Delta OHM HD50 N/1 TC User manual

Operating manual

Web Data Logger

HD50 series

Keep for future reference.

www.deltaohm.com

English

Companies / Brands of

GHM

HD50 - 2 - V1.4

TABLE OF CONTENTS

1INTRODUCTION.................................................................................................... 3

2DESCRIPTION....................................................................................................... 4

2.1AVAILABLE MODELS .............................................................................................. 6

3INSTALLATION ..................................................................................................... 7

3.1POWER SUPPLY M8 CONNECTOR ............................................................................... 7

3.2CONFIGURATION ................................................................................................. 7

3.3HD50GH CONNECTIONS ....................................................................................... 8

4CONNECTION TO THE NETWORK........................................................................... 9

4.1HD35AP-CFR21 SOFTWARE OPTION ...................................................................... 10

5WEB SERVER....................................................................................................... 11

5.1SETTINGS MENU ............................................................................................. 12

5.2MONITOR MENU .............................................................................................. 18

5.3CONNECTIVITY MENU ...................................................................................... 20

5.4FILES MENU.................................................................................................... 27

6MODBUS ............................................................................................................. 28

7TECHNICAL CHARACTERISTICS .......................................................................... 38

8ADAPTER FOR CO2CALIBRATION ....................................................................... 43

9INSTRUMENT STORAGE ...................................................................................... 44

10SAFETY INSTRUCTIONS...................................................................................... 44

11ORDERING CODES .............................................................................................. 45

HD50 - 3 - V1.4

1INTRODUCTION

The data loggers of the HD50 series allow indoor monitoring of various physical quanti-

ties. The data loggers are available for the monitoring of:

•Temperature

•Humidity

•Atmospheric pressure

•Carbon dioxide (CO2)

•Illuminance

The models that measure relative humidity and temperature calculate absolute hu-

midity, Dew Point, wet bulb temperature, mixing ratio and partial vapour pressure.

Models with 4 input channels, with terminal header connections, are available for the

connection of standard analog sensors:

•Transmitters with 0÷20 or 4÷20 mA current output and -50÷50 mV, 0÷50 mV,

0÷1 V or 0÷10 V voltage output

•Pt100 / Pt1000 temperature sensors and K, J, T, N, E type thermocouples

•Sensors with potentiometric output

This allows extending the monitoring capability to countless other quantities, in addi-

tion to those listed above.

The versions with LCD can be equipped with a custom LCD (option L) or with a

graphic LCD (option G).

Three LEDs on the front panel indicate the status of power supply, LAN/WLAN local

network connection and alarm.

The data loggers can be connected to a local network via the Wi-Fi or Ethernet inter-

face. The data logger allows the simultaneous operation of two communication proto-

cols: proprietary and Modbus TCP/IP. The data logger manages up to 10 “TCP/IP Cli-

ent” simultaneously. If the local network is connected to Internet, the data can be

regularly sent to an FTP address, to the Cloud and via e-mail.

For each detected quantity, two alarm thresholds can be set by the user. Exceeding a

threshold is signaled acoustically, by means of the internal buzzer, visually, by lighting

the alarm LED on the front panel, and remotely, by sending alarm e-mails. An alarm

hysteresis and a delay in the generation of the alarm can be configured for each de-

tected quantity.

Thanks to the integrated web server, you can configure the data logger and view the

real time measurements from any PC, tablet or smartphone connected to the same lo-

cal network of the data logger by simply using a web browser.

The PC software HD35AP-S allows configuring the data logger, viewing the real time

measurements, downloading and viewing the data into a database. The HD35AP-S

software allows connecting one data logger at a time. If there are several data loggers

of the HD50 series in the local network, the PC software HDServer1 allows detecting

automatically all the data loggers connected to the network and the simultaneous

connection to all the data loggers, entering the data received by the data loggers into

a database, viewing the data in the database and configuring some basic parameters

of the devices (alarms, logging interval, …). The HD35AP-CFR21 software option

(available with both HD35AP-S and HDServer1) allows the protection of recorded data

and configuration in response to FDA 21 CFR part 11 recommendations.

