Delachaux Conductix Wampfler 0831 User manual

Mounting Instructions

Multipole Conductor Rail System

Program 0831

MV0831-0006e-EN

www.conductix.com translated document Page 1 of 32

Order Number

0831xx-…

Contents

1System description......................................................................................................................................................................2

2Intended use ...............................................................................................................................................................................3

3Control components....................................................................................................................................................................4

4Assembly ....................................................................................................................................................................................5

4.1 Adjusting the lengths ...................................................................................................................................................7

4.2 Installation of the fixed point and the hanger clamp ....................................................................................................8

4.2.1 Fixed point ...................................................................................................................................................................8

4.2.2 Hanger clamps ............................................................................................................................................................9

4.2.3 (Optional) safety catching device ..............................................................................................................................12

4.3 Click the conductor rail into its place .........................................................................................................................13

4.4 Position of the end and center feeds .........................................................................................................................14

4.5 Connect the conductor rail.........................................................................................................................................15

4.6 Remedy in case of damaged connecting pins...........................................................................................................22

5Installation of expansion elements............................................................................................................................................23

6Assembly of the current collectors ............................................................................................................................................25

7Screw tightening torques ..........................................................................................................................................................27

8Index .........................................................................................................................................................................................28

9Index of the animations.............................................................................................................................................................32

