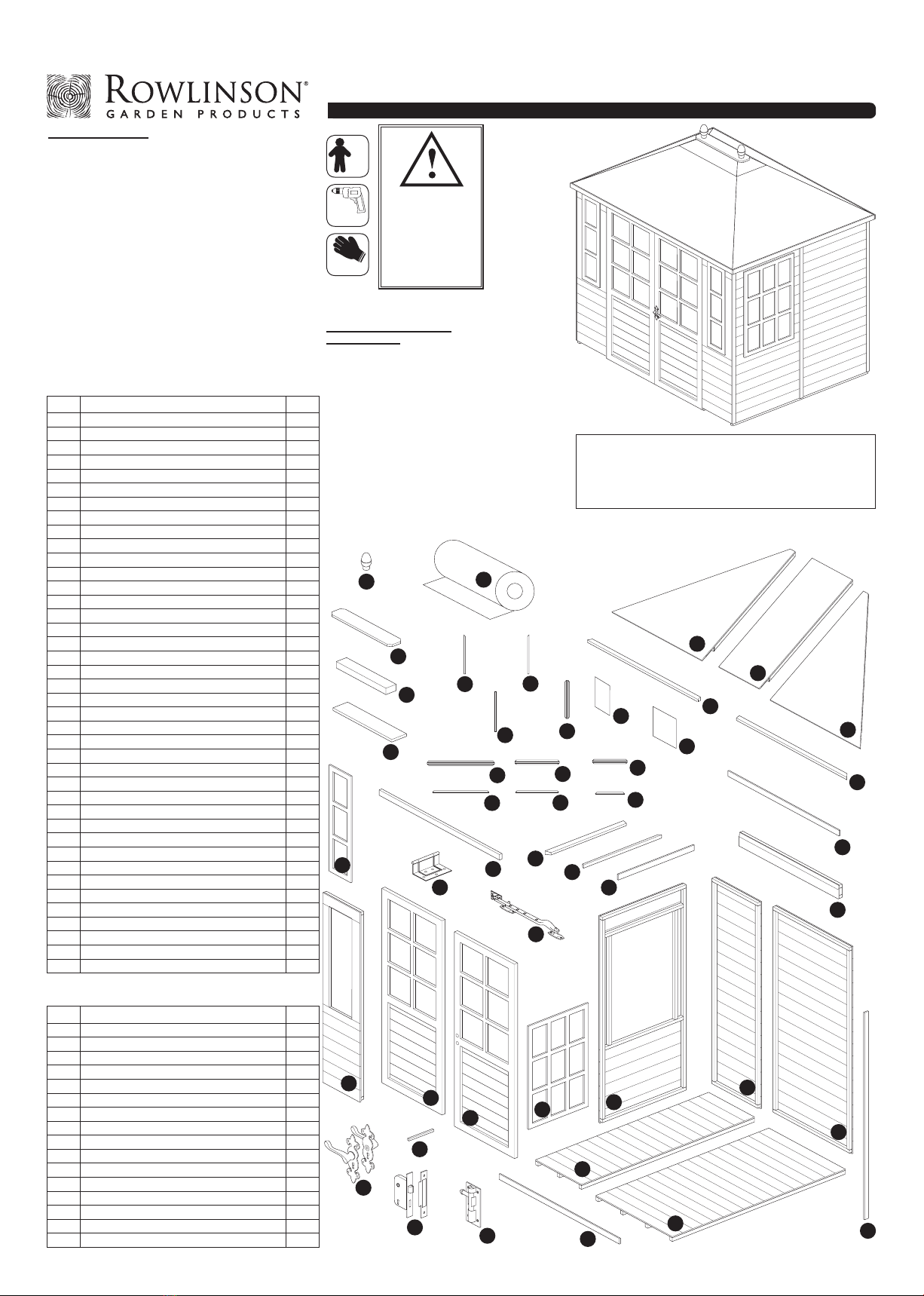

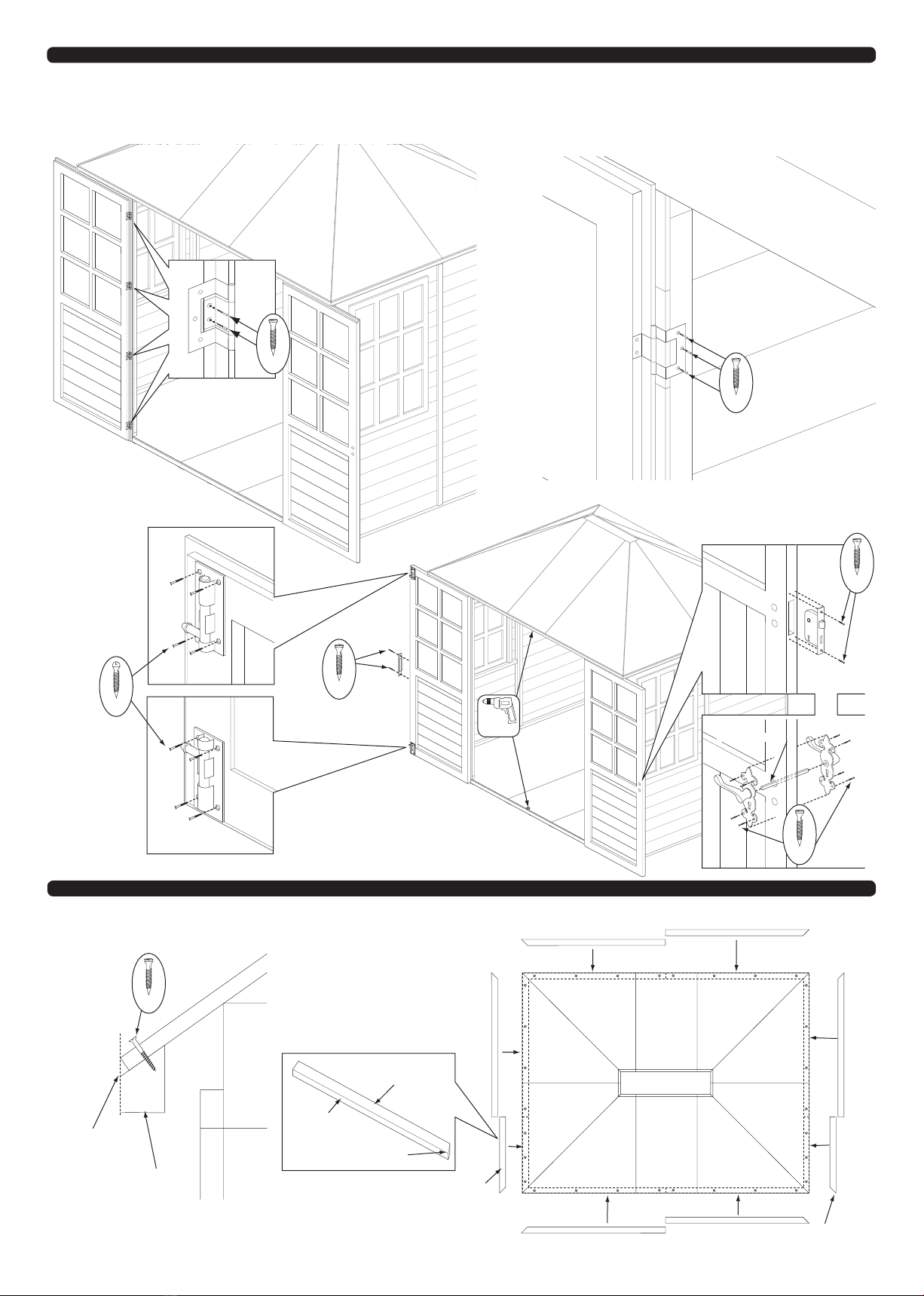

Clarendon Summerhouse English SS428A

x 2

Drill

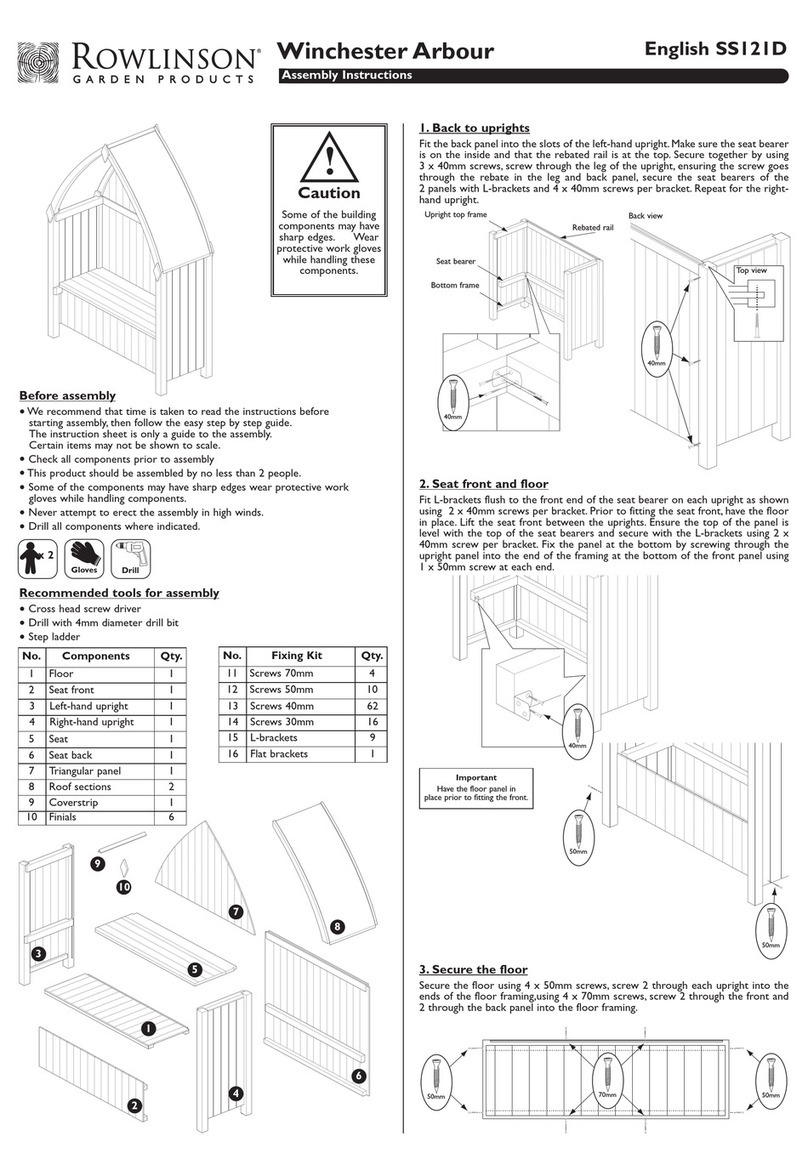

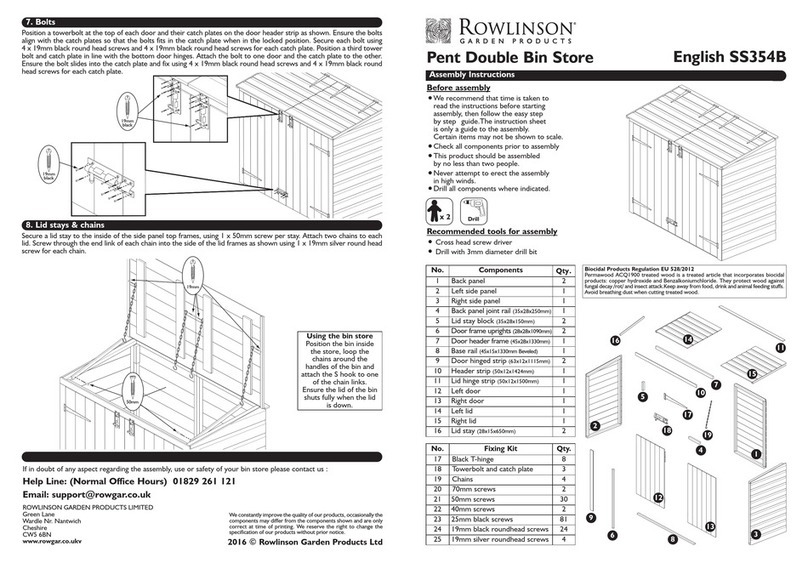