The internal clock can be regularly synchronized with a NIST reference server.

HD50 - 4 - V1.4

2DESCRIPTION

1. LCD (custom for HD50L… models, graphic for HD50G… models).

2. Fixing flange.

3. LEDs.

4. Fixed temperature/RH probe (HD50…TV and HD50…TCV models) or M12 connec-

tor for temperature/RH probe probe with cable (HD50…TC models).

5. M12 connector for illuminance probe (only HD50…I… models).

6. CO2fixed probe (only HD50…B… models).

7. RJ45 connector for Ethernet connection.

8. Power supply input (terminal header for HD50…H, M8 connector for other models).

9. Terminal header inputs (only HD50…H).

HD50 - 5 - V1.4

DISPLAY:

Custom LCD

Graphic LCD

(*) The primary unit of measurement in the custom display and the date/time in the graphic dis-

play are replaced by the IP address of the data logger for 10 seconds every minute. The IP ad-

dress is also displayed after a reset or reconfiguration of the data logger network parameters.

•PRW or POWER LED: indicates the presence of the external power supply.

•NET or NETWORK LED: indicates the status of the connection to the local network.

•ALM or ALARM LED: lights up when a measurement is in alarm.

•LOG symbol: indicates that logging is active.

•CLOUD symbol: indicates that the data logger is configured to send the data to the

Cloud. It blinks until the connection with the server is established.

•HDServer1 symbol: indicates that the data logger is configured to send the data to

the HDServer1 software operating in a PC (server) of the local network. It blinks

until the connection with the software is established.

•Ethernet/WiFi symbol: indicates whether the Ethernet or Wi-Fi interface is active.

PWR (power) LED

NET (network) LED

ALM (alarm) LED

LOG symbol

Primary

measuring row (*)

Secondary

measuring row

CLOUD symbol

POWE

R

LED

NETWOR

K

LED

ALARM LED

Secondary

measuring row

Primary

measuring row

Ethernet/WiFi symbol

HDSe

r

ver1 symbol

Date

(

*

)

CLOUD symbol

Time

(

*

)

WiFi signal level

HDServer1 symbol

LOG symbol

HD50 - 6 - V1.4

2.1 AVAILABLE MODELS

In order to highlight the measured physical quantities, the ordering codes include some

identification characters for the various quantities, according to the following convention:

1 = Humidity

4b = Atmospheric pressure (barometer)

N = Temperature with NTC10K sensor

(N/1 = 1 channel, N/2 = 2 channels, N/3 = 3 channels)

7P = Temperature with Pt100/Pt1000 sensor

B = Carbon dioxide (CO2) low range (0…5,000 ppm)

B2 = Carbon dioxide (CO2) high range (0…10,000 ppm)

I = Illuminance low range (0…20,000 lux)

I2 = Illuminance high range (0…200,000 lux)

To indicate the fixed probe or the probe with cable, the following indications are used:

TC = Probe with cable (M12 connector)

TV = Fixed vertical probe without cable

TCV = Fixed sensors + photometric probe with cable

Available HD50… series models:

MEASURES INPUTS OPTIONAL LCD

L G

Model

NTC10K

Pt100 RH Patm CO2Lux

Number of

M12

connectors

Built-in

sensors Custom Graphic

HD50 N/1 TC •1••

HD50 N/2 TC •2••

HD50 N/3 TC •3••

HD50 N TV ••••

HD50 1N TC ••1••

HD50 17P TC ••1••

HD50 1N TV •••••

HD50 14bN TV ••••••

HD50 14bN TC •••1Patm ••

HD50 14b7P TC •••1Patm ••

HD50 1NB… TV ••••••

HD50 14bNB… TV •••••••

HD501NI…TCV •••1T/RH ••

HD5014bNI…TCV ••••1T/RH/Patm ••

HD501NB…I… TCV ••••1T/RH/CO2••

HD5014bNB..I..TCV •••••1T/RH/CO2

Patm ••

HD50GH (*)