Mounting Instructions

Multipole Conductor Rail System

Program 0831

MV0831-0006e-EN

www.conductix.com translated document Page 2 of 32

1System description

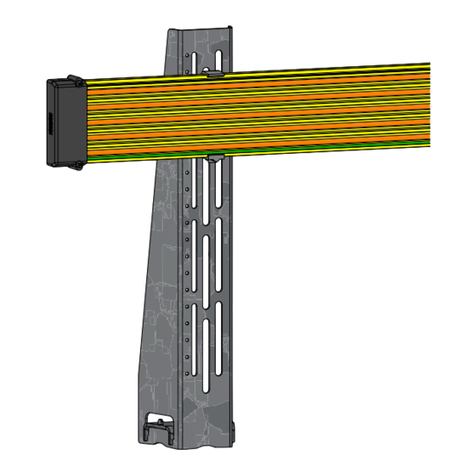

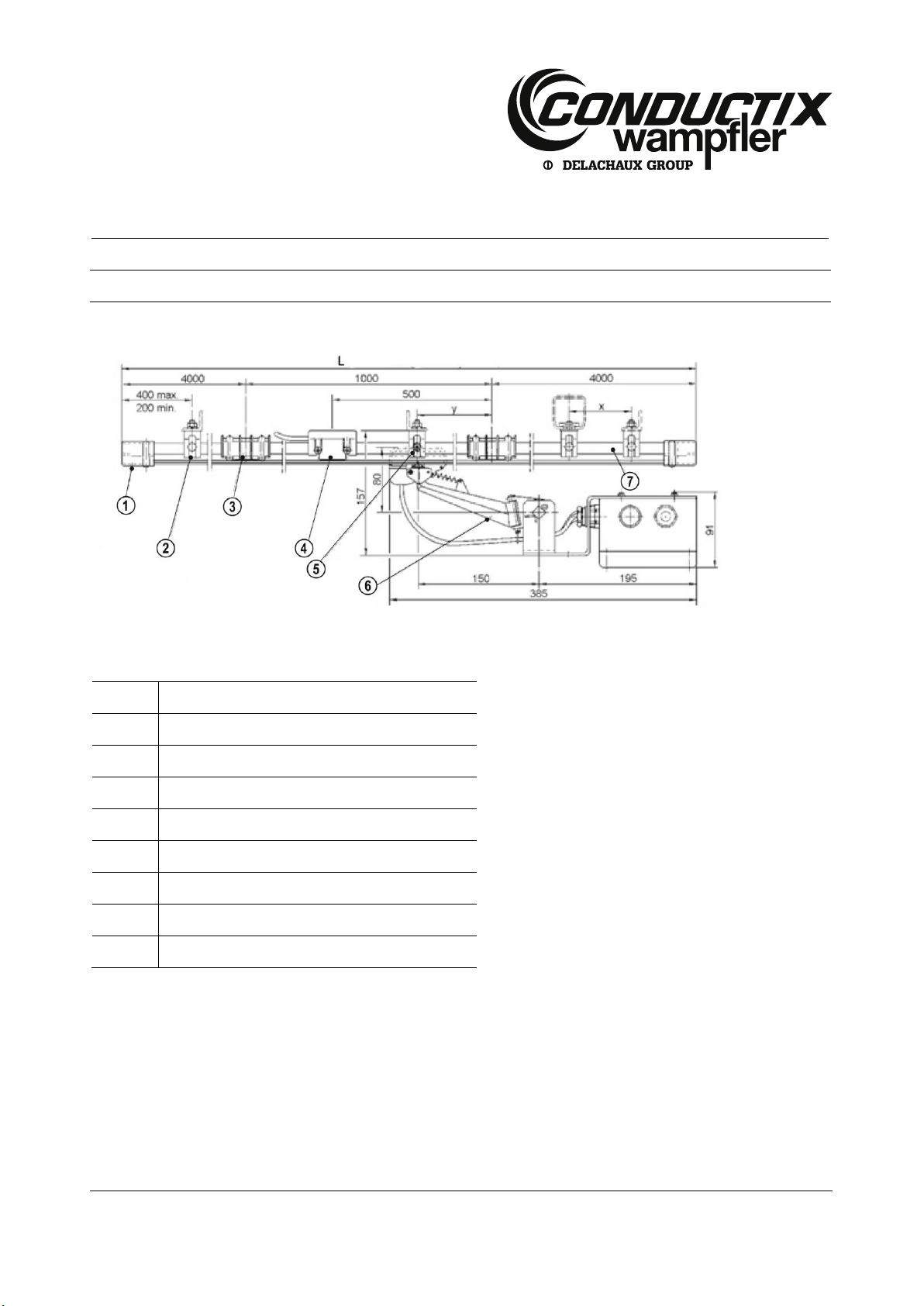

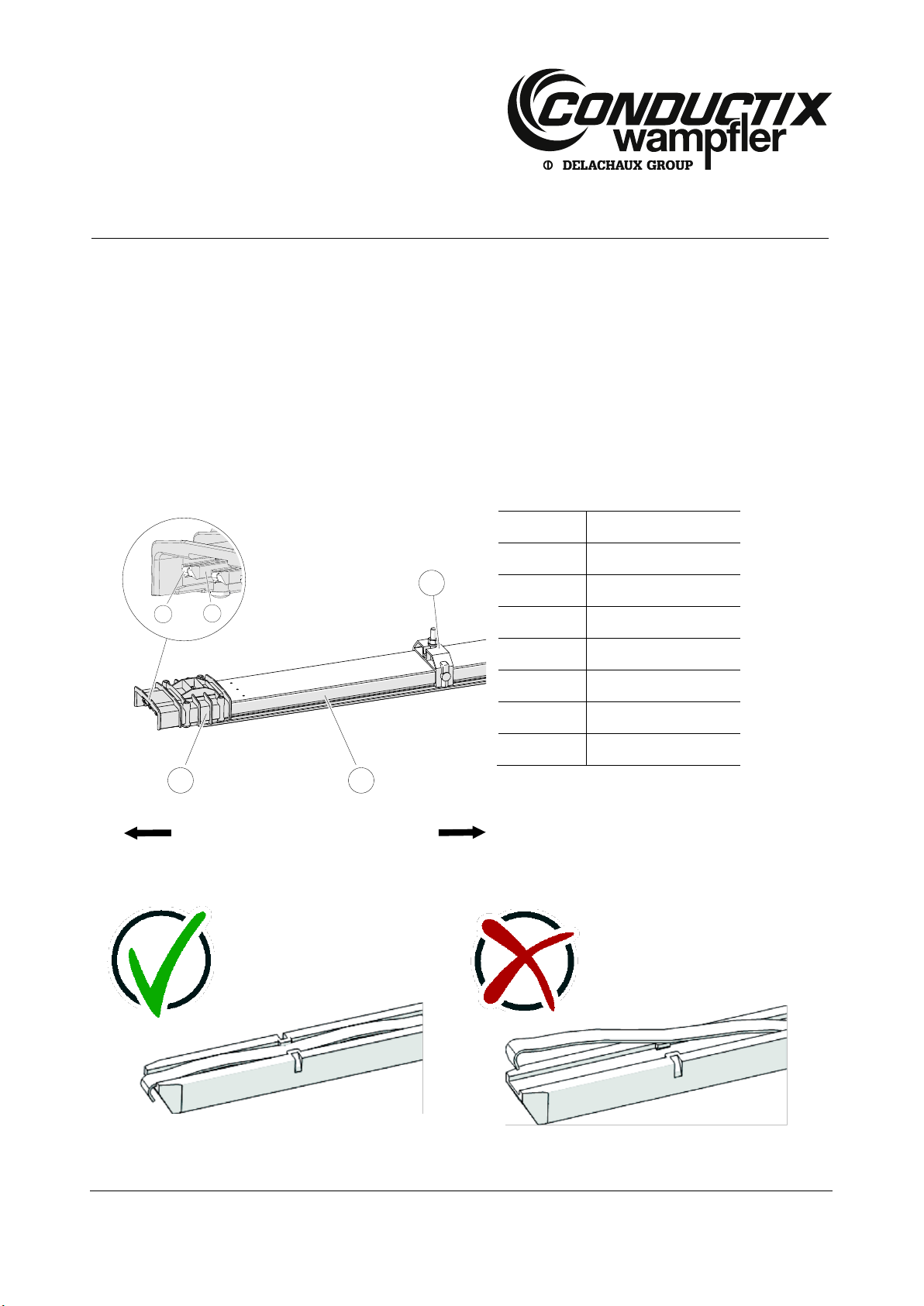

Fig. 1: Components of the multipole conductor rail system program 0831

Item

Designation

1

Conductor rail

2

Hanger clamp

3

Fixed point

4

Centre feed

5

End cap

6

Current collector

7

Towing unit

8

Connector

See chapter 8 for other components of the multipole conductor rail system.

Mounting Instructions

Multipole Conductor Rail System

Program 0831

MV0831-0006e-EN

www.conductix.com translated document Page 3 of 32

2Intended use

The multipole conductor rail system serves for the energy and data transmission on indoor systems and weatherproof outdoor

systems on straight travel paths.

