Delixi CDI-SPD Series User manual

Foreword

I

Foreword

Thank you for choosing CDI-SPD series photovoltaic water pump driver

produced by Delixi (Hangzhou) Inverter Co., Ltd.

Before using CDI-SPD series photovoltaic water pump driver (hereinafter

referred to as “the Product”), please read the manual carefully in order to ensure the

proper use. Improper use may result in the equipment’s abnormal operation,

malfunction, decrease of service life and even personal injury accident. Therefore,

please do read the manual carefully before use and use the Product strictly according

to the manual. The manual is a standard file which must be kept properly after

reading for further repairing and maintenance of the Product in the future.

Besides the operating instructions, the manual also provides wiring diagram for

your reference. If having difficulties or special requirements for usage of the

Product, please feel free to contact our local offices or dealers or call our customer

service center of the headquarters directly. We will offer dedicated service to you.

We may change the contents of this Manual without a prior notice.

Please confirm the followings seriously when unpacking the Product:

1. Check if the Product is damaged, components and parts are damaged and

drop and the body is collided in the transportation process.

2. Check if the rated value labeled on the nameplate of the Product accords with

your order requirements and if the packaging box contains the machine that you

order, product certificate, operation manual and warranty card.

We are strict in the manufacture, packaging and delivery. For any inspection

omissions, please contact us or your supplier to solve the problem.

Table of Contents

II

Table of Contents

Foreword……………………………………………………………………………...I

Chapter I Safety Operation and Attentions.................................................................1

1.1 Acceptance ................................................................................................. 1

1.2 Safety Operation Attentions ....................................................................... 2

Chapter II Product Information ..................................................................................3

2.1 Nameplate Data and Naming Rule............................................................. 3

2.2 Product Specification ................................................................................. 4

2.3 Product List................................................................................................ 4

2.4 Appearance and Installation Dimension ..................................................... 5

2.5 Daily Maintenance and Repairing.............................................................. 9

Chapter III Installation and Wiring...........................................................................11

3.1 Installation Site and Space.........................................................................11

3.2 Standard Wiring........................................................................................ 13

3.2.1 Description of the terminals of frequency inverter.......................... 14

3.2.2 Wiring reference for the main circuit and control circuit is as shown

in the table below..................................................................................................... 16

3.3 Earthing.................................................................................................... 17

Chapter IV Keyboard Operation and Running .........................................................14

4.1 Selection of Operation Mode.................................................................... 18

4.2 Test Run and Inspection ........................................................................... 18

4.2.1 Precautions and inspection prior to test run .................................... 18

4.2.2 Test Run.......................................................................................... 18

4.3 Keyboard Operation Method.................................................................... 19

4.3.1 Keys and functions of keyboard...................................................... 19

4.3.2 Methods to view/give parameters (with digital keyboard).............. 21

4.3.3 Keyboard monitoring data .............................................................. 22

Chapter V Functional Parameters Table ...................................................................23

5.1 Basic Functions of F28 Group........................................................... 24

Chapter VI Troubleshooting .................................................................................... 27

Appendix 1 Recommended Configuration of Solar Cell Modules...........................29

Chapter I Safety Operation and Attentions

Page 1

Chapter I Safety Operation and Attentions

Please read this manual carefully before installation, operation, maintenance

and inspection of the Product.

Please read this chapter before using the Product in order to ensure personal,

equipment and property safety. Attentions related to safety operation in the manual

are classified into “warning” and “cautions”.

1.1Acceptance

The items in the table below must be inspected:

Items Inspected

Note

1. Is the model of frequency inverter

consistent with order?

Check the Model indicated on the

nameplate on one side of the frequency

inverter.

2. Is there any damage to the components?

Survey the external appearance of the

frequency inverter and make sure that no

damage has occurred during

transportation

3. Are the components properly fastened?

Take off front cover of frequency inverter

and use proper tools to inspect all visible

components.