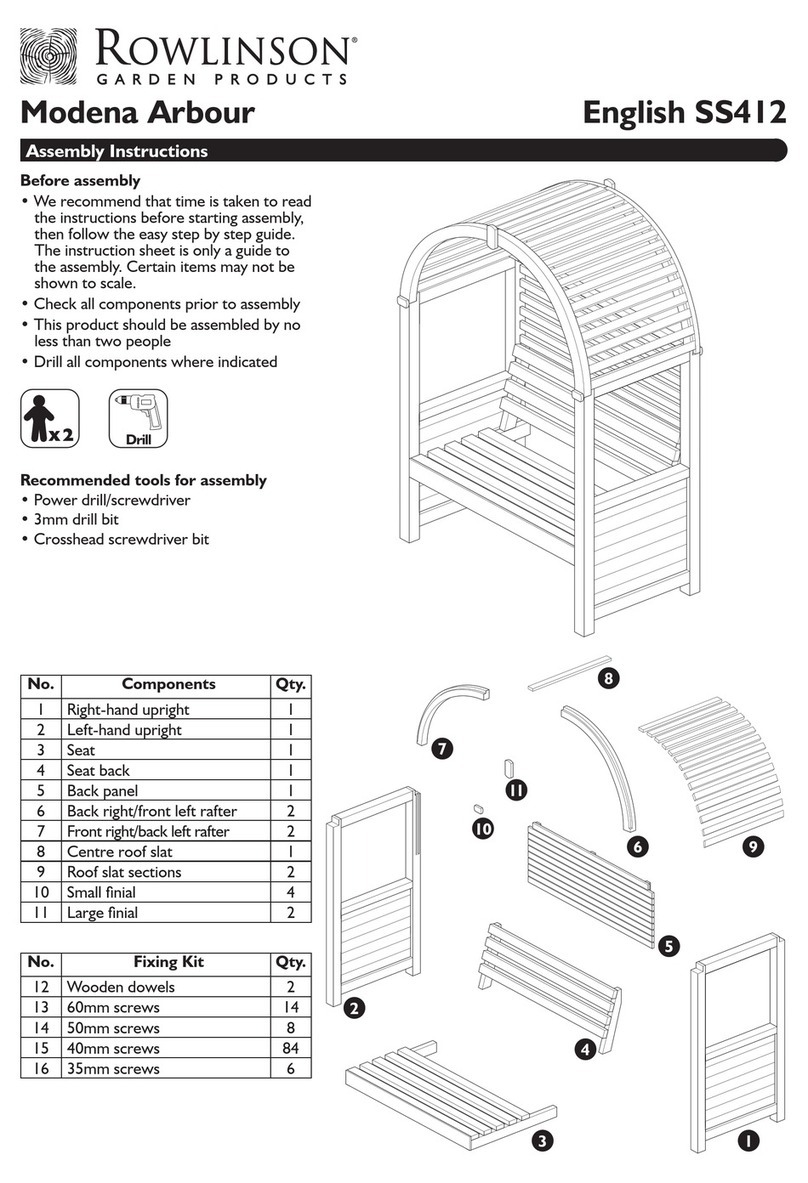

Assembly Instructions

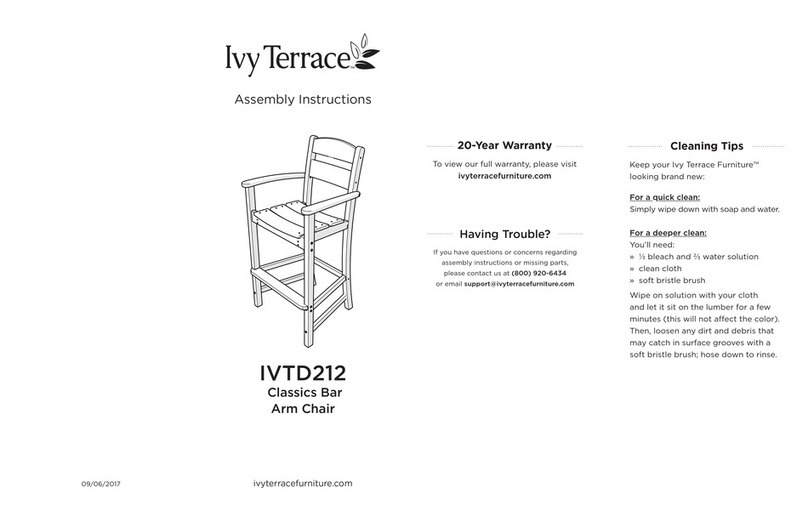

Recommended tools

for assembly

•Power drill/screwdriver

•Cross head drill bit

