Dectron Dry-O-Tron NG Series User manual

DRY COOLERS

NG SERIES

Dectron.com

OPERATION AND MAINTENANCE MANUAL

Table of Contents

General Information .....................................................................................................................................2

Document Scope........................................................................................................................................................ 2

Operating Safety (Warnings, Cautions, and Notes)................................................................................................... 2

Basic Information....................................................................................................................................................... 4

Operation and Control............................................................................................................................................... 7

Layout and Components...............................................................................................................................9

Basic Maintenance ......................................................................................................................................13

Maintenance and Safety.......................................................................................................................................... 13

Maintenance Key Points .......................................................................................................................................... 14

Airside Coil(s) Cleaning. ........................................................................................................................................... 14

Dry Cooler Service.................................................................................................................................................... 15

Warranty......................................................................................................................................................15

Dectron Dry Cooler OMM 2September 2020

General Information

Document Scope

This manual provides operation and maintenance information about the Dry Cooler and its operation.

Additional information regarding installation, maintenance, and equipment commissioning and auxiliary devices is

provided with the system and can also be obtained from the manufacturer.

Contact Us

Dectron

5685 Rue Cypihot

Saint Laurent QC, H4S1R3

Canada

Dectron.com

1-833-DAS-POOL (327-7665)

Schedule / Modify a Start-up:

Start[email protected]

Inquire about Warranty:

Warranty@DehumidifiedAirServices.com

Order Parts:

All Other Product Support:

Support@DehumidifiedAirServices.com

Operating Safety (Warnings, Cautions, and Notes)

FOR YOUR SAFETY: READ BEFORE PERFORMING ANY OPERATIONS, MAINTENANCE OR SERVICE TASKS!

Only qualified technicians should install, operate, maintain or service mechanical equipment

including current dehumidification system.

Read this manual before performing any tasks to familiarize yourself with the equipment as well

as with any potential hazards. Always exercise caution!

Beware of electrical power and high electrical voltage!

•Follow proper safety procedures – lockout, tagout, and other respective procedures

•Failure to follow safety procedures can result in serious injury or death

Beware of moving parts and hot surfaces!

•Make sure to stop all moving parts (fans, blowers, etc.) before accessing the equipment’s

internal compartments

•Be aware of hot surfaces (hot refrigeration, space heating pipes, coils, heaters, etc.)

Beware of pressures and chemicals!

•Operating equipment may contain glycol-based cooling media mixture under pressure!

September 2020 3Dectron Dry Cooler OMM

The following warnings, cautions, and notes appear throughout this manual and referenced documentation

whenever special care must be taken to avoid potential hazards that could result in equipment malfunction or

damage, personal injury, or death.

WARNING

Indicates a potentially hazardous

situation that could result in

serious injury or death if handled

improperly.

CAUTION

Indicates a potentially hazardous

situation that could result in

moderate injury or equipment

damage if handled improperly.

Note

Indicates a situation that could

result in equipment damage or

improper/ineffective operation if

handled improperly.

Attention: Installation and Service Contractors

WARNING! Any work (installation, start up, service, maintenance, repair, etc.) on any mechanical

equipment (HVAC system, dry cooler, etc.) must be performed in accordance with manufacturer’s

recommendations as well as submittal documentation, local Codes and Regulations, and appropriate field

practices. Failure to do so could result in personal injury, equipment damage or malfunction, and will void

equipment warranty. Only qualified and properly trained individuals should perform tasks on this equipment.

Attention: Maintenance Team

CAUTION. To ensure equipment longevity and proper and efficient operation, this mechanical equipment

should be maintained properly and regularly. Failure to do so could negatively affect system performance. It

could also lead to equipment damage, malfunction, premature wear and tear and may void equipment warranty.