Possible fields of application:

Storage and retrieval equipment

Cranes

Transport vehicles and special machines.

The following conditions are applicable for the use of the multipole conductor rail systems:

Designation

Value, unit

Additional information

Range of application

The multipole conductor rail system 0831 is an electrical

energy supply for track-guided, mobile consumers indoors, in

storage areas not accessible for the public.

Installation height

Max. 3000 mm

For the installation beyond 3000 mm installation height or on

systems with a strong risk potential we have provided safety

catching devices that can be supplied as an option. See

chapter 5 for further information.

Installation position

Horizontal installation position with vertical engagement,

optional current collector engagement from underneath.

Vertical engagement e.g. at the pole is possible, please contact

us for advice and provide a safety catching device.

Max. Support distance (distance

between the hanger clamps)

1000 mm

If suspension distances of more than 1000 mm are required,

you can combine the multipole conductor rail system with the

assembly system ProShell (see „KAT0800-0003“).

Max. operating voltage

See type plate

The type plate is located on the end and center feed

Nominal current

Mounting Instructions

Multipole Conductor Rail System

Program 0831

MV0831-0006e-EN

www.conductix.com translated document Page 4 of 32

3Control components

Prior to mounting check the goods (consisting of several packages) for completeness and damage by means of the delivery note:

Ensure that all required packages are on site.

The conductor rails are available with various nominal values and of various conductor materials:

Strength of the conductor

materials

Fig. 2: Strength of the conductors

Conductor material

Ampere I

Catalog

number

B

[mm]

Steel (galvanized)

32 A

083112-...

1

copper

60 A

083115-...

0.6

copper

100 A

083116-...

1

copper

125 A

083117-...

1.4

Data-Metal

10 A

083118-...

1

Mounting Instructions

Multipole Conductor Rail System

Program 0831

MV0831-0006e-EN

www.conductix.com translated document Page 5 of 32

4Assembly

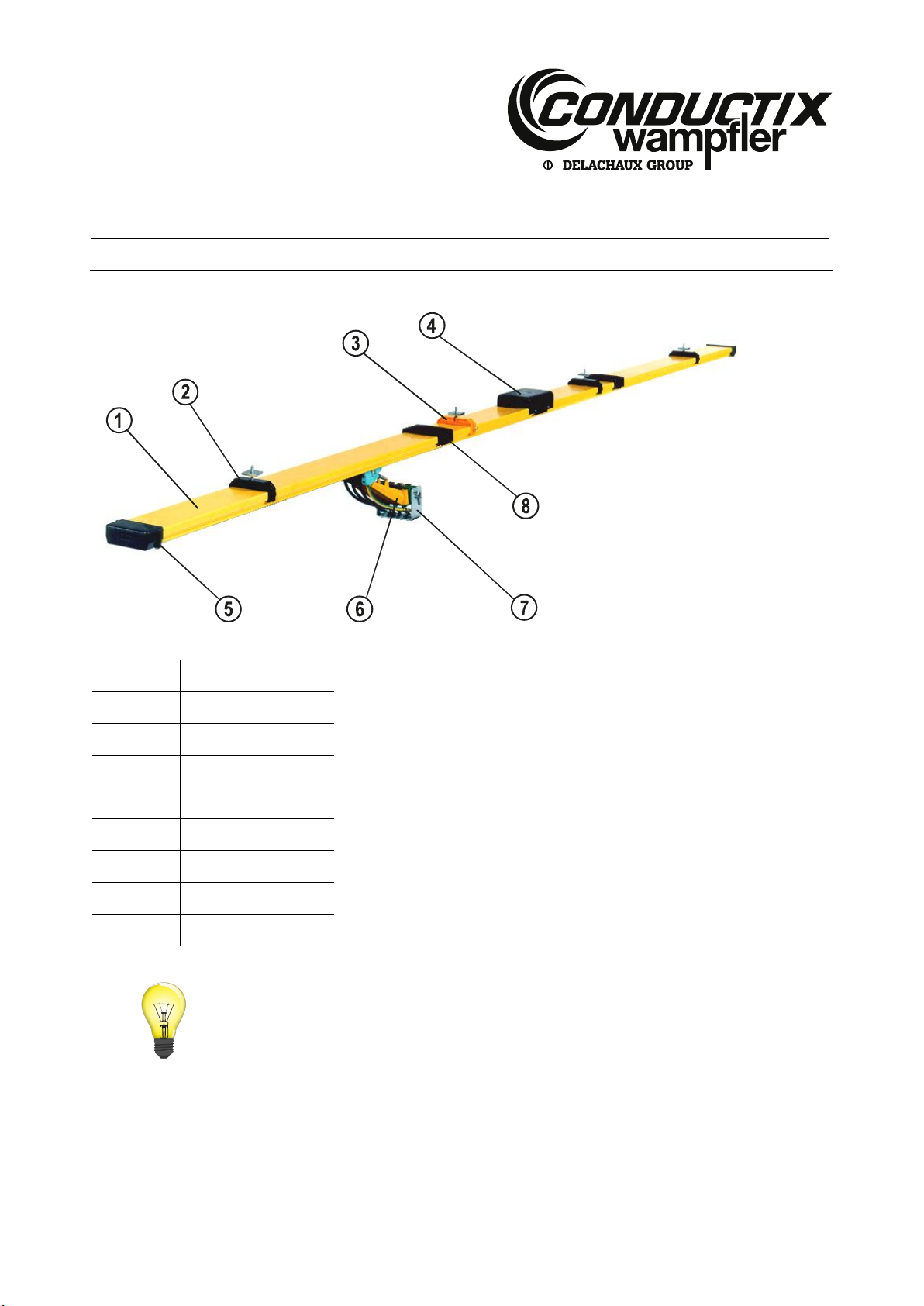

The system sketch shows the mounting distances to the connectors and end and center feed:

