Siemens milltronics ILE-37 User guide

Other Siemens Industrial Equipment manuals

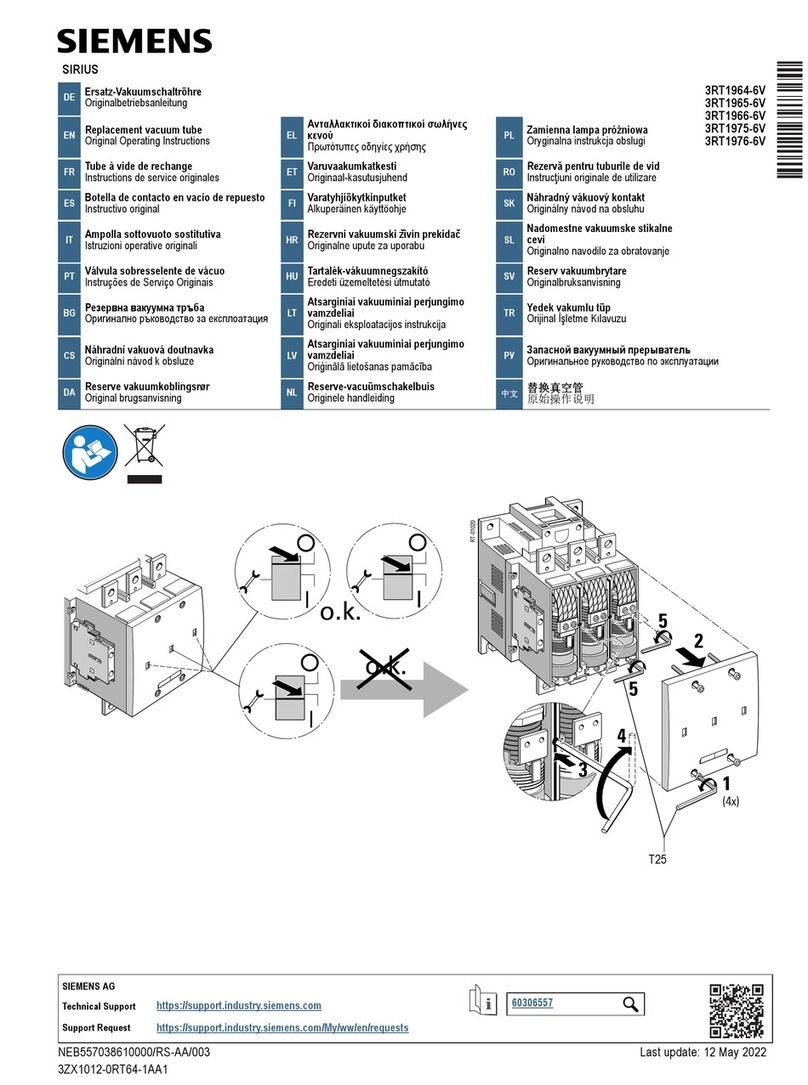

Siemens

Siemens MOTOX BA 2515 User manual

Siemens

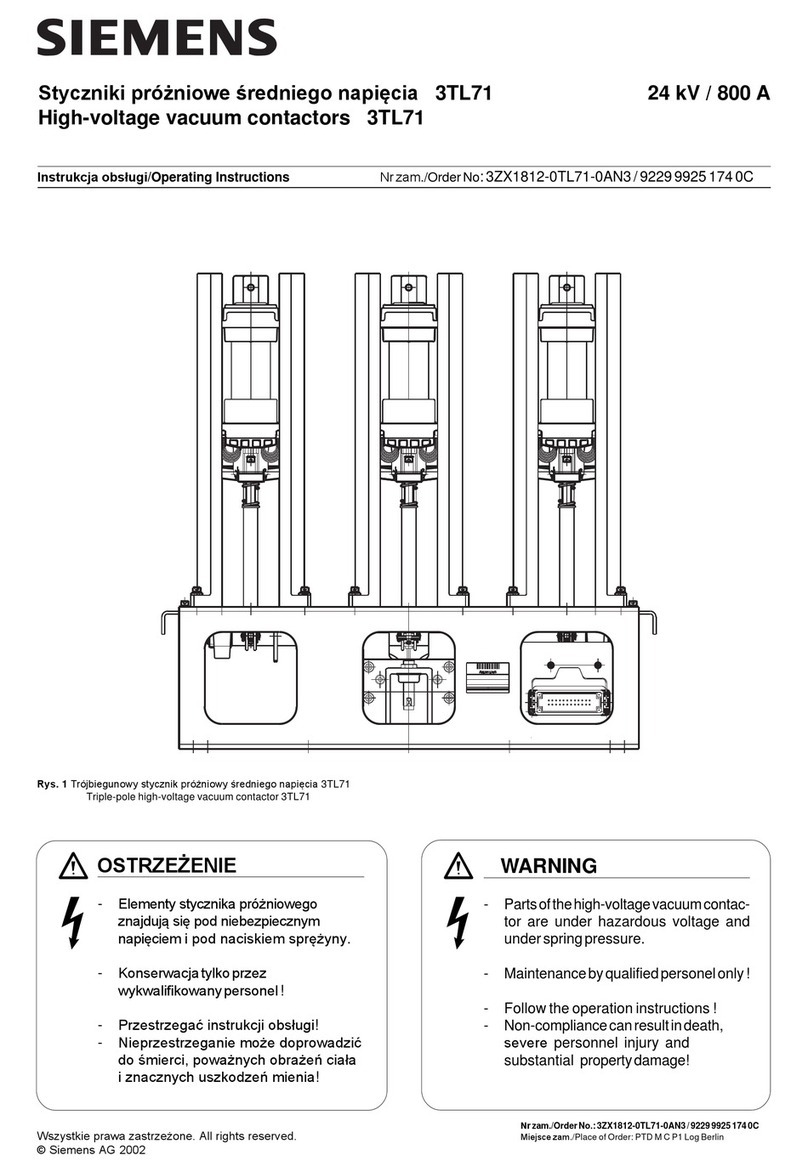

