SAFETY

INSTRUCTIONS

1

Introduction

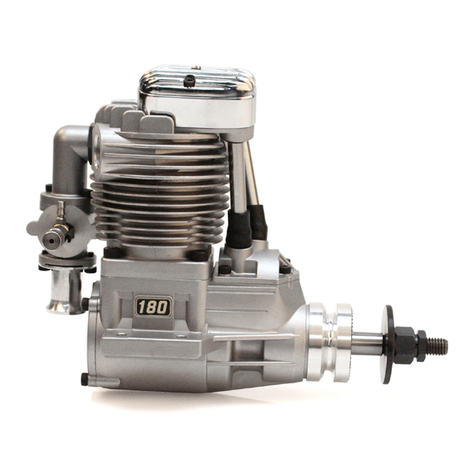

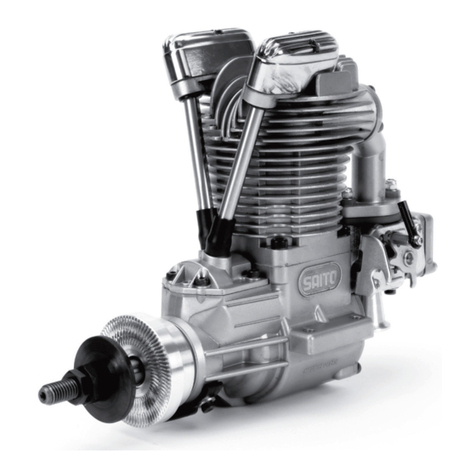

Congratulations on purchasing a Saito

4

-

cycle engine. When cared for

properly, these high

-

quality, finely

crafted engines offer many years of

modeling enjoyment.

This instruction manual has been

developed to ensure optimum

performance from the Saito engine you

have purchased. The instructions must

be read through completely and

understood thoroughly prior to

mounting and running the engine.

Safety lnstruct

ions

This model engine will give you

considerable pleasure, satisfaction, and

performance if you strictly follow

these safety instructions and take heed

of the warnings as

to

its safe and

proper use. Remember at all times

it

is

not

a

toy,

but a precision

-

built

machine with more than enough power

to cause harm if misused or if the

safety precautions are not observed.

You

should

always:

1.

Mount the engine securely in a

“bench mount” or high-quality motor

mount. Never clamp the engine in

a vice.

2.

When running the engine, be sure

all spectators, especially children, are

at least

20

feet away.

3.

Use the correct size and pitch

of propeller for your engine; refer

to the “Propeller Chart”

on

page

16

of

this manual.

4.

It is extremely important to balance

the propeller prior to installation of the

engine. Failure

to

do

so

may cause

damage to the Saito engine and/or the

airframe. Install the propeller with the

convex (curved) side facing forward.

Securely tighten the propeller nut

against the washer and propeller.

An

anti-looaening nut (or “jam” nut) is

suggested for all 4

-

cycle engines.

5.

Inspect the tightness of the propeller

nut prior to each flight.

6.

Keep your face and body away

from the path of the propeller blades

when starting or running your engine.

7.

Never allow your hands

to

come

close

to

the propeller. Utilize either

a “chicken stick” or electric starter

to

start the engine.

8.

Discard any propeller that is nicked,

scratched, cracked

or

damaged in any

way.

9.

Make all carburetor adjustments

from behind the propeller.

10.

To

stop

the engine, cut off the fuel

supply (pinch or disconnect the fuel

line

to

the carburetor) or use the

throttle linkage to shut off the air.