Fig. 3: System sketch

See Fig 5 for suspension distance (x) and center distance (y)

Item

Designation

1

End cap or end feed (not illustrated)

2

Hanger clamp

3

Connector

4

Centre feed

5

Fixed point

6

Current collector (vertical engagement)

7

Conductor rail

L

Total length of the system

Mounting Instructions

Multipole Conductor Rail System

Program 0831

MV0831-0006e-EN

www.conductix.com translated document Page 6 of 32

Use the QR code („click“ or „scan“), to watch our animation

MultiLine 0831 Overview

Use the QR code („click“ or „scan“), to watch our animation

Console Assembly

Use the QR code („click“ or „scan“), to watch our animation

Console Aligning

Mounting Instructions

Multipole Conductor Rail System

Program 0831

MV0831-0006e-EN

www.conductix.com translated document Page 7 of 32

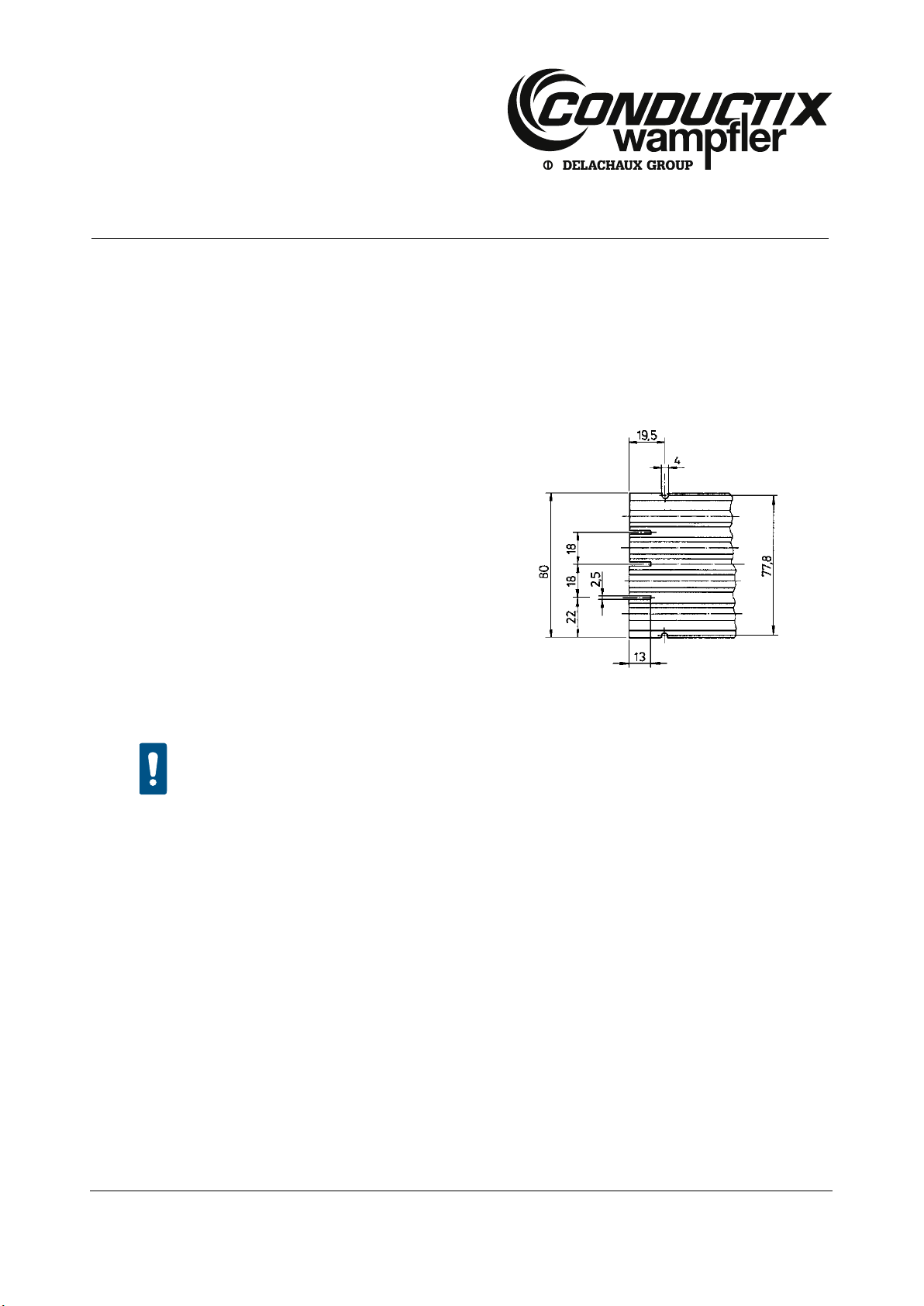

4.1 Adjusting the lengths

The multipole conductor rail systems are supplied by standard in lengths of 4000 mm, 3000 mm, 2000 mm and 1000 mm. All kinds

of system lengths can thus be realized.