Siemens 3TL71 User manual

Siemens

Siemens SINUMERIK 840Di sl Owner's manual

Siemens

Siemens 3RK1405-1SE15-0AA2 User manual

Siemens

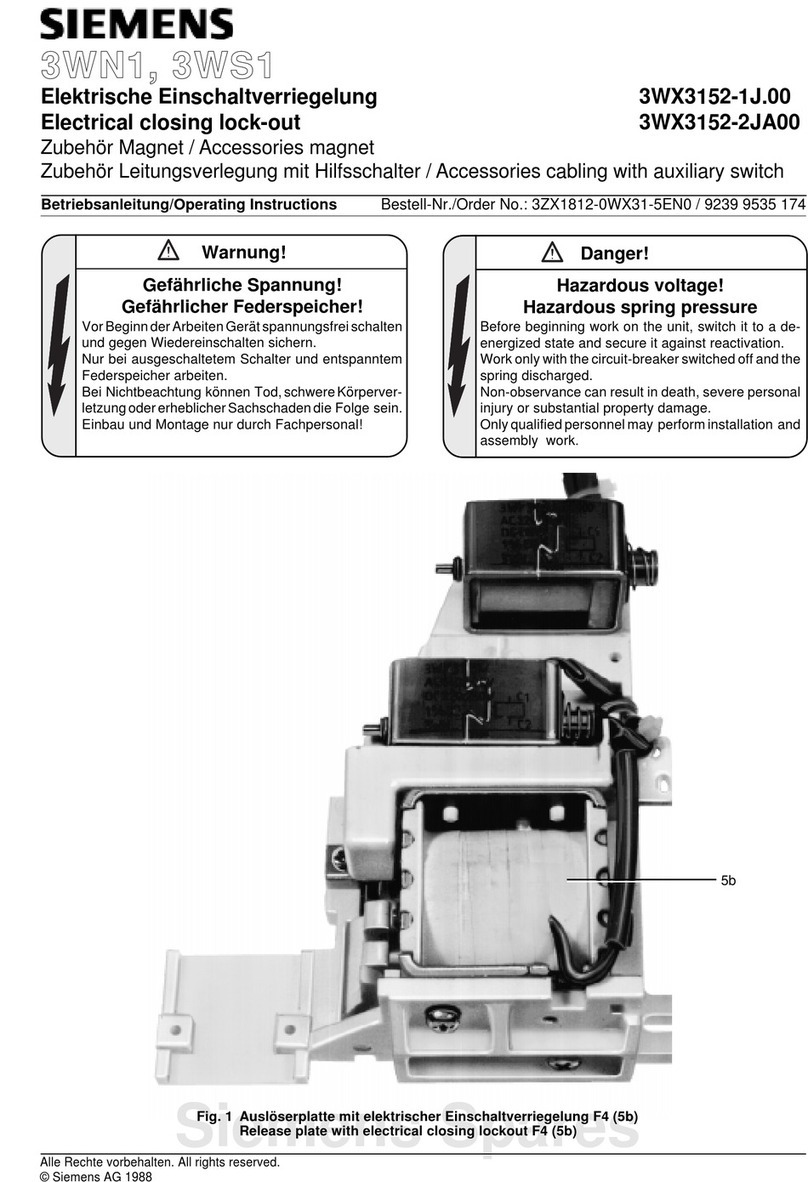