• 3mm diameter drill bit

•12mm diameter drill bit

•Hammer

•Sharp knife

•Spirit level

•Silicon sealant

•Step ladder

1

2

3

11

6

8

5

4

7

25

10

9

12

13

14

15

16

17

18

19

20

22

21

23

24

29

26

28

32

30

31

37

27

39

38

33

34

35 36

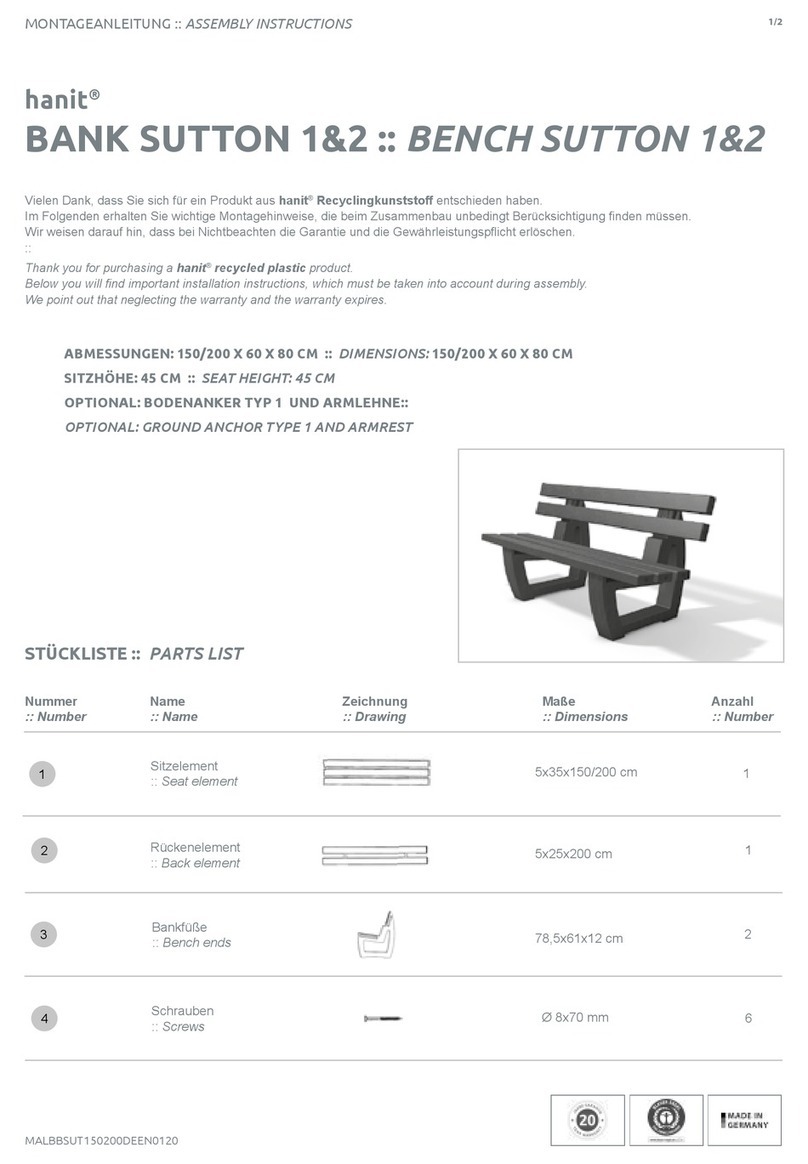

Caution

This product

contains glass.

Wear protective

work gloves while

handling these

components.

