degdrive DGI900 User manual

User Manual

DGI900

1

Preface

DGI900 series is the newgeneration products to meet general purpose and special technical

demand. The new designed sensorless vector control performance of DGI900 inverter have

improved the reliability at low speed, the overload capacity at low frequency and high control

precision at open loop tension control mode. Its function of anti-trip and strong adaptability to

worse grid, temperature, humidity and dust make it meet the high-performance requirement

of the customer application.

DGI900 series inverters built-in RS485 interface which can use software upload, download

and monitoring the parameter of inverter. Built-in PID, 16 multi-speed, traverse control can

realize various complicate high-accuracy drives and widely apply in Textile, paper industry,

machine tool, package, printing, pump and fan.

This manual provides installation and configuration, parameters setting, fault diagnoses and

daily maintenance and relative precautions to customers. Please read this manual carefully

before the installation to ensure a proper installation and operation and high performance of

DGI900 series inverters.

DANGER:indicates the situation in which the failure to follow operating requirements

may result in fire or serious personal injury or even death.

CAUTION: indicates the situation in which the failure to follow operating requirements

may cause moderate or slight injury and damage to equipment.

2

Contents

Preface ············································································································1

Chapter 1 Precautions·······················································································5

1.1 Safety Precautions·························································································5

1.2 Precautions for use························································································8

1.3 Disposal considerations ················································································10

Chapter 2 Product Introduction········································································· 11

2.1 Naming rules······························································································ 11

2.2 Nameplate information·················································································· 11

2.3 Series and Models·······················································································12

2.4 Specifications ·····························································································13

2.5 Products apperance·····················································································16

2.6 Installation size ···························································································17

2.7 Optional Parts·····························································································21

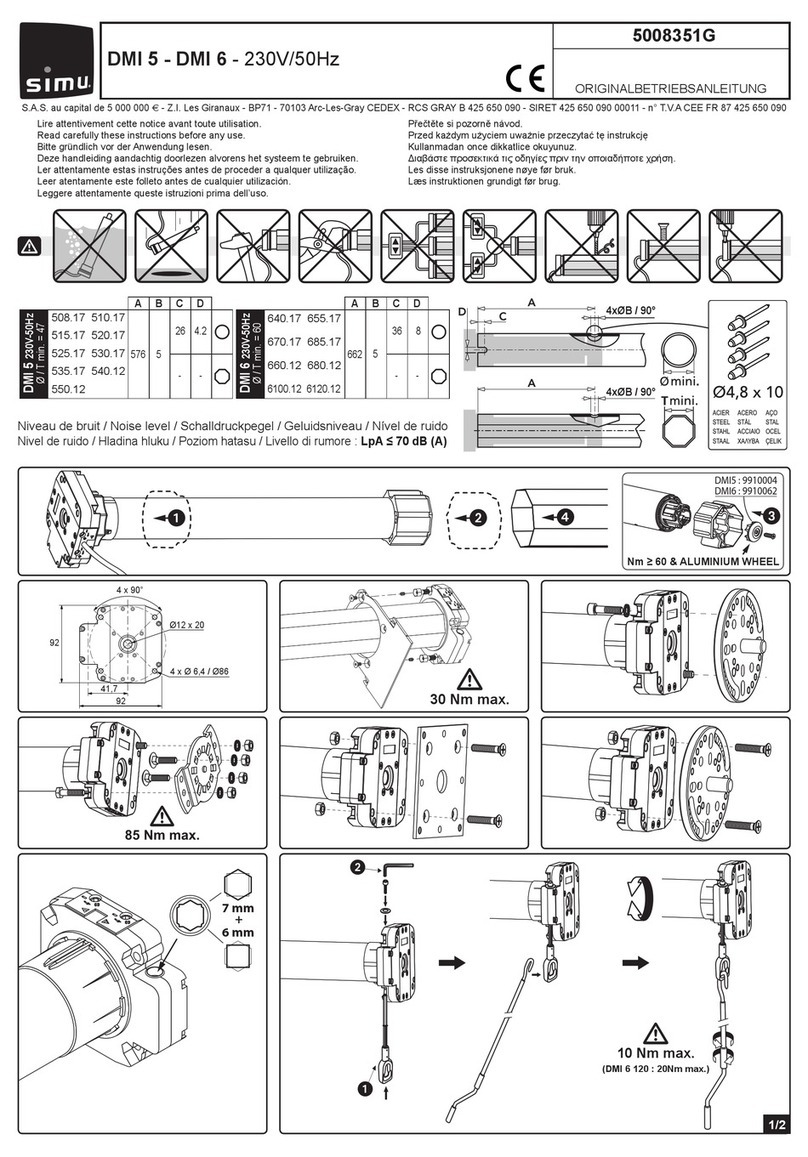

Chapter 3 Installation and Wire Connection························································23

3.1 Mechanical installation··················································································23

3.2 Standard wiring···························································································24

3.3 EMC Installation Instruction ···········································································35

Chapter 4 Operation and operation examples ·····················································39

4.1 Initial power-up ···························································································39

4.2 Inverter operation ························································································40

4.3 Keypad introduce·························································································42

4.4 Display status ·····························································································45

4.5 Keypad operation ························································································48

Chapter 5 Function Code Table········································································· 51

3

5.1 Property description·····················································································51

5.2 Function code table······················································································51

Chapter 6 Detailed Function Parameter Description·············································91

Group P0 Standard Function Parameter································································91

Group P1 Start/Stop Parameter ········································································· 101

Group P2 Auxiliary Functions ············································································ 106

Group P3 Input Terminals··················································································118

Group P4 Output Terminals··············································································· 132

Group P5 V/F curve parameters ········································································ 140

Group P6 PID Function parameters···································································· 145

Group P7 Operation Panel and Display······························································· 152

Group P8 Motor Parameters ············································································· 155

Group P9 Vector Control Parameters·································································· 158

Group PA Fault and Protection ·········································································· 164

Group Pb Multi-Reference and Simple PLC Function ············································· 174

Group PC Communication Parameter·································································177

Group Pd Function Code Management ······························································· 177

Group PE Swing Frequency, Fixed Length and Count············································· 178

Group PF AI/AO Correction andAI Curve Setting ·················································· 182

