3/ 10

CONTENTS

1 Safety Tips ....................................................................................................................................................................... 4

1.1 Explosion may result in death or serious injury.................................................................................4

1.2 Process leaks can cause serious injury or death................................................................................4

1.3 Failure to follow safe installation guidelines may result in death or serious injury................4

2 Product Manual............................................................................................................................................................. 4

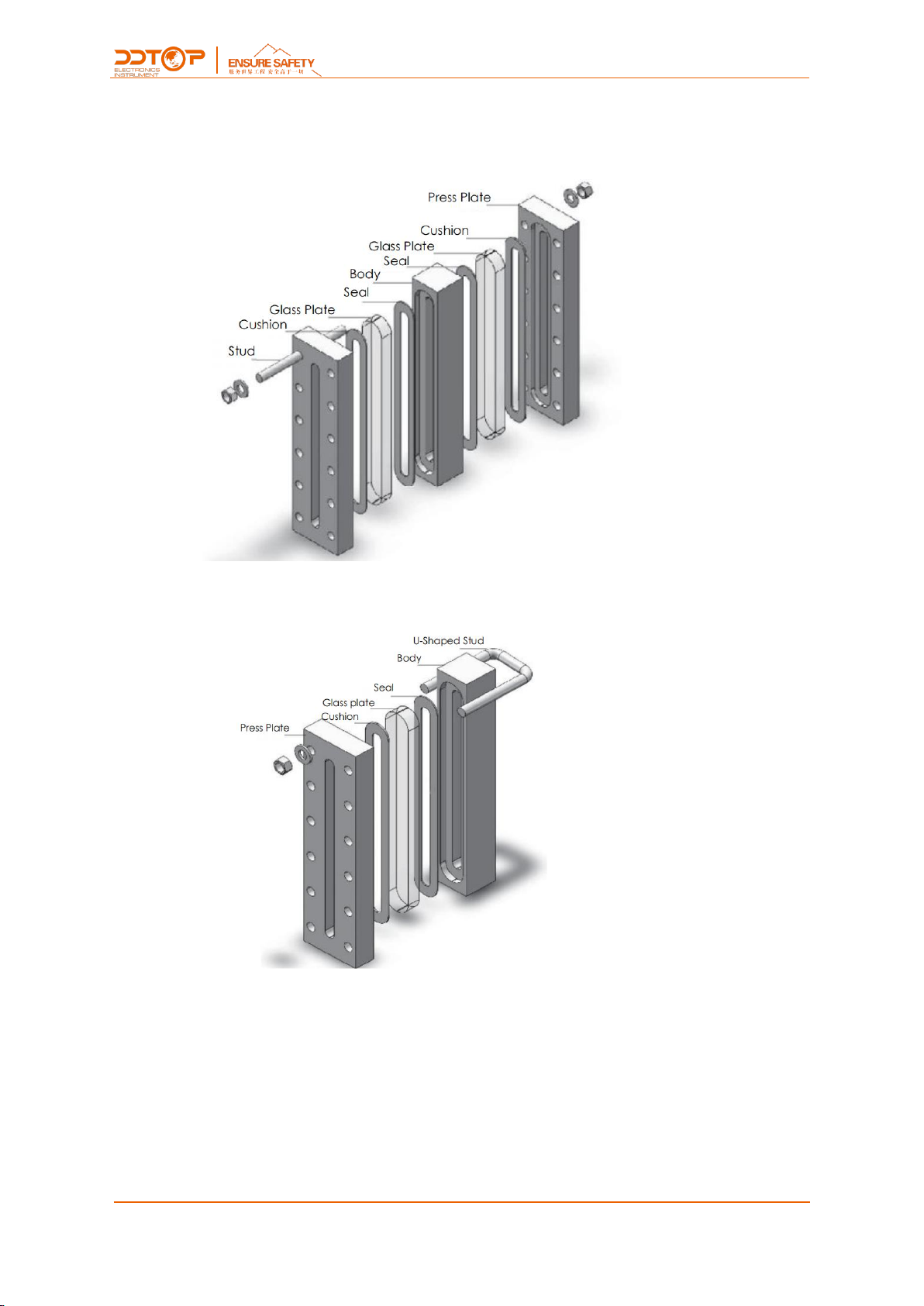

2.1 Main Structure ..............................................................................................................................................4

2.2 Operating Principle .....................................................................................................................................4

2.3 Packaging.......................................................................................................................................................5

2.4 Hoisting and Transporting........................................................................................................................5

2.5 Warehousing.................................................................................................................................................5

3 Technical Characteristics............................................................................................................................................. 5

3.1 Main Performance.......................................................................................................................................5

3.2 Main Parameters..........................................................................................................................................5