Always make the length adjustment at the finally mounted conductor rail!

Shorten conductor rail:

Saw off the conductor rail to the requested length.

Saw the slots according to the sketch.

Deburr the terminations of the conductor rail and the slots with a not

too rough file.

Remove dirt and shavings.

Put on the end cap and bore out the insulating profile (through the

borings 4 mm in the end cap).

See chapter 4.4 for the installation of the end cap.

Fig. 4: Dimensions for slots at the end of the conductor rail

CAUTION!

Bring the connecting point into its original state!

Bring the connecting point into its original state, if a conductor rail must be shortened along the track.

Conductor rails that have not been deburred will cause increased abrasion of the collector heads:

Ensure that the conductor rails (conductors) are properly deburred at their terminations (see Fig. 13)

Mounting Instructions

Multipole Conductor Rail System

Program 0831

MV0831-0006e-EN

www.conductix.com translated document Page 8 of 32

4.2 Installation of the fixed point and the hanger clamp

4.2.1 Fixed point

The fixed point secures the multipole conductor rail system against displacement. The fixed point consists of an orange hanger

clamp and a self-tapping screw.

Working steps:

Put the fixed point preferably in the center of the multipole conductor rail system. Particularly on long systems this will

guarantee a consistent expansion of the multipole conductor rail system in both directions.

When using a center feed install the fixed point next to it, if possible. See chapter 7 for the screw tightening torques.

Fix the fixed point with the enclosed self-tapping screw at the conductor rail.

Use the QR code („click“ or „scan“), to watch our animation

Tightening the Anchor Point Screw

Mounting Instructions

Multipole Conductor Rail System

Program 0831

MV0831-0006e-EN

www.conductix.com translated document Page 9 of 32

4.2.2 Hanger clamps

The hanger clamps are designed as sliding suspensions (see Fig. 3):

Suspension distance x

Center distance y

1000 mm

System length 50.000 mm

System length > 50.000 mm

190 10 mm

320 10 mm

Fig 5: Dimensions of the suspension distance and the center distance

CAUTION!

Ensure a correct alignment of the hanger clamps!

Height offset or angle error during the assembly may result in jamming of the conductor rail on thermal

expansion. This will result in wavy conductor rails!

Pay attention to a correct alignment of the hanger clamps, in order to ensure gliding of the rail in the

hanger clamp on thermal expansion.

Working steps:

Observe the minimum distances to the connector points and feeds for the position of the hanger clamps, in order to avoid

collisions and inhibitions in case of linear extensions. See Fig 5 for suspension and center distance.

Install the hanger clamp. See chapter 7 for the screw tightening torques.

If the multipole conductor rail system is in a vertical arrangement, the clip (see Fig. 6) must point upward.

Fig. 6: In vertical position the clip points upward

In case of collisions/overlapping along the track, there must be an assembly fault at the hanger clamps:

Replace the respective hanger clamp. See Fig 5 for suspension and center distance.