Group E0 Ser function code parameter································································ 184

Group E9 Protection function parameter······························································ 185

2nd, 3rd, and 4th motor parameters (E3, E4, E5 groups)········································· 188

Monitoring parameter group-operation parameter monitoring (group b0))·················· 188

Chapter 7 Fault Diagnosis and Processing······················································· 189

7.1 Failure Phenomena and Countermeasures ····················································· 189

7.2 Fault Record Query···················································································· 193

7.3 Fault Reset ······························································································ 193

4

Chapter 8 Maintenance and Maintenance e······················································· 195

8.1 Daily maintenance and Maintenance ····························································· 195

8.2 Periodic Preservation and Maintenance·························································· 195

8.3 Warranty Description·················································································· 196

Chapter 9 Serial Port RS485 Communication Protocol······································· 198

9.1 Communication Overview············································································ 198

9.2 Communication Protocol Description······························································ 198

9.3 Communication Protocol ············································································ 200

Chapter 10 Appendix····················································································· 208

5

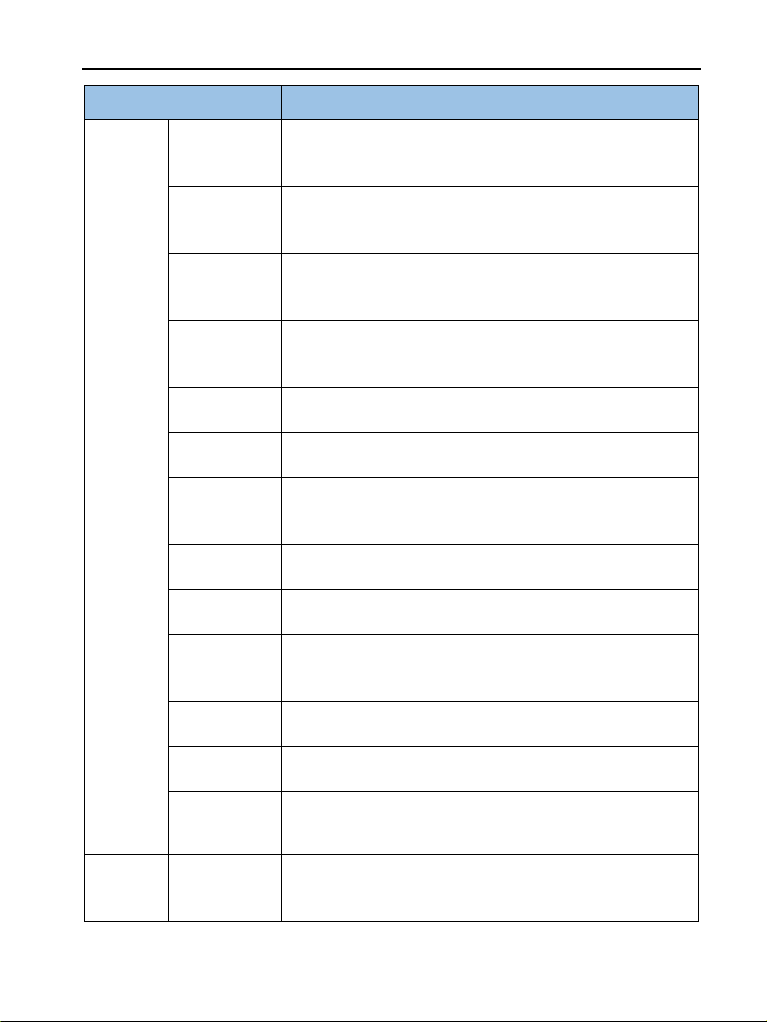

Chapter 1 Precautions

1.1 Safety Precautions

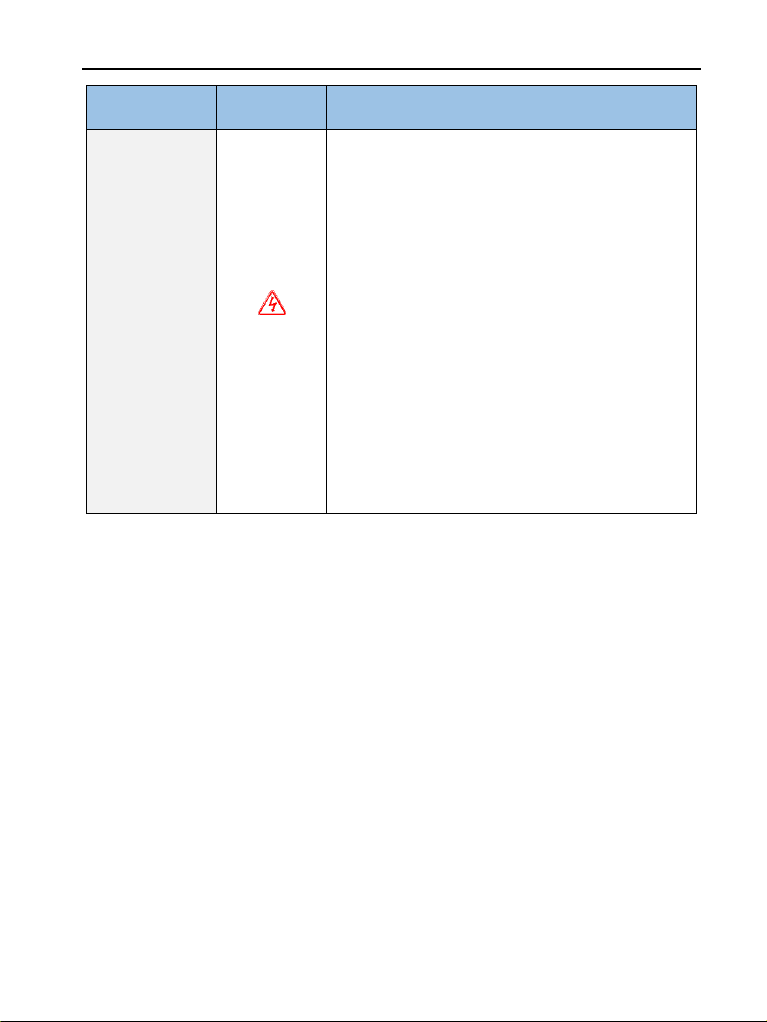

The use phase

Safety class

Precaution

Before

Installation

Danger

Do not install the product if the package is with

water, or component is missing or broken;

Do not install the product if the label on the

package is not identical to that on the inverter.