Transmitters with 0÷20 mA, 4÷20 mA, -50÷50 mV,

0÷50 mV, 0÷1 V or 0÷10 V output

Pt100 /Pt1000 sensors, thermocouples K, J, T, N, E

Sensors with potentiometric output

4

terminal header

inputs •

(*) The model with terminal header inputs always has the graphic display (not available without display).

HD50 - 7 - V1.4

3INSTALLATION

Wall mount the instrument by using the supplied flanges.

3.1 POWER SUPPLY M8 CONNECTOR

M8 connector Function Wire color

1 Power supply positive (+Vdc) Brown

2 Not used

3 Power supply negative (GND) Blue

3.2 CONFIGURATION

The parameters of the instrument (logging parameters, alarm thresholds, quantities

to be acquired, network settings, etc.) can be configured by connecting the instru-

ment to the PC via Ethernet or Wi-Fi local network (see chapter 4) and using the web

server feature of the data logger (see chapter 5) or the HD35AP-S application software

(see the instructions of the software).

Some basic parameters (alarms, logging interval, user code, …) can also be set with

the HDServer1 application software.

Flange

Hole for

fixing screw

+Vdc

GND

M8 male connecto

r

of the instrument

(external view)

CPM8…

cable

HD50 - 8 - V1.4

3.3 HD50GH CONNECTIONS

In the HD50GH model, each of the 4 analog inputs can be configured as a

Pt100/Pt1000, thermocouple, 0/4…20 mA (the shunt resistance is inside), -50…50 mV,

0…50 mV, 0…1 V, 0…10 V or potentiometric input.

To configure an input, open the housing of the instrument by unscrewing the 4 front

screws and set the two switches (A and B) and the two jumpers (C and D) located

above the input terminals as shown below. Next, complete the inputs configuration us-

ing the web server feature of the data logger (see the panel SETTINGS >> INPUTS in pa-

ragraph 5.1) or the HD35AP-S software (see the section Data loggers configuration >>

Inputs setup of the instructions of the software).

Pt100 / Pt1000

2 wires

Pt100 / Pt1000

3 wires

Pt100 / Pt1000

4 wires

0…50 mV

-50…50 mV

0…1 V

0…10 V

0…20 mA

4…20 mA

Thermocouple

K,J,T,N,E

Potentiometer

•The switches A and B are set to the right only in the configuration 0…10 V;

in the other cases, the switches A and B are set to the left.

•If a channel is configured as current input, close the jumper D; in the other

configurations, leave the jumper D open. The current input accepts any val-

ue in the range from 0 to 20 mA.

•If a channel is configured as -50…50 mV, 0…50 mV or thermocouple input,

close the jumper C; in the other configurations, leave the jumper C open.

•The thermocouple inputs are not isolated. Do not connect the internal USB port

when not isolated thermocouple probes are connected, to avoid ground loops.

GND (analog ground)

IN-

IN+

Excitation voltage

ch1/ch2/ch3/ch4

Power supply

Channel 1

Ethernet

Channel 3

Channel 2

Channel 4

Confi

g

uration

switches / jumpers

HD50 - 9 - V1.4

4CONNECTION TO THE NETWORK

The data logger can be connected to the local network via Ethernet (default) or Wi-Fi

(the two interfaces are alternatives, they can not be used simultaneously).

For the Ethernet mode, connect the RJ45 connector of the data logger to a socket of

the local network via a standard Ethernet cable.

The data loggers are preset to get a dynamic IP address from the network DHCP server.

