deconta smart + User guide

Original Instruction Manual

Personnel Lock System

smart +

Manufacturer: deconta GmbH

Im Geer 20, 46419 Isselburg, Germany

Designation :Personnell Lock System smart +

Instruction manual

Personnel Lock System smart +

Version 1 Page 2

Table of Contents

1.Basic Safety Advice...........................................................................................................3

2.Transport ............................................................................................................................4

2.1.Delivery............................................................................................................................................4

2.2.Transport .........................................................................................................................................4

2.3.Storage ............................................................................................................................................4

3.Delivery Contents...............................................................................................................4

4.Technical Description........................................................................................................5

4.1.Article description ............................................................................................................................5

4.2.Description of the Personnel Lock System......................................................................................5

5.Technical data....................................................................................................................6

6.Initial Operation / Assembly..............................................................................................7

6.1.Preperation......................................................................................................................................7

6.2.Assembly: ........................................................................................................................................7

6.3.Automatic shower option: ..............................................................................................................11

7.Maintenance and Care.....................................................................................................12

8.Declaration of Conformity...............................................................................................13

Instruction manual

Personnel Lock System smart +

Version 1 Page 3

The copyright of this instruction manual remains the property of deconta. This manual is intended for

assembly, operation and maintenance personnel. It contains instructions and drafts of technical nature

which may neither be distributed nor used in any unauthorised way for competitive purposes or passed on

to others.

1.Basic Safety Advice

The operation of the Personnel Lock System SMART-LINE must only be carried out by

trained competent personnel. The information and instructions contained within this

publication are of paramount importance to the user.

The manual should always be available in the immediate proximity whilst in use, and

accessible to all personnel.

deconta insists as the shower user you follow the information and instruction contained

within the handbook and only use it in accordance with the regulations and never use this

Personnel Lock System in an inappropriate way. In the event of non-observance,

deconta assumes no liability.

To ensure safe operation of the lock, the following must be strictly observed:

Do not use in potentially explosive atmospheres.

Maintenance work should only be carried out by authorised persons wearing

suitable protective clothing.

The safety and protective systems must be maintained and functioning correctly.

Safety instructions affixed to the unit must be maintained in a legible condition and

must be adhered to.

General, legal and other binding regulations and procedures for accident

prevention and handling of hazardous substances must be observed.

To ensure safety, modifications to the unit are not permitted.

We explicitly point out the additional regional and national safety measures and

regulations for the operation of the appliance technology.

In addition to the instruction manual, general, legal and other binding regulations on

accident prevention and environmental protection must be observed.

Instruction manual

Personnel Lock System smart +

Version 1 Page 4

2.Transport

2.1.Delivery

Unless agreed otherwise, the shower system is delivered from the deconta factory

packed completely and securely for transport.

Transport damage must be immediately documented following delivery by the supplier.

Please note any damages on the consignment note.

2.2.Transport

Care must be taken when transporting the unit, in order to avoid damage by improper

handling or carelessness.

2.3.Storage

The shower system shall only be stored in a decontaminated state.

To avoid damage, the device should only be stored in a clean dry inaccessible rooms

intended for unauthorised persons only.

3.Delivery Contents

Included in the delivery contents of a modular shower system unless other agreements

have been made:

• Personnel lock system (amount of chambers depending on version)

Transport rack

• Instruction manual

Instruction manual

Personnel Lock System smart +

Version 1 Page 5

4.Technical Description

4.1.Article description

Personal lock in a modular system for the separation between contaminated and clean

area.

Any number of chambers can be connected to each other without special components

and without tools. The floor and roof elements are braced via aluminium corner profiles to

achieve a high degree of stability. Floor and roof elements are framed with aluminium

profiles.

In the case of asbestos removal work within containment areas, it is expected that

airborne asbestos fibres will escape the containment area and pose a risk to human

health and environment.