4. Is the user’s manual received?

User’s manual of frequency inverter

Please contact us or our agent if any of the items above fails to pass the

acceptance.

Warning

Cautions

: Potentially dangerous condition, which maybe cause severe body

injuries or dead ifrelevant requirement is ignored.

: Potentially dangerous condition, which maybe cause middle,

light injuries or devicedamage if relevant requirement is ignored,

it also applies to unsafe operation.

Chapter I Safety Operation and Attentions

Page 2

1.2 Safety OperationAttentions

1. Installation and maintenance should be performed by professional only.

2. Verify that rated voltage of the frequency inverter should conform with voltage

level of AC power supply. Otherwise it shall cause hurt to human body or fire

accident.

3. Don’t connect main circuit power with output terminals U, V and W. The

connection will damage equipment, thus warranty cardwill be invalid.

4. Don’t connect input power until panel is well installed. Do not remove the

cover when it is powered; otherwise, electric shock may occur.

5. Don’t touch high voltage terminal within frequency inverter under power-on status;

otherwise, electric shock may occur.

6. Maintain the frequency inverter after powering off it for at least 15 minutes

because it has plenty of capacitance energies. At the moment, charging indicator light

will be off or confirm the positive and negative Bus line voltages are under 36V;

otherwise, electric shock can occur.

7. Don’t turn on or off line and connector when the circuit is powered on Otherwise,

personal injury may occur.

8. Electronic components can be easily damaged by static electricity so please avoid

touching them.

9. This frequency inverter should not undergo voltage withstand test, which might

result indamages to the semiconductor devices in it.

10. Cover plate must be covered up before power on; otherwise, electric shock and

explosion can occur.

11. Never confuse the input and output terminals. Otherwise, explosion or damage to

the property mightoccur.

12. For frequency inverter of which storage period exceeds half year, please increase

the input voltage gradually by using regulator, to prevent from electric shock and

explosion.

13. Don’t operate the frequency inverter with wet hands; otherwise, electric shock

may occur.

14. All parts should be replaced by professional only. It is strictly prohibitive to

remain stub ormetal object in machine, to prevent from fire.

15. After replaced control board, please perform relevant parameter setting before

operation toprevent from damage of materials.

Cautions

1. If the motor is used for the first time or has been in leisure for a long time,

remember tocheck its insulation first. It is advisable to use a 500V megger. Make sure

the insulationresistance should not be less than 5 MΩ.

2. Please consider the tolerance of mechanical device if it needs running above 50 Hz.

3. In the regions with an altitude above 1,000 m, the heat dissipation effect of

frequency inverter will be reduced due to thin air so it must be used with a reduced

capacity. Reduce capacity by 1% for every 100 m after the altitude exceeds 1,000 m.

4. Do not start or stop the frequency inverter with contactors. Otherwise, damage

might occurto the equipment.

5. Do not modify factory set value of frequency inverter without authorization, or

damagemight be caused.

Warning

Anti-static

Chapter II Product Information

Page 3

Chapter II Product Information

2.1 Nameplate Data and Naming Rule

Nameplate data: Take CDI-SPDG1R5S2 as an example:

IP20

Input:DC 200~400V

AC 1PH 220V±15% 50/60Hz

Model:CDI-SPDG1R5S2

Output:AC 3PH 0V~Uinput 0~400Hz

7.0A 1.5kW

Hardware Version:1.1.00

Software Version:1.01.31

SPDG1R5S219K000001

CDI SPD G 1R5 S2

DELIXI inverter

Product series no.

