Delixi HY2 Series User manual

Internal

HY2 Series Reversing Switch

Instruction manual

Standard: GB 14048.3

□Please carefully read this User Manual before

installing and operating the product, and keep

this manual properly for future reference

Internal

1 Overview

HY series reversing switch (hereinafter referred to as

switch) is suitable for AC 50Hz (or 60Hz) circuits with

rated operating voltage up to 380V and with rated

operating current up to 20A, and is primarily used to

directly turn on/off a single squirrel cage induction motor

for start, run, stop, and reverse rotation.

This series of products comply with the standard

GB14048.3 "low-voltage switchgear and controlgear -

Switches, disconnectors, switch-disconnectors and

fuse-combination units".

The product has obtained 3C certification certificate.

The normal operating conditions of the switch are as

follows:

a) The ambient air temperature does not exceed +40°C

and the lower limit of its ambient air temperature is -5°C,

and the average temperature within 24 hours does not

exceed +35°C.

b) The altitude of the installation site does not exceed

2000m.

c) Atmospheric relative humidity at the switch

installation site does not exceed 50% when the ambient

temperature is +40℃, and a higher relative humidity is

allowed at a lower temperature, such as 90% at 20°C.

Special measures are taken for condensation generated

occasionally due to temperature changes.

Internal

d) Pollution level: Level 3.

e) Usage category: AC-3.

f) Protection grade: IP20.

2. Switch Specifications and Its Main Technical

Parameters

The switch specification and its main technical

parameters are listed in Table 1.

Table 1 Switch specification and its main technical parameters

Model

Rated

operating

voltage

Ue V

Resistive

current

Ith A

Rated

operating

current

Ie A

Max. power of

controllable

three-phase induction

motor kW

Ue 380W

HY2-15

380

15

7

3

HY2-30

30

12

5.5

HY2-60

60

20

10

The rated operating frequency of the switch is 120

times/h, and a load factor is 60%.

The model of switch and its meanings and definitions are

described as follows:

Internal

HY 2 - □Basic specification code: (Resistive

current A)

Design code

Reversing switch

3 Structure Characteristics and Electrical Schematic

Diagram

The switch primarily consists of a handle, a cam, and

contacts. Cam and contacts are installed in the housing.

There is a total of 5 pairs of contacts, and they are

double-break bridging contacts, of which one pair is used

to control the forward and reverse rotation, two pairs are

used to control the forward rotation, and the other two

pairs are used to control the reverse rotation of motor.

Turning the handle will drive the cam rotate, thereby

making or breaking the contact.

The electrical wiring diagram of switch is illustrated in Fig. 1.

Fig. 1 Wiring diagram of HY2 series

Internal

4 Outline Dimensions and Installation Dimensions

The outline dimensions and installation dimensions of

the switch are shown in Table 2 and Fig. 2.

Fig. 2 Outline dimensions and installation dimensions of

the reversing switch

Table 2 Outline dimensions and installation dimensions

of the reversing switch

Model

Overall dimensions mm

Installation dimensions

mm

L

B

H

h1

b1

d

HY2-15

78

78

130

70

60

ø6.5

HY2-30/60

90

88

150

80

65

ø7

Internal

5. Installation, Operation, and Maintenance

a) Before installation, check the rated operating current

is consistent with the contract, and check the product for

damage or integrity.

b) The switch should be installed inside the circuit

control switch and fuse. No overload, short circuits or

no-voltage protection is provided for this switch. Its

wiring connection is shown in Fig. 1. Do not install it in

a place whether there is too wet or there is corrosive gas.

c) The switch cannot be used for frequent braking.

d) The metal shell must be grounded.

e) The switch is not suitable for hoisting or lifting

equipment.

f) When the motor is in a forward rotation state, to make

it rotate reversely, turn the handle to the "Stop" position

to stop the motor, and then turn the handle to the

"Reverse" position from the "Forward" position to rotate

it reversely. The stator winding of motor will generate a

very large inverse current due to the sudden reverse

connection of power supply, which easily cause damage

to the motor stator winding due to overheating.

g) Please often check the contact surface and rotating

mechanism during the operation of switch (turn off the

power supply before check); if found that the contact is

burnt or the rotating mechanism works inflexibly, please

timely repair it before use; if the mechanism is rotating

inflexibly, an appropriate amount of grease shall be

applied between the cam rollers.

Internal

6 Ordering Notice

When ordering, please specify the following items: the

complete name, model, specification, and order quantity

of the product.

Company Commitment

Under the premise that users follow the operation and

storage conditions and the product are well sealed, within

24 months from the production date, our company will

provide repair and replacement service free of charge for

any damage or abnormal operation due to poor

manufacture quality. A paid repair will be provided if the

warranty period expires. For any damage caused by one

of the following situations, a paid repair will be provided

even within the warranty period:

(1) Improper operation, maintenance, or storage;

(2) Modification or improper repair without permission;

(3) Damage due to falling off or during installation after

purchase;

(4) Force majeure such as earthquakes, fires, lightning

strikes, abnormal voltages, and secondary disasters.