For these reasons, containment areas are separated from the asbestos-free areas and

kept under dynamic negative pressure by means of negative pressure units

The personnel lock system smart + was developed and built in order to be able to enter

or leave these rooms. It enables the entering and exiting as well as the cleaning of

persons without endangering the environment.

4.2.Description of the Personnel Lock System

The following attributes distinguish the personnel lock system:

Doors with viewing window

Translucent roof element

Good insulating properties against heat and cold

GEKA water connection system

Bright, smooth surfaces enable easy cleaning

Self-closing air supply system in the doors

Doors with magnetic locks

Hand shower

Instruction manual

Personnel Lock System smart +

Version 1 Page 6

5.Technical data

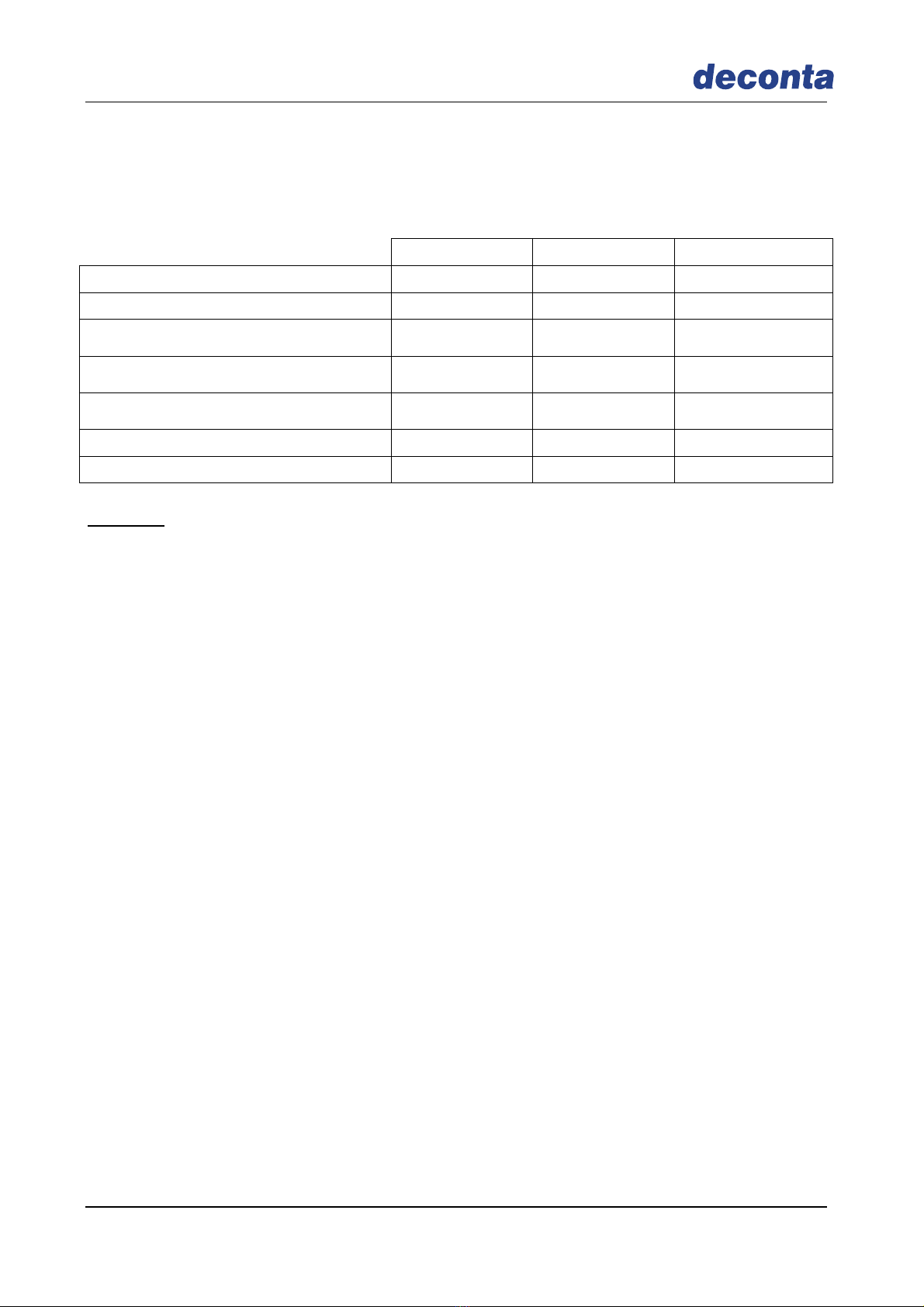

The personnel lock system smart + is available in 3 different sizes:

Model 750 Model 900 Model 1000

Inside dimensions per chamber (in mm) 729 x 729 x 2003 879 x 879 x 2003 979 x 979 x 2003

Outside dimensions per chamber (in mm) 750 x 750 x 2009 900 x 900 x 2009 1000 x 1000 x 2009

Weight 3-chambers (without transport

rack) appox. 130 kg appox. 156 kg approx. 170 kg

Weight 4-chambers (without transport

rack) appox. 169 kg approx. 203 kg approx. 229 kg

Weight 5 chambers (without transport

rack) appox. 210 kg approx. 253 kg approx. 285 kg

Weight transport rack 3-chambers appox. 44 kg approx. 46 kg approx. 70 kg

Weight transport rack 4/5-chambers appox. 85 kg approx. 87 kg approx. 89 kg

Options:

Automatic shower

Technical changes reserved

Instruction manual

Personnel Lock System smart +

Version 1 Page 7

6.Initial Operation / Assembly

6.1.Preperation

Before assembling the personnel lock system:

- Determine the exact location and floor plan

- the underground must be clean and even

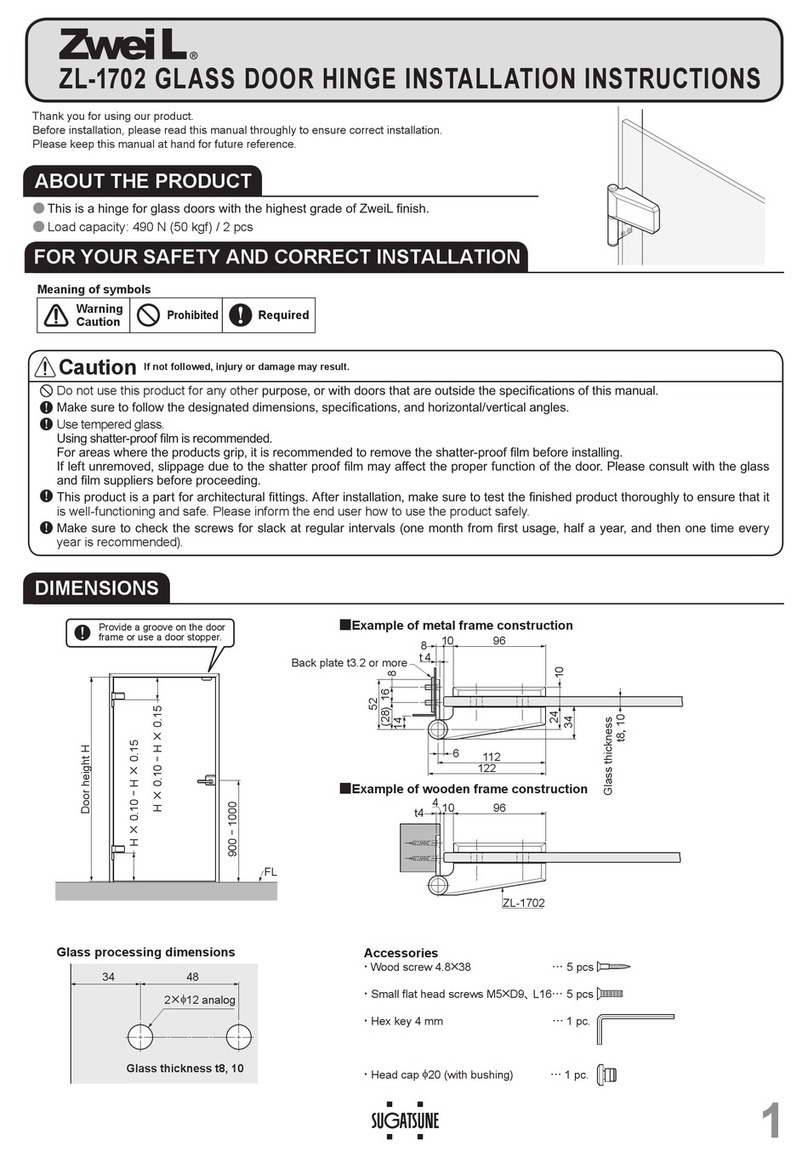

6.2.Assembly:

Place the floor elements flat in front of each other and insert the floor grids.

Note:

The sewage water connection of the shower chamber should have the shortest path to

the water management system in order to avoid unnecessary hose and cable lengths.

The mounting angles of the floor element must be cleaned before inserting the door and

side elements!

Insert the corner profile at the connecting corner of two floor elements into the receiving

angles and brace the quick-release fasteners to the ends of the corner profiles with the

floor elements.

Instruction manual

Personnel Lock System smart +

Version 1 Page 8

Insert a wall element into the mounting angles of the floor element and the corner profile.

The following pictures show the further construction:

Important:

To prevent the shower water from leaking, make absolutely sure that the door

elements to the shower are mounted in the receiving profile of the shower floor

element!

Instruction manual

Personnel Lock System smart +

Version 1 Page 9

Instruction manual

Personnel Lock System smart +

Version 1 Page 10

Instruction manual

Personnel Lock System smart +

Version 1 Page 11

6.3.Automatic shower option:

For the "automatic shower" option, please be sure to pay attention to the position of the

plugs on the roof (red circle) and the reed contacts on the doors (blue circle)!

Instruction manual

Personnel Lock System smart +

Version 1 Page 12

7.Maintenance and Care

Daily maintenance

Check the water pipes for free flow

Clean the personnel lock system area daily

Clean the personnel lock system carefully after each end of shift

Check the floor elements for free flow

Conventional household detergent can be used for cleaning and care.

