INSTALLATION GUIDE

2| ENVIROTILE INSTALLATION GUIDE

All Envirotile roof products are manufactured using 100%

reliably sourced recycled plastic, providing the consumer with

a genuine environmentally friendly roof covering

Outstanding test results conducted by the Bre test facility to

Pr EN15601 established that Envirotile roof covering provides

increased performance against wind loads over that of

conventional roof tiles and slates with standard clip xings

Fully Tested and fully compliant for both the UK BS:5534-2014

and European equivalent DD:CENT/S 15087 External Fire

Exposure Roof Test conducted by Exova to BS476-3 – EXT.S.AA

External Fire Exposure Roof Test conducted by Exova to DD

CEN/TS 1187 test 4 – B Roof t4

Maintains full integrity and provides a leading performance

against wind uplift loads from a minimum low roof pitch of

12.5°

Durable and robust, minimising breakages normally

experienced during the roof installation process

Resists mould, moss and fungus due to the non-porous

attributes of polymer material

Provides future generations with a genuine polymer recycled

application at the end of life, assisting with considerate

constructors’ initiatives

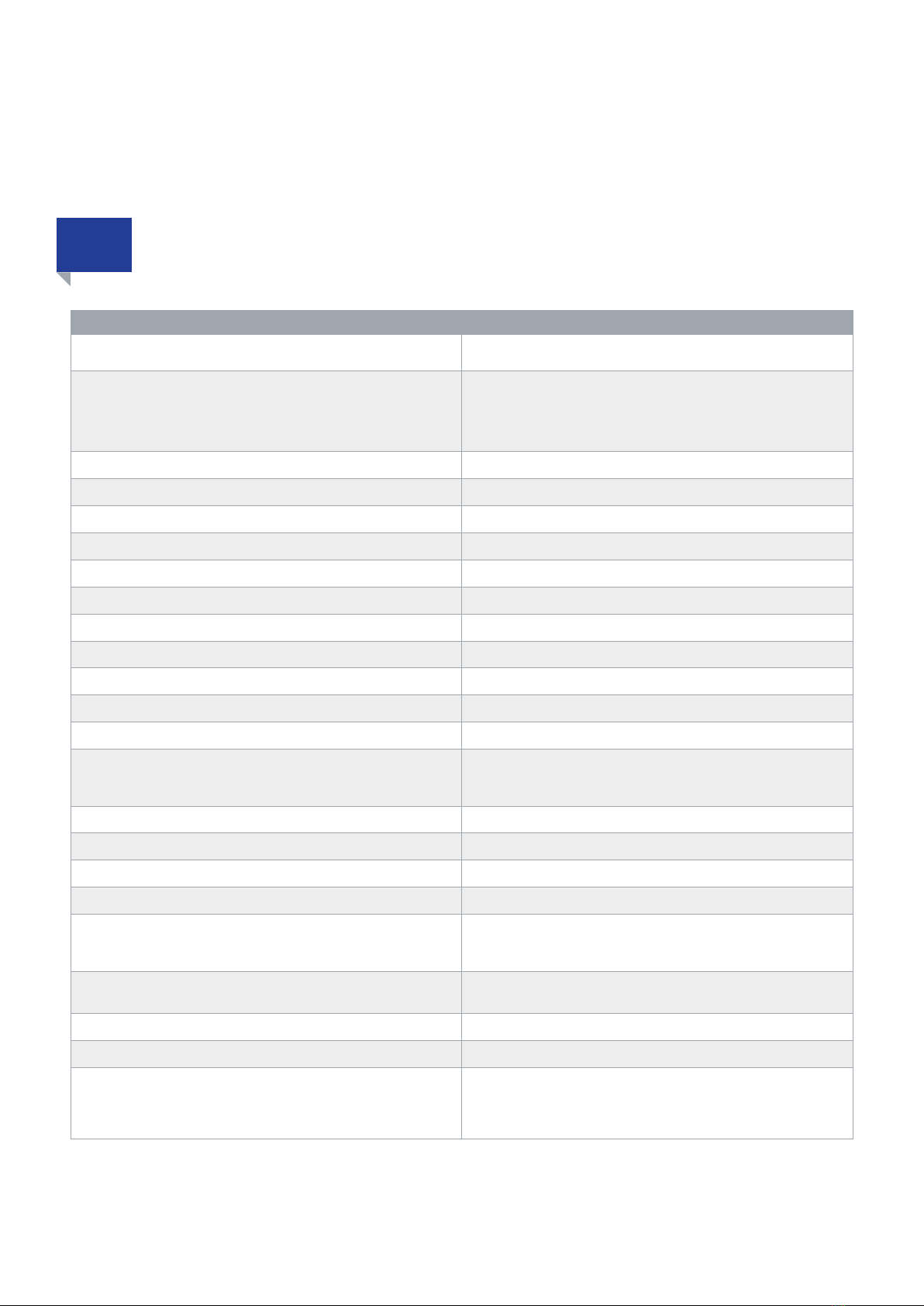

Designed to provide a simple and cost effective roof covering

that is fully mechanically dry xed

Envirotile is a lightweight roof product weighing an average of

just 7.8 kilos per square metre in contrast with conventional

cement or natural slate products that can weigh on average

50 kilos

Less weight results in cheaper transportation, reduced CO²

transport emissions and less structural requirement on