Product type

Power of the adapting motor

G:General Type

SS2:1 PH AC 220V(Input/Output),50/60Hz

DC:200~400V

SPD Series

T4:3 PH AC 380V,50/60Hz,DC:300~750V

S2:1 PH AC 220V,50/60Hz,DC:200~400V

Voltage Level (Rated Voltage)

T2:3 PH AC 220V,50/60Hz,DC:200~400V

Chapter II Product Information

Page 4

2.2 Product Specification

Machine Type

-SS2

Product

-S2

Product

-T2 Product

-T4 Product

AC input voltage (V)

220(±15%)

(1PH)

220(±15%)

(3PH)

380(±15%)

(3PH)

Max. DC voltage (V)

440

440

440

800

Starting voltage (V)

200

200

200

300

Min. working voltage (V)

150

150

150

250

Range of DC input

voltage recommended

(V)

200~400

200~400

200~400

300~750

Recommended MPP

voltage (V)

330

330

330

550

2.3 Product List

Model of Frequency Inverter

Rated Input Current

(A)

Rated Output

Current (A)

Adaptive Motor

(kW)

CDI-SPDG0R4SS2

6.5

5.0

0.4

CDI-SPDG0R7SS2

9.5

7.0

0.7

CDI-SPDG1R5SS2

15.7

10.0

1.5

CDI-SPDG2R2SS2

27.0

14.0

2.2

CDI-SPDG4R0SS2

32.8

17.0

4.0

CDI-SPDG0R4S2

6.5

3.0

0.4

CDI-SPDG0R7S2

9.5

5.0

0.7

CDI-SPDG1R5S2

15.7

7.0

1.5

CDI-SPDG2R2S2

27.0

10.0

2.2

CDI-SPDG4R0S2

32.8

17.0

4.0

CDI-SPDG4R0T2

18.5

17.0

4.0

CDI-SPDG0R7T4

3.4

3.0

0.7

CDI-SPDG1R5T4

5.0

4.5

1.5

CDI-SPDG2R2T4

6.8

6.0

2.2

CDI-SPDG4R0T4

10.5

9.5

4.0

CDI-SPDG5R5T4

15.5

13.0

5.5

CDI-SPDG7R5T4

20.5

17.0

7.5

CDI-SPDG011T4

26

25.0

11

CDI-SPDG015T4

35

32.0

15

CDI-SPDG018.5T4

38.5

37.0

18.5

CDI-SPDG022T4

46.5

45.0

22

CDI-SPDG030T4

62

60.0

30

CDI-SPDG037T4

76

75.0

37

CDI-SPDG045T4

92

90.0

45

CDI-SPDG055T4

113

110.0

55

CDI-SPDG075T4

157

152.0

75

CDI-SPDG090T4

180

176.0

90

CDI-SPDG110T4

214

210.0

110

Ordering instruction:

Chapter II Product Information

Page 5

Please specify the corresponding model and specification of the products

when placing an order. For any special requirements, please contact us for

negotiation.

2.4Appearance and Installation Dimension

Chapter II Product Information

Page 6

Chapter II Product Information

Page 7

Chapter II Product Information

Page 8

Chapter II Product Information

Page 9

2.5 Daily Maintenance and Repairing

(1) Daily maintenance

The influence such as environmental temperature, humidity, dust and vibration

may result in aging of the internal components of frequency inverter,which should

cause potential fault of frequency inverter or reduction of its service life. Therefore,

it is necessary to perform dailymaintenance andregular inspection with the

frequency inverter.

Daily inspection item:

A Check if the sound of motor running has any abnormal change.

B Check if there is any vibration in motor running.

C Check if the installation environment of frequency inverter is changed.

D Check if the cooling fan of frequency inverter works normally.

Daily cleaning:

A Keep frequency inverter always clean and tidy.

B Clean surface dust on the frequency inverter effectively in order to prevent

dust from entering the frequency inverter, especially metal dust.

CClean oil dirt of frequency inverter’s cooling fan effectively.

(2) Regular inspection

Please inspect places that can be hardly inspected regularly.

Regular inspection item:

A Inspect and clean air flue regularly.

B Inspect if the screw is loose.

C Inspect of the frequency inverter is corroded.

D Inspect if there is arc on surface connecting terminal.

