3

TABLE OF CONTENTS

1 INSTALLATION AND UPDATING OF THE PROGRAM ............................................................................................. 4

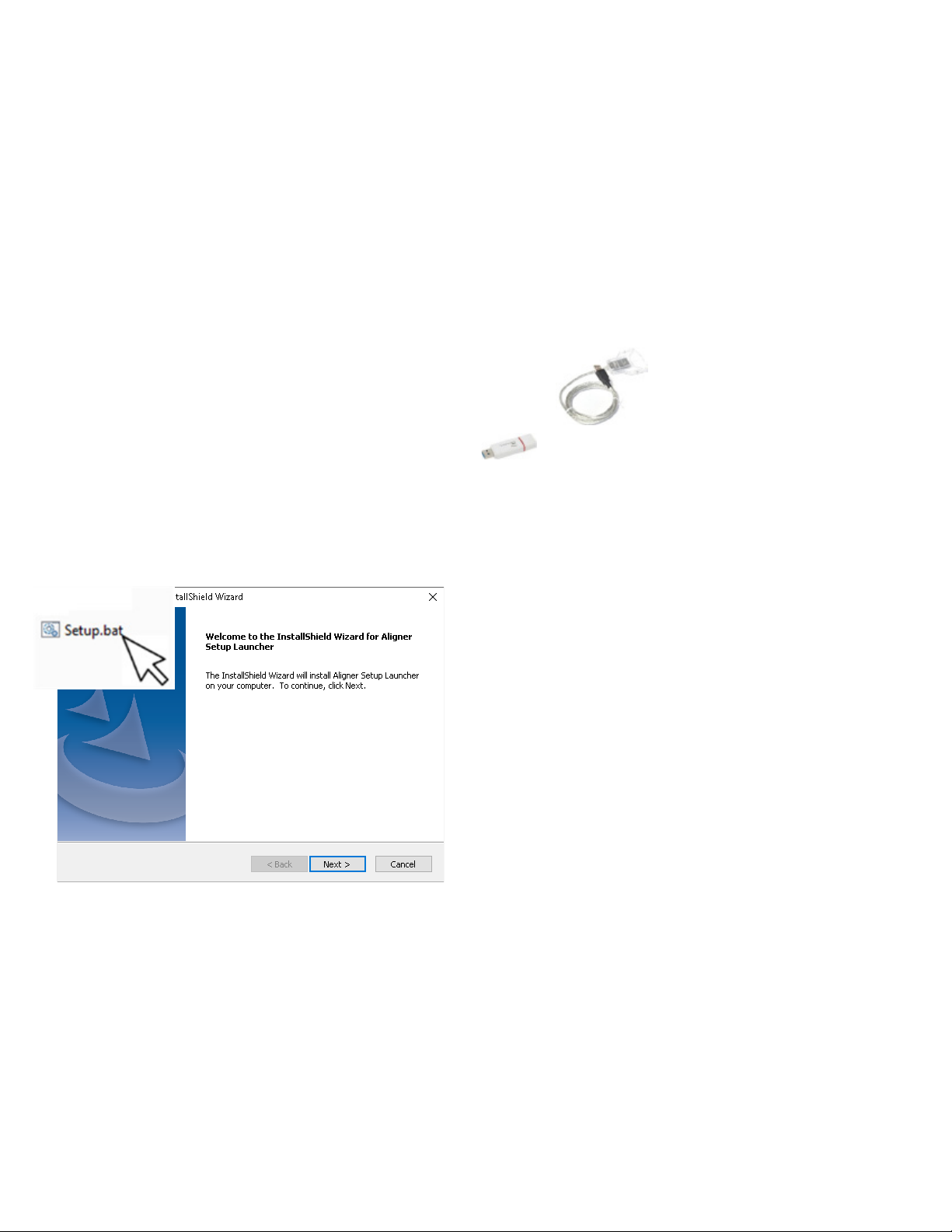

1.1. Installation........................................................................................................................................................................................................... 4

1.2. Start full installation........................................................................................................................................................................................... 4

1.3. Part 1 - Launcher installation........................................................................................................................................................................... 5

1.4. Part 2 - Prerequisite installation...................................................................................................................................................................... 5

1.5. Parts 3 and 4 – Main program and installation update............................................................................................................................... 6