Dectron Dry Cooler OMM 4September 2020

Basic Information

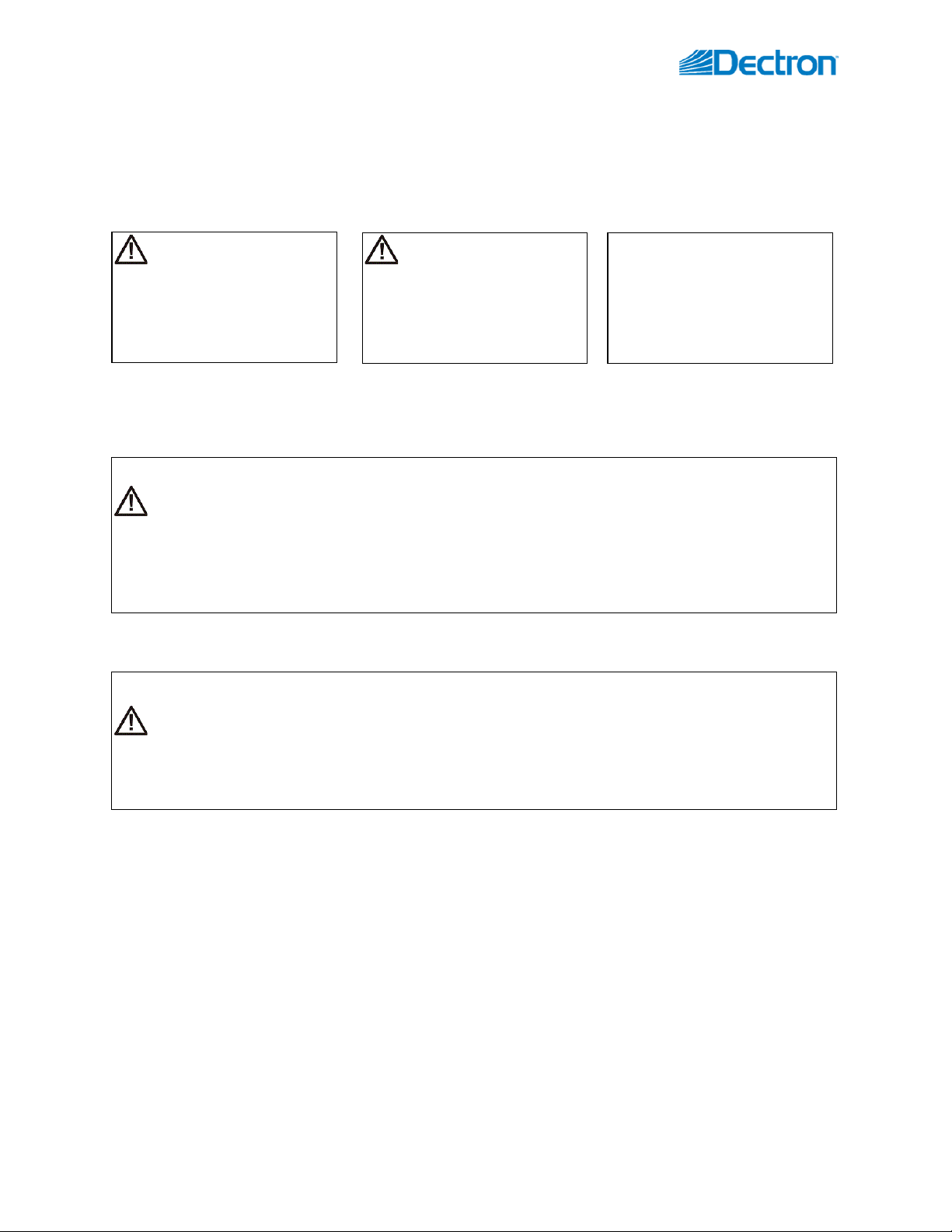

View and Options

The views of standard NG series dry coolers are shown on

Pic.C.1. and C.2 below.

Dry cooler Options

•Capacity. NG series dry coolers range broadly in their

capacities, which depends on factors including physical

size, fluid flow rate, glycol concentration and ambient

conditions. See submittal for specific capacity of your

equipment.

•Coils and Fans - single and multi fan and coil combo.

oPic. C.1 shows single fan dry coolers: NG-Z, NG-

V-01 and -02 are “single fan – single coil” type,

NG-V-11 is “single fan – two coil” cooler.

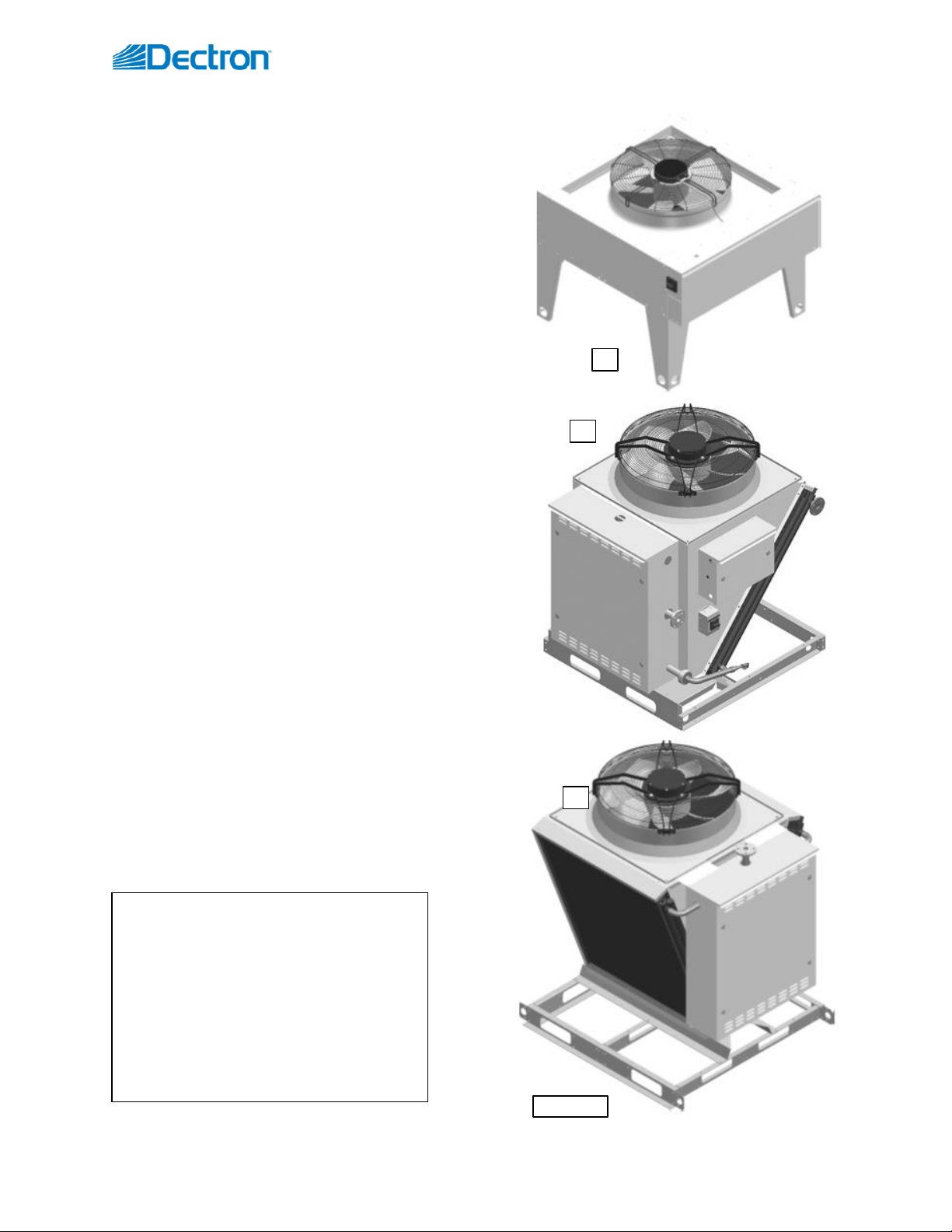

oExcept for NG-V-31 (Pic.C.2 - a), all the multi-fan

coolers (see Pic.C.2) are comprised of number

(up to six) of NG-V-12 (Pic.C.2 –b) coolers

(mounted on the same frame, piped, wired and

operating as one single unit).

oCooler capacity and number of fans are

reflected in its type/nomenclature: Pic. C.2-c

shows NG-V-62 cooler, comprised of six “two

fans –two coils” NG-V-12 sections.