(3) Replacement of vulnerable parts

The vulnerable parts of the frequency inverter include cooling fan and filter

electrolytic capacitor, the service life of which closely depend onoperating

environment and maintenance condition.

Users can confirm replacement period according to running time.

A Cooling fan

Possible damage reasons: Bearing abrasion and blade aging.

Judgment standard: Confirm if the fan blade has cracks and abnormal vibration

sound when starting.

B Filter electrolytic capacitor

Possible damage reasons: Input power with low quality, high environment

temperature, frequent load modulation and electrolyte aging.

Judgment standard: Confirm if the liquid leaks and safety valve has protruded;

measurement of electrostatic capacity and insulation resistance.

(4) Storage of frequency inverter

After purchased the device, please pay attention to following points while

Chapter II Product Information

Page 10

storing it:

A Please store it in original package as much as possible.

B Long term storage should cause aging of electrolytic capacitor. Make sure to

electrifyit once every half a year for at least 5 hours and to raise voltage to rated

value slowly via voltage regulator.

(5) Warranty of frequency inverter

Maintenance free is limited to the frequency inverter only.

We provide life-long paid service for our products, whenever and wherever

they are used.

We bear the responsibilities of repair, replacement and return at most for the

product once quality or product accident happens. If users need more responsibility

compensation warranties, please place insurance at the property insurance company

in advance.

Warranty service should be effective in 18 months after bar code date.

For fault caused in following reasons, a pay-needed maintenanceservice only

is available even warranty term iseffective:

A Faults caused by incorrect operation (subject to user’s manual) or

unauthorized repair and refitting.

B Problems caused by using the frequency inverter beyond requirements of

standard and specification.

C Damage caused by accidental drop and improper handling after purchase.

D Aging or fault caused by severe environment.

E Damage caused by natural disasters such as earthquake, fire disaster, wind,

lightning stroke, abnormal voltage or reasons happening together with disasters.

F Damage in the transportation process (Notes: Transportation mode is

designated by user of themselves. We could assist agent to conduct transfer of

goods).

G When brand, trademark, serial number and nameplate marked by

manufacturers are damaged or can’t be recognized.

H Failure to pay off fund according to purchase contract.

I Failure to describe actual conditions relating to installation, wiring,

operation, maintenance, or othercondition to the Company.

For the repair, replacement and return services, customers need to send the product

back to us. We will provide the corresponding service after confirming the

responsible party.

We still have the ownership of the product for which the buyer doesn’t pay off

the price or pay the residual fund in time. In such case, we do not undertake the

above responsibilities and the buyer cannot propose any disagreement.

All relevant service fees shall be calculated in accordance with the identical

standards of the factory. In the eventthat an agreement or a contract exists, its

priority shall be performed.

Chapter ⅢInstallation and Wiring

Page 11

Chapter III Installation and Wiring

3.1 Installation Site and Space

Installation site:

Warning

1. Avoid direct sunlight and outdoor direct use.

2. Don’t use it under corrosive gas and liquid environment.

3. Don’t use it under oil fog and splashing water environment.

4. Don’t use it under salt fog environment.

5. Don’t use it under raining and moist environment.

6. Please equip the unit with filters device if metal dust or fiber

wadding existing in air.

7. Avoid power noise, such as electric welding machine and

high-power electrical equipment, which can impact operation of

the equipment.

8. Radioactive materials can influence use of the Product.

9. Avoid flammable materials, thinner and solvent.

Environment

Environment temperature: -10℃~+40℃

Storage temperature: -20℃~+65℃

Environment humidity: 90% RH at maximum (noncondensing)

Height: Under 1,000 m. Reduce capacity by 1% for every 100

m after the altitude exceeds 1,000 m.

Vibration: No greater than 5.9 m/s2(0.6 g) at maximum.

Installation direction: Please install the product vertically in

order not to affect the heat dissipation effect of frequency

inverter.