Caution

Be careful of carrying or transportation. Risk of

devices damage.

Do not use damaged product or the inverters

missing component. Risk of injury.

Do not touch the parts of control system with

bare hands. Risk of ESD hazard.

Installation

Danger

Installation base shall be metal or other

non-flammable material. Risk of fire.

Do not install inverter in an environment

containing explosive gases, otherwise there is

danger of explosion.

Do not unscrew the fixing bolts, especially the

bolts with red mark.

Caution

Do not leave cable strips or screws in the

inverter. Risk of inverter damage.

Install the product at the place with less vibration

and no direct sunlight.

Consider the installation space for cooling

purpose when two or more inverters are placed

in the same cabinet.

6

The use phase

Safety class

Precaution

Wiring

Danger

Wiring must be performed by authorized and

qualified personnel. Risk of danger.

Circuit-breaker should be installed between

inverter and the mains. Risk of fire.

Make sure the input power supply has been

completely disconnected before wiring. Failure to

comply may result in personnel injury and/or

equipment damage.

Since overall leakage current of this equipment

may be bigger than 3.5mA, for safety's sake, this

equipment and its associated motor must be well

grounded so as to avoid risk of electric shock.

Never connect the power cables to the output

terminals (U, V, W) of the AC drive. Pay attention

to the marks of the wiring terminals and ensure

correct wiring. Failure to comply will result in

damage to theAC drive.

Install braking resistors at terminals (P+) and (P-

or PB) only. Failure to comply may result in

equipment damage.

Caution

Since all adjustable frequency AC drives from our

company has been subjected to hi-pot test before

delivery, users are prohibited from implementing

such a test on this equipment. Failure to comply

may result in equipment damage.

Signal wires should to the best of the possibility

be away from main power lines. If this cannot be

ensured, vertical cross-arrangement shall be

implemented, otherwise interference noise to

control signal may occur.

If motor cables are longer than 100m, it is

7

The use phase

Safety class

Precaution

recommended outputAC reactor be used.

Failure to comply may result in faults.

Before

Power-on

Danger

Inverter shall be power-on only after the front

cover is assembled. Risk of electrical hazard.

Caution

Verify that the input voltage is identical to the

rated voltage of product, correct wiring of input

terminals R, S, T and output terminals U, V, and

W, wiring of inverter and its peripheral circuits,

and all wires should be in good connection. Risk

of inverter damage.

After Power-on

Danger

Do not open the cover after power. Rick of

electrical hazard.

Do not touches any input/output terminals of

inverter with bare hands. Rick of electrical

hazard.

Caution

If auto tuning is required, be careful of personal

injury when motor is running. Risk of accident.

Do not change the defaults of parameters. Risk

of devices damage.

During

Operation

Danger

Non-professionals shall not detect signals during

operation. Risk of personal injury or device

damage.

Do not touch the fan or the discharging resistor to

check the temperature. Failure to comply will

result in personal burnt.

Caution

Prevent any foreign items from being left in the

devices during operation. Risk of device damage.

Do not control start/stop of inverter by ON/OFF of

contactor. Risk of device damage.

8

The use phase

Safety class

Precaution

Maintenance

Danger

Maintenance and inspection can only be

performed by professionals. Risk of personal

injury.

Maintain and inspect devices after power is off.

Risk of electric hazard.

Repair or maintain the AC drive only ten minutes

after theAC drive is powered off. This allows for

the residual voltage in the capacitor to discharge

to a safe value. Failure to comply will result in

personal injury.

All pluggable components can be inserted or

pulled out only when power has been turned off.

Set and check the parameters again after theAC

drive is replaced.

1.2 Precautions for use

When using the DGI900 series inverter, please pay attention to the following points:

1.2.1 Constant torque and low speed operation

When the inverter is running with a normal motor for a long period of low speed, the heat

dissipation effect will be deteriorated, which will affect the life of the motor. If you need

low-speed constant torque for long-term operation, you must use a dedicated inverter

motor.000000000000000000000000000

1.2.2 Confirmation of motor insulation

When applying the DGI900 series inverter, please confirm the insulation of the motor before

using the motor to prevent damage to the equipment. In addition, please check the insulation

of the motor regularly when the environment of the motor is bad, to ensure the safe operation

of the system.

1.2.3 Negative torque load

For situations such as lifting the load, there is often a negative torque, and the inverter will

trip if an overcurrent or overvoltage fault occurs. In this case, the optional braking resistor

9

should be considered.

1.2.4 Mechanical resonance point of the load device

The inverter may encounter the mechanical resonance point of the load device within a

certain range of output frequency, and must be avoided by setting the jump frequency.

