Delixi LXK3 Series User manual

LXK3 Series Travel Switch

User Manual

□ Please carefully read this User Manual before

installing and operating the product, and keep this

manual properly for future reference

LXK3 Series Travel Switch

User Manual

Safety Notice

Please carefully read this instruction before the installation, operation, run, maintenance, and inspection,

and follow the contents of the instruction to properly install and operate this product.

Danger:

⚫Do not operate the travel switch with wet hands;

⚫It is forbiddent to touch the live parts during operation;

⚫Mark sure that the product is deenergized during the maintenance and service;

Caution:

⚫The installation, maintenance and service shall be performed by the qualified professional;

⚫Various characteristics of product have been set in factory and cannot be disassembled or adjusted

without permission during operation;

⚫Please confirm that the rated voltage, rated current, frequency and characteristics of the product meet

the operating requirements before use;

⚫If found damage or abnormal sound when unpacking, please stop the machine immediately and

contact the supplier;

⚫When scrapping the product, please dispose the product waste properly. Thanks for your cooperation.

About LXK3 Series Travel Switch

●Panel Introduction

Legends:

1. Hit head structure type

2. Company logo

3. Product model

S –Vertical type protective shell, with a wire outlet hole on the bottom

H –Lateral type protective shell, with a wire outlet hole on the bottom and

both sides, respectively

Z –Hit head structural plunger type

4. Standard: GB/T 14048.5

5. Resistive current in free air Ith=10A

6. Protection grade: IP65 (after installation)

7. Certification mark

8. Technical parameters

AC-15 Ue:380V Ie:0.8A

DC -13 Ue:220V Ic:0. 16A

●Hit head structure type and basic data

Hit head structure type and basic data

Product Model

Hit head structure type

Operating

force

Aciton

stroke or

angle

Reset force

Stroke

difference

Full stroke

LXK3 − 20H

S/Z

Plunger type

≤30N

(1.7-2.2)

mm

≥5Н

≤1.2mm

≤6.0mm

LXK3 − 20H

S/L

Roller plunger type

LXK3 − 20H

S/B

Roller rotating arm type

≤0.24 N·m

18-24°

≥0.06 N·m

≤ 15°

≤ 60°

LXK3 − 20H

S/T

Adjustable roller rotating

arm type

LXK3 − 20H

S/J

Adjustable metal rocker

type

LXK3 − 20H

S/D

Elastic rocker type

≤0.22 N·m

≥ 0.03 N·m

LXK3 − 20H

S/H1

"Fork" type, with left wheel

in front and right wheel at

rear

≤0.2 N·m

70-80°

--

40-60°

≤ 90°

LXK3 − 20H

S/H2

"Fork" type, with right

wheel in front and left

wheel at rear

LXK3 − 20H

S/H3

Universal type

LXK3 − 20H

S/W

Hit head structure type

≤0.038 N·m

12-20°

≥0.015 N·m

≤ 8°

--

Normal Operation, Installation and Transport Conditions

●Normal operation and installation conditions

(1) The ambient air temperature is not higher than +40℃, and is not below -5℃; the average value within 24

hours does not exceed +35℃;

(2) The altitude of the installation site does not exceed 2000m;

(3) The relative humidity of the atmosphere does not exceed 50% at the maximum ambient temperature of +40℃,

and a higher relative humidity is allowed at lower temperatures, such as 90% at 20℃. Special measures shall be

taken for condensation occasionally generated due to temperature changes.

(4) The product can be installed in any installation angle;

(5) Installed in a place where there is shock vibration for obvious shaking without rain or snow erosion;

(6) Pollution level: Level 3;

(7) Installation category: Class II;

(8) Rated impulse withstand voltage: 6kV;

(9) Protection grade: IP65 after installation.

●Normal Storage and Transport Conditions

(1) Temperature: -25℃~+55℃;

(2) Relative humidity: ≤90%;

(3) During transport, please gently handle the product, do not upside the product down, and prevent harsh

collision;

Install products

●Outline and Installation Dimensions

(1) LXK3-20S/B, T, D, J and H type outline and installation dimensions are shown in the figure and table

Figure LXK3-20S/B, T, D, J and H type outline and installation dimensions

Table LXK3-20S/B, T, D, J and H type outline and installation dimensions Unit: mm

Install product

(2) LXК3 − 20H

S/w, Z, L type outline and installation dimensions are shown in the figure and table

Table LXK3-20S/W, Z, L and LXK3-20S/W, Z, L type outline and installation dimensions Unit: mm

Model

(3) LXK3-20HI/B, T, D, J and H type outline and installation dimensions are shown in the figure and table

Figure LXK3-20H/B, T, D, J and H type outline and installation dimensions

Table LXK3-20H/B, T, D, J and H type outline and installation dimensions Unit: mm

Product model

Debugging and Operation

(1) Check whether the technical parameters on the product nameplate meet the working requirements

(2) Fix and tighten the product with screws. (It is recommended to use spring washer and flat gaskets)

(3) After installation, carefully check whether the hit head for blockage when pushing the hit head, and whether

the switch core works within the specified range; if found fault, check it and re-install, and then connect the lead

wire.

(4) The lead wire selects 1~2 pieces of copper wire with a cross-sectional area of 0.75mm²~1.5mm².

(5) Connect the lead wire according to the wiring diagram above the core (see Figure below); NC is a normally

closed contact and NO is a normally on contact. Please carefully distinguish the normally open and normally

closed contact terminal sets of the core terminal block of the switch to prevent reserve or wrong connection.