•Fan type. NG series dry coolers have EC motor fans,

varying speed via 0-10vdc signal. Legacy models pre-

2020 may have been equipped with two-speed fans. See

submittal and wiring diagram.

Cooling media. Typically, water-glycol (rust inhibitor-infused

food-grade propylene glycol is used) mixture is used as

cooling media, with recommended concentration of 35% to

prevent pipe bursting. However higher or lower

concentrations could be used. Refer to dry cooler main label

for details on glycol type, ratio etc.

Pic. C.1

a

b

c

Attention: Glycol Concentration

NOTE. Equipment capacity is typically rated for

35% prop. glycol concentration in water mixture,

however dry coolers may be sold for different

specified concentrations. Be careful when

changing glycol concentration in the field as the

pump may become improperly sized as a result

of different required fluid flow rate. Contact the

factory for more information.

September 2020 5Dectron Dry Cooler OMM

•

•

•Optional Installed

Disconnect.

•Other equipment

integration. Cooler

could be directly

integrated/attached

into system/equipment

it serves (mounted on

the same frame and

piped and wired at the

factory). Alternatively,

it could be provided as

stand-alone piece of

equipment, that has to

be installed and

connected to the

equipment/system it

serves on site.

•Control (for more

details –see Basic

Operation Chapter):

oControls by

others.

oStand-alone

(self-

controlled):

cooler is

equipped with

aquastat to

control based

off fluid

temperature.

•Dehumidifier-

Controlled. Dry coolers

can be controlled by up to three Dehumidified Air Solutions dehumidifiers.

•Pump package (optional). As needed, dry

cooler could be equipped with pump package

–to establish cooling media flow (or to serve

as additional/booster pump).

oFor multi-fans coolers: If pump

package is required, each “two-fan”

section, normally, would get its own

package (Pic. C.2-c shows NG-V-62

type cooler, equipped with six pump

packages –one per section).

•Discharge Airflow –Dry cooler Installation.

All dry coolers are designed for vertical air

discharge (horizontally mounted cooler).

Pic. C.2

a

b

c

Dectron Dry Cooler OMM 6September 2020

External Systems Connection

Normally, the only systems need to be connected to the dry cooler are cooling media piping and electrical power

(control wiring connection is required also, unless dry cooler is self-controlled).

Cooling Media Piping Connection. Normally dry cooler is provided with two piping connections (one –inlet,

another –outlet) for cooling media. Connections are normally identified/labeled in respect to cooling media flow

direction (hot/warm media entering the dry cooler –IN, cool media leaving the dry cooler –OUT).

•If dry cooler is provided with pump package option, cooler connections might be located within pump package

–refer to specific dry cooler labels and submittal documentation (drawings etc.).

Electric Power and Control Connection. Electric power is normally brought to the dry cooler disconnect (if cooler is

equipped with one) or to power distribution block, located in cooler’s electrical box. Control wiring is normally

brought to the control terminals within electrical box.

•Dry coolers, equipped with multiple electrical boxes, normally required power and control connection only to

one box (indicated as”main”) – power and control wiring between boxes is normally done at the factory.

•Self-controlled dry coolers normally do not require external controls connected.