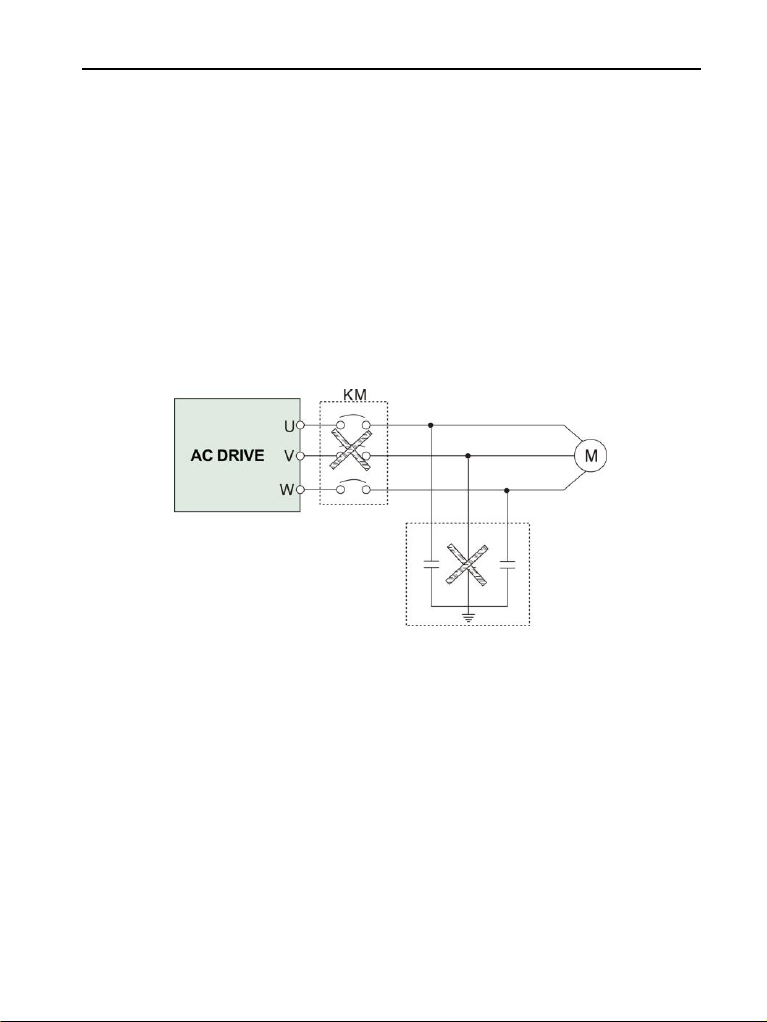

1.2.5 Capacitance or varistor for improving power factor

Since the output voltage of the inverter is pulse wave type, if the output side is equipped with

a capacitor with improved power factor or a varistor for lightning protection, it will cause the

inverter to trip or damage the device. Be sure to remove it, and it is recommended not to be

on the output side. Add switching devices such as air switches and contactors, as shown in

Figure 1-1. (If the output of the inverter must be zero when the output side switch device is

activated)

Figure 1-1 Disabling the capacitor at the output of the inverter

1.2.6 Derate at Basic frequency setting

When the fundamental frequency setting is lower than the rated frequency, please pay

attention to the derating of the motor to avoid overheating of the motor.

1.2.7 Operating at frequencies above 50Hz

If it is operated above 50 Hz, in addition to considering the vibration and noise of the motor, it

is necessary to ensure the speed range of the motor bearings and mechanical devices.

1.2.8 Electronic thermal protection value of the motor

When the adapter motor is selected, the inverter can thermally protect the motor. If the motor

does not match the rated capacity of the inverter, be sure to adjust the protection value or

take other protective measures to ensure the safe operation of the motor.

10

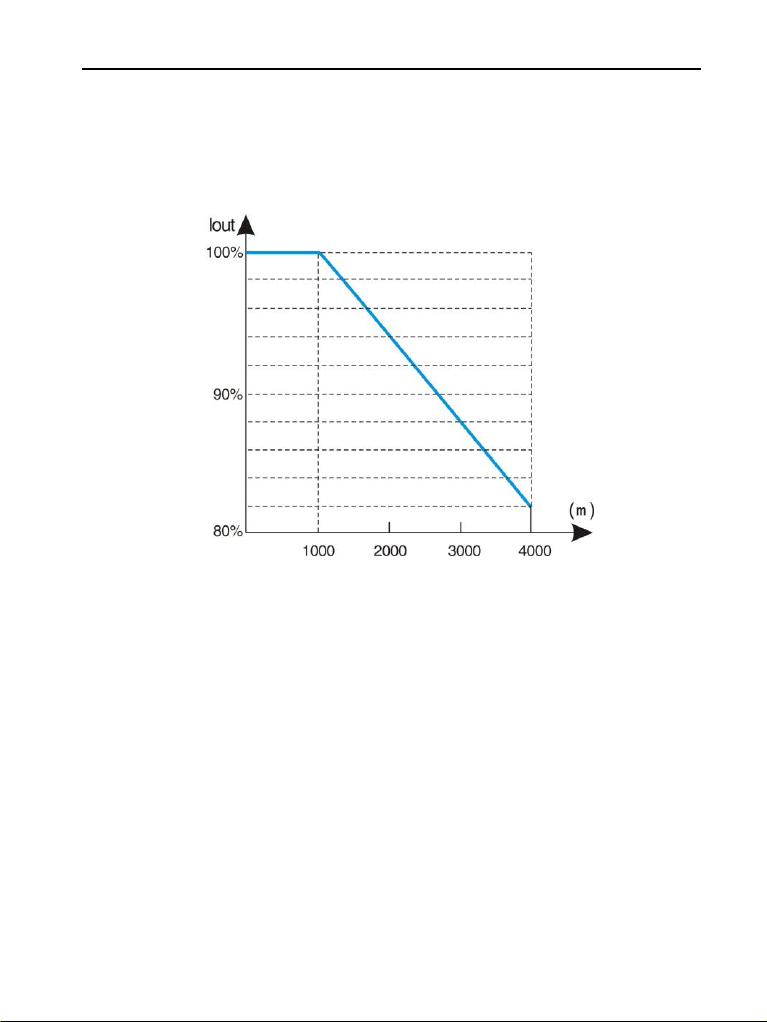

1.2.9 Altitude and derating

In areas where the altitude is more than 1000 meters, the heat dissipation effect of the

inverter is deteriorated due to the thin air, and it is necessary to derate the use. Figure 1-2

shows the relationship between the rated current of the inverter and the altitude.

Figure 1-2 Inverter rated output current and altitude derating diagram

1.2.10 About the degree of protection

The protection level IP20 of the DGI900 inverter refers to the degree of protection achieved

when the status display unit or keyboard is selected.

1.3 Disposal considerations

When scrapping the inverter, please note:

The electrolytic capacitor of the main circuit and the electrolytic capacitor on the printed

circuit board may explode when incinerated. Poisonous gas is generated when plastic parts

are incinerated body. Please treat as industrial waste.

