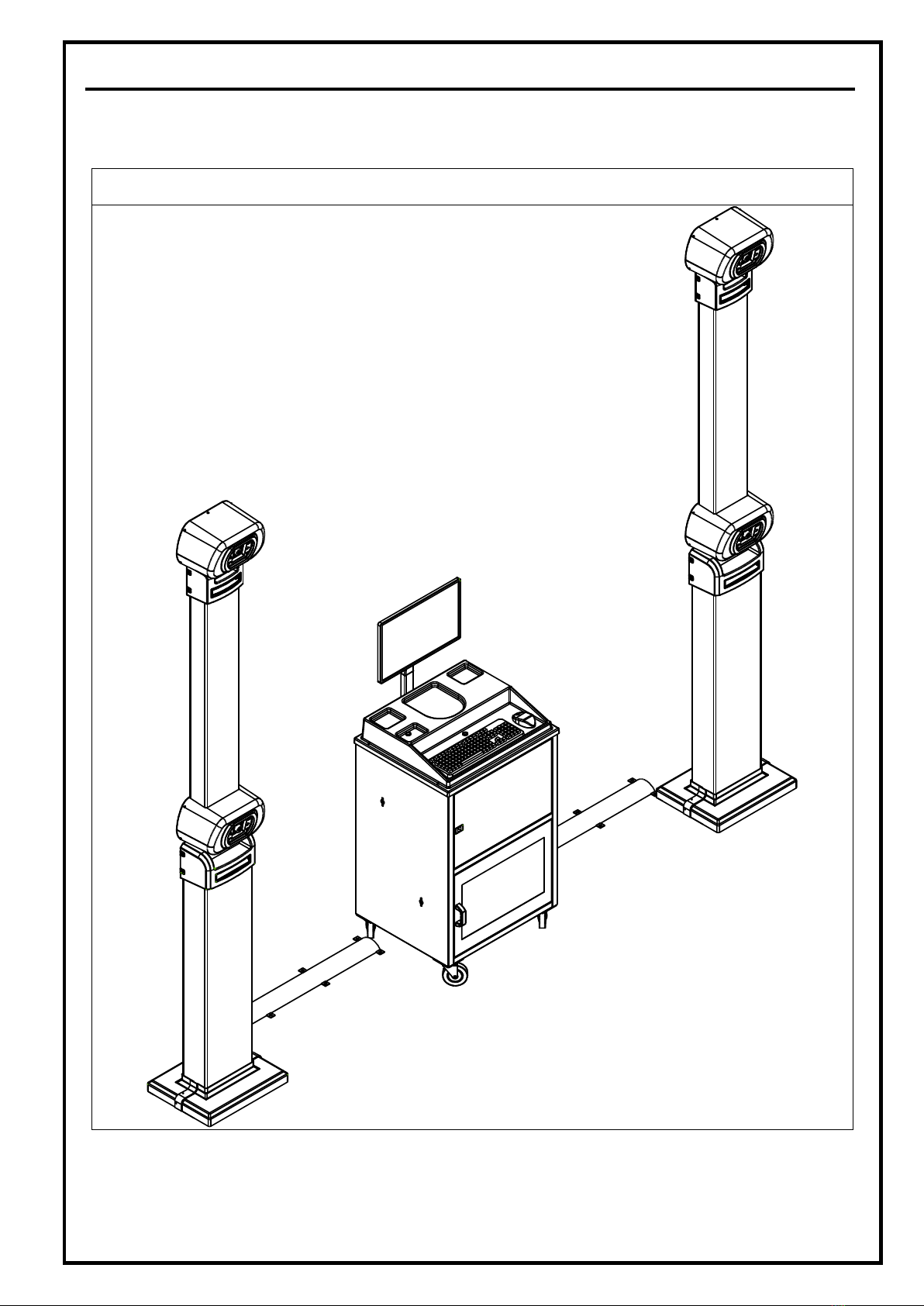

7.2. PRELIMINARY ALIGNMENT PREPARATION 41

7.3. MAIN MENU 47

7.4. ALIGNMENT 48

7.4.1. VEHICLE SELECTION 49

7.4.2. WHEEL RUNOUT 51

7.4.2.1. CUSTOMER DATA INPUT 53

7.4.3. CASTER & KINGPIN SWING 56

7.4.3.1. TURN LEFT 56

7.4.3.2. TURN RIGHT 57

7.4.3.3. STRAIGHT AHEAD 57

7.4.4. ALIGNMENT PARAMETERS & RESULTS 59

7.4.4.1. THRUST ANGLE ADJUSTMENT 60

7.4.4.2. REAR WHEEL PARAMETERS 61

7.4.4.3. FRONT WHEEL PARAMETERS 61

7.4.4.4. DIFFERENTIAL TOE ADJUSTMENT 62

7.4.4.5. PARALLELISM ADJUSTMENT 63

7.4.4.6. PUSHER AXLE ADJUSTMENT (Single Tie rod) 64

7.4.4.7. SCRUB ANGLE ADJUSTMENT 65

7.4.4.8. TAG AXLE ADJUSTMENT 66

7.4.4.9. CAM / BUSH / SHIM ADJUSTMENT 66

7.4.5. MULTI-AXLE CONFIGURATIONS & APPLICABLE SEQUENCE (Drive Axle Reference) 71

7.4.5.1. CARs and LCVs (6A/5A/4A) 71

7.4.5.2. HEAVY TRUCK –1 Front Axle & 1 Rear Axle (6A/5A/4A) 71

7.4.5.3. HEAVY TRUCK –1 Front Axle & 2 Rear Axles (6A/5A/4A) 71

7.4.5.4. HEAVY TRUCK –1 Front Axle & 3 Rear Axles (6A/5A/4A) 72

7.4.5.5. HEAVY TRUCK –2 Front Axles & 1 Rear Axle (6A/5A/4A) 72

7.4.5.6. HEAVY TRUCK –2 Front Axles & 2 Rear Axles (6A/5A/4A) 72

7.4.5.7. HEAVY TRUCK –2 Front Axles & 3 Rear Axles (6A/5A) 73

7.4.5.8. HEAVY TRUCK –1 Front & 3 Rear Axles (including 1 Pusher 3rd Axle) (6A/5A/4A) 73

7.4.5.9. HEAVY TRUCK –1 Front Axle & 3 Rear Axles (including 1 Tag 1st Axle) (6A/5A/4A) 73

7.4.5.10. HEAVY TRUCK –2 Front & 3 Rear Axles (including 1 Pusher 3rd Axle) (6A/5A) 74

7.4.5.11. HEAVY TRUCK –2 Front Axles & 3 Rear Axles (including 1 Tag 1st Axle) (6A/5A) 74