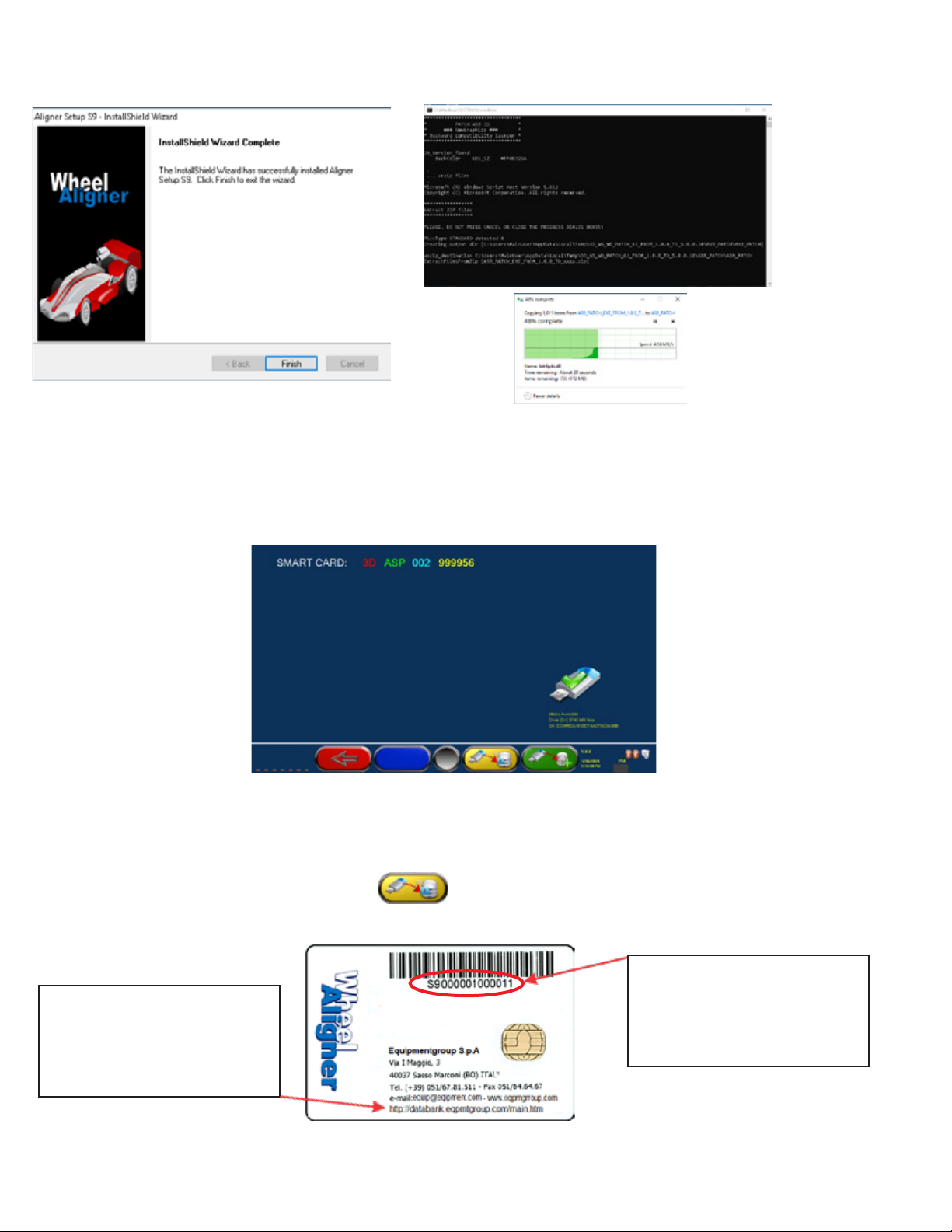

1.6. Uninstallation..................................................................................................................................................................................................... 8

1.7. DEMO MODE ..................................................................................................................................................................................................... 8

1.8. Upgrade.............................................................................................................................................................................................................. 8

