Delta Regis Tools Inc.

7370 Commercial Circle

Fort Pierce, FL 34951

www.deltaregis.com

5

* Before using your new spring balancer, please read this manual carefully to ensure proper use and

prolong the life of the unit.

The following safety notaons are used throughout the manual to highlight safety precauons for

the user and for the machine.

!

!

!

DANGER

WARNING

CAUTION

DANGER indicates a potenally hazardous situaon which, if not

avoided by following the instrucons given, could result in death or

serious injury .

WARING indicates a potenally hazardous situaon which, if not

avoided by following the instrucons given, could result in death or

serious injury.

CAUTION indicates a potenally hazardous situaon which, if not

avoided by following the instrucons given, could result in injury or

material damage.

1. SAFETY INSTRUCTIONS(Spring Balancer)

Important safety instrucons for all spring balancers. When using spring balancers,

basic safety precauons should always be followed to reduce risk of personal injury.

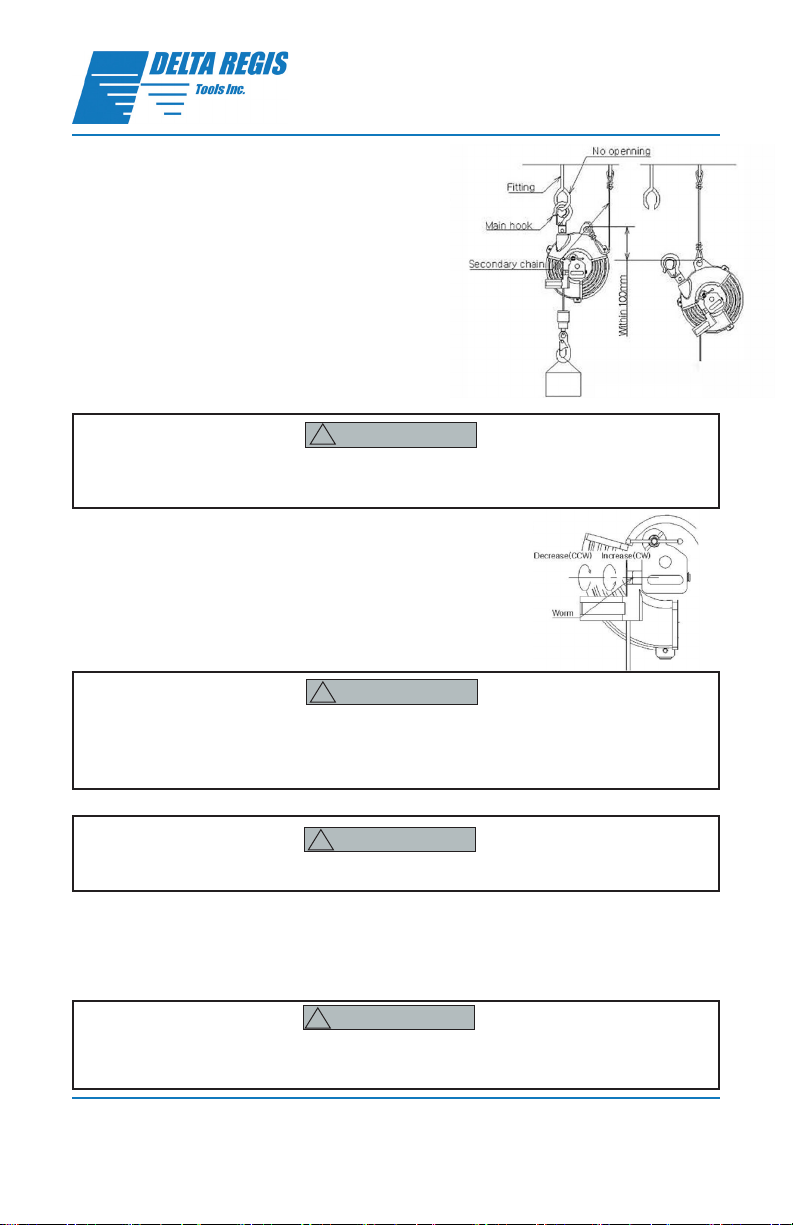

1-1 Spring Balancer Installaon

• Install the balancer correctly. Incorrect installaon could cause personal injury or damage to

the Spring Balancer or other equipment.