For sound performance and long service life, the frequency inverter shall be

installed according to the above installation environment suggestions to prevent

damages.

警

告

Chapter ⅢInstallation and Wiring

Page 12

Installation space:

When frequency inverters are installed vertically, enough heat dissipation space

shall be reserved in order to ensure effective cooling.

Installation Space of Frequency Inverter

1. Necessary clearance for open-frame type (IP00) and

enclosed wall-mounted type (IP20) is the same at the

top/bottom and both sides.

2. Air temperature at the permitted inlet of frequency inverter:

-10℃~+40℃.

3. Enough heat dissipation space shall be reserved in the upper

and lower areas in order to ensure smooth air intake and

emission of frequency inverter.

4. Don’t let foreign objects fall inside air duct during

installation lest fan damage.

5. Add filtering device at air intake when silk fibers fly or it is

very dusty.

Cautions

Air outlet

Air inlet

Air outlet

Larger than

150 mm

Larger than

150 mm

Air

outlet

Air

inlet

Chapter ⅢInstallation and Wiring

Page 13

3.2 Standard Wiring

See the standard wiring diagram of the main circuit and control circuit of the

Product in the figure below:

(DC-)

(DC+)

DI2

DI3

COM

Low-level switch

High-level switch

Water

pump

PV input

CDI-SPD frequency inverter

(S)

(R)

(T)

AC input

Gravity circuit breaker Q1

AC circuit breaker Q2

DI4

DI1

Forward rotation

Common Terminal

Reverse rotation

COM

Water tower Water well

U

V

W

(L1)

(L2)

Common Terminal

1. DC circuit breaker Q1 must be installed as the protection switch of PV DC

input.

2. Frequency inverter must not be in AC and DC connection at the same time.

If it requires AC/DC connection at the same time, switching control circuit

shall be configured externally.

3. Special PV combiner boxes shall be used for the parallel connection of

components.

4. When PV cell module is more than 10 m from frequency inverter, Type II

lightning arrester shall be configured at DC input end.

5. When water pump is more than 50 m from frequency inverter, it is

suggested to select output reactor.

6. Self-running upon power-up is defaulted for frequency inverter. If it needs

to configure parameters, please set in strict accordance with the instruction

steps of Chapter IV.

7. Tighten terminal screws according to the specified tightening torque.

8. Make sure the earthing terminals have been earthed before connecting the

main circuit.

9. Terminal arrangement sequence shall be subject to physical objects.

Cautions

Chapter ⅢInstallation and Wiring

Page 14

3.2.1 Description of the terminals of frequency inverter

Description of the Main Circuit Terminals of Frequency Inverter:

Identification

Name

Function Description

R, S, T

(L1, L2)

AC input

3-phase (single-phase) AC input terminal,

connected to power grid

DC+, DC-

PV DC input

Input terminal of PV cell panel

U, V, W

Output of

frequency

Inverter

3-phase (single-phase) AC output terminal,

generally connected to the motor of water pump

Safe protection

earthing

Safe protection earthing terminal; each machine

must be earthed reliably

Description for -SS2 single-phase output models

1) Generally, the output terminals U and W of the inverter connect to the phase

cables of the single-phase motor.

2) If the single-phase pump cannot be started, the two-phase control method

must be used, and the start-up and running capacitors (if any) of the motor must be

removed. The figure below shows the internal wiring of the common single-phase

motor. In the figure, L1, L2, C1, and C2 indicate the running winding, start-up

winding, running capacitor, and start-up capacitor. When the motor speed exceeds

75% of the rated speed, the start-up capacitor is switched off.

U2

U1

L1

V2

V1

L2

C1

C2

L

N

Internal wiring of the single-phase motor winding after removing the starting

and running capacitor:

Chapter ⅢInstallation and Wiring

Page 15

U2

U1

L1

V2

V1

L2

C1

C2 U2

U1

L1

V2

V1

L2

U

W

V

U1 and V1 are the common terminals of the windings. Connect them to the

output terminal W of the solar pumping inverter. Connect U2 to the output terminal

U of the inverter. Connect V2 to the output terminal V of the inverter. (Note: Use the

screws equipped with the inverter.) Now F28.39=1.