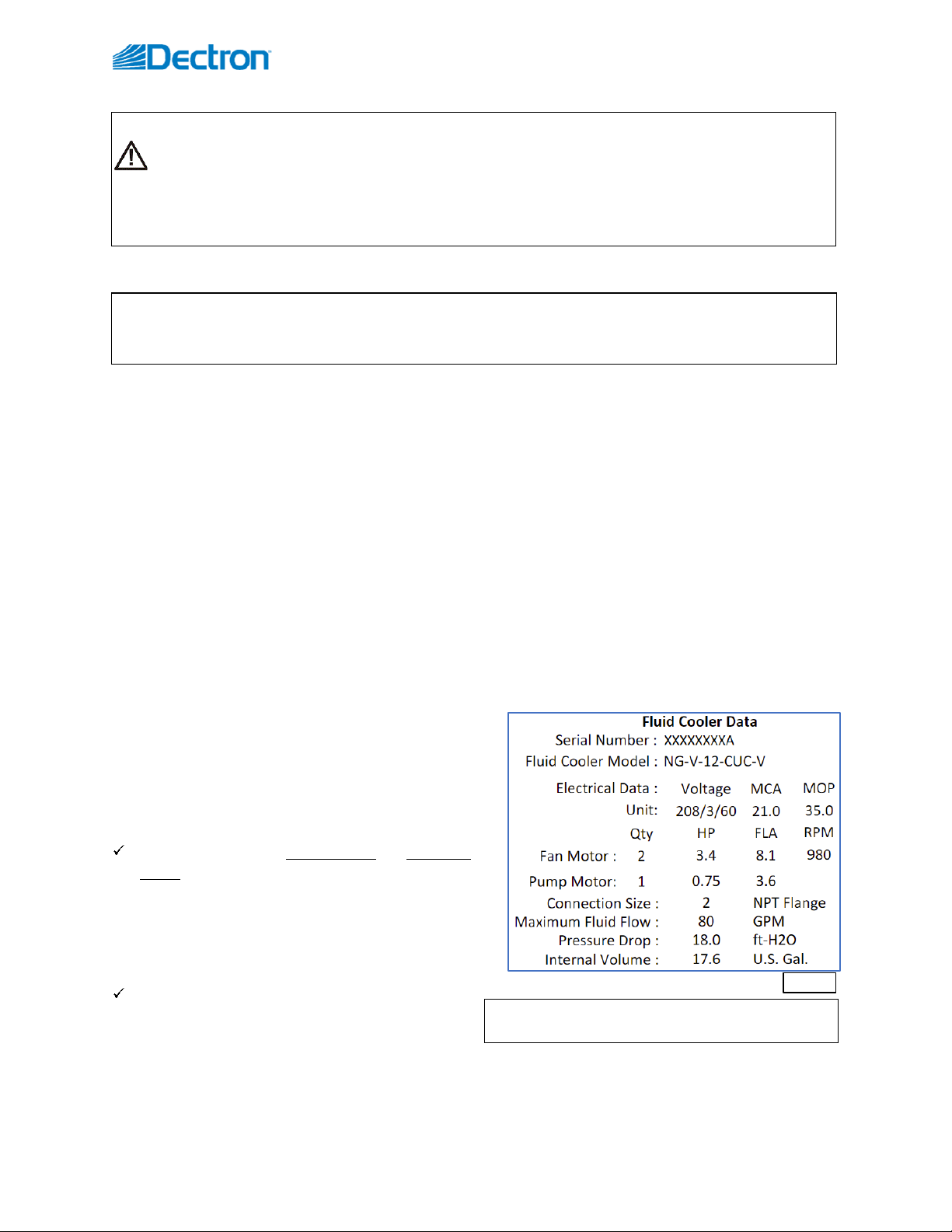

Equipment Specific Data

Specific information for individual dry cooler is provided in

the following methods:

Main Label (Pic. C.3):the manufacturer tag attached to the

dry cooler, that includes its most critical data:

General data including Serial Number and Dry cooler

Model (nomenclature)

oSerial Number is usually composed of 8 digits.

Additional letter “A”, placed at the end of

serial number, usually indicates that given dry

cooler is provided together with another

equipment it serves (dehumidifier etc.).

Operational data:

oElectrical (voltage, amp draw, HP etc.)

oCooling media (GPM, connection size etc.)

Note: The main label shown above is just an example.

CAUTION! Current manual refers to/depicts general/default external systems connection location. For details

regarding specific dry cooler’s connections (location/elevation, piping sizes, flow direction, wiring terminals etc.),

refer to the submittal documentation as well as dry cooler diagrams, labels and stickers.

Attention! Equipment Clearances!

CAUTION! Proper clearances should be maintained for adequate airflow and heat rejection, as well as for

maintenance and service of the equipment! Generally, up to 36” sides (all around) and 96” top clearances are

required. For more information on clearances as well as equipment dimensions and other details, refer to the

submittal documentation.

Pic. C.3

September 2020 7Dectron Dry Cooler OMM

Labels and Stickers: attached normally to indicate dry cooler external systems connections (piping, electrical etc.),

terminals designation, to display warning etc.

Wiring Diagrams:typically, attached to the interior side of the dry cooler main electrical panel, depicting control

and power wiring.