The data loggers with LCD display the IP address (see pag. 5). For the data loggers

without LCD, the IP address can be displayed on the PC by using the HDServer1 soft-

ware, which can automatically detect the data loggers connected to the network. A static

IP address can be set by using the web server feature of the data logger (see chapter 5)

or the HD35AP-S application software.

To connect the data logger to a Wi-Fi network, you must first change the setting of the

data logger interface by connecting the data logger to the PC via Ethernet and using

the web server feature of the data logger (see the panel CONNECTIVITY >> NETWORK

in paragraph 5.3) or the HD35AP-S software. Alternatively, connect the data logger to

the PC via USB through the internal mini-USB connector (open the housing of the in-

strument by unscrewing the 4 front screws, the mini-USB connector is located to the

right of the display) and use the HD35AP-S software.

The data logger can be accessed from any PC of the local network. To download the da-

ta in a database, the HD35AP-S (it allows connecting one data logger at a time) or

HDServer1 (it allows connecting several data loggers simultaneously) application soft-

ware and the MySQL database management system (included in the HD35AP-S soft-

ware package) must be installed.

Thanks to the availability of two TCP/IP virtual ports, each of which can operate with

proprietary (for the connection with HD35AP-S software) or MODBUS TCP/IP proto-

col, and ten sockets (in total, to be divided between the two ports), the data logger

allows the simultaneous operation of two communication protocols (proprietary and

Modbus TCP/IP) and manages up to 10 “TCP/IP Client” simultaneously. The default

setting of the ports is the following:

•Port number = 5100 for proprietary protocol (8 sockets)

•Port number = 502 for Modbus TCP/IP protocol (2 sockets)

If the local network is connected to Internet, the data can be regularly sent to an FTP

address, to the Cloud and via e-mail (as attachments).

Note: if the communication with the Cloud is used, the maximum number of “clients”

with proprietary or MODBUS TCP/IP protocol is nine.

To configure the TCP/IP ports and the sending of data over the Internet, use the web

server feature of the data logger (see chapter 5) or the HD35AP-S software.

Restoring the factory LAN/WLAN configuration:

It is always possible to restore the default LAN/WLAN settings by following these steps:

1) Open the housing of the instrument by unscrewing the 4 front screws.

2) Place the short jumper over the NET RST push-button (to the left of the display)

between the “2” and “3” indications.

3) Press the NET RST push-button.

4) After the reset, replace the short jumper between the “2” and “1 (NORMAL)” indi-

cations.

HD50 - 10 - V1.4

4.1 HD35AP-CFR21 SOFTWARE OPTION

The HD35AP-CFR21 option allows, in addition to the features of the basic software

(both HD35AP-S and HDServer1), the protection of recorded data and instrument con-

figuration in response to FDA 21 CFR part 11 recommendations. In particular be-

come available:

•The traceability of activities (Audit Trail) performed with the software; for exam-

ple, which users connected and what changes were possibly made to the configu-

ration of the instrument.

•The management of users access for the instrument configuration and viewing of

data in the database. Each user can be assigned a different password for using the

software. There are also three levels of access (Administrator, Super-user and stan-

dard User); for each level, the allowed operations can be defined.

The HD35AP-CFR21 option works with USB hardware key to be connected to any PC con-

nected to the same local network of the PC in which the basic software is installed.

Note: if the HD35AP-CFR21 option is used, the data logger integrated web server allows view-

ing measurements and configuration, but not the modification of the data logger configuration,

because the settings changed via web server can not be traced.

ETHERNET connection

Wi-Fi connection

HD50 - 11 - V1.4

5WEB SERVER

The data logger has an integrated web server through which you can configure the data

logger and view the real time measurements from any PC, tablet or smartphone con-

nected to the same local network of the data logger by simply using a web browser.

To connect to the web server, type the IP address of the data logger in the address

bar of the web browser of your device (PC, tablet, smartphone, …).