roong supports

No additional roof tiles required to accommodate top and

bottom eaves courses due to the innovative patented design,

providing customers with reduced material cost

Manufactured from environmentally sustainable products

otherwise destined for landll

Provides an environmentally friendly building roof product

that genuinely provides a great application for reusable plastic

Complies with the Code for Sustainable Homes

http://www.breeam.org/index.jsp

Offers a genuine alternative to meet the growing public

demand for more sustainable build options

Completely recyclable at the end of life

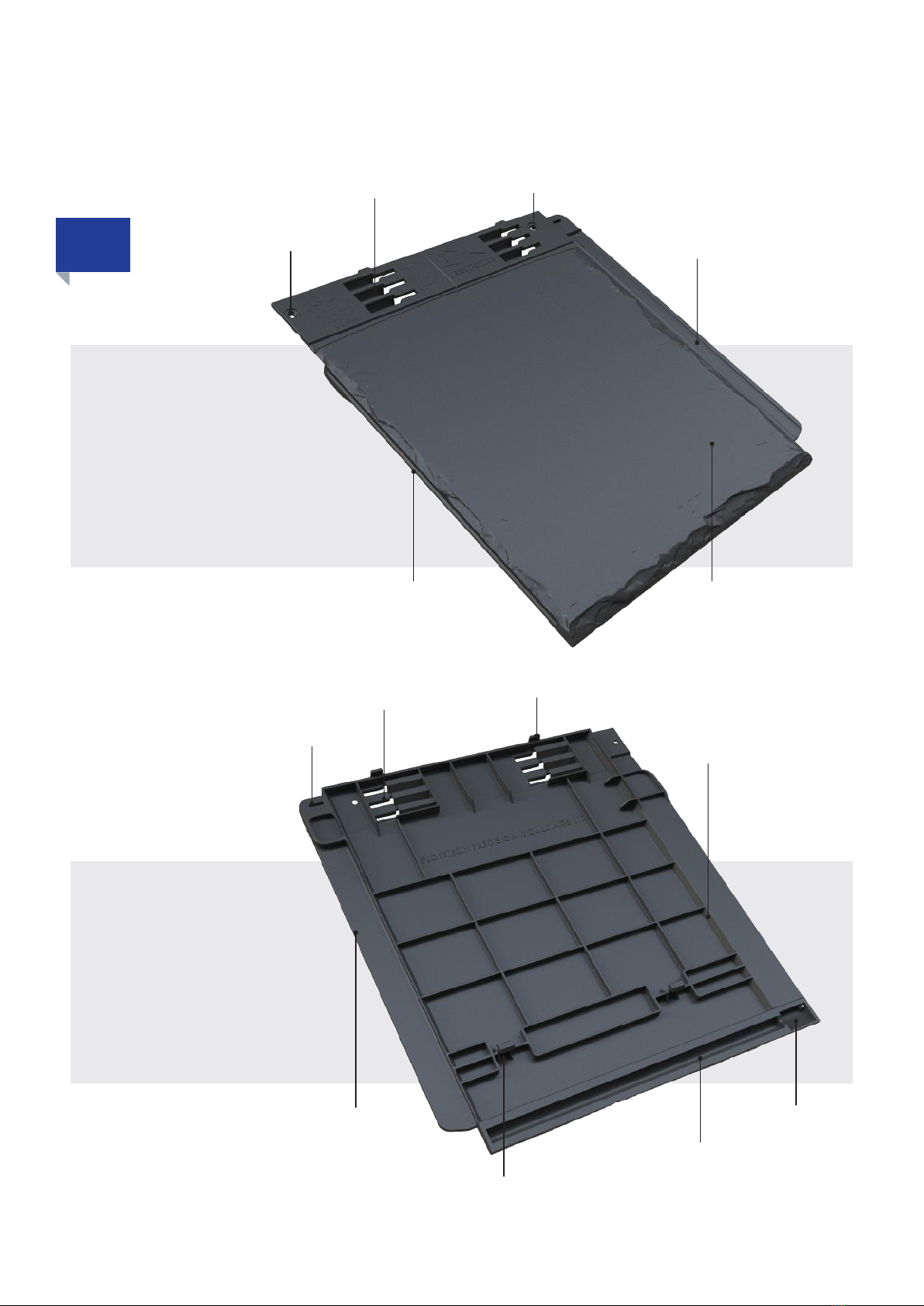

Virtually unbreakable; interlocks in eight places, making it

signicantly more vandal and burglar proof

This step by step installation and technical guide is aimed at

all new users of the Award Winning Envirotile mechanically

dry xed lightweight Roof System.

Envirotile offers unrivalled technical performance along

with excellent eco-credentials. It’s precision crafted design

fully utilises the latest in recycled material technology which

ensures every roof tile meets the strictest level of quality.

The lightweight Envirotile Interlocking Roof System must be

installed in full compliance with recommendations outlined

in BS:5534-2014 code of practice for slating and tiling

and BS:8000-6-1990 code of practice for workmanship on

building sites for slating and tiling of roofs and cladding.

ENVIRONMENTALLY SUSTAINABLE LEADING PERFORMANCE

ENVIROTILE: BENEFITS THAT REDUCE OVERALL BUILDING COSTS

ENVIROTILE: GENUINELY SUSTAINABLE

ENVIROTILE: MORE SECURE