11

Chapter 2 Product Introduction

2.1 Naming rules

2.1 Nameplate information

Below the right side panel of the inverter, a nameplate indicating the inverter model and

rating is attached. The meanings are as follows:

Voltage

Code

220V

2

380V

4

Input voltage

Code

Single phase

S

Three phases

T

Code

Inverter type

G

Constant torque

P

Pump& Fan

Code

Power rate

0007

0.75KW

0015

1.5KW

0075

7.5KW

Fig 2-1. Models description

Abbreviatio

n

DGI900-4 T 0015 G

12

Fig 2-2. Name Designation Rules

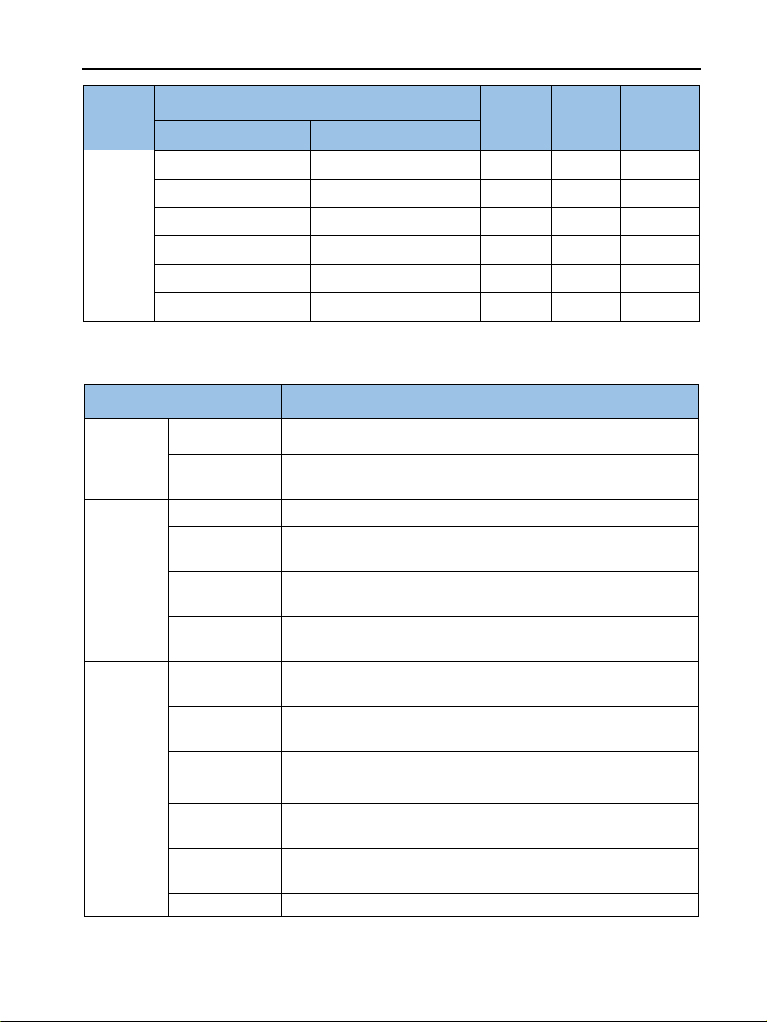

2.3 Series and Models

Voltage

level

Model

Rated

capacity

(KVA)

Rated

output

Current

(A)

Applicable

Motor

(KW

)

GType

PType

380V

Three

phase

DGI900-4T0007G

DGI900-4T0015P

1.5

2.5

0.75

DGI900-4T0015G

DGI900-4T0022P

2.5

4.0

1.5

DGI900-4T0022G

DGI900-4T0022P

3.0

6.0

2.2

DGI900-4T0037G

DGI900-4T0037P

5.9

9.6

3.7

DGI900-4T0055G

DGI900-4T0055P

8.5

14.0

5.5

DGI900-4T0075G

DGI900-4T0075P

11

17.0

7.5

DGI900-4T0110G

DGI900-4T0110P

17

25

11

DGI900-4T0150G

DGI900-4T0150P

21.7

32

15

DGI900-4T0185G

DGI900-4T0185P

25.7

39

18.5

DGI900-4T0220G

DGI900-4T0220P

29.6

45

22

DGI900-4T0300G

DGI900-4T0300P

39.5

60

30

DGI900-4T0370G

DGI900-4T0370P

49.4

75

37

DGI900-4T0450G

DGI900-4T0450P

60

91

45

DGI900-4T0550G

DGI900-4T0550P

73.7

112

55

DGI900-4T0750G

DGI900-4T0750P

99

150

75

DGI900-4T0900G

DGI900-4T0900P

116

176

90

DGI900-4T1100G

DGI900-4T1100P

138

210

110

DGI900-4T1320G

DGI900-4T1320P

167

253

132

DGI900-4T1600G

DGI900-4T1600P

200

304

160

DGI900-4T1850G

DGI900-4T1850P

234

355

187

DGI900-4T2000G

DGI900-4T2000P

248

377

200

DGI900-4T2200G

DGI900-4T2200P

280

426

220

DGI900-4T2500G

DGI900-4T2500P

318

474

250

DGI900-4T2800G

DGI900-4T2800P

342

520

280

DGI900-4T3150G

DGI900-4T3150P

390

600

315

13

Voltage

level

Model

Rated

capacity

(KVA)

Rated

output

Current

(A)

Applicable

Motor

(KW

)