Gloves

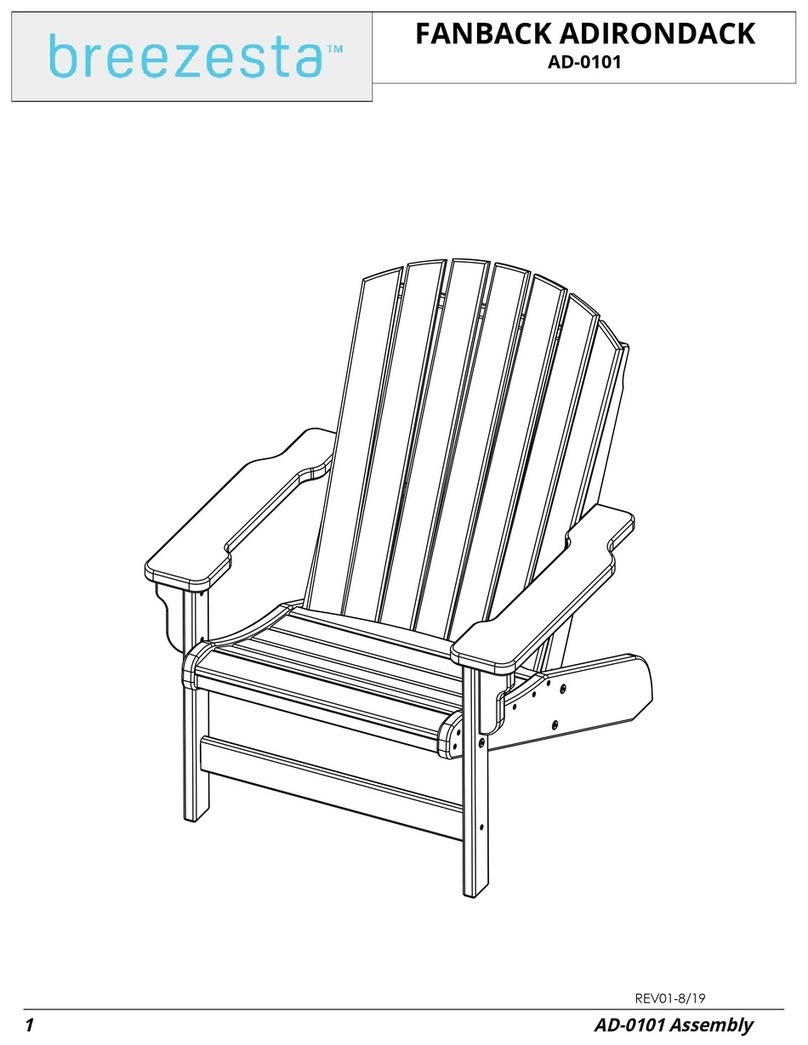

Dimensions:

Overall external:

Height = 2745mm

Width = 2650mm

Depth = 2170mm

Footprint:

Width = 2340mm

Depth = 1870mm

Min. base area:

Width = 2440mm

Depth = 1970mm

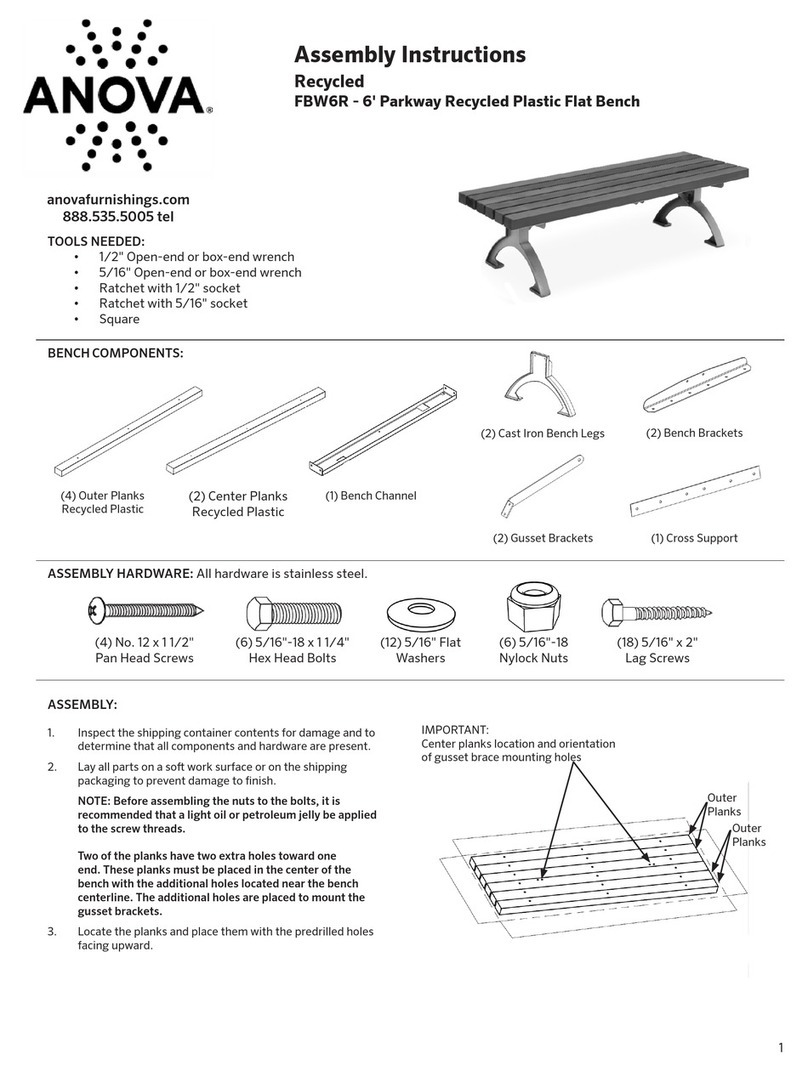

No. Fixing Kit Qty.

41 Hinges 12

42 Towerbolts 2

43 Door handle set 1

44 Metal handle bar 1

45 Door lock kit 1

46 Window stay 2

47 63mm screws 26

48 50mm screws 108

49 25mm screws 90

50 25mm black countersunk screws 20

51 25mm brass screws 4

52 20mm screws 8

53 19mm round head screws 8

54 40mm nails 62

55 25mm panel pins 234

56 10mm felt nails 200

No. Components Qty.