Description of the Control Circuit Terminals of Frequency Inverter:

Classifica

tion

Terminal

Name

Function Description

Digital

quantity

input

DI1

Forward running

DI1: Forward running of frequency

Inverter

DI2: level switch (low-level switch)

connected to the normally on

contact by default

DI3: level switch (high-level switch)

connected to the normally on

contact by default

DI4: Reverse running of frequency

Inverter

DI2

Low-level switch

DI3

High-level switch

DI4

Reverse running

T1 relay

T1A

Failure output

TA-TB is normally on

TTA-TC is normally off

Driving capability:

AC 250 V below 3 A

DC 30 V below 3 A

T1B

T1C

+24 V

power

supply

COM

24 V power output

Provide DC 24 V power voltage to

the external.

Driving capability: Maximum

output current 300 mA

+24V

Chapter ⅢInstallation and Wiring

Page 16

3.2.2 Wiring reference for the main circuit and control circuit is as

shown in the table below

Model of Frequency

Inverter

Wire Gauge of Main Circuit (mm2)

Wire Gauge of Main

Circuit (mm2)

DC+/DC-, R/S/T, U/V/W

PE

CDI-SPDG0R4SS2

2.5

2.5

1.0

CDI-SPDG0R7SS2

2.5

2.5

1.0

CDI-SPDG1R5SS2

4

4

1.0

CDI-SPDG2R2SS2

4

4

1.0

CDI-SPDG4R0SS2

6

6

1.0

CDI-SPDG0R4S2

2.5

2.5

1.0

CDI-SPDG0R7S2

2.5

2.5

1.0

CDI-SPDG1R5S2

2.5

2.5

1.0

CDI-SPDG2R2S2

4

4

1.0

CDI-SPDG4R0S2

6

6

1.0

CDI-SPDG4R0T2

6

6

1.0.

CDI-SPDG0R7T4

2.5

2.5

1.0

CDI-SPDG1R5T4

2.5

2.5

1.0

CDI-SPDG2R2T4

2.5

2.5

1.0

CDI-SPDG4R0T4

4

4

1.0

CDI-SPDG5R5T4

4

4

1.0

CDI-SPDG7R5T4

6

6

1.0

CDI-SPDG011T4

6

6

1.0

CDI-SPDG015T4

10

10

1.0

CDI-SPDG018.5T4

16

16

1.0

CDI-SPDG022T4

16

16

1.0

CDI-SPDG030T4

25

16

1.5

CDI-SPDG037T4

25

16

1.5

CDI-SPDG045T4

35

16

1.5

CDI-SPDG055T4

35

16

1.5

CDI-SPDG075T4

50

25

1.5

CDI-SPDG090T4

70

35

1.5

CDI-SPDG110T4

120

60

1.5

Chapter ⅢInstallation and Wiring

Page 17

3.3 Earthing

1. Earthing resistance:

200 V level: 100 Ω or below

400 V level: 10 Ω or below

2. Don’t earth frequency Inverter, electric welder, motor or other large-current

electrical equipment commonly. Make sure all earth wires inside conduit are laid

separately from the leads of large-current electrical equipment.

3. Use earth wires up to the specified standard and shorten their length as much

as possible.

4. When several frequency Inverters are used in a row, please earth the device

as shown in Fig. (a) and Don’t make earth wires form a circuit as shown in Fig. (c).

5. Frequency Inverters and motors shall be earthed according to the connections

given in Fig. (d).

(a) Correct (b) Incorrect (c) Not recommended

(d) Correct (e) Not recommended

6. Wiring inspection:

Inspect the following items after installation and wiring are completed.

A. Check if the wiring is correct.

B Check if there is broken wire residues or screws left inside the device.