GType

PType

DGI900-4T3500G

DGI900-4T3500P

435

660

350

DGI900-4T4000G

DGI900-4T4000P

493

750

400

DGI900-4T4500G

DGI900-4T4500P

560

850

450

DGI900-4T5000G

DGI900-4T5600P

625

860

500

DGI900-4T5600G

DGI900-4T6300P

691

990

560

DGI900-4T6300G

DGI900-4T7100P

770

1100

630

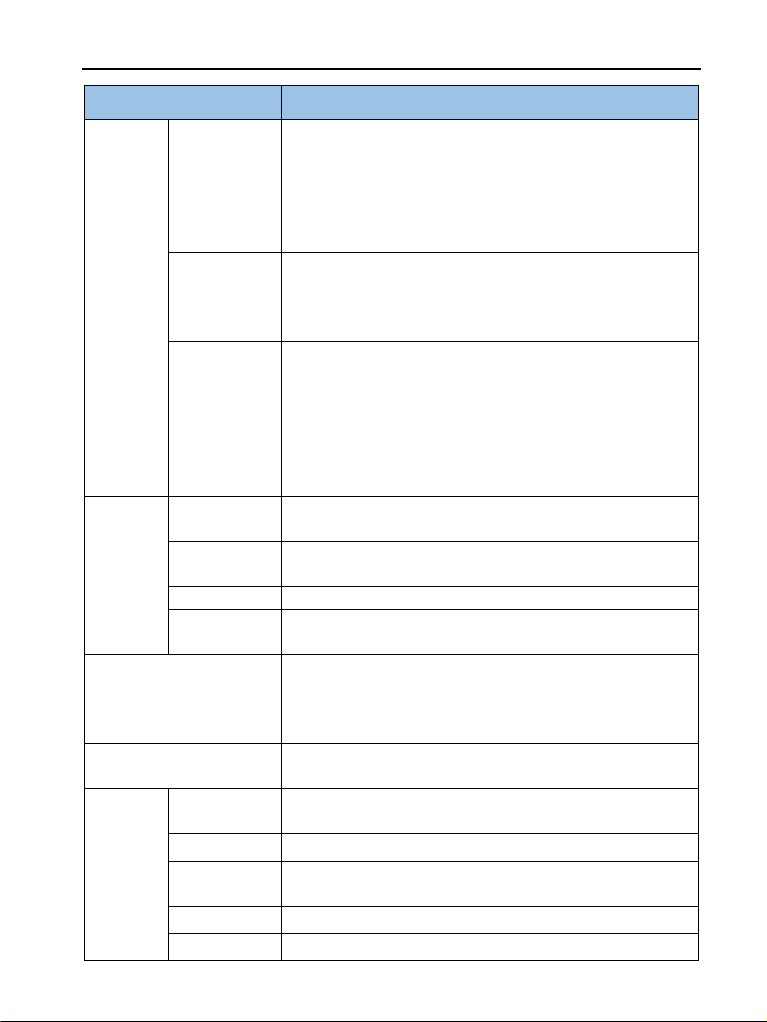

2.4 Specifications

Items

Specifications

Input

Rated Voltage

Three phase 380V / 415V / 440V/460V; 50Hz/60Hz

Range

Voltage: ±20% voltage unbalance rate:<3%; frequency:

±5%

Output

Rated voltage

0~380V / 415V / 440V/460V

Frequency

range

0Hz~5000Hz

Frequency

resolution

0.01Hz

Overload

ability

150% rated current for1minute, 180% rated current for3

seconds

Control function

Control

function

Torque control

accuracy

±5%(FVC)

Control mode

V/F, Sensorless vector control (SVC), Speed Sensor vector

control (FVC)

Frequency

accuracy

Digital setting: The highest frequency×±0.01% Analog

setting: The highest frequency ×±0.2%

Frequency

resolution

Digital setting: 0.01Hz; Analog setting: The highest

frequency×0.1%

Start

frequency

0.40Hz~20.00Hz

Torque boost

Auto torque boost, manual torque boost 0.1%~30.0%

14

Items

Specifications

V/F curve

Five ways: constant torque V/F curve, 1 kind of user defined

V/F curve ,3 kinds of down torque curve (2.0/1.7/1.2times

the power)

Acc./Dec.

curve

Two ways: linear Acc./Dec., S-curve Acc./Dec.;7 kinds of

Acc./Dec. time, Time unit(minute/second) optional, max.

time: 6000 minutes.

DC braking

DC Braking Frequency: 000Hz~ Max Frequency

Braking Time: 0.0s~36.0s

Braking Action Current Value: 0.0%~100.0%

Energy

consuming

braking

Below 22KW drive built-in energy consuming braking unit,

30-37KW built-in braking unit optional, external braking

resistor is optional.

Jog running

Jog frequency range:0.1Hz~50.00Hz, JOG Acc./Dec. time:

0.1~60.0s

Build-in

Double PID

Easily constitute a close loop control system

Multi-stage

speed

running

Max 16 multi-stage speed running via build-in PLC or

control terminals

Textile swing

frequency

Swing frequency available with preset and central

frequency adjustable

Auto voltage

regulation

Keep a stable voltage automatically when the grid voltage

transients

Auto energy

saving

running

Saving energy by auto optimizing V/F curve according to

the load

Auto current

limiting

Auto current limiting to prevent frequent over current fault

trip

Multi pumps

control

With water supply card, the function can implement multi

pumps constant pressure water supply

Communicati

on

4 field bus: Modbus, Profibus, CANlink, CANopen

Running

command

channel

Control panel: control terminal :serial port :3 channels

switchable

15

Items

Specifications

Running

function

Frequency

setting

channel

Control panel potentiometer setting: ▲、▼control panel

keys setting; Function code setting: Serial port setting;

Terminal up/down setting: Input Analog voltage setting:

Input Analog current setting: Input pulse setting;

Combination ways setting;

Above ways are switchable.

Input channel

8 digital input terminals, 1 of which supports up to 100KHZ

high speed pulse input

2 analog input terminals, 1 support 0~10V voltage input

1 support 0~10V voltage input or 0~20mA current input

Output

channel

1 high-speed pulse output terminal (optional open collector

type), supporting square wave signal output of 0~100Khz

1 digital output terminal

2 relay output terminals (≥5.5kw), one relay below 5.5kw

2 analog output terminals, support 0~20mA current output

or 0~10V voltage output (≥5.5kw 2 terminals) <5.5kw 1

terminal

Control panel

LED digital

display

Display setting frequency, output voltage, output current,

etc.

External

meter display

Display output frequency, output current, output voltage,

etc.

Key lock

All the keys can be locked

Parameter

copy

Function code parameters can be copied between

inverters when use remote control panel

Protection function

Over current tprotection:

overvoltageprotection:undervoltageprotection:overheating

protection: overload protection, etc.

Input phase loss protection ( model>2.2kw)

Optional parts

Braking unit: remote control panel: cable: panel mounting

feet, etc.

