ES150 DELTA ELEKTRONIKA BV

rev. March 2017 OPERATING MAINTENANCE TROUBLE SHOOTING Page 4 - 3

OPERATING AND STORAGE

CONDITIONS

1) TEMPERATURE

°The operating temperature range at full load is -20 to

+50 °C.

°Please note: a lower temperature extends the life

of the power supply.

°The storage temperature range is -40 to +85 °C.

2) HUMIDITY

°During normal operation humidity will not harm the

power supply, provided the air is not aggressive.

The heat normally produced in the power supply will

keep it dry.

°Condensation. Avoid condensation inside the power

supply, break-down could be the result. Condensation

canoccurduringaperiodthepowersupplyisswitched

off (or operating at no load) and the ambient

temperature is increasing .

Always allow the power supply to dry before switching

it on again.

3) GALVANIC INDUSTRY

°For using the power supplies in the galvanic industry it

is strongly recommended to take precautions against

an aggressive environment.

°An aggressive environment with acid, salt, etc. can

harm the electronic components. Sometimes even the

copper traces of the pc-boards dissolve.

°To avoid problems the power supplies should be

mounted in a relative clean room, or mounted in a

cabinet receiving clean air with over pressure.

Or in a cabinet with a heat exchanger.

MAINTENANCE & TROUBLE

SHOOTING

1) GENERAL

°The ES-series power supplies normally need no

maintenance or calibration. Only care must be taken

that the cooling of the unit is not obstructed.

2) NO OUTPUT (normal operation)

°Remove load from output.

°Checkpositionof prog.switches attherearpanel,they

should be on MANUAL.

°Switch on unit.

°Turn both the CV and CC potentiometer a few turns

clock-wise.Avoltageshouldbepresentontheoutput.

3) PROGRAMMING DOES NOT WORK OK

°Check position of prog. switches at rear panel.

°The unit works OK in manual control, but in

programming mode the output voltage / current has a

large error.

Probably the fuse in series with Ø(pin 1) of prog.

connector tripped, the fuse (F7_1 = 650 mA) is a

self-resetting type.

°To check the fuse (F7_1) measure the voltage

between Øand the minus output, during the fault

condition. The voltage should onlybe a few mV, a high

voltage means that an unwanted current is flowing

through pin 1 of the prog. connector.

Please check why current is flowing through pin 1 (see

also next paragraph 4) and fig. 4- 8).