Siemens 3WX3152-1J.00 Series User manual

Siemens

Siemens SIMOGEAR BA 2730 User manual

Siemens

Siemens SIMOTION ADI4 Technical Document

Siemens

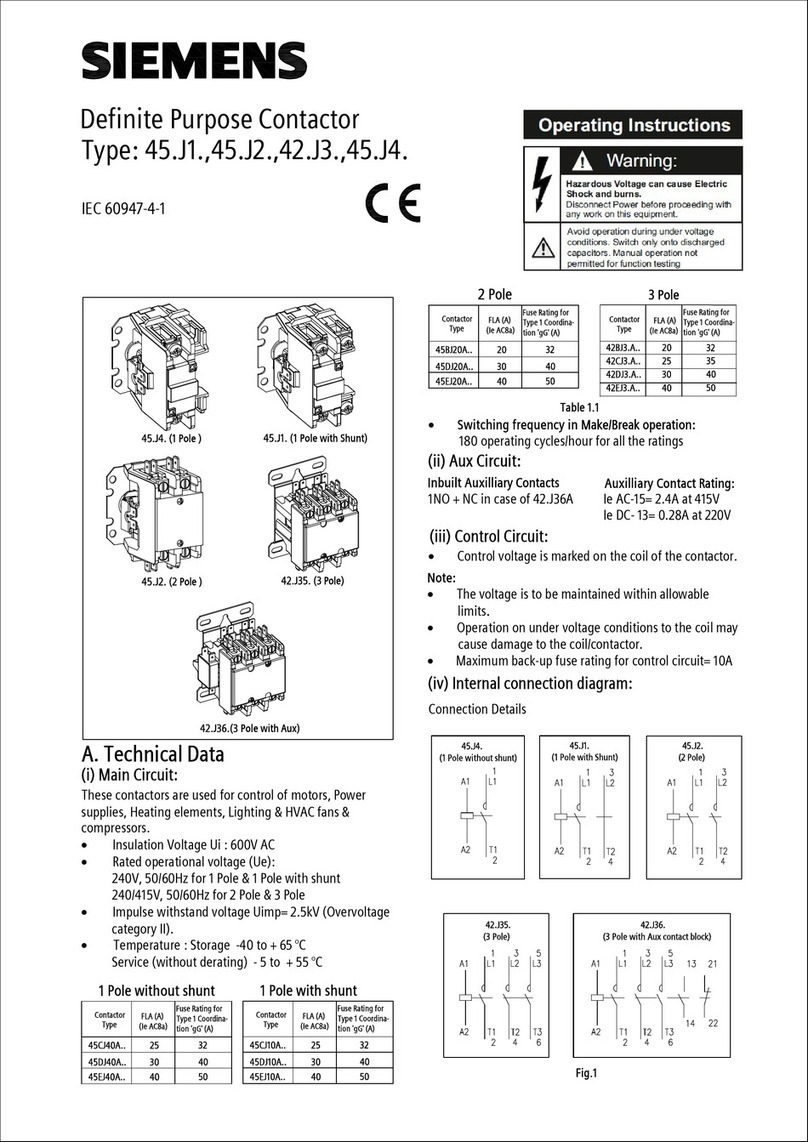