Environment

Environment

Indoors, free from direct sunlight, dust, corrosive gas, oil

mist, steam, water dropper salt, etc

Altitude

Lower than 1000m (derating is necessary above 1000m)

Ambient

temperature

-10℃~+40℃

Humidity

<90%RH, no condensation

Vibration

Lower than 5.9m/s (0.6g)

16

Items

Specifications

Storage

temperature

-20℃~+60℃

Structure

Protection

level

IP20(In the selection of state display unit or the keyboard

state)

Cooling

Forced air cooling

Installation

Wall mounted; Floor mounted

2.5 Products apperance

Fig 2-3 parts of Inverter

17

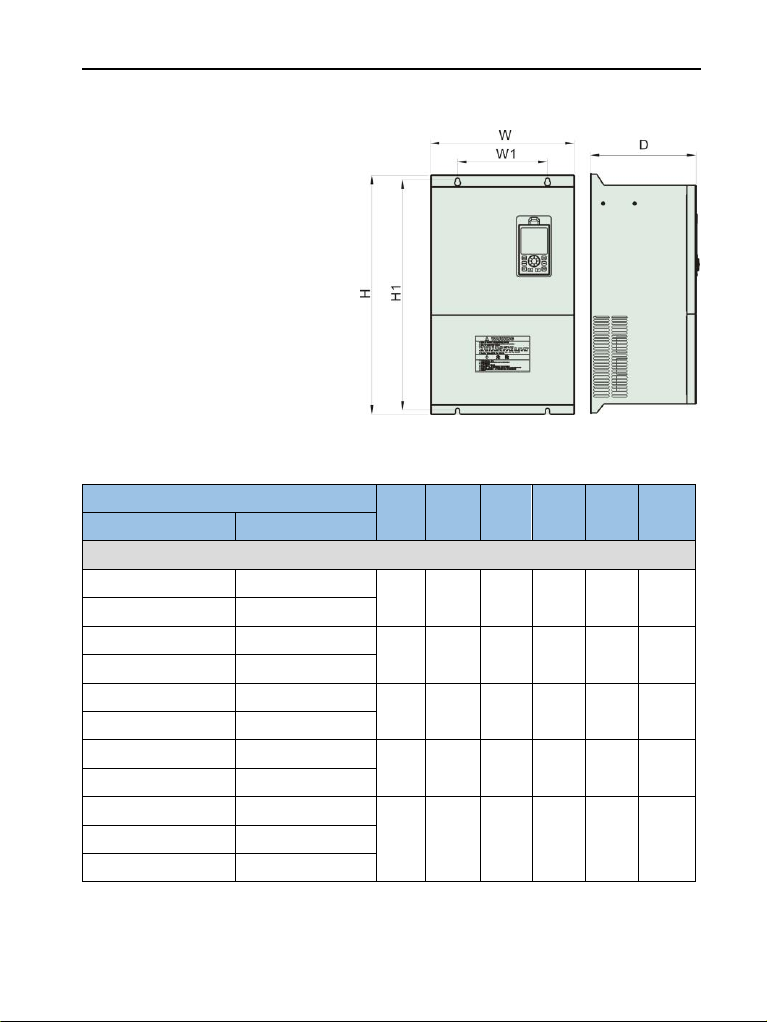

2.6 Installation size

2.6.1 0.75~7.5KW (Wall mounting)

Inverter Model

W1

(mm)

W

(mm)

H1

(mm)

H

(mm)

D

(mm)

Mount

hole

G Type

P Type

DGI900 series/Input voltage: 220V single phase

DGI900-2S0004G

74

85

144

142

113

Φ5

DGI900-2S0007G

DGI900-2S0015G

DGI900-2S0022G

88

98

174

184

135

Φ5

DGI900 series/Input voltage: 380V three-phase

DGI900-4T0007G

DGI900-4T0015P

90

104

177

190

148

Φ5

DGI900-4T0015G

DGI900-4T0022P

DGI900-4T0022G

DGI900-4T0037P

116

130

223

236

175

Φ5

DGI900-4T0037G

DGI900-4T0055P

DGI900-4T0055G

DGI900-4T0075P

155

172

256

271

183

Φ5

DGI900-4T0075G

DGI900-4T0110P

Fig 2-4

18

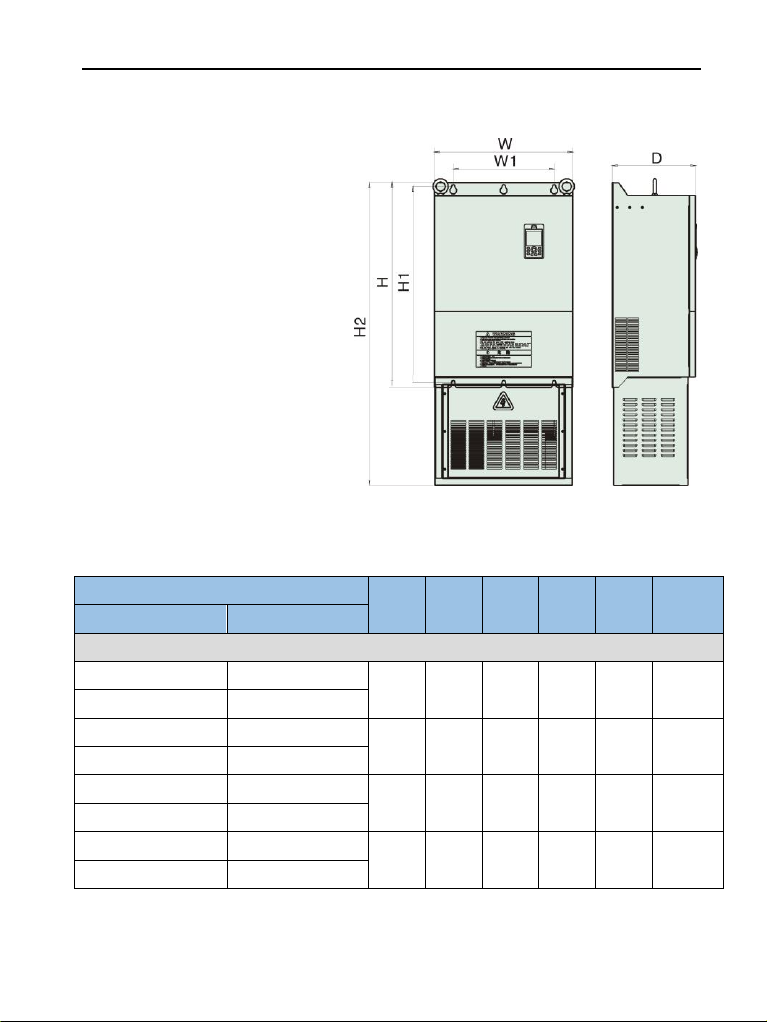

2.6.2 11~90KW (Wall mounting)