Item

Designation

1

Clip

Mounting Instructions

Multipole Conductor Rail System

Program 0831

MV0831-0006e-EN

www.conductix.com translated document Page 10 of 32

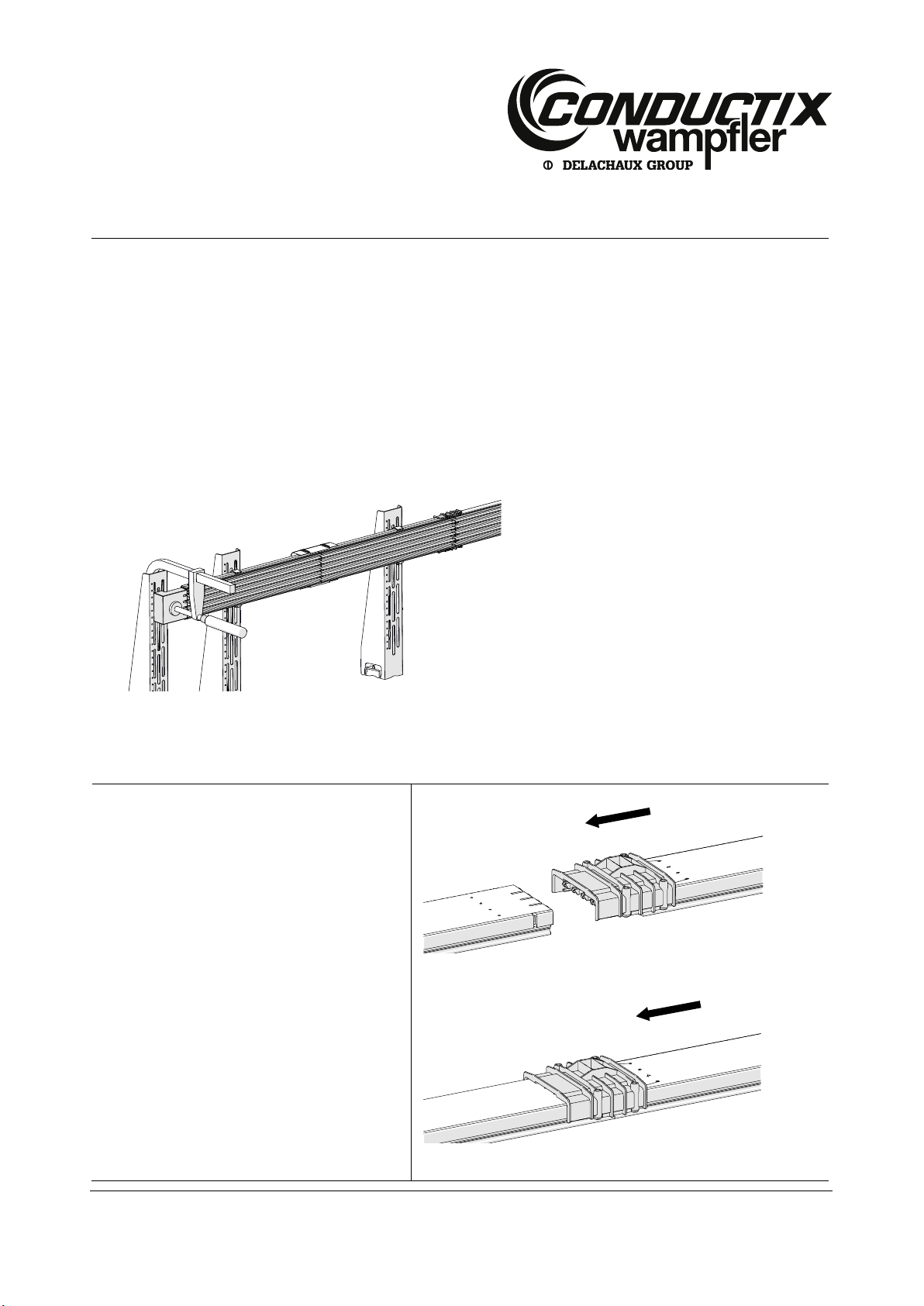

Fig. 7: Distribution of hanger clamps, rail connectors and fixed points

Item

Designation

1

Conductor rail

2

Hanger clamp

3

Connector

4

Fixed point

Max. length of track (without expansion units):

Length

Temperature

Without expansion units

On systems with lengths L ≤ 200.000 mm

Systems in a normal temperature range and a max.

temperature change of 30 K

With expansion units

On systems with lengths L ≤ 200.000 mm

Changed range of temperature (see chapter 5)

The multipole conductor rail system can be combined with an assembly system ProShell!

If suspension distances (distance between the hanger clamps) of more than 1000 mm are

required, you can combine the multipole conductor rail system with the assembly system ProShell.

ProShell is a modular supporting structure for the Conductix-Wampfler conductor rail systems 0812

and 0831. With ProShell you can choose a suspension distance of up to 3200 mm. See „KAT0800-

0003“ for further information.

Mounting Instructions

Multipole Conductor Rail System

Program 0831

MV0831-0006e-EN

www.conductix.com translated document Page 11 of 32

Use the QR code („click“ or „scan“), to watch our animation

Hanger Clamp and Anchor Point Assembly (horizontal operation)

Use the QR code („click“ or „scan“), to watch our animation

Hanger Clamp and Anchor Point Assembly (vertical operation)

Mounting Instructions

Multipole Conductor Rail System

Program 0831

MV0831-0006e-EN

www.conductix.com translated document Page 12 of 32

4.2.3 (Optional) safety catching device

The conductor rail is equipped with a catching clip including catch-rope, if the installation height is more than 3.000 mm or there is

an increased risk potential. In the event of a collision or another damaging event the multipole conductor rail system will be secured

by the catch-rope at the framework of the supporting construction. The safety catching device consists of 2 clamp halves including

mounting screws and a catch-rope. If required, please ask your distribution partner.

Catalog number of the safety catching device: 08-S280-0613

Working steps:

Lay both clamp halves to the back of the rail and screw the two components together by means of the enclosed screw/bolt.

Attach the catch-rope to the on-site structure and connect it with the clamp.

Fig. 8: Optional safety catching device

Use the QR code („click“ or „scan“), to watch our animation

Safety Catching Device (vertical operation)

Mounting Instructions

Multipole Conductor Rail System

Program 0831

MV0831-0006e-EN

www.conductix.com translated document Page 13 of 32

4.3 Click the conductor rail into its place

Observe the alignment of the conductor rail.

Click the conductor rail into the hanger clamp.

CAUTION!

In a vertical arrangement the clip must point upward (see Fig. 6)!

Fig. 9: Click the conductor rail into the hanger clamp.

Use the QR code („click“ or „scan“), to watch our animation

Conductor Rail Clipping and Connecting

Mounting Instructions

Multipole Conductor Rail System

Program 0831

MV0831-0006e-EN

www.conductix.com translated document Page 14 of 32

4.4 Position of the end and center feeds

The position of the end and center feeds is specified by the connecting points on site. The alignment of the end and center feed,

among others, determines the position of the protective earth conductor.