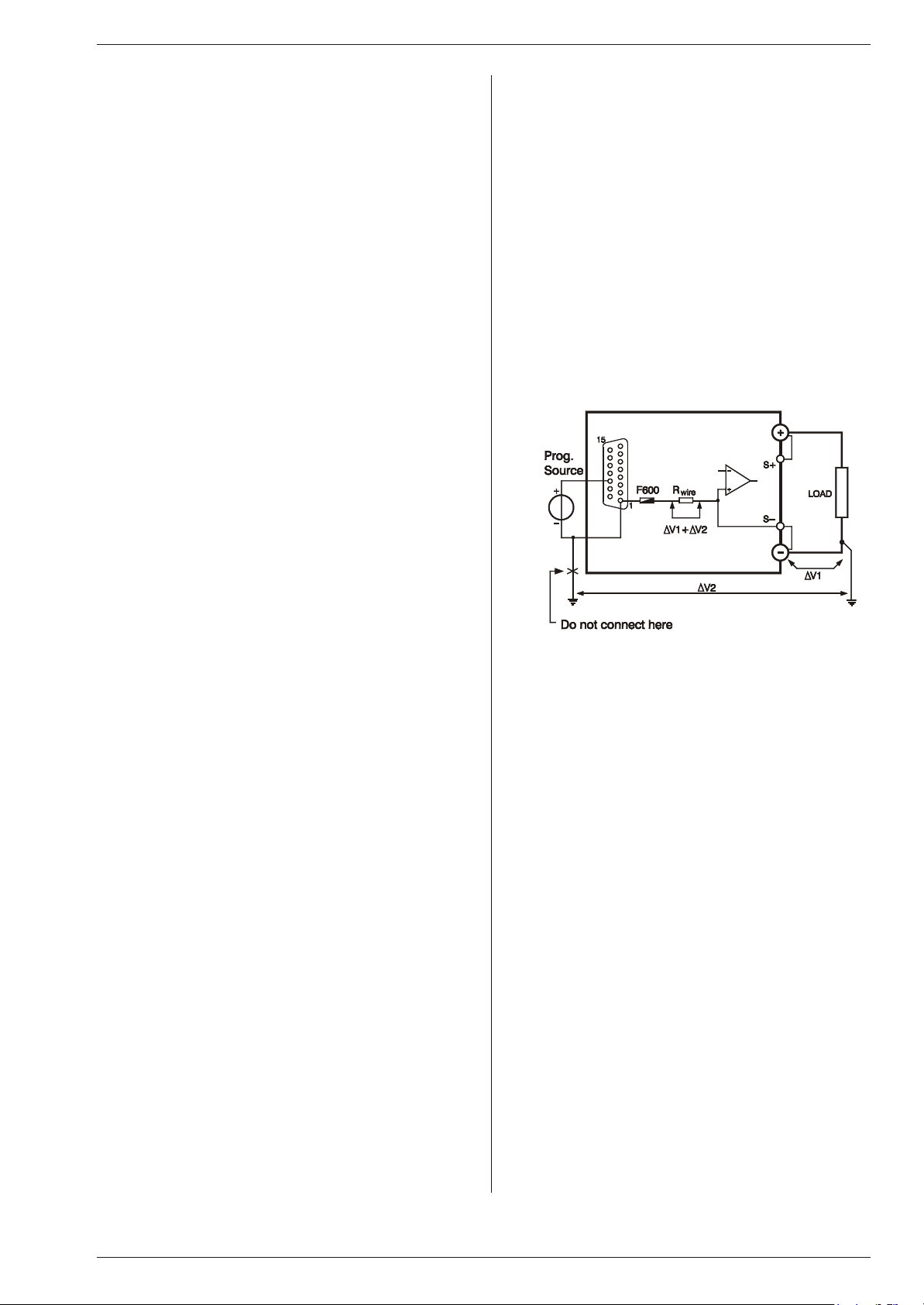

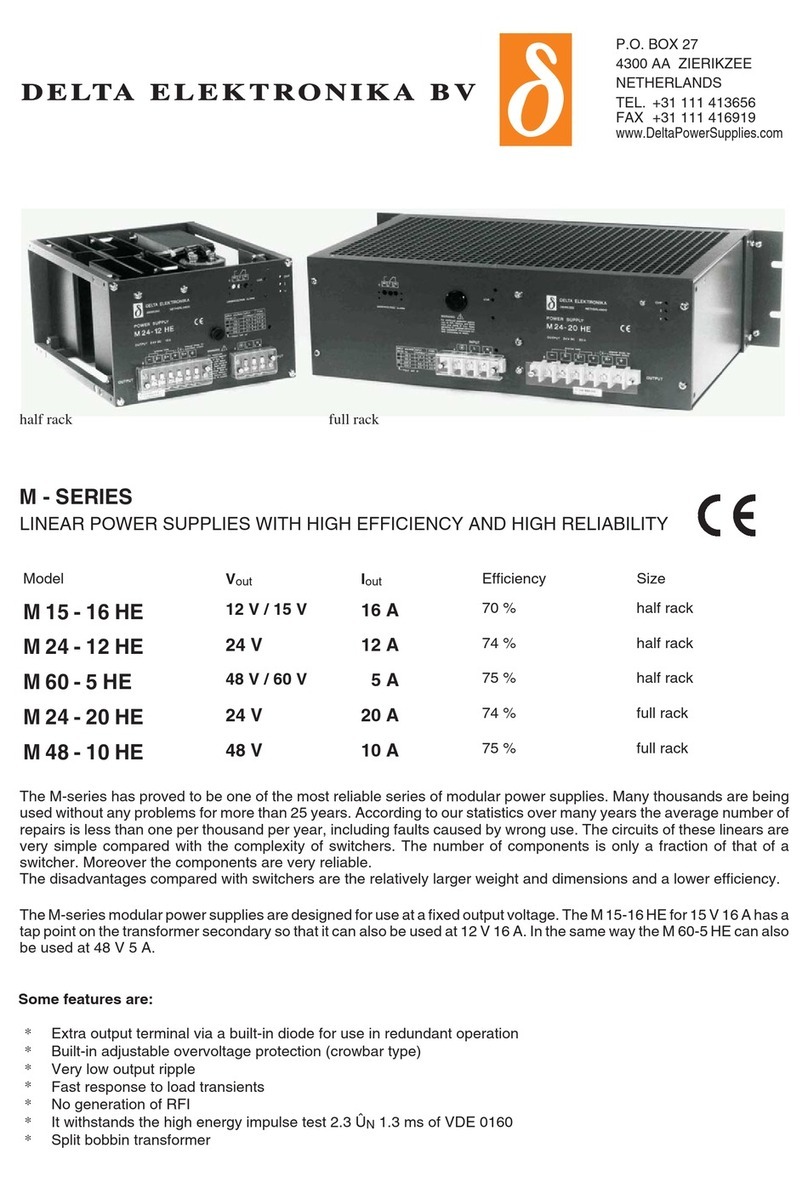

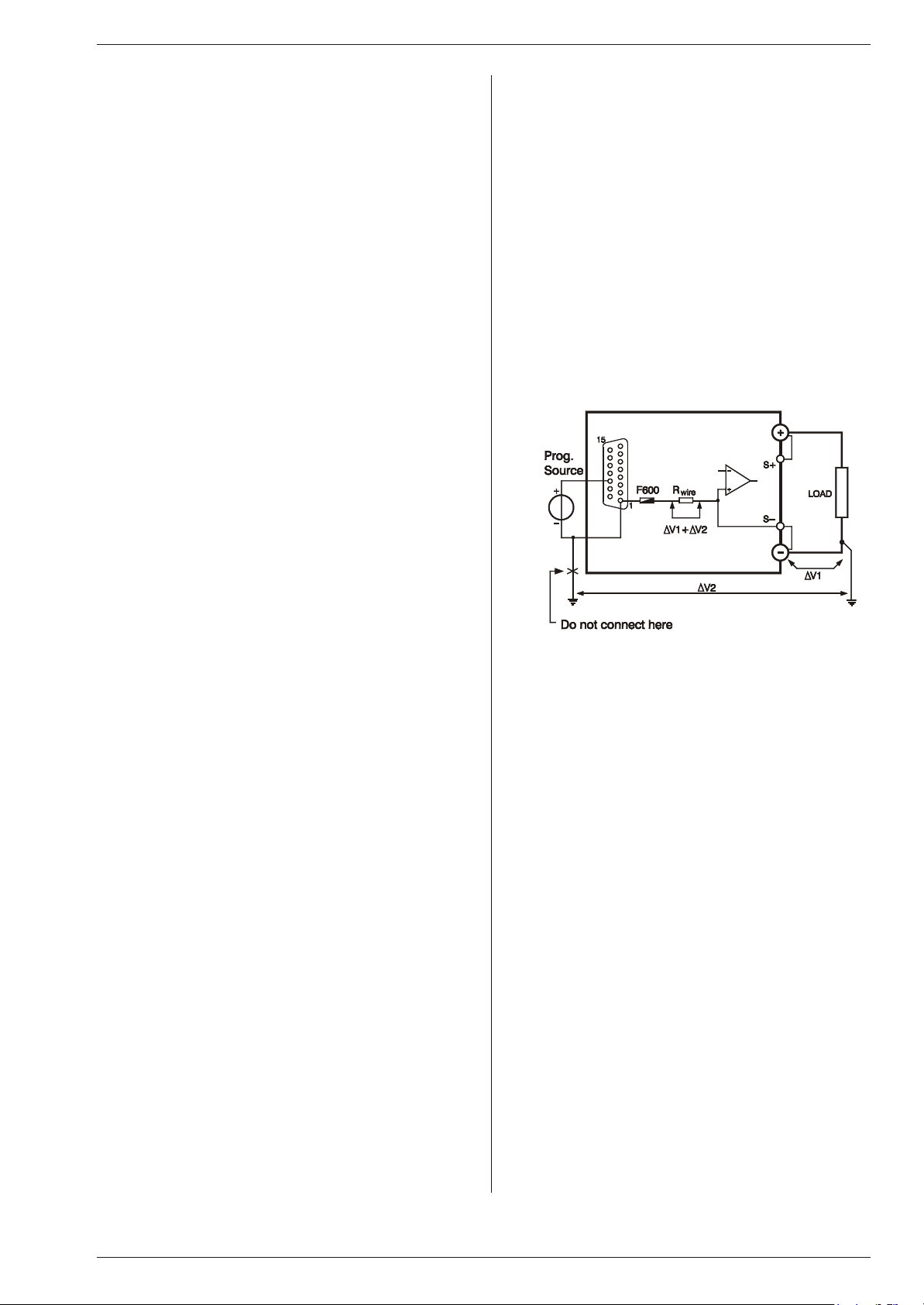

4) PROGRAMMING OFFSETS

°Unwanted offsets in the programming can be

caused by earth loops.

Fig.4-8 showsatypicalearthingproblem.Incasethe

load has a connection to earth and the programming

source as well, problems could occur. Improper

choice of the earthing point of the load can give a

voltage drop of ∆V1. Connecting the minus or zero to

aseparateearthconnectioncangiveavoltagedropof

∆V2. Because the internal wires of the programming

input are thin, the voltage drops ∆V1 and ∆V2 will be

accrosstheinternal wiringaswell.Resulting ina error

voltage in series with the programming voltage.

°The best solution for this is using a floating program-

ming source with the help of the ISO AMP MODULE

(δ-product) or a floating load.

5) STATUS OUTPUT FAILS

°Check fuse F7_2 in series with Ø(pin 8 of program-

ming connector). To check the fuse measure the

resistance between Øand the minus output, an open

circuit means a blown fuse. F7_2 = 650 mA.

6) MASTER / SLAVE PARALLEL PROBLEMS

°Accidental interruption of aminus lead ofa unit during

operation will cause fuse F7_1 to blow. To check the

fuse, measure the resistance between Ø(pin 1 of

prog. conn.) and the minus output, the fuse is a self

resetting type. F7_1 = 650 mA

°Check link between pin 9 and 11 on the programming

connector of the slaves.

7) NO LEDS on.

°Overheatingcanbethecause,cooling downwillreset

the thermal protection.

°Check input power.

°Check fuses inside unit.

fig. 4- 8

Unwanted programming offsets