Note: the data loggers with LCD display the IP address (see pag. 5); for the data loggers

without LCD, the IP address can be displayed on the PC by using the HDServer1 soft-

ware, which can automatically detect the data loggers connected to the network.

Note: if a port number other than the standard HTTP (80) has been set in the data

logger, the port number must be specified after the IP address (IPaddress:port num-

ber).

In the web server starting window, enter the user name and the password supplied

with the data logger, then press Submit.

Structure of the web server menu:

SETTINGS

INFO Data logger general information

CONFIGURATION Modbus address, user code and belonging group

MEASURES Selection of the quantities to be displayed

LOGGING Logging settings

ALARMS Alarm thresholds and hysteresis

UNITS Units of measurement

CHANNELS/INPUTS Selection of the quantities to be displayed with the Monitor function (ex-

cept HD50GH ) or configuration of the input channels (only HD50GH)

MONITOR

MEASURES Display of the real time measurements

CHART Graphs of the measurements acquired by the Monitor function

SETUP Settings of the graphs of the measurements

TABLE Numeric table of the measurements acquired by the Monitor function

CONNECTIVITY

NETWORK LAN/WLAN settings(Wi-Fi or Ethernet choice, IP address, etc.)

WIFI List of the Wi-Fi networks to which the data logger connects

EMAIL Settings for sending e-mails

FTP Settings for sending data via FTP

CLOUD Settings for sending data to the Cloud

SERVER Settings for the connection with the HDServer1 software

CLOCK Setting of the automatic clock synchronization

FILES

LOAD Import of data files

CHART Graphs of imported measurements

SETUP Settings of the graphs of imported measurements

TABLE Numeric table of imported measurements

HD50 - 12 - V1.4

5.1 SETTINGS MENU

The SETTINGS menu allows viewing the data logger general information and configuring

the Modbus address, the user code, the belonging group, the logging parameters, the

alarms and the units of measurement. It also allows choosing the measurements to be

stored in the internal memory and displayed in real time (Monitor) and in what order.

•INFO panel

Displays the general information of the instrument:

omodel, serial number

ouser code

obelonging group

oWi-Fi signal level (only if the Wi-Fi interface is active)

obehaviour when the internal memory is full (cyclic overwriting or not)

ologging status

obuzzer activation status

oModbus address, firmware version

ologging interval

omeasurement interval

ocalibration date

•CONFIGURATION panel

Setting of Modbus address, user code and belonging group (defining a group is useful

for identifying subsets of devices, for example the devices installed in the same envi-

ronment). Press “Apply” to send the changes to the data logger.

Button to refresh

the settings

HD50 - 13 - V1.4

•MEASURES panel

Selection of the quantities to be displayed cyclically on the data logger display. For

each quantity, a custom name can be defined. In the panel, the resolution and the

unit of measurement of each quantity are also indicated. The quantities available de-

pend on the data logger model type.

•LOGGING panel

Setting of logging interval, measuring interval, logging status (active or not active),

memory management mode when it is full (cyclic overwriting or stop logging).

If the logging interval is greater than the measuring interval, the average of the mea-

surements acquired during the logging interval will be stored.

The “Erase Memory” button allows erasing the data in the data logger memory.

Select the quantities to be displayed cyclically on the display

Custom name

Select to define a custom name

Button to refresh

the settings

Press “Apply” to send the changes to the data logger

Logging

interval

Measuring

interval

Press “Apply” to send the

changes to the data logger

Cycli

c

: cyclic overwriting of the memory

NO Cyclic: logging is stopped when the memory is full

Button to erase the memory

Button to refresh

the settings

Activ

e

: logging is active

NO Active: logging is not active

HD50 - 14 - V1.4

•ALARMS panel

Setting of the alarm thresholds for each of the available quantities. The alarm is gen-

erated if the measured value falls below the lower threshold or rises above the upper

threshold. The hysteresis and the delay time of the alarm can be configured.