Operation and Control

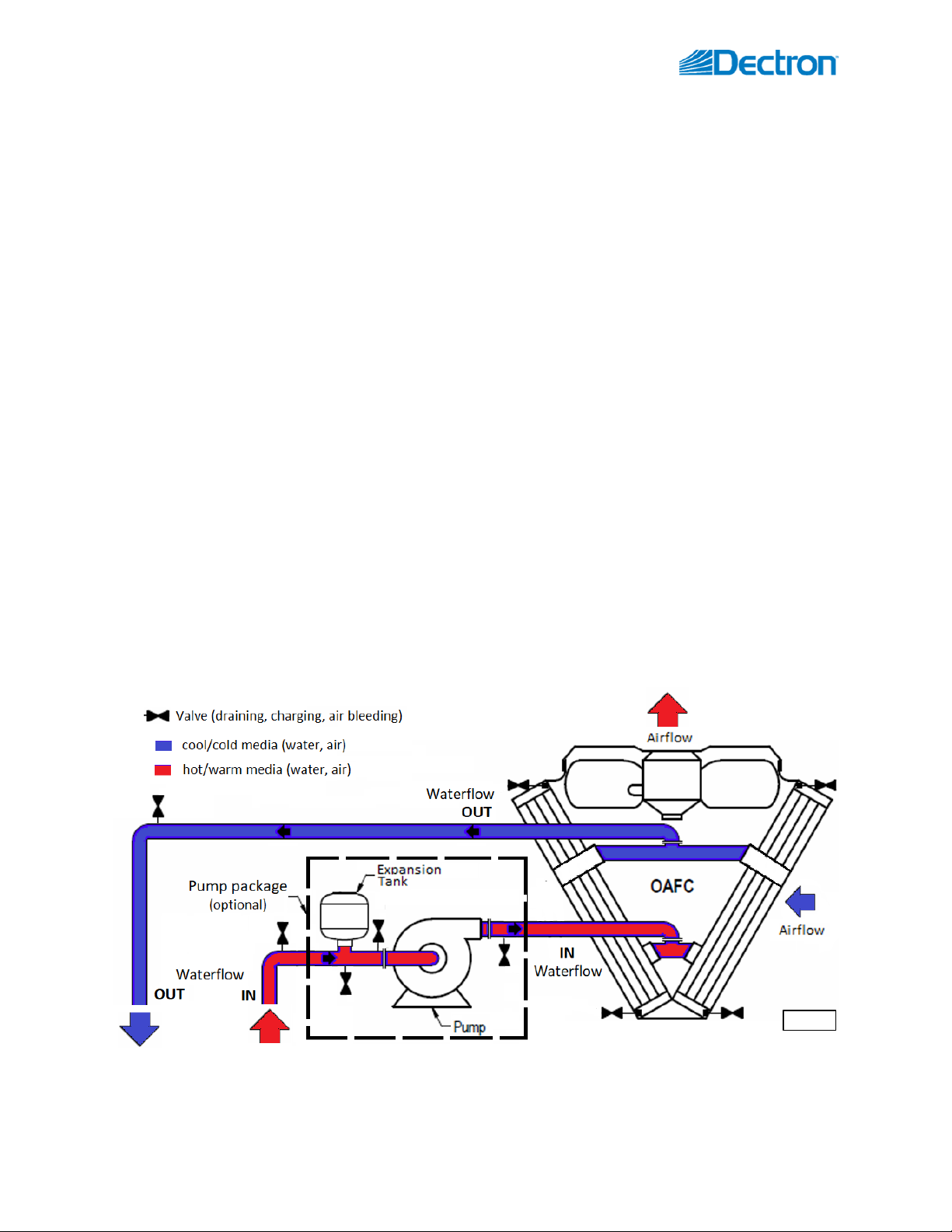

Dry cooler rejects the heat, absorbed by the cooling media (water etc.) from the external system(s) that dry cooler

serves, to the outdoor air.

Operation and Media Flow

Dry cooler operation is quite simple:

•Upon the command (when heat rejection is needed) dry cooler engages its fan(s) to establish the airflow

across the coil(s).

oDepending on the type of fans (modulating EC-type or two-speed), control type and command

received, cooler total airflow is adjusted by varying fan(s) speed and/or number of operating fans.

•Cooling media flow must be established also –either by separately controlled pump (part of the external

system) or by the built-in pump package pump. In latter case, pump would engage with the fan(s) and will stay

engaged while the command exists (while at least one fan is running).

•Until call for heat rejection is satisfied and command to dry cooler is removed, fan(s) and pump will run; once

command removed, all fans and the pump will stop.

Pic. C.4 below shows schematic layout of dry cooler operation and media (air and water/glycol) flow.

For more details on dry cooler piping connection refer to Installation Manual, submittal documentation etc. as well

as local Codes and proper field practices.

Pic. C.4

Dectron Dry Cooler OMM 8September 2020

Control

There may be some different types of controls used with NG series dry coolers.

Fan type:

•Modulating (EC-type) fans are capable of varying their speed (from 0 to 100%) based on 0-10VDC signal. These

fans are standard on NG series dry coolers built since 2020 and may be found on some built prior.

•Two-speed fans are capable of running in two alternative speed (low or high); normally done by switching

between “star” and “delta” motor wiring (fans are pre-wired from the factory to switch from one to another,

based on respective contactor –low or high speed –being engaged). These fans typically are used on legacy

mid- to large size multi-fans dry coolers.

oStaging. Standard (and the most simplistic) staging uses just two stages –low speed and high speed –

where all fans are running together (in low or high speed, as commanded).

Control Type (all control types referenced below are applicable to all fans type described above):

•Externally controlled Dry cooler. Fan(s) speed signal (modulating or stage switch-over) is provided from

external system (usually –the one that dry cooler serves, to satisfy said system operational requirement). This

is typical for dry cooler serving single systems. Typical signal type for this control type are modulating (0-

10VDC) or two-speed switch-over (however, other arrangements are available). It may control the fan

according to head pressure or another control method chosen by installer.

•Self-controlled (“stand-alone”) Dry cooler. Fan(s) speed signal (modulating or stage switch-over) is based on

built-in control device. Most commonly used one is an aquastate, monitoring temperature of the cooling

media (water/glycol mixture), leaving the dry cooler.

oTypically, aquastat is pre-set to maintain entering cooling media temperature at certain level: the

sensor issues the signal to start the fan(s) and increase their speed as temperature increases (and,

respectively, reduce fans’ speed when temperature reduces). Typically, this signal is 0-10vdc –it

could be accepted by EC-type fans directly or translated into staging signal with additional device (this

allows to set more than two stages to finetune dry cooler operation).

Dry cooler is normally provided with the wiring diagram, depicting its specific control schematic –refer to it as

needed.

September 2020 9Dectron Dry Cooler OMM

Layout and Components

General layout of the various NG-series dry coolers is shown on Pic.D.1 below. While layout and main components

are similar for all applicable dry coolers, there are some deviations (number of fans and coils, composition, etc.).

Refer to Views and Options (Basic Information chapter) for additional information:

Dry cooler Main Components

36

35

33

37

31

33

31

Dectron Dry Cooler OMM 10 September 2020

32

September 2020 11 Dectron Dry Cooler OMM

Fig. 1, 2 and 4 show NG-V type dry coolers (two, six and single-fan models, respectively), while Fig. 3

shows NG-Z type dry cooler.

Examples show all/most available options (like pump package etc.); some of shown options may not be

present on your dry cooler –refer to submittal documentation as needed.

•Cooling airside coil(s) (31) (where heat from glycol mixture is rejected to the ambient air) is mounted onto

metal frame, upstream (before) the fan(s) (32), that pulls the air through the coils to absorb the heat.

oDepending on the equipment type and required capacity, dry cooler may have one or multiple coils

and fans –refer to Views and Options (Basic Information chapter).

•Dry cooler piping connections (33) are identified in respect to cooling media flow direction (hot/warm media

entering the dry cooler –IN, cool media leaving the dry cooler –OUT);

oIn some cases, dry cooler piping connection(s) may be located within pump package box (37), if dry

cooler is provided with one.

oPiping connection location may vary –refer to particular cooler labels, stickers, submittal and other

documentation.

oDry cooler manifold/connection, normally, is not equipped with isolating valves, filters etc. (this also

applies to pump package, if dry cooler is equipped with such option; see pump package layout

below).

