DEL RollEasy2 Owner's manual

RollEasy2

AUTOMATIC ABOVE-GROUND COVER

TECHNICAL INSTRUCTIONS Installation / Use / Cleaning / Maintenance / Safety advice

2

information

NOTICE TO BE GIVEN TO THE USER AFTER INSTALLATION IS COMPLETE

PLEASE READ CAREFULLY AND KEEP IN A SAFE PLACE.

Electric and solar versions

The motor is located in the stand and can be accessed from inside the housing.

The power supply comes from an electric box located in the technical room, or from 2 batteries

placed in the terminal on the motor side for the solar version.

The automatic stops are adjusted directly on the motor.

Manual version

Rolling and unrolling operations are carried out using the removable wheel.

The cover is composed of watertight PVC articulated

slats that float on the surface of the water.

Currently covers with overflows and covers with removable steps on the side are not

compliant with standard NF P 90-308.

Unless otherwise specified by the manufacturer, immersion alarms are not compatible

with roll-Easy 2 covers.

1

2 3

3

information

-The motor (compliant with electric standards) is located in the tube and can

be accessed from the exterior of the terminal.

- Adjustment of the “mechanical automatic stop” locking the cover in place once

it has been fully unrolled or rolled, is done

directly on the motor.

- Solar version: The solar panel and batteries are built into the tube fitted.

- Electric version: The electrical control box is fitted in a technical room close to

the pool. (see page 13 for the box size)

Slats:

- The cover itself is made from unleaded PVC slats (this material conforms to

anti-ageing requirements as defined in the NF T 54 405-1 Standard), they are

watertight and hinged and will float on the surface of the water.

- The gap between the side and the cover must be <= 70 mm.

- The cover is connected to the tube using white straps that are attached to the

first slat of the cover.

- There are fixture straps at the start and end of the cover used to fix the cover

to the fastening kit fixed to the side of the pool.

Fastening kits:

1-Push-lock 2-Quick-Lock 3-Passe-sangle

3 fixture modes: (surface mount – insert mount – hanging mount)

- The fastening kits are positioned on each width of the pool.

(the number varies depending on the pool configuration)

- These fastening systems are triggered by a tool or a double action.

Optional:

- “Chlorinator coupling” (electric version only):

Connected to the roller and chlorinator control box, this option is used

to automatically reduce chlorine production when the pool is closed in order

to avoid excess chlorine in the water.

Cover control:

- Wi-Key “wireless”

Or

- Key switch

x1 x1 x1

x1

x6

x6 x4 x4 x2

x1

x8 x6 x12 x8

x1x1

x6

x6 x4 x6x8 x1

x2

x1 x1

x4

4

DELIVERED PARTS

Slats (variable number of packs) Locking kits (1 pack)

Free

terminal

Electric

terminal

or or

Solar

terminal

Manual

terminal

3 fastener models:

surface mounted – insert mounted – hanging mounted

69 mm Slats

Electric box

Motor

Motorised roller

stand

Manual roller

stand

or

or or

Electric or solar version assembly pack

Lag screw

M8x80

Ø12

Plug

THEF screw

M8x30

TBHC screw

M6x30

TF screw

M3x16

adjustment

ring

M6 Ø12x1.2

washer

M8 Ø24x2

washer

M6 Nut M8 nut

Wrench

pen

Male Allen key

size 4

2

wrenches and

a keyring in

the document

bag

Manual version assembly pack

Lag screw

M8x80

Ø12

Plug

THEF screw

M8x30

M8 Ø24x2

washer

M8 nut

Male Allen key

size 4

electric version

battery

solar version

battery

charger

solar version

wheel

manual version

M6 wavy

washer

Description

T22

Ø8 - 12

5

PACKING LIST

e.g. - for a 4 x 8 m pool

1 0.80 x 0.60 x 0.55 pallet —- 40kg

1 4.30 x 0.20 m pack —– 25 kg

4 5 x 0.25 x 0.20 m packs —– 150 kg

Total weight: 205 Kg

ASSEMBLY INSTRUCTIONS

3 hours

TOOLS REQUIRED FOR ASSEMBLY (INSTALLATION – 2 PERSONS)

information

AB

A = B

6

x2 x4

x8

x4

1

2

60 cm max

Quicklock :

15 cm mini

15 cm mini

Quick-lock

6

60 cm max

Quicklock :

15 cm mini

ASSEMBLING AND FIXING THE ROLLER

Installation

Centre of the pool

Remove the terminal door.