Fig. Wiring diagram

Maintenance and Service

●The maintenance and service must be conducted by the qualified professional;

●Make sure that the product is de-energized during maintenance and service;

●Under normal operating conditions, maintenance and service shall be conducted once a year, and the

maintenance contents are shown in the table.

Table Maintenance and service

Item

Contents

Appearance

No dust, no condensation; clean if necessary

No damage

No color changes on the shell and wiring terminal

Wiring terminal connection

Tighten it according to 0.6~0.8 N·m without looseness

Switch making and breaking

realiabilty

Check whether the switch is turned on or off before and after action

Company Commitment

Under the condition that users follow the use and storage conditions and the product are well sealed, within 36

months from the production date, our company will provide repair and replacement service free of charge for any

damage or abnormal operation due to poor manufacture quality. A paid repair will be provided if the warranty

period expires. For any damage due to one of the following situations, a paid repair will be given even if within

the warranty period:

(1) Improper operation, maintenance, or storage;

(2) Modified without permission or improper repair;

(3) Damage due to falling off or caused during installation after purchase;

(4) Force majeure such as earthquakes, fires, lightning strikes, abnormal voltages, and secondary disasters;

If you have any question, please contact the dealer or our company’s customer service department.

Customer service hotline:400-826-8008

Certificate

DELIXI ELECTRIC LTD

Name: Travel switch

Model: LXK3 series

This product passes the inspection and is allowed to be

shipped

Standard: GB/T 14048.5

Inspector: Check 05

Production date: See label on inner box

Manufacturer: Zhejiang Delixi Electrical Co., Ltd.

Address: Delixi High-Tech Industrial Park, Liushi Town, Yueqing City, Zhejiang P/C: 325604

Tel: (86-577) 61778888

Fax: (86-577) 61778000

Customer Service Hotline: 400-826-8008

www.delixi-electric.com

The first edition of this User Manual was issued in May 2018.

This manual suits for next models

10

Table of contents

Other Delixi Switch manuals

Popular Switch manuals by other brands

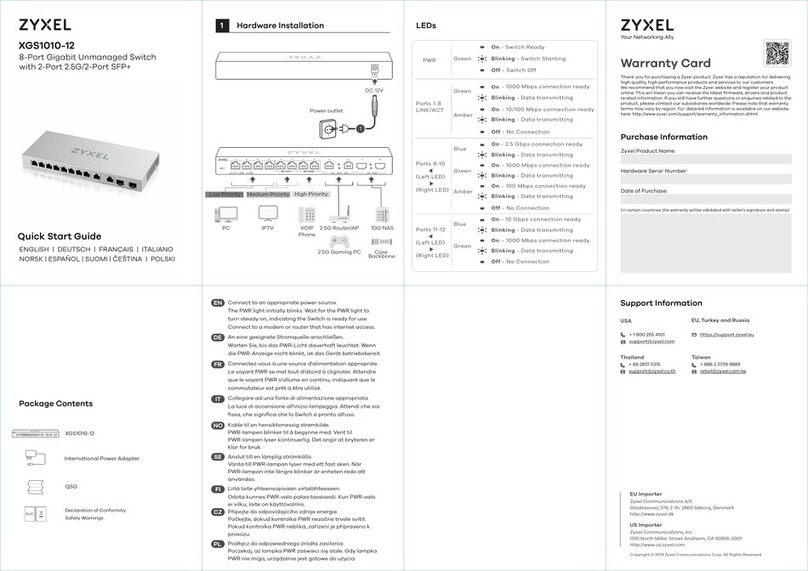

ZyXEL Communications

ZyXEL Communications XGS1010-12 quick start guide

Arista

Arista 7000 Series quick start guide

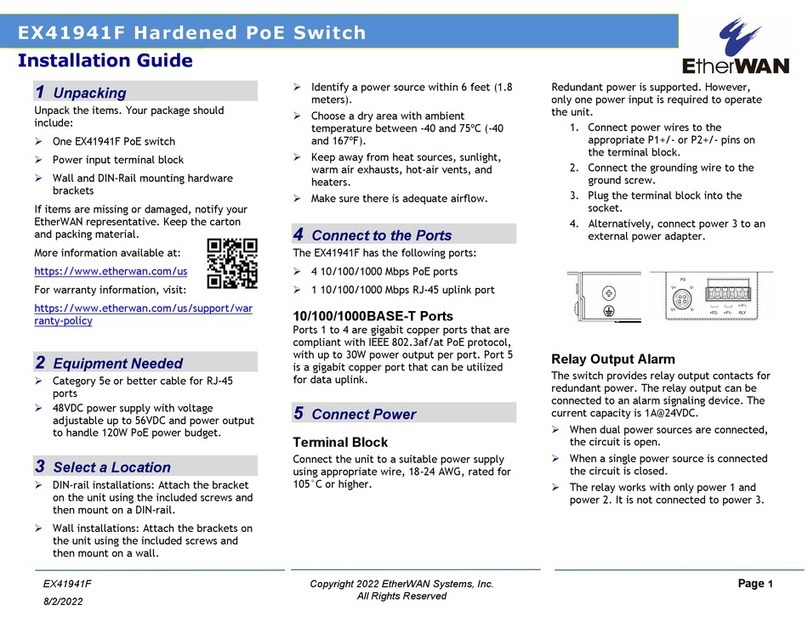

EtherWAN

EtherWAN EX41941F installation guide

Altimium

Altimium COD401B user manual

Aruba

Aruba 3810M Quick setup guide and safety/regulatory information

Comtrol

Comtrol RocketLinx ES7506 user guide