Inverter Model

W1

(mm)

W

(mm)

H1

(mm)

H

(mm)

D

(mm)

Mount

hole

G Type

P Type

DGI900 series/Input voltage: 380V three-phase

DGI900-4T0110G

DGI900-4T0150P

170

226

310

325

190

Φ6

DGI900-4T0150G

DGI900-4T0185P

DGI900-4T0185G

DGI900-4T0220P

200

280

427

445

200

Φ6

DGI900-4T0220G

DGI900-4T0300P

DGI900-4T0300G

DGI900-4T0370P

200

320

512

530

235

Φ8

DGI900-4T0370G

DGI900-4T0450P

DGI900-4T0450G

DGI900-4T0550P

250

310

530

555

260

Φ10

DGI900-4T0550G

DGI900-4T0750P

DGI900-4T0750G

DGI900-4T0900P

280

400

620

650

300

Φ14

DGI900-4T0900G

DGI900-4T1100P

DGI900-4T1100G

DGI900-4T1320P

Fig 2-5

19

2.6.3 132~250KW (Wall mounting)

Inverter Model

W1

(mm)

W

(mm)

H1

(mm)

H

(mm)

D

(mm)

Mount

hole

G Type

P Type

DGI900 series/Input voltage: 380V three-phase

DGI900-4T1320G

DGI900-4T1600P

280

450

756

790

300

Φ14

DGI900-4T1600G

DGI900-4T1850P

DGI900-4T1850G

DGI900-4T2000P

P P P P G

280

550

776

810

330

Φ14

DGI900-4T2000G

DGI900-4T2200P

PP G

DGI900-4T2200G

DGI900-4T2500P

G

480

640

776

810

350

Φ14

DGI900-4T2500G

DGI900-4T2800P

G

DGI900-4T2800G

DGI900-4T3150P

G

500

720

1150

1200

372

Φ20

DGI900-4T3150G

DGI900-4T3500P

G

Fig 2-6

Other manuals for DGI900

1

This manual suits for next models

61

Table of contents

Other degdrive DC Drive manuals

Popular DC Drive manuals by other brands

Simu

Simu DMI 6 Original instructions

Bodine

Bodine BSL06T3FL installation instructions

Bosch

Bosch Active Line Plus BDU 350 Original operating instructions

ZF-DUOPLAN

ZF-DUOPLAN 2K800 operating instructions

Siemens

Siemens COMBIMASTER 411 operating instructions

Eaton

Eaton PowerXL DM1 Series Applications manual

Canworld

Canworld CDE360 Series manual

Rockwell Automation

Rockwell Automation Allen-Bradley PowerFlex 700 Series Migration guide

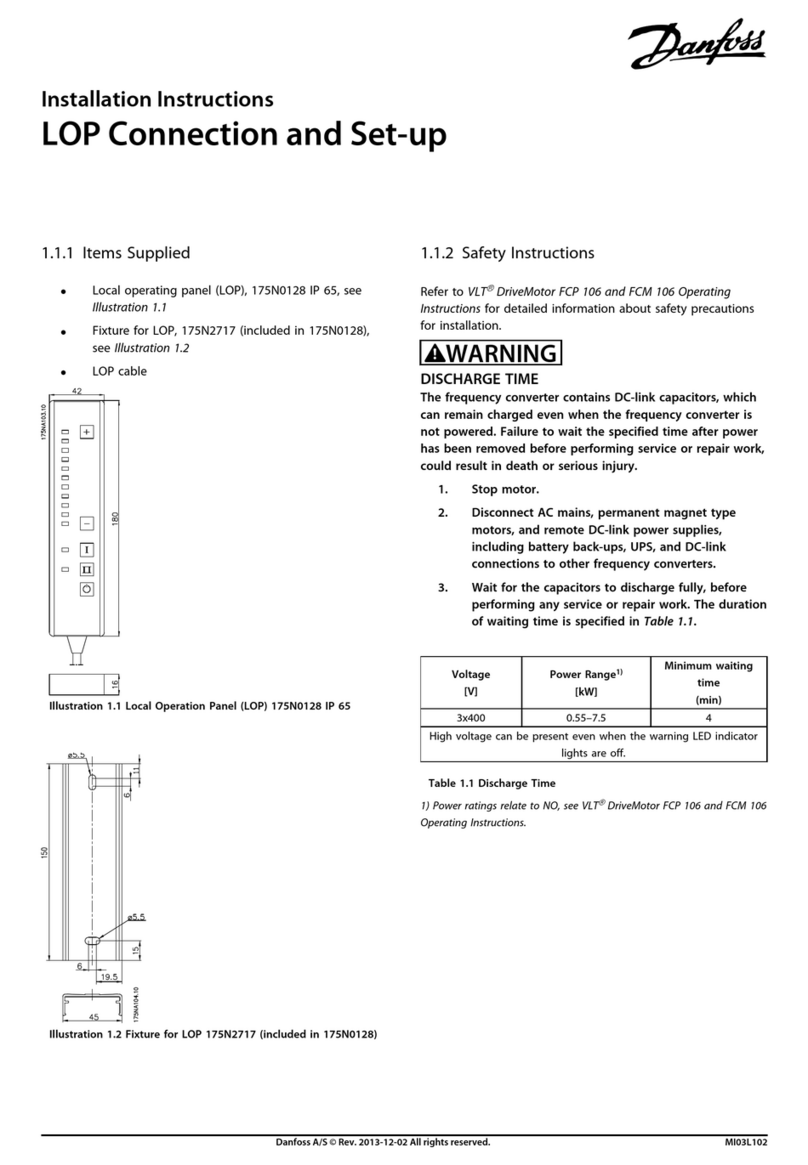

Danfoss

Danfoss VLT DriveMotor FCP 106 installation instructions

GFA

GFA ELEKTROMAT SI 40.24-40,00 installation instructions

gefran

gefran ADV200-HC instruction manual

Eaton

Eaton PowerXL DC1 manual