Free side

Free side Free side

Free side

Motor side

Motor side

Motor side

Wheel side

Stand Stand

x2

THEF screw

M8x30

x4

M8 nut

x10

M6 nut

x4

TBHC screw

M6x30

only for the electric and solar versions on the

motor side

Assembling and placing the roller on the pool

assembling the terminals

Solar and electric version Manual version

Sharp corner

Rounded corners or

Filtration unit or other

Ø12

x3

x3

x2

x1

x8

x3

x4 x4

7

Installation

Free side

Lag screw

M8x80

Ø12

Plug

TF screw

M3x16

adjustment

ring

M6 Ø12x1.2

washer

M6 Ø12x1.2

washer

M8 Ø24x2

washer

M6 nut

Solar and electric version

Fixture of the roller to the ground

Installing the motor (electric and solar version)

Make small rotating

movement with the motor to

facilitate the insertion

align the key with the notch

21

3

4

8

ELECTRIC VERSION WIRING

Installation

230 V Power supply

(Sheathed RO2V)

2 x 4 mm² - up to 16 m in length.

2 x 6 mm² - from 16 to 25 m in length.

The electric box must be fitted in a dry place.

The installation must be compliant with standard C15-

100.

(Last applicable version) ask your electrician for advice

or ask your electricity provider)

All our boxes have a single phase 230 Volt (50Hz)

power supply.

The power required at the input terminals is 0.15 Kw.

A suitably sized circuit breaker must be fitted before the

junction box and equipped with a 30 mA ground fault

system.

21

3

4

9

ELECTRIC VERSION WIRING

Installation

10

21

3

4

-+ F

CO

Installation

WIRING - SOLAR VERSION - WI-KEY

230 V Power supply

(Sheathed RO2V)

2 x 4 mm² - up to 16 m in length.

2 x 6 mm² - from 16 to 25 m in length.

The electric box must be fitted in a dry place.

The installation must be compliant with standard C15-

100.

(Last applicable version) ask your electrician for advice

or ask your electricity provider)

All our boxes have a single phase 230 Volt (50Hz)

power supply.

The power required at the input terminals is 0.15 Kw.

A suitably sized circuit breaker must be fitted before the

junction box and equipped with a 30 mA ground fault

system.

11

++

--

21

3

4

-+ F

CO

Installation

WIRING - ELECTRIC VERSION - WI-KEY

12

INSTALAÇÃOInstallation

WI-KEY INSTALLING THE CONTROL BOX

- It must be located in a place from which it is possible to check

that no one enters the pool during the manoeuvre.

- It is mandatory to install the locking «strip».

- Before fixing the control box, check that the emitter is

communicating with the receiver.

”if the motor does not run => check the power supply polarity

The support must be attached to a fixed support

Closing

Opening Stops the current action

Keyboard lock

red / green flashing = emitter locked

Emitter unlocking procedure see «page 27»

The emitter must be located outside volume 0.

The distance between the emitter and the receiver must not exceed:

- 50 m in an obstacle-free zone.

- 25 m behind a basic wall.

- 15 m behind several walls or an especially thick wall.

13

1

2

45°

INSTALAÇÃOInstallation

Slat assembly

COVER INSTALLATION

skid

Cover start (“début de volet”) pack

Steps (“escalier”) pack

End of cover (“fin de volet”) pack

“CLICK”

along the whole

length of the slat

Repeat the movement until all the slats are completely clipped together

Make sure the slats are in the right direction

Roller

water

By clipping

By sliding

remove the cap

35 cm

If necessary, cut

the sides to ease

the passage of the

cover and avoid

rubbing

strap

14

Installation

notch

skid assembly

The skids are used to orient the cover at the start of closure.

The holes are drilled at the factory.

Assembly of the strap between the cover and the tube

The surface to

be glued must

be clean and

dry

I

0

II

I

0

II

1

2

3

4

15

Installation

Command logic verification

Adjustment

AUTOMATIC STOP ADJUSTMENT

The arrows indicate the cover’s

direction of movement

Turning in the +direction increases the extension of the cover

Turning in the -direction decreases the extension of the cover

If the command logic is incorrect,

reverse cables 1 and 2 on

the motor output.

(see wiring diagram)

Opening the

cover

Closing the

cover

x* х х х

хх х х х х х х

х

16

Installation

The positions of the locking kits on the

pool are shown on the plans delivered

with the slats.

OF THE LOCKING KITS

Positioning rules

Any changes to the positions of the locking kits must follow the rules explained below.

Please contact us for any other cases.

