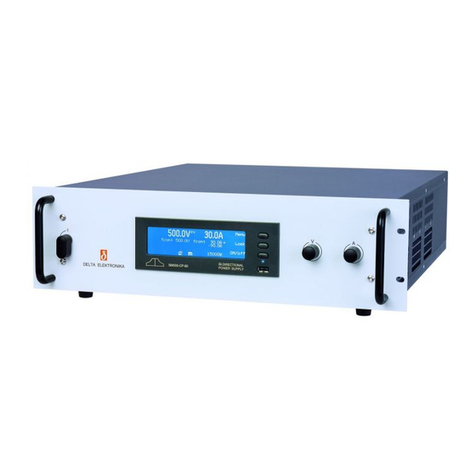

DELTA ELEKTRONIKA BV SM3000

Page 3 - 6 DESCRIPTIONS 1991, rev. May 2008

26) SERIES OPERATION

Series operation is allowed up to 600 V total voltage. The power supplies

can be connected in series without special precautions.

For easier control, Master / Slave operation is recommended (see fig. 3 -

20). By using the Master / Slave Series feature a dual tracking power sup-

ply can be made with one unit as master and one as slave.

For series operation in combination with Power Sink option, all units must

have a Power Sink built inside otherwise no power can be absorbed.

27) PARALLEL OPERATION

Paralleling of the units has no limitations. The power supplies can be con-

nected in parallel without special precautions. For easier control, Master /

Slave operation is recommended (see fig. 3 - 20 and fig. 3 - 21).

Normal parallel operation of Fast Programming units can give problems,

each combination has to be tested first, in combination with the load !

For parallel operation in combination with Power Sink option, only one unit

can have a Power Sink. Refer to Power Sink manual for details and restric-

tions.

28) MASTER / SLAVE OPERATION

The Master / Slave feature makes it possible to use the power supplies as

building blocks to form one large unit (see fig. 3 - 21).

The resulting combination of units behaves like one power supply and can

be programmed on the master. Figure 3 - 23 shows a computer controlled

M/S parallel combination.

Mixed parallel - series operation is also possible (see fig. 3 - 22), to a maxi-

mum of 600 V. Here the MASTER / SLAVE SERIES ADAPTER(δ-product)

must be used. For parallel operation connections can easily be made on

the analog programming connector.

In series mode the master controls one slave, which in turn controls the

second slave and so on. In parallel mode the master controls all the slaves.

The result is true current or voltage sharing in the parallel or series mode

respectively.

Note: Master / Slave parallel operation is not recommended for more

than 3 units or in combination with Fast Programming option.

Consult factory for a solution.

29) REMOTE SENSING

The voltage at the load can be kept constant by remote sensing. This fea-

ture is not recommended for normal use but only when the load voltage is

not allowed to vary a few millivolts. Always use a shielded cable for sens-

ing.

In order to compensate for the voltage drop across the load leads, the unit

will have to supply a higher voltage: Uout = (voltage drop across each lead)

+ (voltage across the load) (see fig. 3 - 24). The OVP reads the voltage di-

rectly at the output and the setting must be increased by the total voltage

drop across the load leads.

The voltmeter is connected to the sense leads and therefore reads the volt-

age across the load and not the voltage on the output terminals.

The sense leads are protected for accidental interruption, in which case

the output voltage will go to a max. of 115% of the set value.

Warning: Do not interrupt the minus lead while the S– lead is still con-

nected to the load, during operation.

For sensing on a pulsating load, see previous paragraph 17).

30) OVP

The Over Voltage Protector will protect your circuit from unwanted high

voltages.

A high output voltage could be caused by accidental interruption of leads,

accidentally turning up the voltage potmeter or a defect in the power sup-

ply. The OVP circuit uses a separate voltage divider connected directly to

the output terminals.

The OVP limits the output voltage to a value which can be set by the OVP

potmeter on the front panel. While doing this, press the DISPLAY OVP

SETTING button to read the limit value in the left display. The led on the

front panel will indicate whether the OVP has reached the limit. The OVP

status output will give a logic 1 (+5 V).

Note: The Thermal ShutDown and Remote ShutDown will also cause the

OVP-led to burn and the OVP-status will be high.

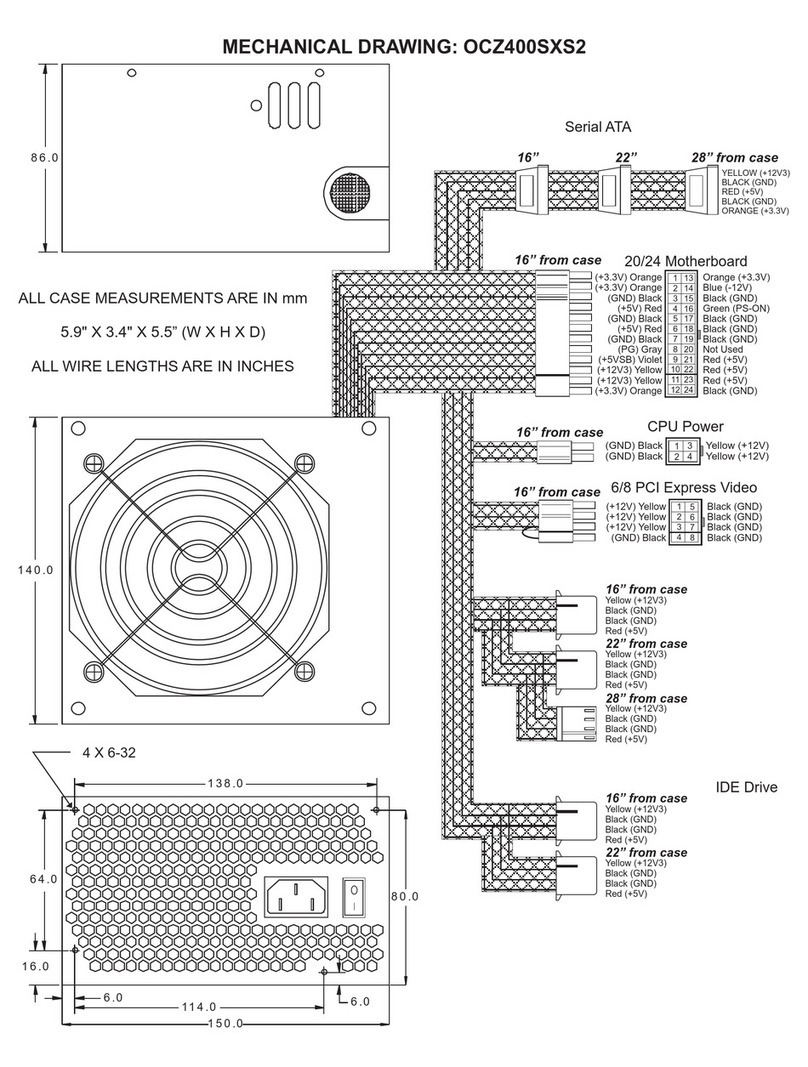

fig. 3 - 20

Master / Slave series operation

fig. 3 - 21

Master / Slave parallel operation

fig. 3 - 22

Master / Slave mixed series-parallel

fig. 3 - 23

The Master / Slave combination can also

be programmed with the interfaces

PSC-488 or the PSC-232