The connecting cables must not exert any tensile strength onto the end or center feed. A tensile force may, e.g. be generated by

thermal expansion of the multipole conductor rail system. Therefore the cables must be installed flexibly at the end or center feed

(e.g. by sufficiently large cable loops). See Fig. 3 for the arrangement of the mounting distances to the connectors and end and

center feed.

Use the QR code („click“ or „scan“), to watch our animation

Center Feed Mounting

Use the QR code („click“ or „scan“), to watch our animation

End Feed Assembly

Mounting Instructions

Multipole Conductor Rail System

Program 0831

MV0831-0006e-EN

www.conductix.com translated document Page 15 of 32

4.5 Connect the conductor rail

Prerequisites:

The hanger clamps are mounted as in chapter 4.

The conductor rails that are to be connected must be completely clicked into the hanger clamps.

The connector pins with spring elements must be straight and undamaged.

Each conductor rail is equipped with sockets on both sides. On one side connecting pins with spring elements have been

introduced into the sockets and a connector cap has been pre-assembled. The connecting pins must be pushed into the sockets as

far as they will go until they touch the PVC profile.

Fig. 10: Pin side in detail

Fig. 11:Correct position of the clamp

Fig. 12:Wrong position of the clamp

5

4

B

A

3

1

2

Item

Designation

1

Connecting pin

2

Spring element

3

Connector cap

4

Insulating profile

5

Hanger clamp

A

Pin side

B

Socket side

Mounting Instructions

Multipole Conductor Rail System

Program 0831

MV0831-0006e-EN

www.conductix.com translated document Page 16 of 32

Fig. 13:Detailed view socket side

Fig. 14:Detailed view pin side

Item

Designation

1

Insulating profile

2

Connector cap

3

Cross-head screw

4

Socket

5

Pin side

6

Connecting clamp

7

Conductor rail (conductor)

8

Connecting pin with spring element

9

Stop position of the connecting pin

1

6

7

4

1

2

3

9

7

8

5

6

Mounting Instructions

Multipole Conductor Rail System

Program 0831

MV0831-0006e-EN

www.conductix.com translated document Page 17 of 32

CAUTION!

Prior to making a rail connection, check if connecting pin and socket are in perfect condition!

On the pin side it must be checked if:

Connecting pins and connecting clamps are existing and in the same position (see Fig. 10, item 1

and Fig. 14, item 6),

Connecting pins with spring are fitting and not deformed (see Fig. 10, item 1).

On the pin side it must be checked if:

Connecting clamp in the reception area for the connecting pin (socket side) is available and in a

correct position (see Fig. 13, item 6).

CAUTION!

Always insert the side with the connecting pins into the socket, never vice versa!

The connecting pins will be damaged, if the socket side is forcibly pushed onto the connecting pins.

Fig. 15:Mount the pin side onto the socket side

Fig. 16:Never push the socket onto the connecting pins!

When inserting the connecting pins, ensure a precise alignment on the sockets.

Mounting Instructions

Multipole Conductor Rail System

Program 0831

MV0831-0006e-EN

www.conductix.com translated document Page 18 of 32

Working steps:

The assembly always starts at one end of the multipole conductor rail systems and not in the center:

Click the first conductor rail into the hanger clamp in such a way that the pin end is the end (or the beginning) of the multipole

conductor rail system. The socket end points in the direction where the installation is made.

Pull the connecting pins out of the pin end of the first conductor rail and put them aside (can be used as spare parts).

Dismount connector cap and put it aside (can be used as spare part).

Install the mounting block (Order Number: 08-V015-0492-00x) in front of the conductor rail with a screw clamp (see Fig. 17).

The mounting block variant depends on the number of poles of the conductor rail. It might be necessary to mount a temporary

console to fasten the mounting block.

Fig. 17:Mounting block (Order Number: 08-V015-0492-00x) fasten with a screw clamp

Click the next conductor rail into the hanger clamp.

Establish the plug and socket connection:

Align the pin side in straight line at a distance of

approx. 50 mm with the fixed conductor rail.

Fix the connecting pins in straight line and

regularly at the sockets.

Push the pin side manually onto the fixed

conductor rail, so that all chamfered connecting

pins are introduced into the sockets of the fixed

conductor rail.