1Large floor panel 2

2Small floor panel 1

3Large wall panel 4

4Small back panel 1

5Side window panel 2

6Front window panel 2

7Side window frame 2

8Front window frame 2

9front header panel 2

10 Left-hand door 1

11 Right-hand door 1

12 Door header rail (29x35x1438mm) 1

13 Kick/header coverstrip (12x36x1438mm) 2

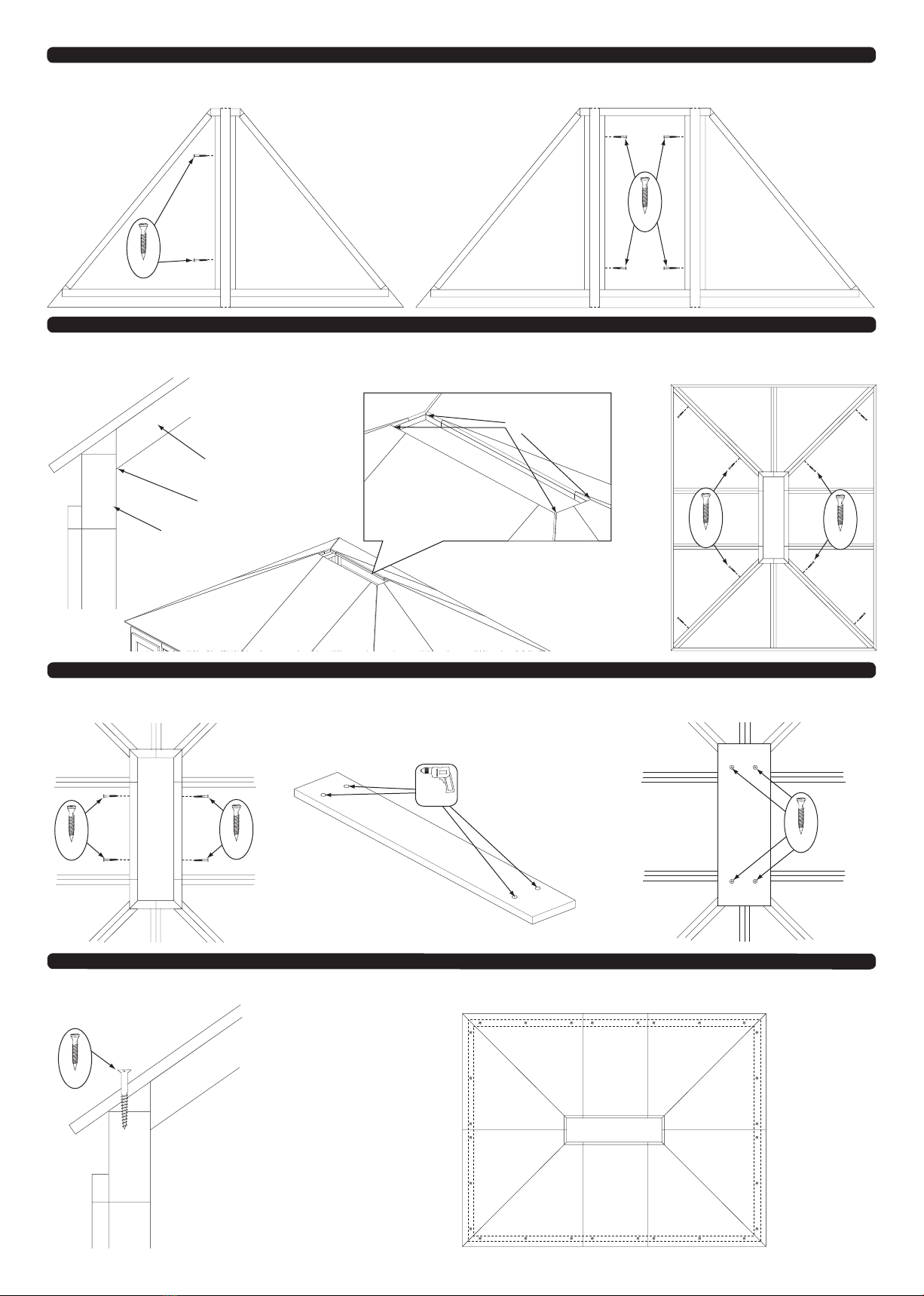

14 Left-hand triangular roof panel 4

15 Rectangular roof panel 2

16 Right-hand triangular roof panel 4

17 Roof centre block 1

18 Inside roof cover (615x140mm) 1

19 Long angled felt batten (right) 3

20 Long angle felt batten (left) 3

21 Short angle felt batten (right) 1

22 Short angle felt batten (left) 1

23 Roof felt Roll (10m) 1