Instruction manual

Personnel Lock System smart +

Version 1 Page 13

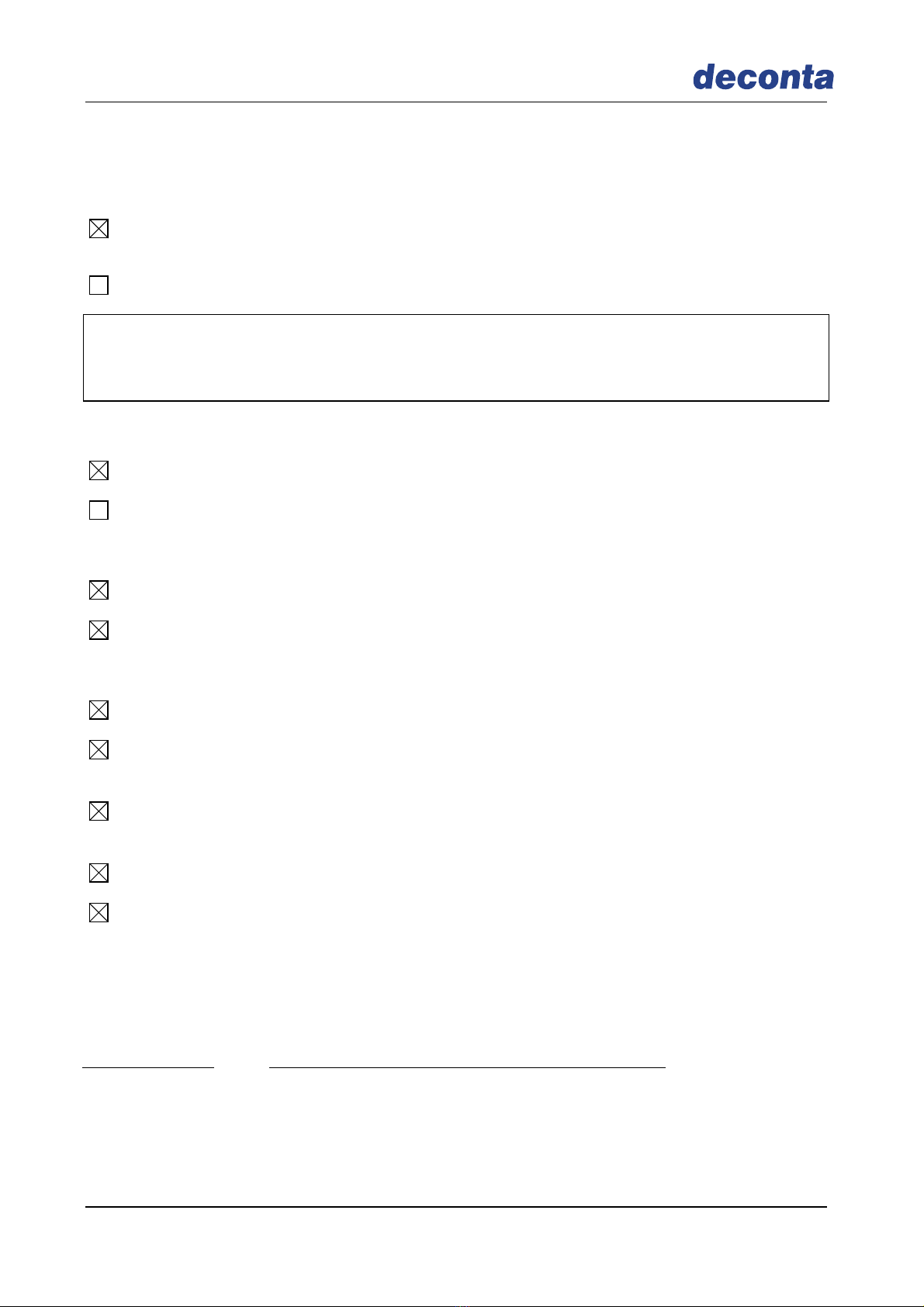

8.Declaration of Conformity

In accordance with the EC directives

Machines/plants (2006/42/EC)

Low voltage (2006/95/EC)

The type of the machine/plant:

Product / type designation: Personnel Lock System smart +

is designed, constructed and manufactured in accordance with the above marked directive(s).

Following harmonising standards apply:

DIN EN 292, safety of machines, devices and plants

DIN EN 60 204.1, electrical equipment for industrial machines

Following national norms, directives and specifications apply:

DIN 8586, bend forming

DIN 8588, fragmentation

Following national norms, directives and specifications apply:

Overall plan of the machine/plant with circuit diagram

Detailed and complete dossiers for the verification of the compliance of the machine/plant

with the essential health and safety requirements

A list of the fundamental requirements of EC directives, standards and specifications, which

were taken into account when designing the machine/plant

A description of the solutions for the prevention of threads from the machine/plant

A copy of the instruction manual of the machine/plant

Manufacturer/

Documentation Authorised

Representative:

Deconta GmbH

Im Geer 20

46419 Isselburg

30.04.2021 Christian Krolle

Date Managing Director Name

Table of contents

Popular Shower Cabin manuals by other brands

Sterling

Sterling Neo-Angle Shower Door SP1900A Homeowner's guide

Luxury Spas

Luxury Spas AX-613 instruction manual

ERLIT

ERLIT Elegance ER 5508TP Installation and operation instruction

Radaway

Radaway Essenza New PTJ Assembling Instruction

Radaway

Radaway Almatea PDJ Assembly instruction

AM.PM

AM.PM BLISS ROUND 120 manual