Models PT-70CE and PT-24-35

These models are designed for hard-wiring into the a.c. system. Input voltage

selection is made at the time of a.c. wiring installation, as follows:

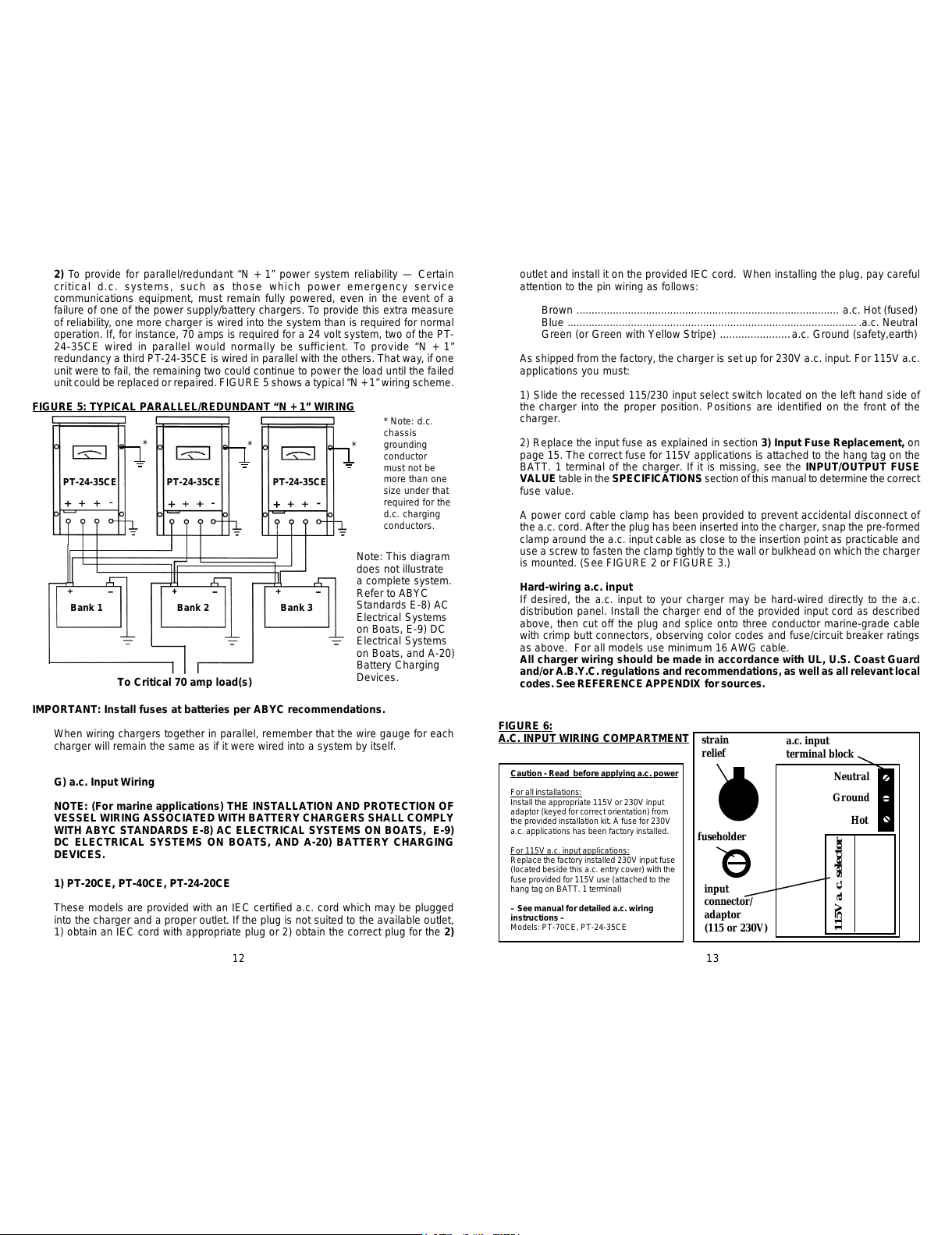

1) Read and remove the warning label (copy below) which covers the a.c. input

wiring compartment (see FIGURE 6.)

2)Select theproper connector/adaptor for your application(provided inthe installation

kit and labeled either 115V or 230V). Snap it into the adaptor receptacle. It is keyed

to ensure that it is properly positioned. Note: If the charger has previously been

used in a 115V application and must be converted for 230V use or vice-versa, the

existing connector/adaptor must be removed first. Do this by pinching hard on the

retaining tabs on either side and pulling firmly outward.

3) Snap the provided strain relief into the charger housing (oriented as shown in

FIGURE 6) and loosen the compression screw.