24 Corner coverstrips (1920x48x12mm) 8

25 Short bargeboard (835x40x12mm) 2

26 Long bargeboard (1325x40x12mm) 6

27 Capping (645x140mm) 1

28 Acorn finials 2

29 Door glazing (284 x 306mm) 12

30 Front & side window glazing (193 x 304mm) 24

31 Door bead top/bottom (14x10x590mm) 4

32 Door/window bead TR/BL* (14x10x315mm) 12

33 Door/window bead TL/BR* (14x10x315mm) 12

34 Door/window bead middle (14x10x320mm) 12

35 Window bead top/bottom (14x10x620mm) 4

36 Window bead top/bottom (14x10x205mm) 4

37 Door horizontal spar (44x10x575mm) 4

38 Window horizontal spar (44x10x605mm) 4

39 Window horizontal spar (44x10x190mm) 4

40 Door/window vertical spar (44x10x605mm) 18

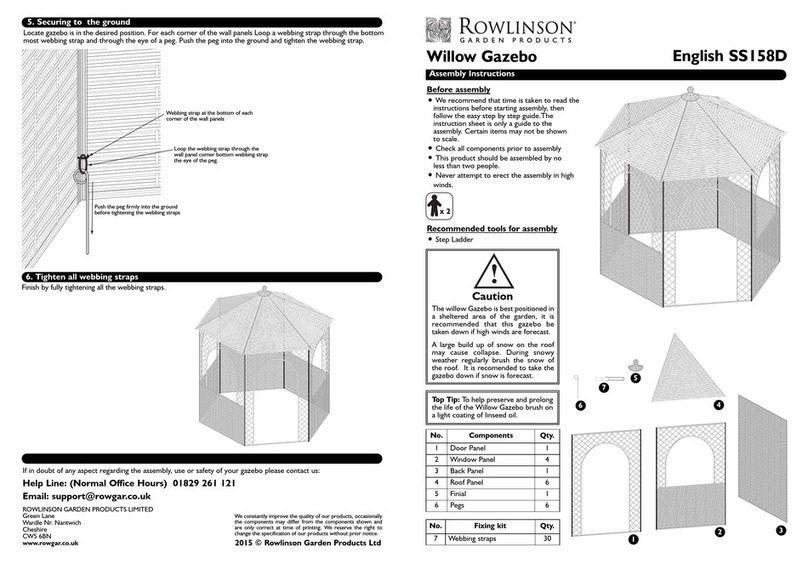

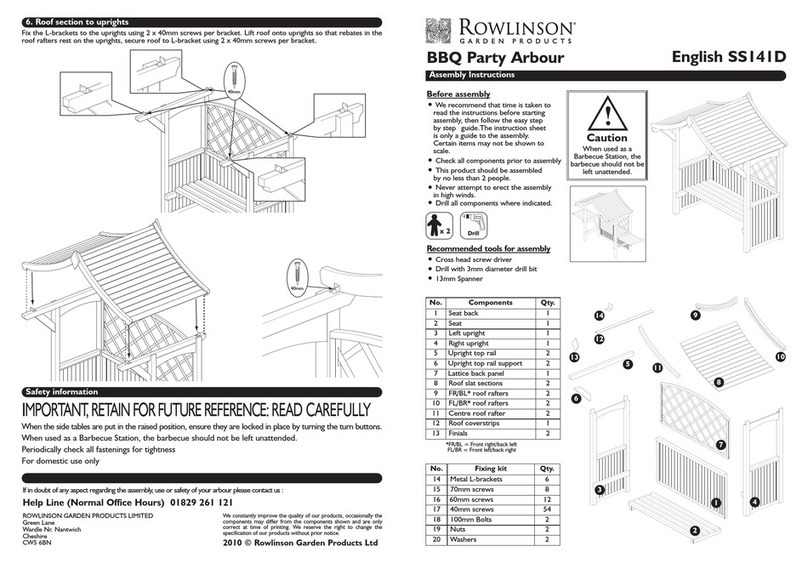