Without

step unit With Roman

step unit

kit at the end

of a roman

step unit

2 kits at max

50 cm from

the edge

kit at max 50 cm

from the edge

1 kit centred if < 1 m

1 kit at 50 cm from the edge if < 2 m

2 kits if > 2 m

* X must never exceed 2 m

With side

step unit

With straight

or

diagonal

step unit

Ø8 17

5 cm

mini

For concrete and panel pools

PUSH-LOCK INSTALLATION

For concrete and panel pools

50 mm

water level

Acceptable limit of

level variation

50 mm

Hang mounted version

Insert mounted model

Installation

A water level regulator is mandatory

50 mm

50 mm

recommended

5 cm

mini

50 mm

50 mm

For concrete and concrete block pools, as well as pools with

wall thickness greater than or equal to 8 mm

Surface mounted model

60 mm “minimum” Once the resistance

point has been

reached stop screwing,

this would deteriorate

the fixture quality.

Concrete

After reaching the

resistance point, make

3 more turns of the

screwdriver

to finish tightening.

Concrete block

Plug

Washer Washer

5 cm

Ø8

VBA TF Torx

stainless steel A4 Ø6

x 50 wood screw

Screw cap

Hollow white

Ø16 washer

Inserted

part

Screw cap

Hang mount support

Ø12 Nylon

plug

Stainless steel nut

A4 M10

Cale

13 mm

VBA TF Torx

stainless steel A4

Ø6 x 50 wood screw

Hollow white

Ø16 washer

INOX

M6 washer

water level

Acceptable limit of

level variation

recommended

water level

Acceptable limit of

level variation

recommended

Universal 8 x 40 plug

VBA TF Torx stainless

steel A4 Ø6 x 50 wood

screw

Hollow white Ø16

washer

Screw cap

Ø8

18

INSTALLATION QUICK-LOCK

A water level regulator is mandatory

5 cm

mini

VBA TF Torx

stainless steel A4 Ø6

x 50 wood screw

Hollow white

Ø16 washer

Inserted

part

adjustement

For concrete and panel pools

5 cm

5 cm

For concrete and panel pools

5 cm

5 cm

5 cm

mini

5 cm

5 cm

For concrete and concrete block pools, as well as pools with

wall thickness greater than or equal to 8 mm

5 cm

Ø8

60 mm “minimum”

Plug

Washer

Once the resistance

point has been

reached stop screwing,

this would deteriorate

the fixture quality.

Concrete

After reaching the

resistance point, make

3 more turns of the

screwdriver

to finish tightening.

Washer

Concrete block

water level

Acceptable limit of

level variation

recommended

water level

Acceptable limit of

level variation

recommended

water level

Acceptable limit of

level variation

recommended

Hang mounted version

Insert mounted model

Surface mounted model

Hang mount support

Ø12 Nylon

plug

Stainless steel nut

A4 M10

adjustment

VBA TF Torx stainless steel

A4 Ø6 x 50 wood screw

Hollow white Ø16

washer

Cale

13 mm

Inox M6 washer

Universal 8 x 40 plugs

adjustment

VBA TF Torx stainless

steel A4 Ø6 x 50 wood

screw

Hollow white Ø16

washer

Installation

Ø8 19

INSTALLATION PASSE-SANGLE

A water level regulator is mandatory

5 cm

mini

5 cm

mini

For concrete and panel pools

For concrete and panel pools

For concrete and concrete block pools, as well as pools with

wall thickness greater than or equal to 8 mm

5 cm

5 cm

5 cm

60 mm “minimum”

Plug

Washer

Once the resistance

point has been

reached stop screwing,

this would deteriorate

the fixture quality.

Concrete

After reaching the

resistance point, make

3 more turns of the

screwdriver

to finish tightening.