Siemens 45BJ20A Series User manual

Siemens

Siemens SIMATIC S7-GRAPH User manual

Siemens

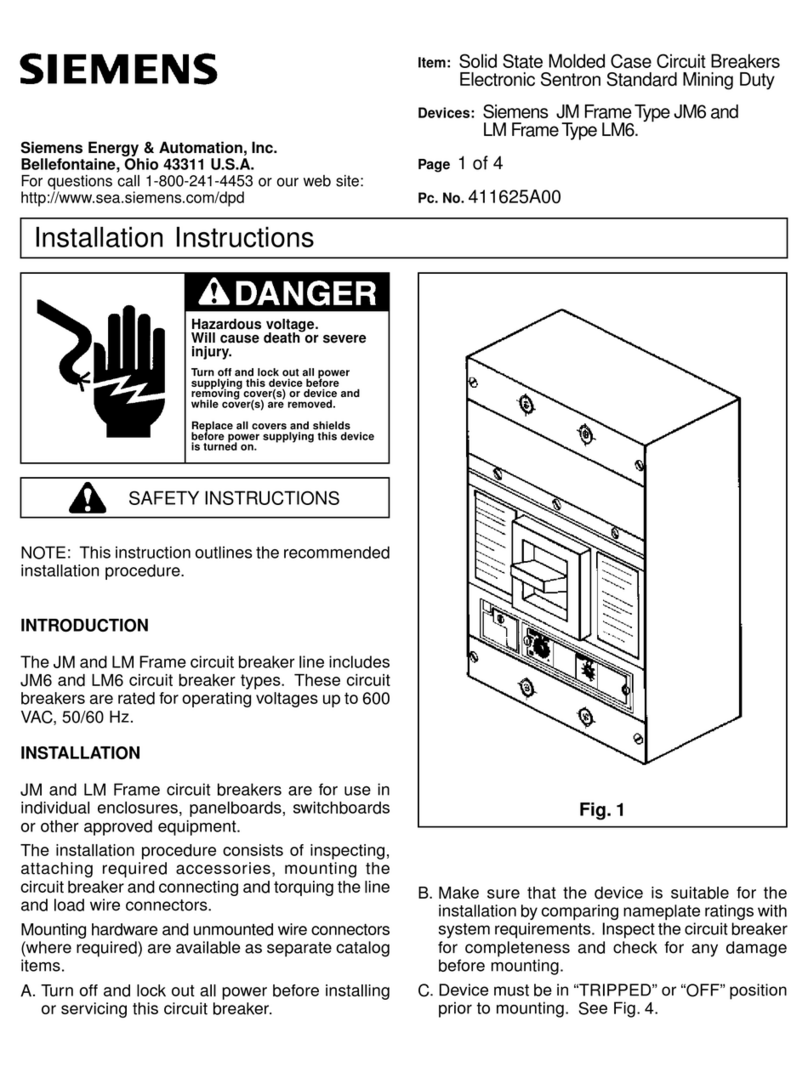

Siemens 411625A00 User manual

Siemens

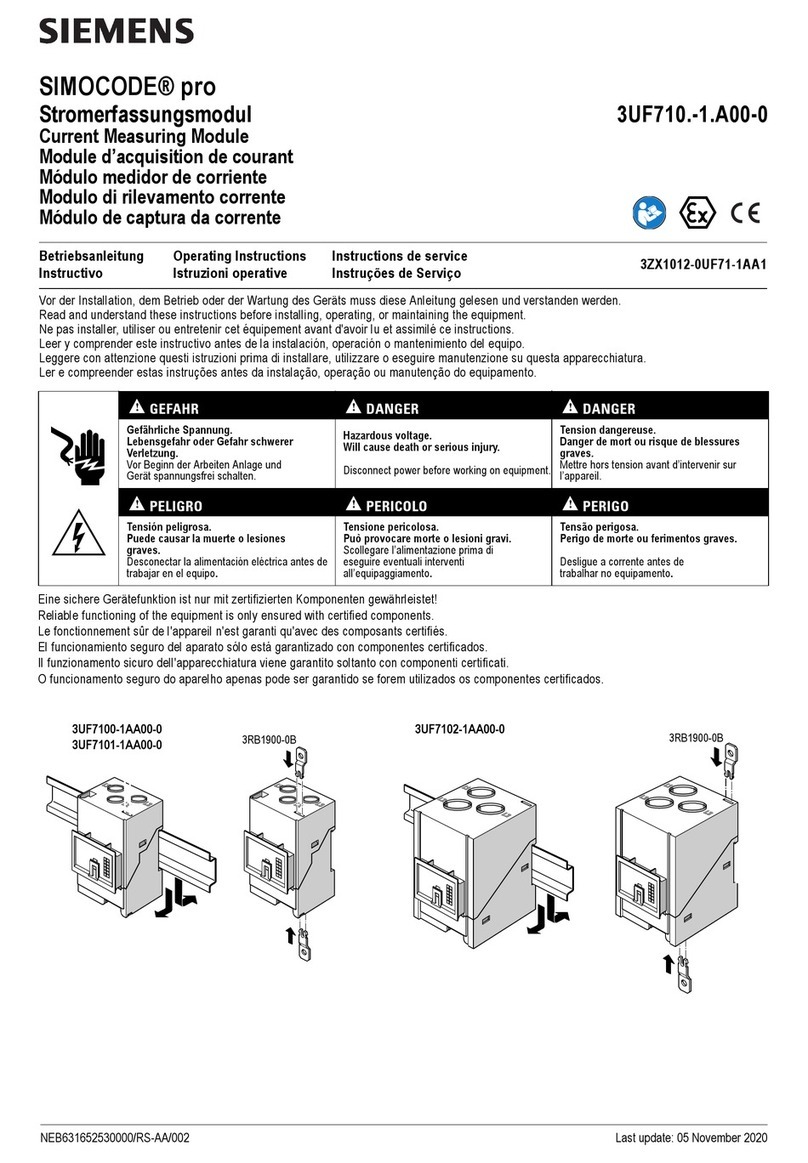