•For NG-Z type (Fig. 3) ONLY! Said dry cooler ships with set of legs (34) to provide sufficient space between

horizontal mounting surface and airflow intake. On-site assembly is required for these legs. For more details

on the installation refer to the Installation Manual.

•Electric power is normally to be brought to disconnect (35) (if cooler is equipped with such), which feeds it to

the electrical box (36), that contains dry cooler power and control apparatuses.

oDepending on dry cooler specifics, location of electrical box may slightly differ; in some cases,

electrical box may be incorporated into pump package or located on the opposite side of the dry

cooler.

Pic. D.1

32

36

35

33

34

37

31

31

Dectron Dry Cooler OMM 12 September 2020

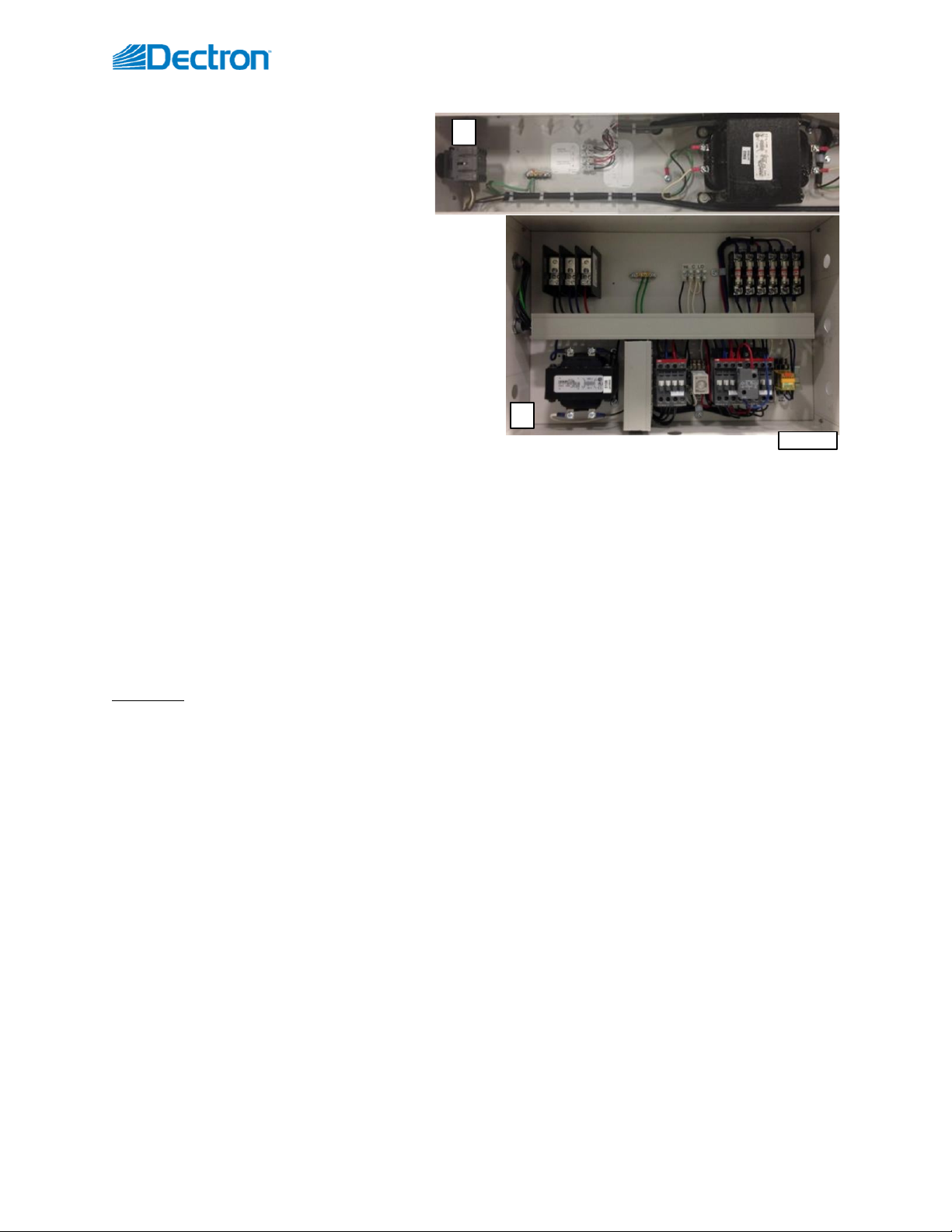

Electrical Box –Power and Control

Dry cooler power and control wiring and

apparatuses (transformer, contactor(s), fuses,

wiring terminals etc., as applicable) are located

in the electrical box, shown on Pic. D.2: typical box of dry

cooler type NG-Z (a) and type NG-V (b):

•In some cases dry cooler electrical box could be

incorporated within pump package.

•NG-V type dry cooler with multiple fans would have

multiple boxes (typically –one box per one pair of

fans).

oMultiple electrical boxes on one dry cooler are

normally connected to each other at the

factory, so external power and control wiring

has to be brought only to one (main) electrical box.

•Depending on the specifics of the dry cooler (size, type of fans, control method etc.), electrical box layout and

components may vary –refer to your dry cooler submittal, wiring diagram and other documentation.

Pump Package

If equipped with such option, dry cooler would have a pump package box. Pic.D.3 below shows general layout of

pump packages, used for NG-V model dry coolers. Note, that the package could be mounted onto the dry cooler

directly (standard) or provided separately.

Dry coolers Pump Package

Dry coolers, if equipped with such option, would have a pump package box. Pic.D.6 below shows general layout of

pump packages, used for NG series: NG-Z (a) and NG-V (b) type, respectively. Note that the package used with NG-

V coolers is normally mounted onto the cooler directly, however, it also could be provided separately.