7.4.5.12. HEAVY TRUCK –2 Front & 4 Rear Axles (including 1 Pusher & 1 Tag Axle) (6A) 75

7.4.5.13. BUS –1 Front Axle & 1 Rear Axle (6A/5A/4A) 75

7.4.5.14. BUS –1 Front Axle & 2 Rear Axles (including 1 Pusher Axle) (6A/5A/4A) 75

7.4.5.15. BUS –1 Front Axle & 2 Rear Axles (including 1 Tag Axle) (6A/5A/4A) 76

7.4.5.16. BUS –1 Front Axle & 2 Rear Axles (including 1 Rear Steering Tag Axle) (6A/5A/4A) 76

7.4.5.17. BUS –2 Front Axles & 1 Rear Axle (6A/5A/4A) 76

7.4.5.18. BUS –2 Front Axles & 2 Rear Axles (including 1 Pusher Axle) (6A/5A/4A) 77

7.4.5.19. BUS –2 Front Axles & 2 Rear Axles (including 1 Tag Axle) (6A/5A/4A) 77

7.4.5.20. TRAILER (Forward parking) –1 Rear Axle (6A/5A/4A) 77

7.4.5.21. TRAILER (Forward parking) –2 Rear Axles (6A/5A/4A) 78

7.4.5.22. TRAILER (Forward parking) –3 Rear Axles (6A/5A/4A) 78

7.4.5.23. TRAILER (Forward parking) –4 Rear Axles (6A/5A/4A) 78

7.4.5.24. TRAILER (Forward parking) –5 Rear Axles (6A/5A/4A) 79

7.4.5.25. TRAILER (Reverse parking) –1 Rear Axle (6A/5A/4A) 80

7.4.5.26. TRAILER (Reverse parking) –2 Rear Axles (6A/5A/4A) 80

7.4.5.27. TRAILER (Reverse parking) –3 Rear Axles (6A/5A/4A) 80

7.4.5.28. TRAILER (Reverse parking) –4 Rear Axles (6A/5A/4A) 81

7.4.5.29. TRAILER (Reverse parking) –5 Rear Axles (6A/5A/4A) 81

7.4.5.30. TRAILER (Reverse parking) –6 Rear Axles (6A/5A/4A) 82

7.4.5.31. TRAILER (Reverse parking) –7 Rear Axles 83

7.4.5.32. TRAILER (Reverse parking) –8 Rear Axles 84