4) Strip about 1/4" of insulation off the ends of each a.c. input wire and feed the a.c.

input cord through the strain relief. 16 gauge (AWG) wire is sufficient for most

installations up to 20 feet in length. (Maximum gauge wiring terminal will

accommodate is 12 (AWG). Consult ABYC or USCG regulations for installations

with a.c. input wiring over 20 feet.

5) With narrow blade (1/8") flat tip screwdriver loosen the compression screw

terminals on the a.c. terminal block beside the connector/adaptor. Insert each a.c.

input wire into the appropriate terminal. The HOT and NEUTRAL terminals are the

outer terminals and are labeled on the circuit board to which terminal block is

attached. The GROUND wire is attached to the center terminal. Standard color

coding of a.c. wiring is as follows:

Europe USA

Brown........................................................Black ........................... .a.c. Hot (fused)

Blue...........................................................White ...................................a.c. Neutral

Green (or Green with Yellow Stripe)....... Green ............a.c. Ground (safety,earth)

6) Tighten the compression screw on the strain relief. Install the a.c. input wiring

cover which is provided in the installation kit. The screws which attach the wiring

cover to the charger have already been installed and will need to be removed first.

ALL MODELS: a.c. input for the charger must be plugged into an appropriate,

over-current protected three prong outlet (PT-20CE, PT-40CE and PT-24-20CE)

OR routed through a separate dedicated fuse or circuit breaker on an a.c.

distribution panel (PT-70CE, PT-24-35CE) with proper safety/earth chassis

ground in accordance with all local codes and ordinances.

Use the table below to determine the proper fuse or circuit breaker value,

depending on model and whether the application is 115 or 230V a.c.:

a.c. Fuse/Circuit Breaker Table

Model 115V a.c. 230V a.c

PT-20CE 10 amp 5 amp

PT-40CE, PT-24-20CE 15 amp 10 amp

PT-70CE, PT-24-35CE 20 amp 10 amp

CAUTION (230 V a.c applications only): If a.c. input is derived from a source

consisting of two HOT leads (phase-to-phase 230V a.c. input voltage), an

external fuse or circuit breaker must be used to protect the unfused (formerly

NEUTRAL, now HOT) lead.

3) Input Fuse Replacement

The a.c. input of your charger is protected by an input fuse. The input fuseholder is

located near the bottom of the unit on the left side (20 and 40 amp models) or on the

bottom of the unit, beside the a.c. strain relief (35 and 70 amp models). The proper

value for the input fuse is indicated on the lower left corner of the front panel. If the

input fuse needs replacing it must be replaced with the proper type and value. Use

standard or fast-blow fuses. Never use a slow-blow fuse.

Caution: Ensure that a.c. power to the charger has been disconnected before

attempting to open the fuseholder. To remove the fuse for replacement, insert a flat

tip screwdriver into the fuseholder cover and turn counterclockwise until the spring-

loaded cover releases. To replace the fuseholder cover, depress it fully into the

fuseholder and turn it clockwise until it locks into position (about a quarter turn).

Warning: Do Not replace the gray slotted cap of the fuseholder without a fuse

installed. It will not be retrievable. If this occurs, contact the factory.

All charger wiring should be made in accordance with UL, U.S. Coast Guard

and/or A.B.Y.C. regulations and recommendations, as well as all relevant local

codes. See section IX) REFERENCE APPENDIX. for sources.

IV) OPERATION

A) Three Stage Charge Regimen

The Phase Three Battery Charger features the three stage charge regimen which is

widely recommended by battery manufacturers for allowing the fastest possible

rechargetime without loss of batteries’ electrolyte (gel or liquid) which may be caused

by sustained charging at higher voltages.

This three stage regimen is initiated each time a.c. is first applied, when drained

batteries are most likely to be encountered. (This also occurs when the reinitialize

button on the optional remote panel is activated — see section D - Remote Panel

Option on page 18) The regimen proceeds as follows:

1) Bulk Charge - When batteries are significantly discharged the charger responds

initially by delivering a high amount of d.c. current, at or near the charger’s maximum

rated output, in order to rapidly replenish them. It is during this stage that charging

current is maintained at a high level as battery voltage increases. Bulk charging

continues until battery voltage reaches the “charge” voltage level (where batteries

are at about 75-80% of capacity). A current limit circuit prevents charger overload

during this maximum output stage.

2) Absorption Charge -During thissecond stageof thecharge cycle,battery voltage

is maintained at the “charge” voltage level. Output current begins to taper off as the

battery plates become saturated. Charge voltage is maintained until the current

sensing circuit detects that output current has tapered to about 5-15 % of charger

rating*. At this point the batteries are at about 95 % of full charge and the Phase

Three charger switches to the third and final stage of the charge cycle.

* Note: The absorption phase may also be ended by the time-out circuit. See section

B following for a complete explanation of the purpose and functioning of the time-

out circuit.

14 15