•Pump (38) establishes glycol mixture circulation through the dry cooler and dehumidifier;

•Expansion tank (39) compensates for temperature-based glycol/cooling fluid volume fluctuation;

•The pump package electrical sub-panel (40) contains the pump package electrical power and control

apparatuses.

oIn some cases, pump package electrical sub-panel may contain power and control apparatuses for the

entire dry cooler (fan(s) and pump package).

•The pump package manifolds are usually equipped with pressure gauges, automatic air venting and manual

draining/charging valves.

Pic. D.2

b

a

September 2020 13 Dectron Dry Cooler OMM

Basic Maintenance

Although dry cooler is built for minimal service downtime, periodic preventative maintenance is required to

ensure maximum reliability, safety, and operating efficiency.

Maintenance and Safety

Only qualified/properly trained personnel should attempt to perform respective maintenance tasks.

•Live Electric Power! When necessary, have a licensed electrician or other qualified professional to perform the

required task.

•Turn the power off. Before performing any maintenance, disconnect all electrical power, including remote

disconnect, and discharge all energy storing devices (capacitors, VFDs, etc.) before servicing. Follow proper

lockout procedures to ensure that power cannot be accidentally restored. Failure to follow provided safety

warnings and labels could result in serious injury or death.

40

38

39

38

40

39

Pic. D.3

a

b

WARNING! To ensure equipment longevity and proper and efficient operation, it must be maintained

properly. It is recommended to create a facility-specific Routine Maintenance Program.

Failure to perform necessary maintenance task(s) properly and regularly could result in personal injury,

equipment damage or malfunction and will void the equipment warranty.

Dectron Dry Cooler OMM 14 September 2020

•Be properly trained and equipped. Some maintenance tasks may involve usage of power tools, chemicals, etc.

Refer to such tools and materials data (manuals, MSDS, etc.). Personnel performing such maintenance tasks

should be:

oProperly trained to handle such tools and materials safely

oEquipped with proper personal protective equipment

•Be aware of potential hazards. The equipment contains moving mechanical parts, components with water-

glycol mixture under the pressure (refer to the equipment main label for the details as eeded) and some

hot/warm surfaces. Before performing any equipment maintenance work, make sure that all moving parts are

stopped, and it is safe to perform required task.

Maintenance Key Points

Dry cooler is rather low-maintenance equipment, yet there are some basic/key maintenance considerations:

•Ensure that the equipment is accessible (minimum clearances are maintained): approaches are not

restricted/limited (with materials, other equipment, manifolds, snow etc.).

•Maintain clean airside coils surfaces: make sure to clean coils from cobweb, dust, leaves etc. regularly.

Routine Maintenance Program

Creating facility-specific routine maintenance program and following it is vital to equipment longevity and efficient

operation.

Detailed maintenance recommendations for specific components, as/if needed, could be sourced from respective

component manufacturer or other documentation.

The suggested general maintenance tasks and their frequency/intervals, listed below, can be used to create

mentioned maintenance program (be aware that list below is a suggestion only - frequency and tasks may vary per

installation, based on various factors like ambient environment cleanliness, type of equipment etc.):

Monthly –Quartely

Observe equipment general operation (for unusual vibration, noise etc.)

Verify control settings (applicable to “self-controlled” equipment)

Inspect the airside coils for dirt, cobweb build-up, etc.; clean as needed

Semi-Annually –

Annually

Check electrical connections (both, power and control), tighten as needed

Check the frame and fasteners for being structurally sound (loose fasteners,

corroded/deteriorating components etc.)

Check glycol/water mixture ratio/percentage, adjust as needed.

Specific Components Maintenance and Special Tasks.

Airside Coil(s) Cleaning.

•Warning: Hazardous chemicals! Cleaning agents can be highly acidic or alkaline. Handle all chemicals carefully

and use appropriate personal protective equipment (PPE). Refer to the cleaning agent manufacturer's Materials

Safety Data Sheet (MSDS) for safety and handling information. Failure to follow all safety instructions could

result in serious injury or death.

To clean the coil:

•Disconnect all electrical power to the equipment

•Use a soft brush to remove loose debris from the coil

•Mix a high-quality coil cleaning detergent with water according to the manufacturer's instructions

September 2020 15 Dectron Dry Cooler OMM

•Clean coil according to suggested instructions

•Thoroughly rinse both sides of the coil and the drain pan with, clean water

•Straighten any coil fins that have been bent during the cleaning process

•Replace all panels and parts and restore electrical power to the equipment

Dry Cooler Service.

Normally dry coolers are filled with glycol mixture to prevent the system and the dry cooler from freezing and

potentially rupturing pipes when exposed to temperatures below freezing point.

When dry cooler is used with media that, when exposed to low temperatures, could freeze (pure water or very

low-percentage glycol mixture), one way to protect the equipment is to drain it (also known as “winterization” of

the equipment).

Though dry cooler itself is normally equipped with means to be drained properly/fully, it is recommended to have

same means in place for entire system/equipment dry cooler serves:

•Have each local high point of the system equipped with means to bleed the air (air bleeding valve etc.)

•Have each local low point of the system equipped with means to drain the fluid.

Warranty

General Policy

All Dectron service and warranty work is managed exclusively by Dehumidified Air Services (DASV). All warranties

apply to the original equipment owner and are not transferable. All warranty inquiries should be made to

Dehumidified Air Services.

Dehumidified Air Services:

Phone: 1-833-327-7665 Email: Warranty@DehumidifiedAirServices.com

Dectron warrants as set forth and for the time periods shown below that it will provide through either a DASV

Service Technician or an authorized service organization specified and approved by DASV, a new or rebuilt part to

replace a factory installed part which has failed because of defect in workmanship or material.

NOTE: EVERY REQUEST RELATED TO WARRANTY OF ANY NATURE AS DESCRIBED BELOW MUST BE OFFICIALLY

AUTHORIZED AND DOCUMENTED IN ADVANCE BY DASV TO QUALIFY FOR WARRANTY COVERAGE.