If you have any question, please contact the dealer or our

company’s customer service department.

Customer service hotline: 400-826-8008

Tips:

The scrapped electrical products must not be

disposed with household waste, and they can be

recycled in specific facility environments. How to

recycle them, please contact the local authorities or

dealers.

Please keep this manual properly for further

reference.

Internal

Certificate

Name: Reversing Switch

Model: HY2 series

This product complies with the GB14048.3

standard, and passes the inspection and is

allowed to be shipped.

Inspector: Check 01

Inspection date: See product or package

Sold by Delixi Electric LTD.

Manufactured by Zhejiang Delixi Electrical Co., Ltd.

Address: No. 396-398, Chezhan Road, Xiangjinyang, Liushi Town,

Leqing City, Zhejiang

Tel: (86-577)6177 8888 P/C: 325604

Fax: (86-577)6177 80000

Customer service hotline: 400-826-8008

www.delixi-electric.com

The first edition of this user manual was issued in July 2015.

This manual suits for next models

4

Table of contents

Other Delixi Switch manuals

Popular Switch manuals by other brands

Eaton

Eaton H-T6-160 Series Instruction leaflet

TRENDnet

TRENDnet TE100-S5Pplus Specifications

D-Link

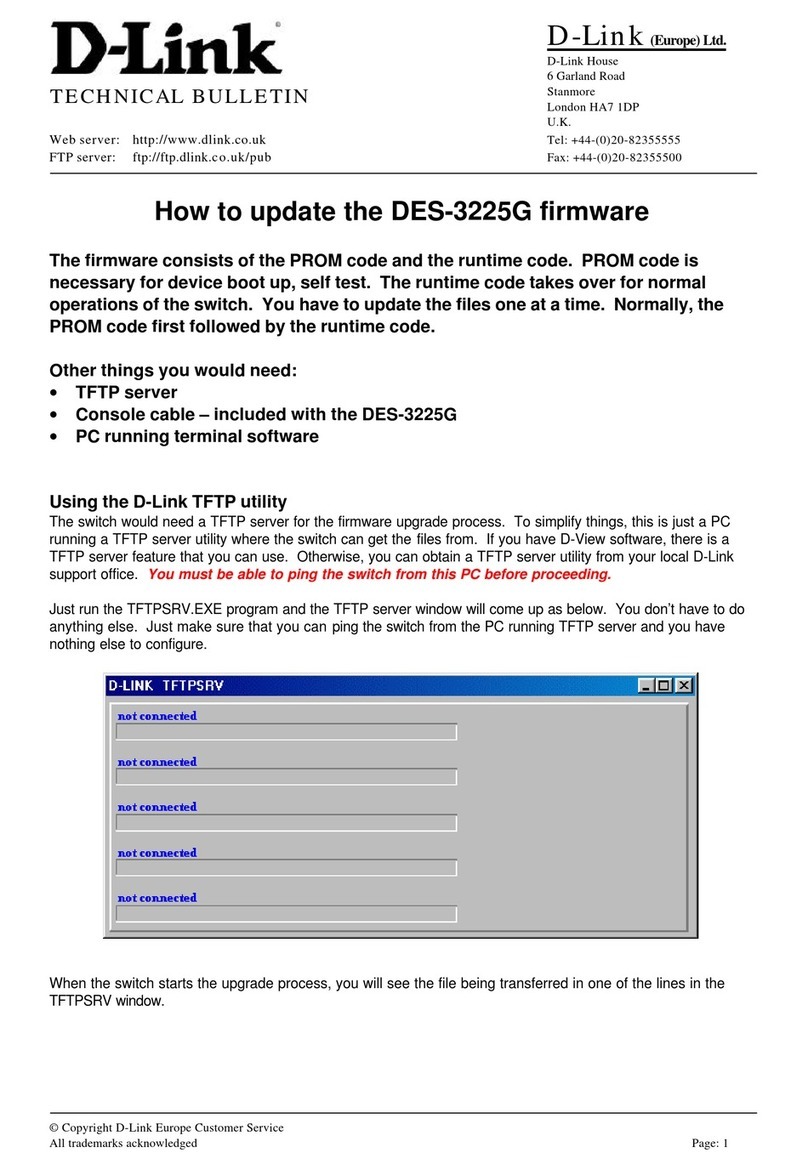

D-Link DES-3225G Series Technical bulletin

D-Link

D-Link DGS-1024D - Switch Quick install guide

Belkin

Belkin F1DN104K-3 Configuration manual

Moxa Technologies

Moxa Technologies PowerTrans PT-7728-PTP Quick installation guide