7.4.5.33. FULL TRAILER (Forward parking) –1 Front Axle & 1 Rear Axle (6A/5A/4A) 85

7.4.5.34. FULL TRAILER (Forward parking) –1 Front Axle & 2 Rear Axles (6A/5A/4A) 85

7.4.5.35. FULL TRAILER (Foward parking) –1 Front Axle & 3 Rear Axles (6A/5A) 86

7.4.5.36. FULL TRAILER (Forward parking) –2 Front Axles & 1 Rear Axle (6A/5A/4A) 87

7.4.5.37. FULL TRAILER (Forward parking) –2 Front Axles & 2 Rear Axles (6A/5A) 87

7.4.5.38. FULL TRAILER (Forward parking) –2 Front Axles & 3 Rear Axles (6A) 88

7.4.5.39. FULL TRAILER (Reverse parking) –1 Front Axle & 1 Rear Axle (6A/5A/4A) 89

7.4.5.40. FULL TRAILER (Reverse parking) –1 Front Axle & 2 Rear Axles (6A/5A/4A) 89

7.4.5.41. FULL TRAILER (Reverse parking) –1 Front Axle & 3 Rear Axles (6A/5A) 90

7.4.5.42. FULL TRAILER (Reverse parking) –2 Front Axles & 1 Rear Axle (6A/5A/4A) 91

7.4.5.43. FULL TRAILER (Reverse parking) –2 Front Axles & 2 Rear Axles (6A/5A) 91

7.4.5.44. FULL TRAILER (Reverse parking) –2 Front Axles & 3 Rear Axles 92

7.4.5.45. FULL TRAILER FORWARD PARKING ALIGNMENT PROCEDURE (6A Model) 93

7.4.5.46. FULL TRAILER REVERSE PARKING ALIGNMENT PROCEDURE 99

7.4.5.47. ARTICULATED BUS –1 Front Axle & 2 Rear Axles 105

7.4.5.48. ARTICULATED BUS –1 Front Axle & 3 Rear Axles 106

7.4.5.49. ARTICULATED BUS –1 Front Axle & 4 Rear Axles 107

7.5. DATA MANAGER 109

7.5.1. DATE BASED ALIGNMENT REPORT 109

7.5.2. REGISTRATION NUMBER BASED ALIGNMENT REPORT 110

7.5.3. YEAR BASED ALIGNMENT REPORT 111

7.5.4. TECHNICIAN BASED ALIGNMENT REPORT 112

7.5.5. CUSTOMER DATABASE 113

7.5.6. REMINDER TO CUSTOMER 113