Fig. 18:Align conductor rail

Fig. 19:Insert the connecting pins into the sockets of the fixed conductor rail

Mounting Instructions

Multipole Conductor Rail System

Program 0831

MV0831-0006e-EN

www.conductix.com translated document Page 19 of 32

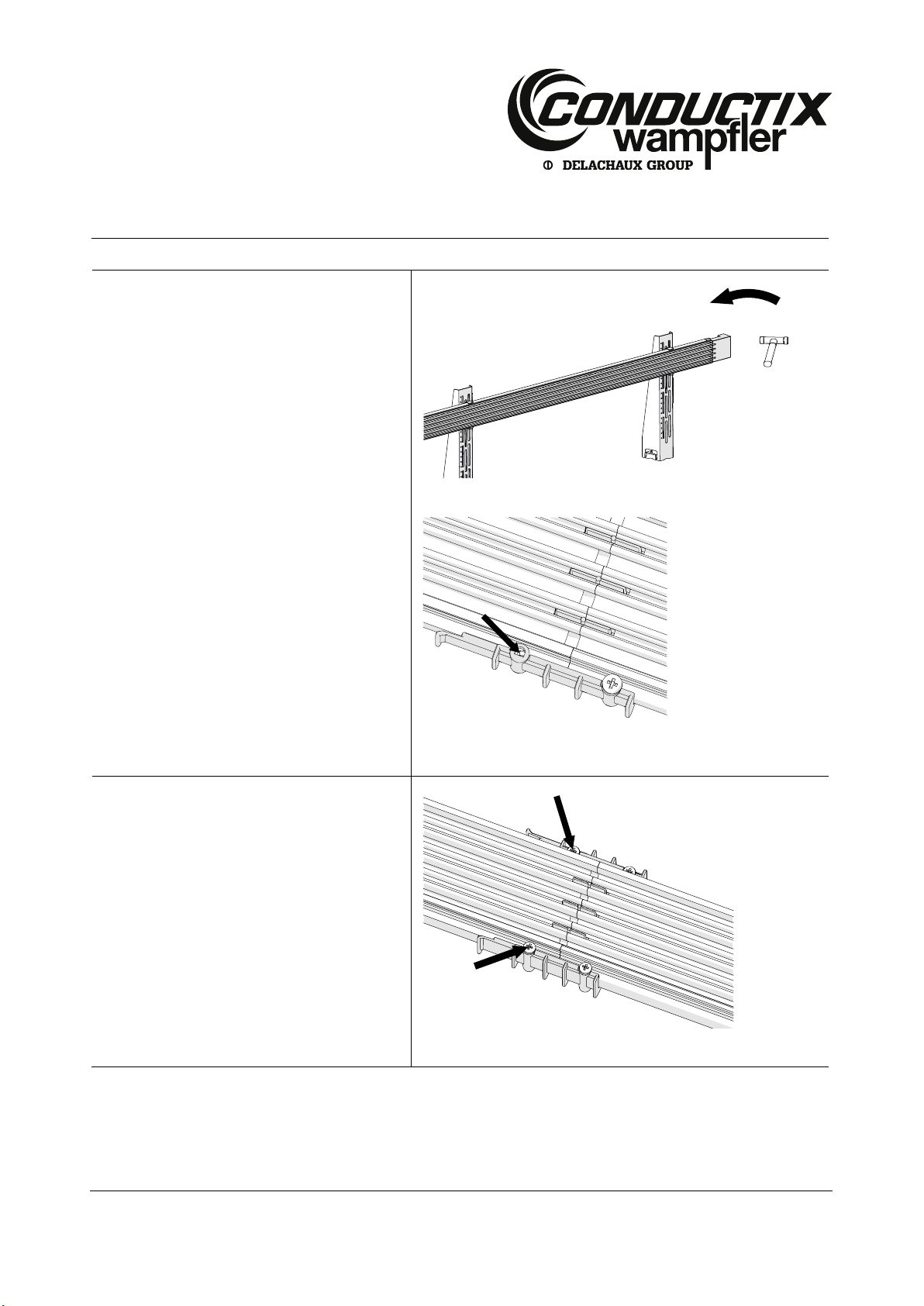

There are 2 different possibilities to make a plug

and socket connection:

1. Push the connector side manually over the open

rail end until it stops (see Fig. 15).

2. Place the mounting block next to the socket side

of the conductor rail to be mounted. Then force

the conductor rail carefully into the opposite

conductor rail by means of slight taps with a

soft-head hammer (see Fig. 20).

Control the correct position:

If the lateral cut-outs in the insulating profile match

with the screw holes in the connecting cap, you have

found the correct position (see Fig. 21).

Fig. 20:Force the conductor rail into its place by means of a soft-head hammer

Fig. 21:Correct position

Fix the connector cap and the insulating profile

with the 2 cross-head screws, as soon as the

conductor rail has been pushed on completely

(see Fig. 22).

Fig. 22:Fix the connector cap on both sides with cross-head screws.

Mounting Instructions

Multipole Conductor Rail System

Program 0831

MV0831-0006e-EN

www.conductix.com translated document Page 20 of 32

CAUTION!

A gap between the conductors is non-critical!

Conductor material and plastic profile have different coefficients of expansion. By pre-assembly the

conductor material is 2 mm shorter than the insulating profile (temperature 20°C), to compensate for

the expansion. Depending on the installation and operating temperature the gap can be up to 8 mm.

This gap is for physical reasons and does not have any influence on the multipole conductor rail

system.

Do not close the gap by a correction of the conductor position!

Mount all the other conductor rails, power feeds and expansion units in the same way.

Use the QR code („click“ or „scan“), to watch our animation

Power Feed Mounting

Check if the mounted length corresponds to the order-related length. If the installation was made too short, make it longer und

shorten the last conductor rail. See chapter 4.1 for further information.

Remove mounting block (see Fig. 17).

Depending on the position of the end and center feed, mount a power feed or end caps as a termination at the end of the

system.

WARNING!

Danger to life by electric shock and risk of injury at sharp edges!

In any case the terminations of the conductor rail must be protected against accidental contact by an

end or center feed or end caps!

Use the QR code („click“ or „scan“), to watch our animation

Conductor Rail Clipping and Connecting

Secure the end caps with the enclosed screws (2 pc.) (see Fig. 23).

Table of contents

Other Delachaux Industrial Equipment manuals