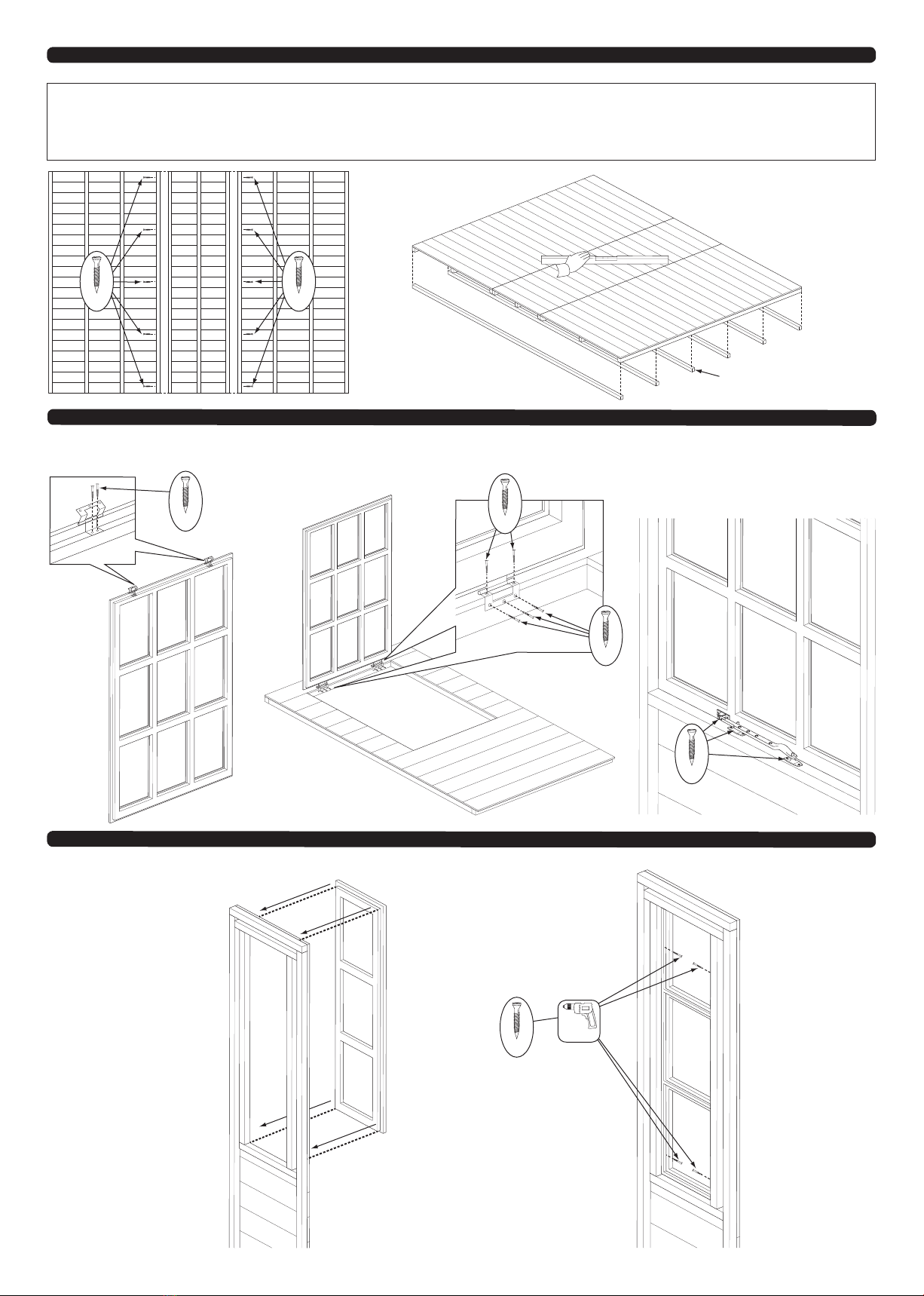

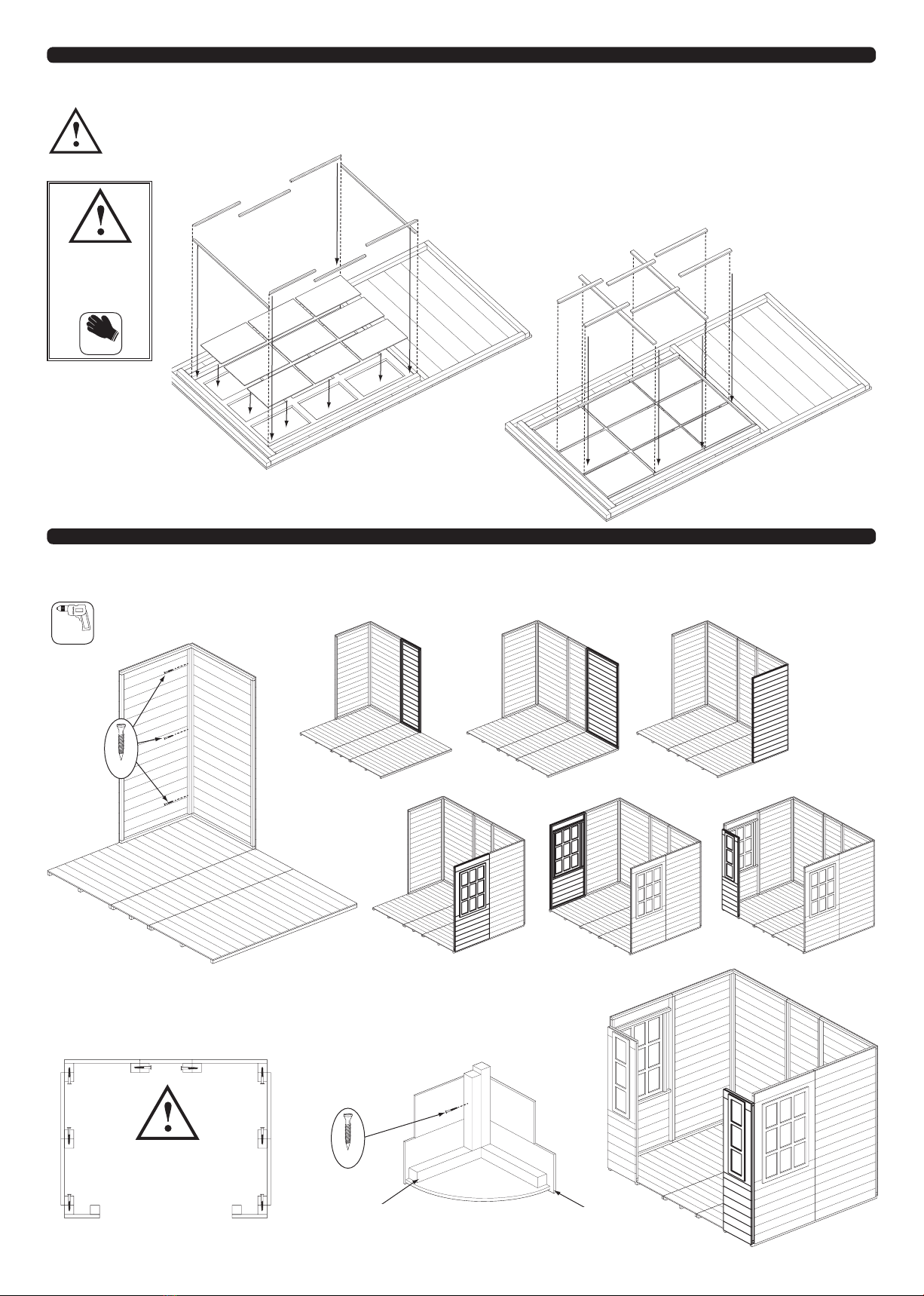

Before assembly

•We recommend that time is taken to read the

instructions before starting assembly, then follow

the easy step by step guide. The instruction sheet is

only a guide to the assembly. Certain items may not

be shown to scale.

•Check all components prior to assembly

•This product should be assembled by no less than

two people.

•Never attempt to erect the assembly in high winds.

•Drill components where indicated.

•Some of the components may have sharp

edges wear protective work gloves while

handling components.

*TR/BL = Top right/bottom left

TL/BR = Top left/bottom right

40

41

42

43

44

45

46