3/ 9

Contents

1. Safety Tips ...................................................................................................................................................................... 4

1.1 Explosion May Result In Death or Serious Injury. ...................................................................................... 4

1.2 Process Leaks Can Cause Serious Injury or Death..................................................................................... 4

1.3 Failure to Follow Safe Installation Guidelines May Result In Death or Serious Injury.................... 4

2. Product Manual............................................................................................................................................................ 4

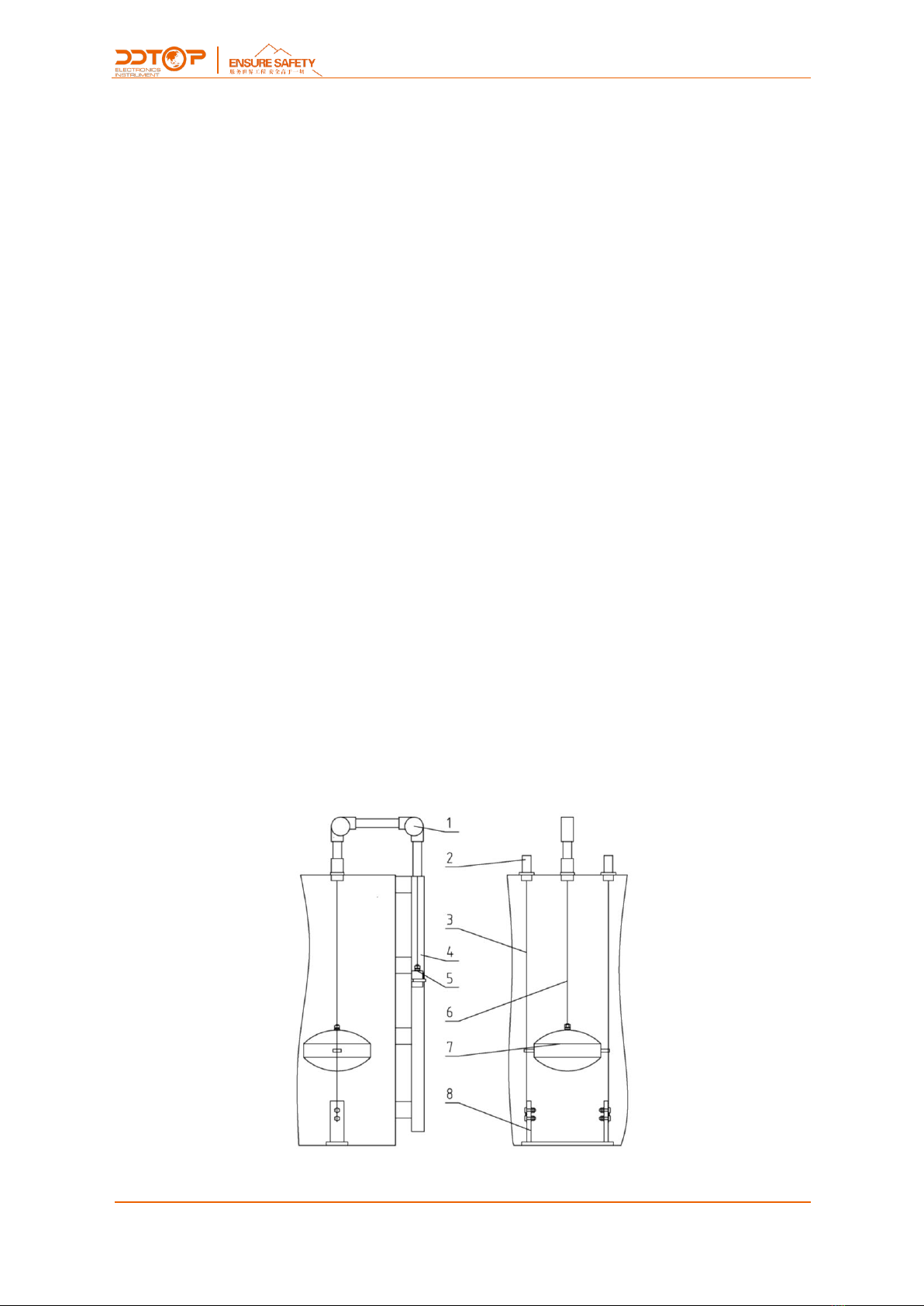

2.1Main Structure of Product-Figure 1..................................................................................................................... 4

2.2 Operating Principle.............................................................................................................................................. 5

2.3 Packing..................................................................................................................................................................... 5

2.4 2.4 Transporting.................................................................................................................................................... 5

2.5 Warehousing.......................................................................................................................................................... 5

3. Technical Characteristics............................................................................................................................................ 5

3.1 Main Performance................................................................................................................................................ 5