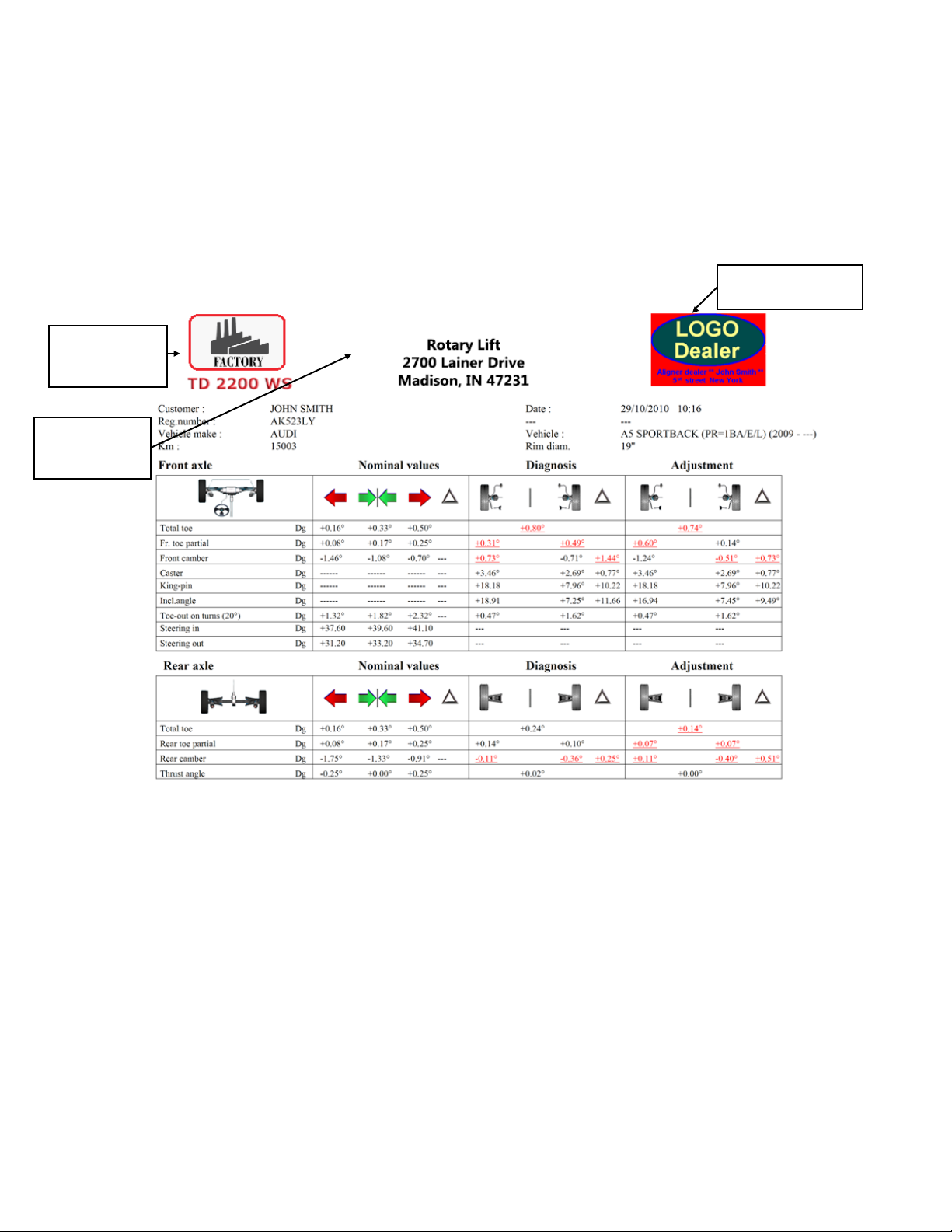

1.9. Insertion of the distributor logo...................................................................................................................................................................... 9