Washer

Concrete block

5 cm

5 cm

5 cm

Ø8

water level

Acceptable limit of

level variation

recommended

water level

Acceptable limit of

level variation

recommended

water level

Acceptable limit of

level variation

recommended

Hang mounted version

Insert mounted model

Surface mounted model

Universal 8 x 40 plugs

Universal 8 x 40 plugs

VBA TF Torx stainless

steel A4 Ø6 x 50 wood

screw

Hollow white Ø16

washer

VBA TF Torx stainless steel

A4 Ø6 x 50 wood screw

VBA TF Torx stainless steel

A4 Ø6 x 50 wood screw

Hollow white

Ø16 washer

Hollow white Ø16 washer

Inserted

part

Installation

++ +

1

20

INSTALLATION OF THE STRAP-HOLDER ANCHOR EYEBOLT

INSTALLATION OF THE STRAPLOCK STRAP

Centre of the straplock

between

25 et 40 cm

Eyebolt for concrete beach

Eyebolt for wooden beach

depth : 5 cm

depth : 4,5 cm

The head of the

eyebolt must be

higher than the

beach surface

Do not force the eyebolt into a drill

hole of a smaller diameter than this

Cruciform

Ø4 x 25

Protective

sheath

single strap

strap

sheath

staple

loop

Stretch the strap

the cover must touch the

underside of the straplock

Place the strap in position after

the loop and crimp

the 2 strap thicknesses pass inside the stable

double strap

stapleloop

or

Place the sheath around the staple

and heat using a liester

thermostat 5 to 6

Be careful not to burn the strap

Ø20

Ø20

côté mât

Installation

Table of contents

Other DEL Lighting Equipment manuals

Popular Lighting Equipment manuals by other brands

LIVARNO LUX

LIVARNO LUX 970-K manual

Lightmybricks

Lightmybricks LEGO HARRY POTTER THE SHRIEKING SHACK & WHOMPING... installation guide

IMG STAGE LINE

IMG STAGE LINE LED-10SPOT instruction manual

North Light

North Light OCL-573-BR-UK Installation

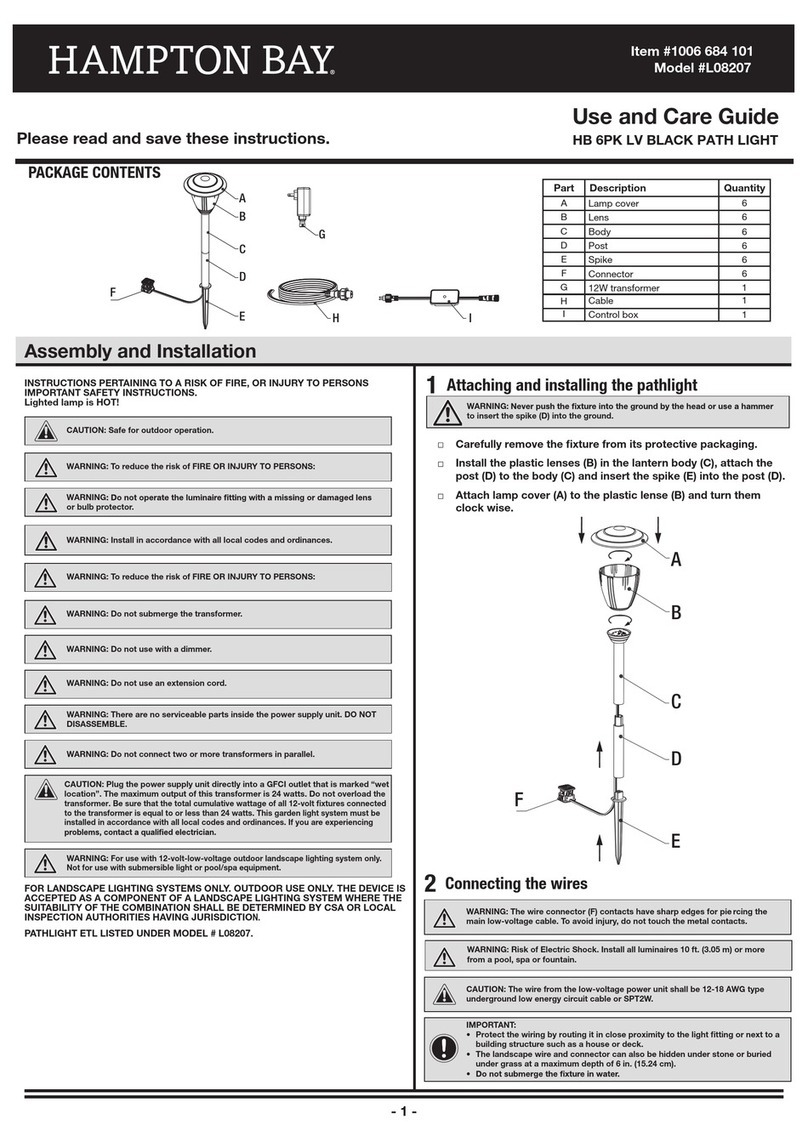

HAMPTON BAY

HAMPTON BAY HB-4133-OR Use and care guide

HAMPTON BAY

HAMPTON BAY L08207 Use and care guide