The amplitude of the hysteresis is in percentage (0...100%) of the difference between the

two alarm thresholds. For example, if the hysteresis is 2%, the lower threshold is 10 °C

and the upper threshold is 60 °C, the hysteresis in °C is equal to (60-10)x2/100= 1 °C.

The alarm is generated after the set delay time (or immediately if the “no delay” op-

tion is selected). If the alarm condition disappears before the delay time has elapsed,

the alarm is not generated.

Press “Apply” to send the

changes to the data logger

Lower

threshold

Upper

threshold

Button to refresh

the settings

Alarm

hysteresis

Alarm

delay

Enable/Disable

Buzzer

Send e-mail if the upper

threshold is exceeded

Send e-mail if the lower

threshold is exceeded

O

K

O

K

ALARM

ALARM

O

K

Hysteresis

Hysteresis

Upper threshold

Lower threshold

HD50 - 15 - V1.4

•UNITS panel

Setting of the temperature (°C or °F) and pressure (mbar, bar, Pa, hPa, kPa, atm,

mmHg, mmH2O, inHg, inH2O, kgf/cm2or PSI) units of measurement.

•CHANNELS panel (not present in HD50GH model)

Allows choosing the measurements to be stored in the internal memory and displayed

in real time with the Monitor function and in what order. The panel has two lists: the

quantities available (to the left) and the quantities to be displayed (to the right). The

quantities are displayed in the order in which they appear in the list on the right.

Temperature unit

of measurement

Press “Apply” to send the

changes to the data logger

Pressure unit

of measurement

Activates all

the quantities

Delete the quantity selected

in the list on the right

Moves upwards or

downwards the quantity

selected in the list on

the right

Press “Apply” to send the

changes to the data logger

Button to refresh

the settings

Button to refresh

the settin

g

s

HD50 - 16 - V1.4

•INPUTS panel (present only in HD50GH model)

Allows configuring the inputs of the HD50GH model. For each of the four inputs (Input

1, Input 2, Input 3, Input 4) select the input type.

The available input types are:

•Temperature PT100 …: Pt100 sensor (2W=2 wires, 3W=3 wires, 4W=4 wires)

•Temperature PT1000 …: Pt1000 sensor (2W=2 wires, 3W=3 wires, 4W=4 wires)

•Temperature TC …: thermocouple (K, J, T, N, R, S, B or E type)

•Voltage 0-1V: 0…1 V voltage input

•Voltage 0-50mV: 0…50 mV voltage input

•Current 4-20mA: 4…20 mA current input

•Potentiometer: potentiometric input

•Mapped Voltage 0-1V: 0…1 V voltage input with associated physical quantity

•Mapped Voltage 0-50mV: 0…50 mV voltage input with associated physical quantity

•Mapped Current 4-20mA: 4…20 mA current input with associated physical quantity

•Mapped Potentiometer: potentiometric input with associated physical quantity

•Voltage 0-10V: 0…10 V voltage input

•Mapped Voltage 0-10V: 0…10 V voltage input with associated physical quantity

•Voltage -50-50mV: -50…50 mV voltage input

•Mapped Voltage -50-50mV: -50…50 mV voltage input with associated physical quan-

tity

If the input is not used, select Not Defined (last option of the list).

Note: select Current 4-20mA or Mapped Current 4-20mA also for 0…20 mA input signals.

Press “Apply” to send the

changes to the data logger

Button to refresh

the settings

Selection of the

input type

HD50 - 17 - V1.4

If a Mapped input type is selected, additional fields appear to define the correspon-

dence between the input signal and a physical quantity.