4 Dimensional Schematic............................................................................................................................................... 5

5 Unpacking and Inspection ......................................................................................................................................... 6

5.1 Unpacking Inspection Notice...................................................................................................................6

5.2 Check Content ..............................................................................................................................................7

6 Installation ....................................................................................................................................................................... 7

6.1 Installation Tool............................................................................................................................................7

6.2 Installation Technical Requirements......................................................................................................7

7 Debugging ...................................................................................................................................................................... 7

8 Fault Analysis and Elimination .................................................................................................................................. 8

9 Maintenance.................................................................................................................................................................... 8

9.1 Warning ..........................................................................................................................................................8

9.2 Disassembly ...................................................................................................................................................8

9.3 Cleaning..........................................................................................................................................................8

9.4 Assembly ........................................................................................................................................................9

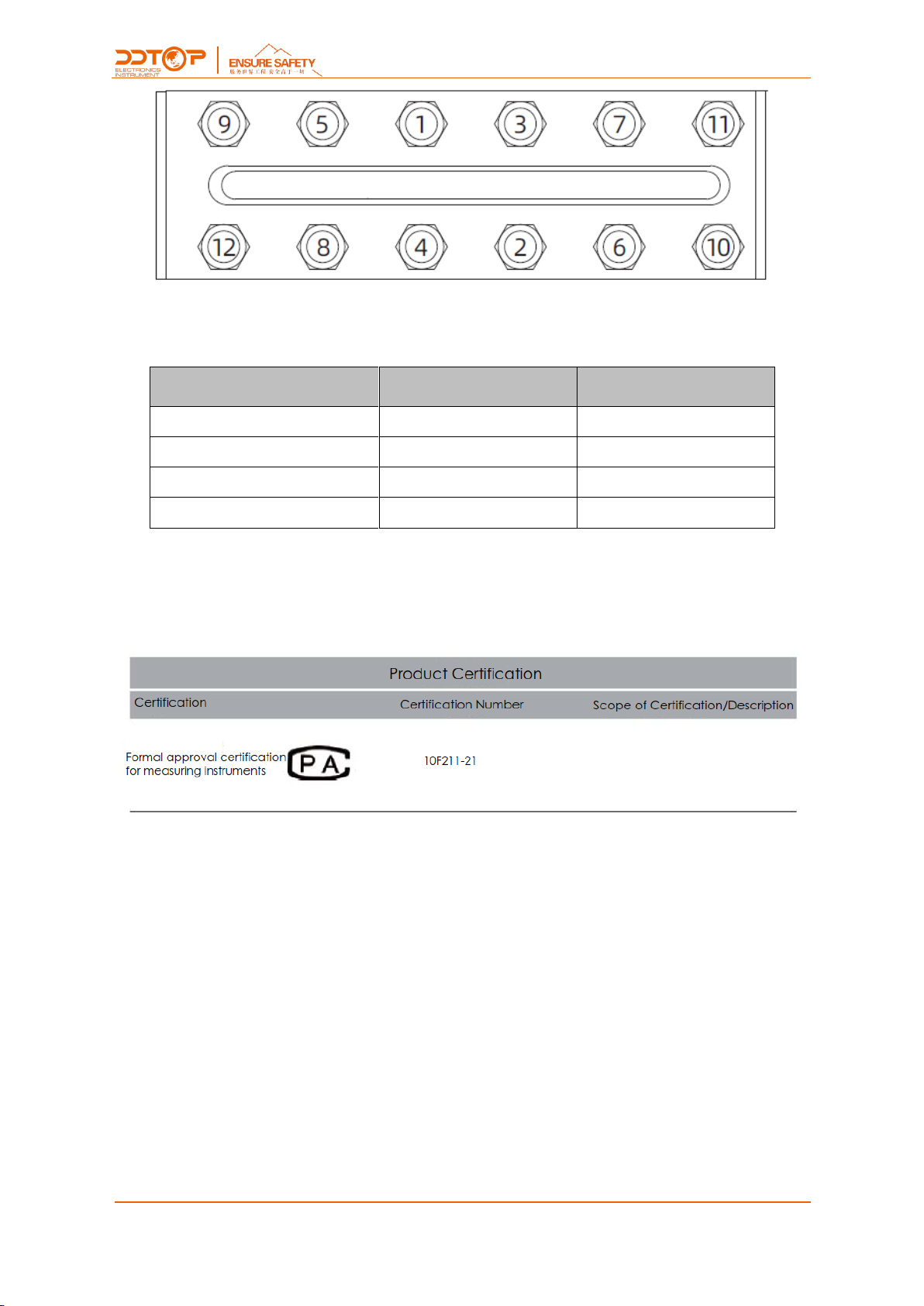

10 Product Certification................................................................................................................................................10