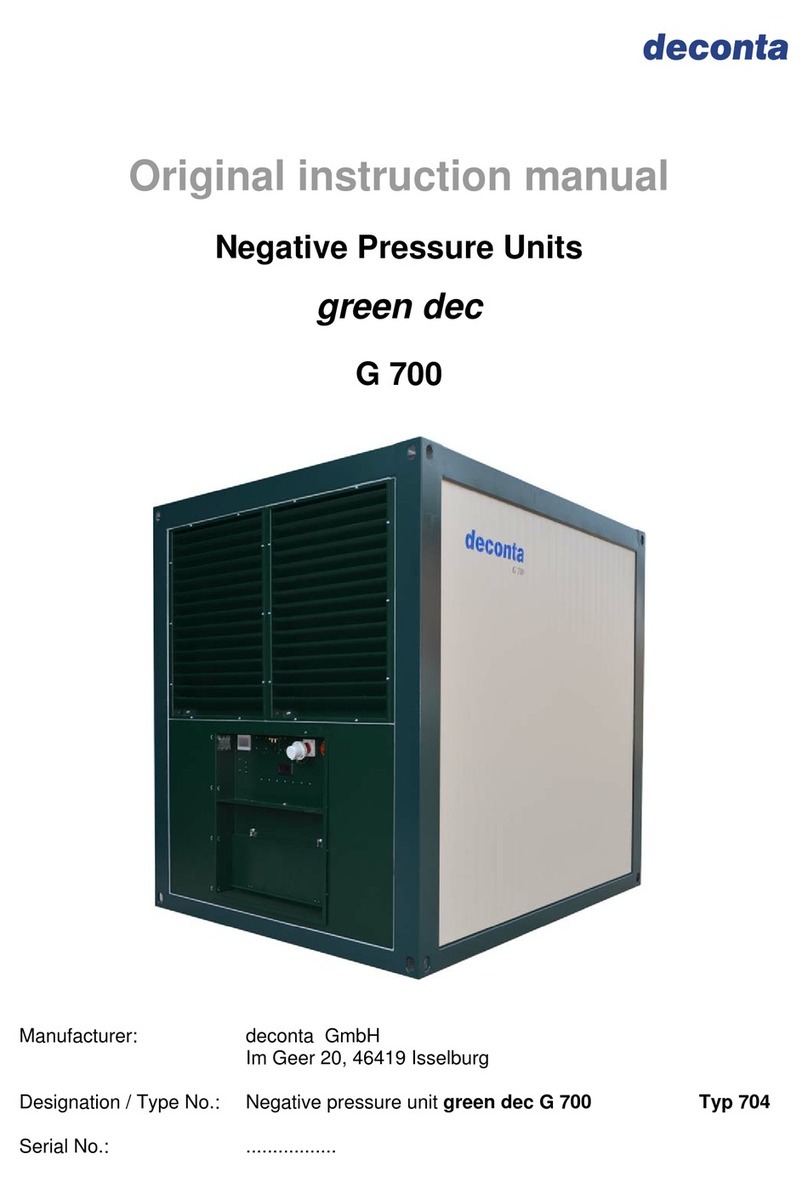

Instruction Manual

Negative Pressure Unit green dec

Version 1 Page 2

Table of contents

1.Basic safety advice............................................................................................................4

1.1.Intended use....................................................................................................................................5

1.2.Dangers ...........................................................................................................................................6

2.Transport and storage.......................................................................................................7

2.1.Delivery............................................................................................................................................7

2.2.Transport..........................................................................................................................................7

2.3.Storage ............................................................................................................................................7

3.Delivery contents ...............................................................................................................8

4.Technical data....................................................................................................................9

4.1.Performance data G 50 / G 55 ........................................................................................................9

4.2.Performance data G 100 .................................................................................................................9

4.3.Performance data G 200 ...............................................................................................................10

4.4.Performance data G 300 ...............................................................................................................10

4.5.Performance data G 400 ...............................................................................................................11

4.6.Performance data G 500 ...............................................................................................................11

4.7.Connections, dimensions, weights ................................................................................................12

4.8.Filter description / classification.....................................................................................................13

5.Technical description ......................................................................................................15

5.1.Unit description..............................................................................................................................15

5.2.Control SE......................................................................................................................................16

5.3.Control SRE +................................................................................................................................16

5.4.Control SRE connect.....................................................................................................................17

6.Assembly instruction.......................................................................................................18

7.Initial operation ................................................................................................................19

7.1.Control SE......................................................................................................................................19

7.1.1.Room pressurisation..............................................................................................................19

7.2.Control SRE +................................................................................................................................20

7.2.1.Set display language .............................................................................................................21

7.2.2.Language table......................................................................................................................22

7.2.3.Manual mode.........................................................................................................................25

7.2.4.Automatic operation negative pressure.................................................................................26

7.2.5.Automatic operation volume flow...........................................................................................28

7.2.6.Changing operation mode .....................................................................................................30

7.2.7.Stand-by mode ......................................................................................................................31

7.2.8.Filter sensor...........................................................................................................................33

7.2.9.Additional settings..................................................................................................................34

7.2.10.Warnings and indications.......................................................................................................35

7.3.Control SRE connect.....................................................................................................................36

7.3.1.Create your user account ......................................................................................................37

7.3.2.Add the device to your user account.....................................................................................38

7.3.3.Manual mode.........................................................................................................................41

7.3.4.Automatic mode.....................................................................................................................42

7.3.5.Day / Night setting .................................................................................................................43

7.3.6.Stand-by mode ......................................................................................................................43

7.3.7.Consumption..........................................................................................................................44

7.3.8.Dust sensor............................................................................................................................44