Siemens SIMOCODE pro 3UF710-1 A00-0 Series User manual

Siemens

Siemens SIMATIC NET RUGGEDCOM RX1524 User manual

Siemens

Siemens SIMATIC S7-400H User manual

Siemens

Siemens Reyrolle 7SR5 User manual

Siemens

Siemens SIMATIC CP 4163-5 User manual

Siemens

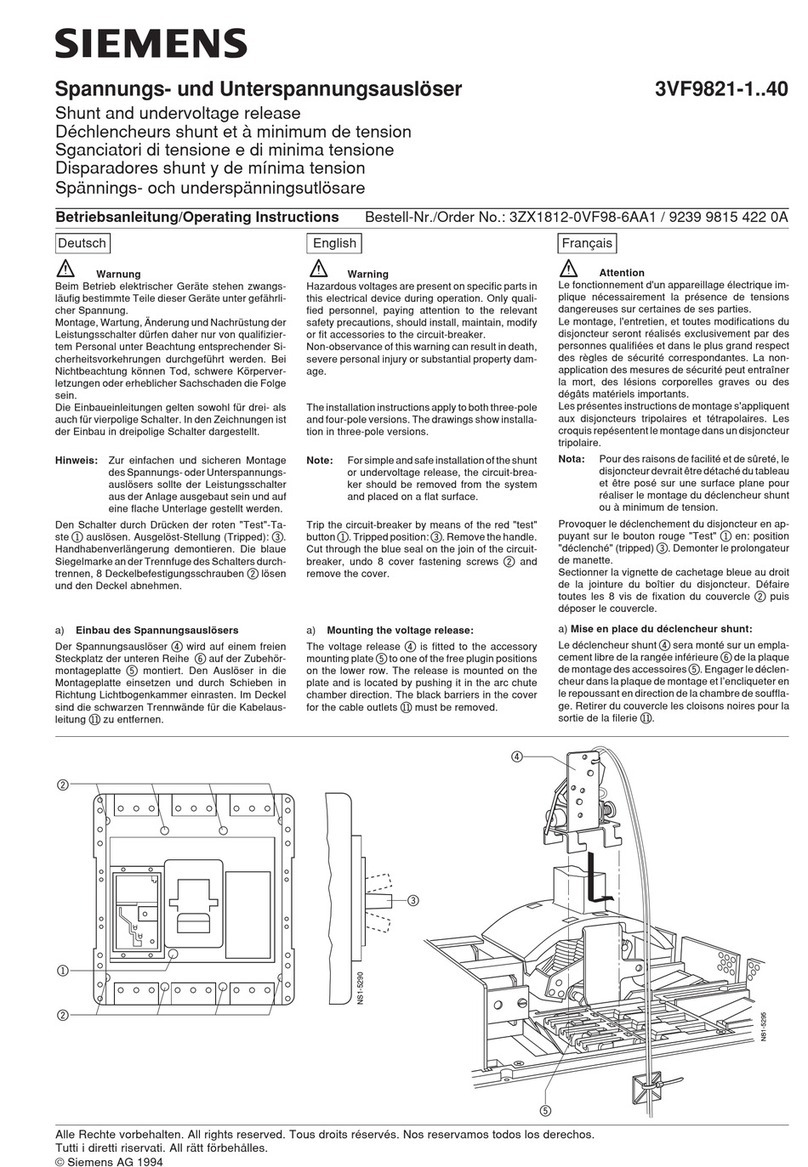

Siemens 3VF9821-1 40 Series User manual

Siemens

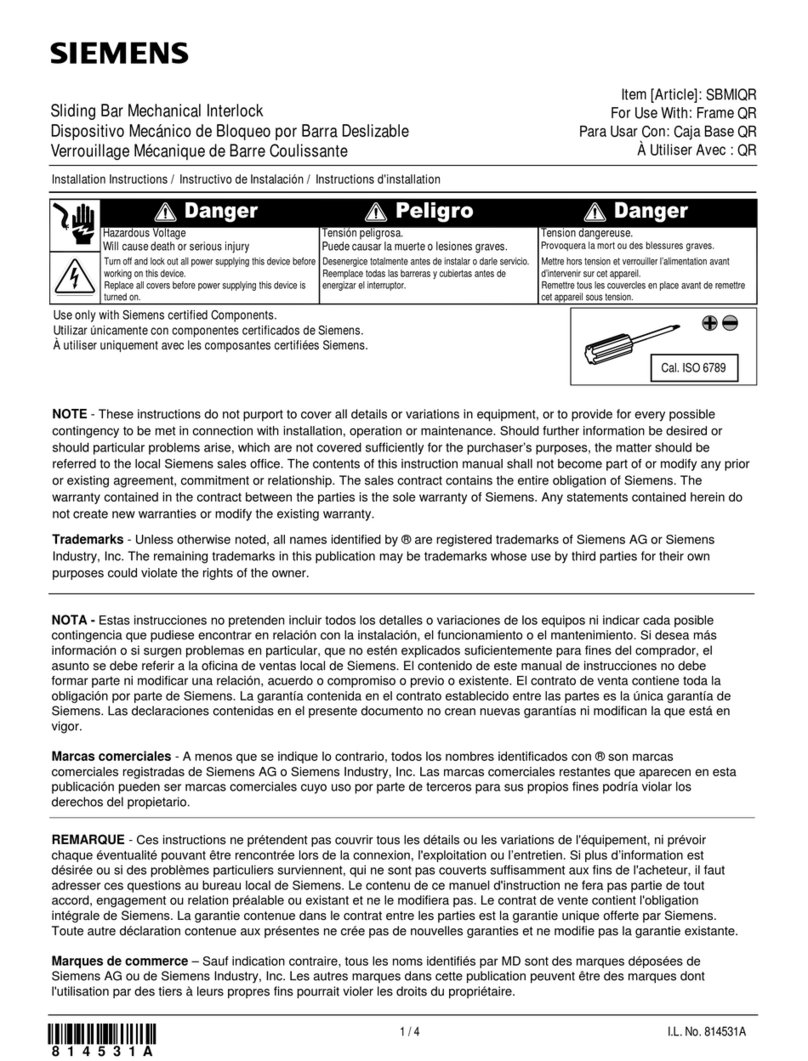