Select the unit of measurement and the resolution of the physical quantity associated

to the input. Enter in the fields X1, X2, Y1 and Y2 the coordinates of the linear relation

between the input signal and the physical quantity:

X1 = value of input signal in the first point (e.g. 4.00 mA)

Y1 = value of the physical quantity corresponding to the input value X1 (e.g. 0.0 °C)

X2 = value of input signal in the second point (e.g. 20.00 mA)

Y2 = value of the physical quantity corresponding to the input value X2 (e.g. 70.0 °C)

xx = 4.00 mA

1

y

x = 20.00 mA

2

y = 70.0 °C

1

y=0.0°C

2

Press the key Set to apply to the measure an offset equal to the opposite of the cur-

rently measured value (the current measure becomes equal to zero). Press the key

Clear to cancel the applied offset.

If a Mapped input type is selected, the data logger doesn’t store the input value in V

or mA, but the corresponding value of the physical quantity associated to the input.

Physical quantity

(e.g. temperature)

Input signal

(e.g. 4…20 mA)

HD50 - 18 - V1.4

5.2 MONITOR MENU

The MONITOR menu allows viewing the real time measurements, both in graphic and

table form. The measurements and the corresponding date/time are updated at inter-

vals equal to the logging interval. The measurements acquired by the Monitor function

can be saved in a log file and exported in CSV format.

•MEASURES panel

Displays the current value of the quantities (only those selected for logging).

The measurements in alarm are highlighted with a red background. The Land Hsym-

bols indicate whether the lower (L) or higher (H) threshold has been exceeded.

•CHART panel

Displays the graphs of the measurements acquired by the Monitor function. The quanti-

ties can be displayed on the same graph or in separate graphs (see the SETUP panel).

Wi-Fi

signal level

Measurement in alarm

Button fo

r

exporting the graph

(jpg or png format)

HD50 - 19 - V1.4

•SETUP panel

Setting of the quantities and information to be displayed in the graphs.

•TABLE panel

Displays in numerical form the measurements acquired by the Monitor function.

Time extension of

the graph (X axis)

X axis manual

scroll interval X axis manual scroll buttons

Pause/Start automatic scroll

Displays the data in the

“From” … “To” … interval

Single: all quantities on the same graph

Multiple: a graph for each quantity

Y axis minimum and maximum values

Automatic or manual Y axis scale

Selection of the quantities to be plotted

Selection of the information to be displayed in the graphs

Button fo

r

exporting data

(log or csv format)

Graphs

refresh interval

HD50 - 20 - V1.4

5.3 CONNECTIVITY MENU

The CONNECTIVITY menu allows configuring the network (Wi-Fi or Ethernet) and the

sending of data via e-mail, FTP or to the Cloud (if the network has an Internet con-

nection). It also allows setting the automatic clock synchronization and the time zone.

•NETWORK panel

Setting of the network interface type (Wi-Fi or Ethernet), of the protocols, of the

TCP/IP ports, of the IP address and of the DNS server address.

Note: if the data logger IP address is changed, the new address must be entered in

the web browser to connect to the web server.

If a port number other than the standard HTTP (80) is set as web server listening

port, the port number must be specified after the IP address in the web browser. For

example, if 40 is set as listening port number of a data logger with IP address

192.168.1.2, in the web browser you need to type 192.168.1.2:40.

The WLAN/LAN module has two TCP/IP ports. For each of the two ports, set the fol-

lowing:

othe protocol : select Proprietary TCP (proprietary protocol) or Modbus TCP.

othe port number : the numbers set by default are 5100 for the proprietary proto-

col and 502 for the Modbus TCP/IP protocol.

othe number of sockets of the port : the number of sockets corresponds to the

maximum number of connections that can be active at the same time through

the port. In total there are 10 sockets to be divided between the two ports

(for example, if 8 sockets are assigned to the first port, the second port can have

a maximum of 2 sockets).

