Service Manual

2

Table of Contents

CHAPTER 1- PRECAUTIONS & SAFETY NOTICES.....................................................................................................................0

H3

1. SAFETY PRECAUTIONS .................................................................................................................................................... 1

H3

2. PRODUCT SAFETY NOTICE.............................................................................................................................................. 2

H3

3. SERVICE NOTES.................................................................................................................................................................. 3

H3

CHAPTER 2- SERVICE TOOLS & EQUIPMENT REQUIRED .....................................................................................................4

H4

CHAPTER 3- CIRCUIT THEORY ......................................................................................................................................................5

H5

1. BLOCK DIAGRAM ................................................................................................................................................................... 6

H5

2. ELECTRONIC CIRCUIT THEORY ............................................................................................................................................... 7

H5

3. FACTORY PRESET TIMING TABLE ................................................................................................................................ 8

H11

4. POWER ON/OFF SEQUENCY .................................................................................................................................................. 9

H11

5. D-SUB CONNECTOR PIN ASSIGNMENT................................................................................................................................. 12

6. AC OUTLET PIN ASSIGNMENT .............................................................................................................................................. 12

7. INNER CONNECTOR PIN ASSIGNMENT................................................................................................................................... 10

H13

8. KEY PARTS PIN ASSIGNMENTS .............................................................................................................................................. 14

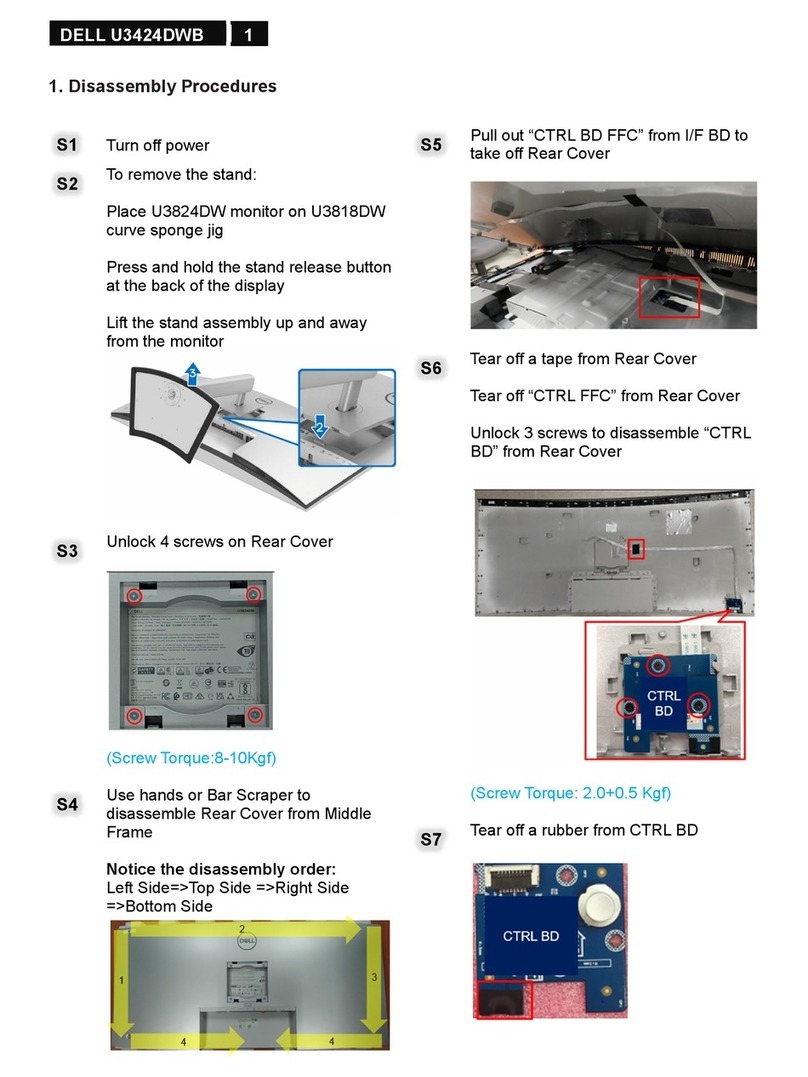

CHAPTER 4- DISASSEMBLY &ASSEMBLY.................................................................................................................................11

H18

1. EXPLODED DIAGRAM ........................................................................................................................................................... 12

H18

2. E190SF DISASSEMBLY BLOCK.............................................................................................................................................. 19

3. ASSEMBLY BLOCK ................................................................................................................................................................ 20

CHAPTER 5- TESTAND ADJUSTMENT........................................................................................................................................ 21

1. FUNCTION KEY DEFINITIONS ................................................................................................................................................ 13

H21

2. OSD CONTROL ...................................................................................................................................錯誤!尚未定義書籤。

3. FACTORY MODE INTRODUCTION........................................................................................................................................... 14

H22

4. BURN-IN PATTERN................................................................................................................................................................. 15

H22

5. AUTO COLOR BALANCE (AUTOMATICALLY CALIBRATE CHIP ADC PARAMETER BY USING CHIP INTERNAL DAC.)................ 16

H22

6. EDID (REWRITE EDID DATA TO EEPROM).........................................................................................................................17

H23

7. UPLOAD FIRMWARE TO MCU VIA VGA CABLE .................................................................................................................... 18

H23

8. AFTER REPAIR,TO ENSURE THE QUALITY YOU SHOULD DO THE FOLLOWING TEST AND ADJUSTMENT. ................................... 19

H25

CHAPTER 6- TROUBLE SHOOTING..............................................................................................................................................20

H25

1. COMMON ACKNOWLEDGE .................................................................................................................................................... 21

H25

2. NO POWER &POWER LED OFF............................................................................................................................................ 22

H26

3. POWER LED AMBER............................................................................................................................................................. 23

H26

4. BACKLIGHT CAN’T BE TURNED ON ........................................................................................................................................ 27

5. NO PICTURE &BACKLIGHT ON ............................................................................................................................................. 24

H29

6. AT 32-GRAY SCALE PATTERN,COLOR LOST IN SOME SCALE ................................................................................................... 29

7. DIAGNOSTIC TEST PAT T E R N .................................................................................................................................................. 29

CHAPTER 7- RECOMMENDED PART LIST ................................................................................................................................. 32

ATTACHMENT 1- BILLOF MATERIAL......................................................................................................................................... 25

H34

ATTACHMENT 2- SCHEMATIC.......................................................................................................................................................26

H44

ATTACHMENT 3- PCB LAYOUT..................................................................................................................................................... 54