Siemens SBMIQR User manual

Siemens

Siemens MFI User manual

Siemens

Siemens FLENDER FLUDEX Series User manual

Siemens

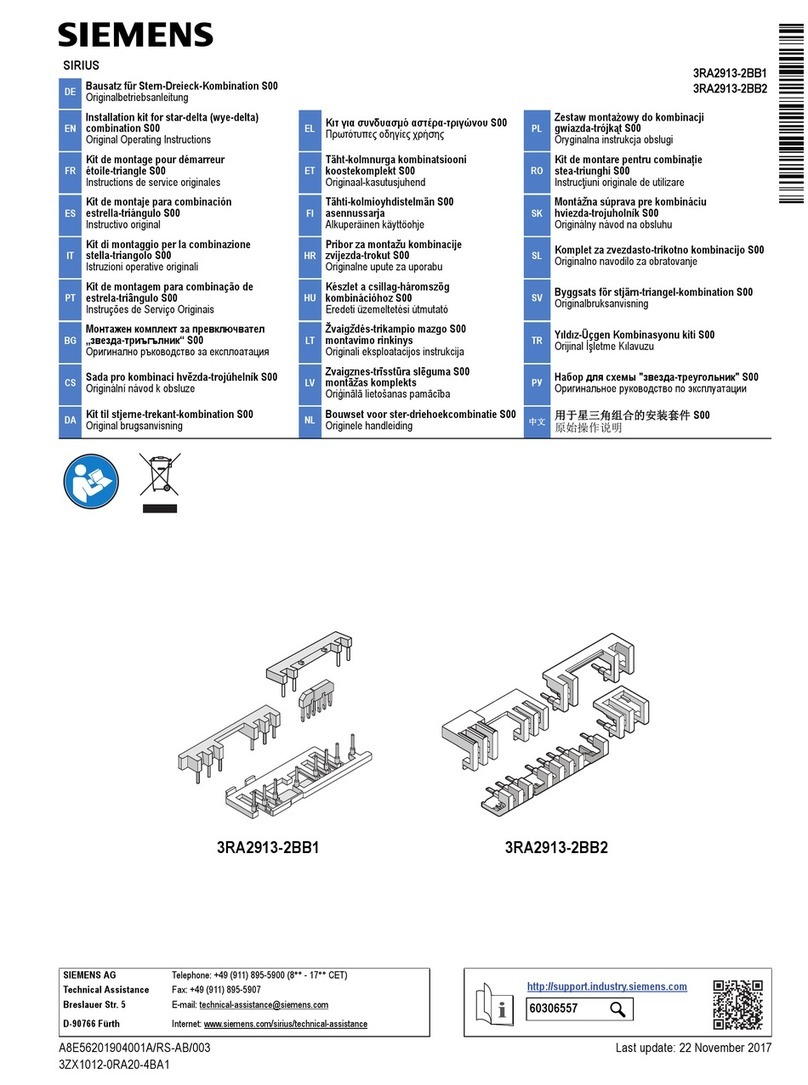

Siemens SIRIUS S00 User manual