Protocols, por

t

s and

number of sockets

Web serve

r

listening port

Enable/disable the

WLAN

/

LAN module

DNS se

r

ve

r

s

Button to refresh

the settings

Reset of the

WLAN/LAN module

Press “Apply” to send the

changes to the data logger

IP

address

Wi-Fi o

r

Etherne

t

selection

This manual suits for next models

16

Table of contents

Other Delta OHM Other manuals

Popular Other manuals by other brands

Siemens

Siemens SIMATIC RF1060R operating instructions

Counter Assault

Counter Assault Pentagon user manual

DV8

DV8 RS-14 installation guide

Quadratec

Quadratec 92122.203 series Assembly and installation manual

Hortitek

Hortitek Defender Series instruction manual

EMG

EMG MMTW Dual Mode Installation information

Mallory

Mallory 3146A Installation instructions manual

Greenheck

Greenheck FSD-3XXV Series Installation, operation and maintenance

EWM

EWM Trolly Y operating instructions

Costalab

Costalab Natural Drive MKII quick start guide

Measurement Computing

Measurement Computing USB-5100 Series Software Help

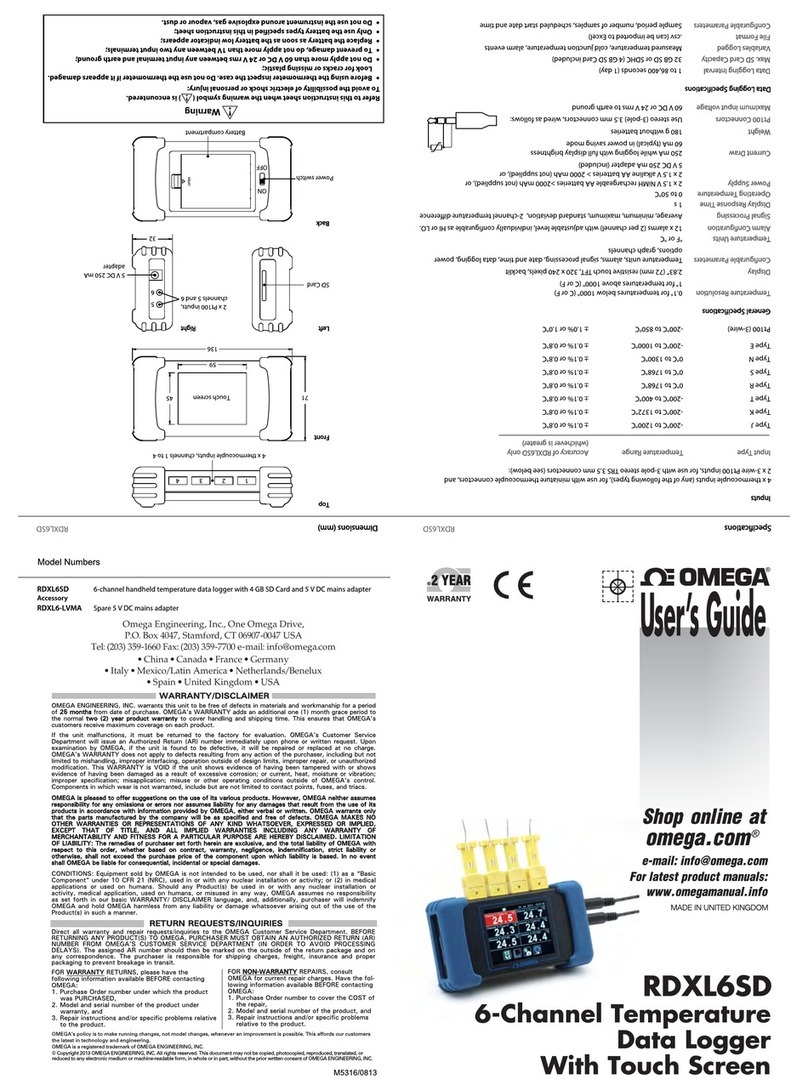

Omega

Omega RDXL6SD user guide

![Delta OHM HD33[L]M.GSM User manual Delta OHM HD33[L]M.GSM User manual](/data/manuals/1r/8/1r86k/sources/delta-ohm-hd33-l-m-gsm-manual.jpg)