3.2 Main Performance................................................................................................................................................ 5

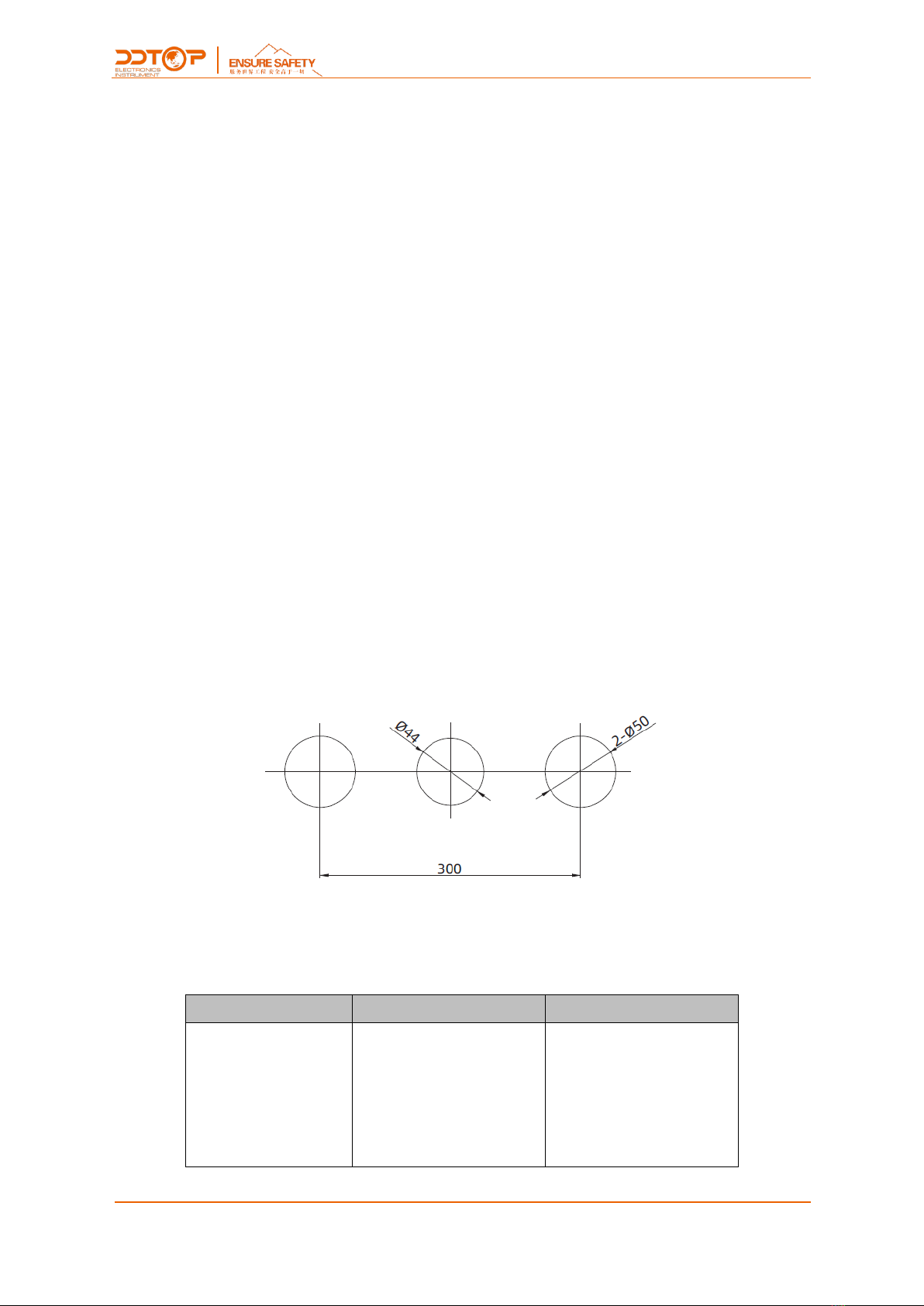

4 Dimensional Schematic -Figure 2 ........................................................................................................................... 6

5 Unpacking and Inspection ......................................................................................................................................... 6

5.1 Unpacking Inspection Notice ........................................................................................................................... 6

5.2 Check Content....................................................................................................................................................... 6

6 Installation ....................................................................................................................................................................... 7

6.1 Installation Tool..................................................................................................................................................... 7

6.2 Installation Technical Requirements............................................................................................................... 7

6.3 Installation Process-Figure 6 ............................................................................................................................ 8

7. Fault Analysis and Elimination ................................................................................................................................. 8

8 Disassembly .................................................................................................................................................................... 9

8.1 Warning ................................................................................................................................................................... 9

8.2 Waste Removal...................................................................................................................................................... 9

9 Product Certification.................................................................................................................................................... 9