C Check if the screws are tightened firmly.

D Check if the naked leads on terminal contact with other terminals.

This manual suits for next models

28

Table of contents

Popular DC Drive manuals by other brands

Control Techniques

Control Techniques Emerson Focus 1 user guide

Eaton

Eaton PowerXL DH1 manual

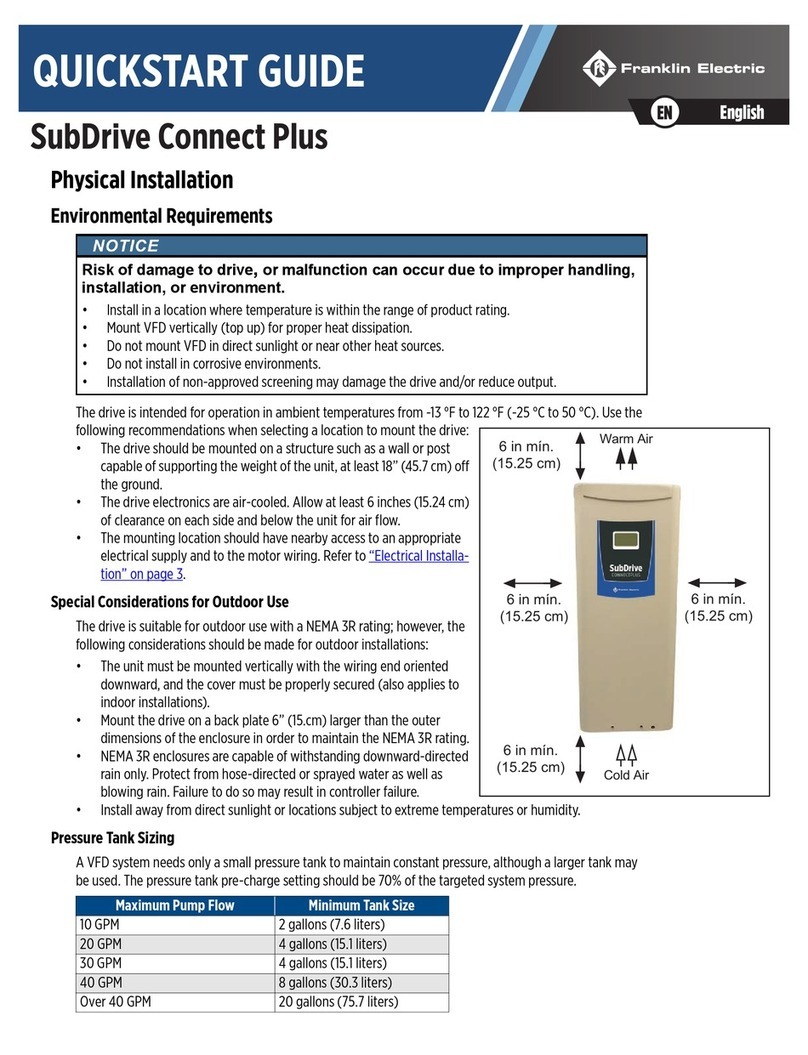

Franklin Electric

Franklin Electric SubDrive Connect Plus SDCP-SUB2043 quick start guide

Kruger

Kruger Ecowatt K320 Series Operation manual

Nidec

Nidec COMMANDER S100 user guide

SEW-Eurodrive

SEW-Eurodrive MGF-DSM Series Addendum to the operating instructions

Digital Equipment

Digital Equipment DSP2022-S installation guide

Lenze

Lenze L-force EWS Series Mounting instructions

Danfoss

Danfoss VLT HVAC Drive FC 102 operating instructions

TB-Electronics

TB-Electronics F-SCAN MOBILE NT instruction manual

Danfoss

Danfoss VLT Design guide

Coelbo

Coelbo SPEEDMATIC SET 2010 Installation and operating instructions