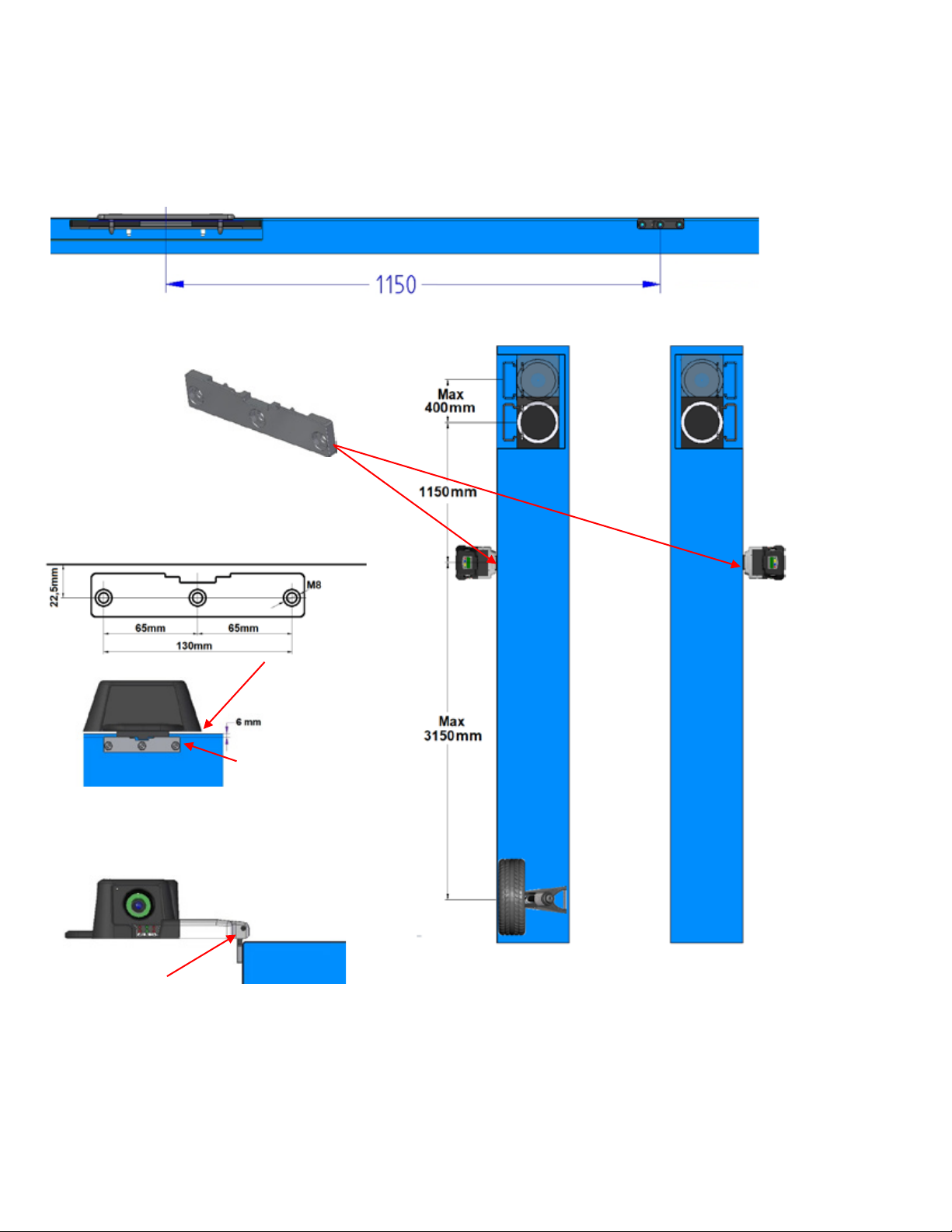

1.10. ATTACHING THE MEASURING HEAD SUPPORTS...................................................................................................................................... 10

2 CONNECTIONS.............................................................................................................................................................11

2.1. Power line connection..................................................................................................................................................................................... 11

2.2. Connecting the sensors to the cabinet......................................................................................................................................................... 11

2.2.1. Pairing the sensors with the cabinet............................................................................................................................................................ 12

2.3. Entering target characterization files........................................................................................................................................................... 14

2.3.1. Target Replacement........................................................................................................................................................................................ 15

2.4. Connecting the sensors and internal devices of the measuring heads................................................................................................. 16

2.4.1. Measuring head - main components........................................................................................................................................................... 16

2.4.2. Measuring head cover.................................................................................................................................................................................... 17

2.4.3. Replacing the CPU board .............................................................................................................................................................................. 19

2.4.4. Setting up the CPU board............................................................................................................................................................................... 20

2.4.5. FW Update........................................................................................................................................................................................................ 22

2.4.6. Replacing the side camera and light........................................................................................................................................................... 23

2.4.7. Replacing front / rear cameras and lights.................................................................................................................................................. 23

3 CALIBRATIONS........................................................................................................................................................... 24

3.1. Complete procedure with calibration tool.................................................................................................................................................. 24

3.1.1. Calibration procedure of the “Vertical” Central Cameras....................................................................................................................... 24

3.2. Incidence compensation adjustment.......................................................................................................................................................... 25

3.3. Steering wheel compensation adjustment................................................................................................................................................ 25

4 TEST PROCEDURES................................................................................................................................................... 26

4.1. Keyboard Test and FW Release................................................................................................................................................................... 26

4.2. Test of Inclinometers “X”and”Y” and central cameras “H” and “V”................................................................................................... 27

4.3. Test for displaying the positions of the spheres in the targets.............................................................................................................. 27

4.4. Test of the measurement of angles measured by the cameras............................................................................................................ 28

4.5. Testing Target and Side Camera................................................................................................................................................................. 29

4.6. Count of number of tests performed.......................................................................................................................................................... 30