CAR-MON PRODUCTS, INC. 1225 Davis Road, Elgin, IL 60123 Phone (847) 695-9000

INSTALLATION - OPERATION - MAINTENANCE

HEIGHT ADJUSTMENT

TO ADD TENSION

1. Fully retract balancer to release tension. You may need to remove tube assembly. Do not adjust with

tube assembly attached to the balancer unless properly supported.

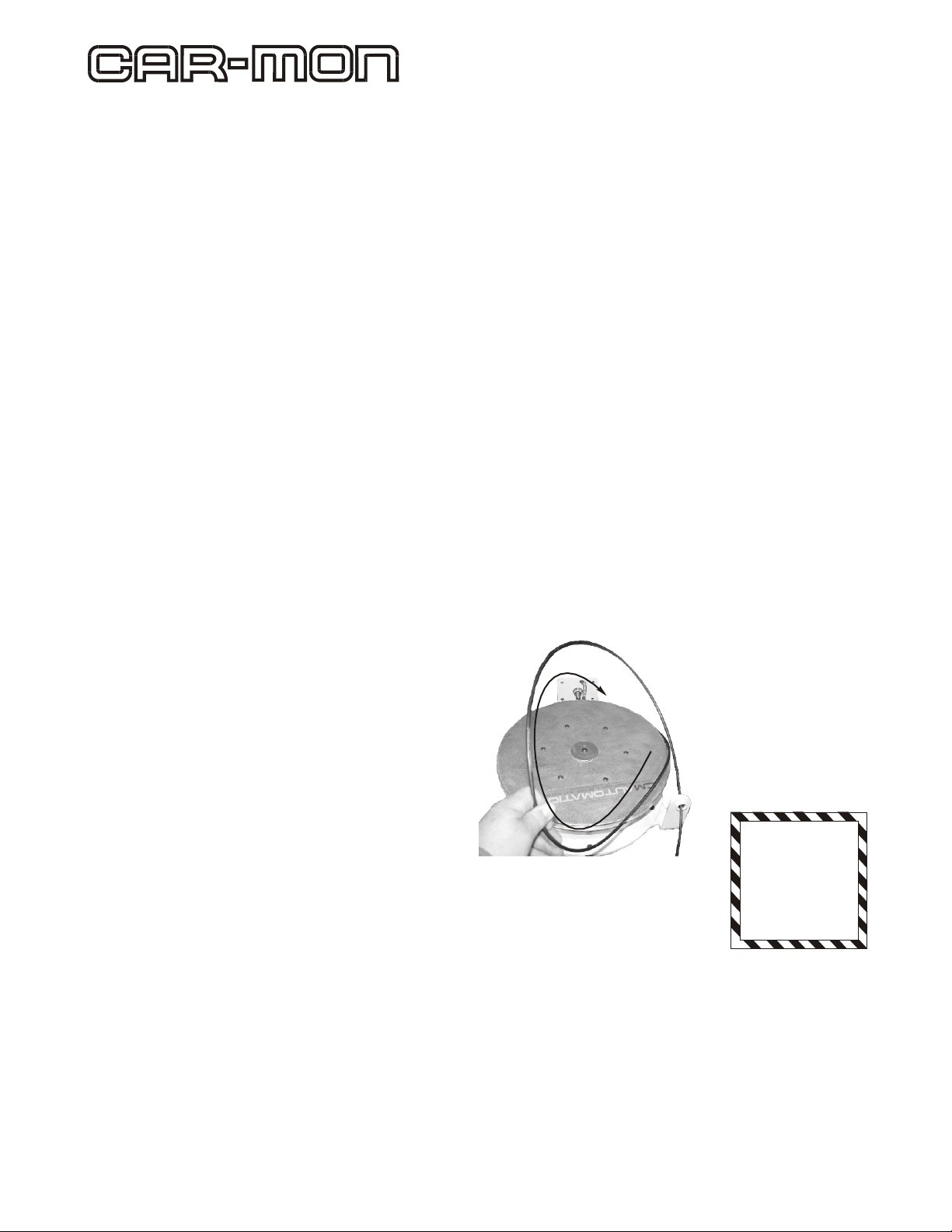

2. Manually pull the cable by the adjustable stop until about 6' of cable is hanging and ratchet stop is

engaged in one of the ratchets. Make one wrap of cable clockwise around the cable reel. Grab the

adjustable stop and carefully release the tension on the cable. Now check the position of the ratchets

and ratchet stop. The ratchet stop should not be engaged in any of the ratchets, and the ratchets on the

cable reel should be at the 9 and 3 o'clock position. If they are not, pull the cable out manually and move

the adjustable stop (make sure to tighten securely) so that when the stop is in the resting position, the

ratchet stop is not engaged.

3. Repeat the procedure if necessary, adjusting only one wrap at a time.

ADD TENSION BY WRAPPING THE CABLE

CLOCKWISE USING THE PROCEDURE

DESCRIBED.

DECREASE TENSION BY UNWRAPPING

THE CABLE COUNTERCLOCKWISE

USING THE PROCEDURE DESCRIBED.

Check cable termination condition frequently for any fraying or damage. Call factory or a Car-Mon

representative for any replacement parts or repair.

DO NOT ATTEMPT TO OPEN UNIT TO MAKE ANY REPAIRS. THERE ARE NO USER SERVICEABLE

PARTS INSIDE.

TO DECREASE TENSION

1. Fully retract balancer to release tension.

2. Manually pull the cable by the adjustable stop

until about 2’ of cable is hanging and ratchet

stop is engaged in one of the ratchets. While

supporting the tube assembly unwrap the

cable (one wrap) counter clockwise around

the cable reel.

3. Repeat procedure if necessary, adjusting only

one wrap at a time.

Grab the adjustable stop and

carefully release the tension on the cable.

Now check the position of the ratchets and

ratchet stop. The ratchet stop should not be

engaged in any of the ratchets and the

ratchets on the cable reel should be at the 9

and 3 o'clock position. If they are not pull the

cable out manually and move the adjustable

stop (make sure to tighten securely) so that

when the stop is in the resting position, the

ratchet teeth are at the 9 & 3 o'clock position.

If you have any questions on this procedure, please call the factory at 847-695-9000,

or e-mail us at the address provided below.fax at 847-695-9078,

CAUTION!

DO NOT

DISASSEMBLE

LFT BALANCER.

NO USER

SERVICEABLE

PARTS INSIDE.

USE EXTREME CAUTION

AND ALWAYS MAKE SURE

THE RATCHET STOP IS

ENGAGED IN ONE OF THE

RATCHETS WHEN

WRAPPING CABLE.

NOTE: If tube assembly cannot be safely and properly supported during the adjustment process, it

should be removed.

NOTE: If tube assembly cannot be safely

and properly supported during the

adjustment process, it should be

removed.