Warranty Void Unless Registered

All Warranties are void unless the start-up of the equipment is approved by a DASV service technician. Upon

completion of the start-up, a “Warranty Registration Certificate” will be issued, along with the Start-Up Report,

which activates the Warranty Period of the equipment. The Warranty Period will commence either upon

completion of start-up registration of the equipment or 6 months from factory ship date, whichever comes first.

CAUTION. Draining and re-filling the dry cooler must be performed by trained personnel, according to proper

field practice and system layout. Improper draining or re-filling the system could lead to equipment damage,

malfunction, premature wear and tear and may void equipment warranty. Ensuring that the dry cooler and associated

system(s) equipped with proper means of draining, creating draining and re-filling procedures as well as determining

whether draining is warranted to protect the equipment is outside of manufacturer’s scope and is a sole responsibility

of installing contractor and local maintenance team.

Dectron Dry Cooler OMM 16 September 2020

Initial 90‐Day Comprehensive Warranty

During the first 90 days from initial start-up, all parts and repairs related to factory defects or replacement parts

are covered by Dectron manufacturer warranty. All parts and labor requirements will either be handled by DASV

technicians directly or managed and approved in advance by DASV through DASV authorized technicians.

Internet Connected, Conditional One Year Repair Warranty

If and only if the equipment is connected to the internet from the date of warranty activation, a Repair Warranty

will be provided for an additional 9 months subsequent to the initial 90-Day Comprehensive Warranty for a total of

12 months of parts and labor warranty coverage. The unit must be connected and communicating to Dectron

Vision 2.0 for the entire term from start-up in order to qualify.

If qualified, Dectron will provide or pay for the required part and direct labor only, related to the part replacement.

Only the labor required to replace the defective part is under warranty for this 9-month extension. Travel time,

diagnostic time, per diems, truck charges, shipping charges etc. are not covered under this Conditional Repair

Warranty.

Two-Year Parts Warranty

If any factory installed part supplied by Dectron fails because of a defect in workmanship or material prior to the

completion of the 24th month from date of completion of the warranty activation, Dectron will provide a new or

rebuilt part F.O.B. factory. No labor reimbursement will be made for expenses incurred in replacing the part except

as set in the Initial 90‐day Comprehensive or Internet Connected, Conditional One-Year Repair Warranty.

Dectron reserves the right to have the defective part returned to the factory in order to determine the warranty

applicability. Parts shipping and handling costs (to and from the factory) are not covered outside of the Initial 90‐

day Warranty.

September 2020 17 Dectron Dry Cooler OMM

Replacement Part Warranty

If a replacement part provided by Dectron under this warranty fails due to a material defect prior to the end of the

Two-Year Parts Warranty (or the end of the extended warranty period if applicable), whichever comes first,

Dectron will provide a new or rebuilt part F.O.B. factory.

Applicability

This warranty is applicable only to products that are purchased and installed in the United States and Canada. This

warranty is NOT applicable to:

1. Products that have become defective or damaged as a result of non-DASV or unauthorized service work,

poor maintenance, faulty electrical supply, act of God, or any other circumstances outside of the specified

care, maintenance or operation of the equipment including:

•Components that have been relocated from their original placement during manufacturing.

•Any portion of the system not supplied by Dectron.

•Components on which the model and/or serial number plates have been removed or defaced.

•Components which have become defective or damaged as a result of unauthorized opening of the

refrigeration circuit, improper wiring, electrical supply characteristics, poor maintenance, accidents,

transportation, misuse, abuse, fire, flood, alteration and/or misapplication of the product.

•Products not installed, operated and maintained as per the Dectron Operating and Maintenance

Manual.

•Products operating in mechanical rooms that house chemicals (i.e. chlorine, bromine, water

treatment chemicals).

•Products on which payment is in default.

2. Parts that wear out due to normal usage, such as air filters, fuses and sensors are not covered by this

warranty.

NOTE: Refrigerant lost during the Initial 90‐day Comprehensive or Internet Connected, Conditional One-Year

Repair Warranty will be reimbursed in accordance to the current market price of refrigerant at the time of

repair and upon discretion of DASV’s Customer Support team. Dectron will not be responsible for refrigerant

lost from the system due to improperly installed contractor piping to the remote outdoor air-cooled

condenser.

Limitations

1. DASV is a Manufacturer Service organization, not a first-response or urgent response local service

company. As such, we highly recommend that equipment owners have a relationship with their own

qualified first response service organization or one recommended by DASV.

DASV hours of operation are from 8:00 AM to 6:00 PM Eastern, Monday through Friday unless otherwise

agreed to under a separate agreement.

Parts replacement can be subject to availability. We highly recommend for mission-critical applications

that owners purchase and maintain a local stock of critical components in case immediate replacement be

required. If for any reason one of those components is replaced under applicable warranty conditions,

Dectron will reimburse the original cost of any component used under terms of Warranty.

NOTE: Dectron expressly disclaims any liability for parts replacement delays due to parts unavailability or

shipping delays.

2. This warranty is given in lieu of all other warranties. Anything in the warranty notwithstanding, any

implied warranties of fitness for particular purpose and merchantability shall be limited to the duration of

Dectron Dry Cooler OMM 18 September 2020

the warranties described above. Dectron expressly disclaims and excludes any liability for consequential

or incidental damage for breach of any express or implied warranty.

Where a jurisdiction does not allow limitations or exclusions in a warranty, the foregoing limitations and

exclusions shall not apply to the extent of the legislation, however, in such case the balance of the above

warranty shall remain in full force and effect.

This warranty gives specific legal rights. Other rights may vary according to local legislation.

Force Majeure

Dectron will not be liable for delay or failure to provide warranty service due to government restrictions or

restraints, war, strikes, material shortages, acts of God or other causes beyond Dectron control.

Table of contents