• Install secondary wire rope or chain to the spring balancer. If the spring balancer’s main

hanger of ng link is damaged, it could protect workers’ safety from accidents.

• Make sure that the assist wire rope or secondary chain should be mounted

to a dierent locaon than the Spring Balancer’s main hanger.

• Make sure that there is enough slack in assist wire rope or secondary chain, so that it is able

to move freely. ln this installaon, if the main hanger breaks or falls down,

make sure to leave only a small amount of slack to avoid injury.

• Install stronger ng link than the maximum capacity of the Spring Balancer.

• The ng link must be closed so that it does not fall when even Spring Balancer’s shakes.

• Do not x the main hanger of Spring Balancer. Make sure it can swivel freely.

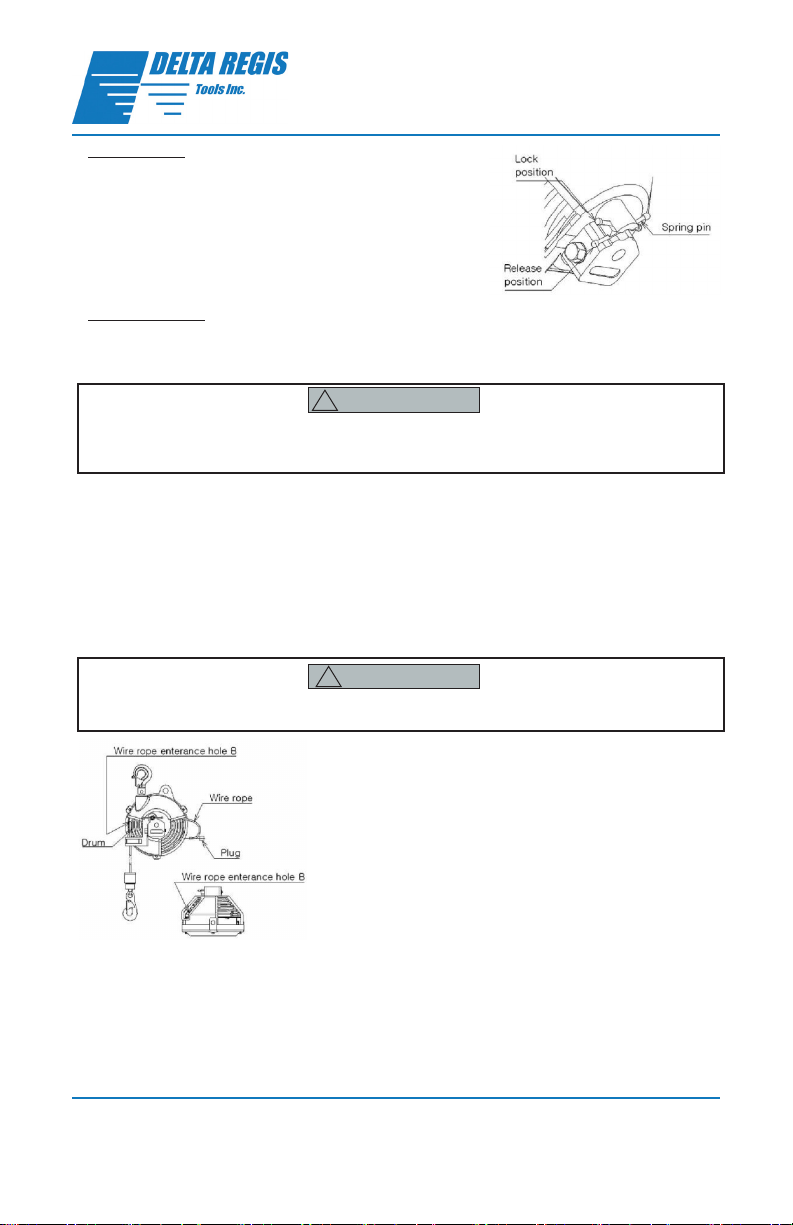

1-2 Direcons for the use of Spring Balancer

• Never pull down the cable while releasing spring tension.

• Never remove the tool from the Spring Balancer’s hook while the cable is extended. The

fast winding of cable could cause personal injury when you let go of the cable.

• Never work right under the suspended spring balancer and tool.

• Never Alter the Spring Balancer.

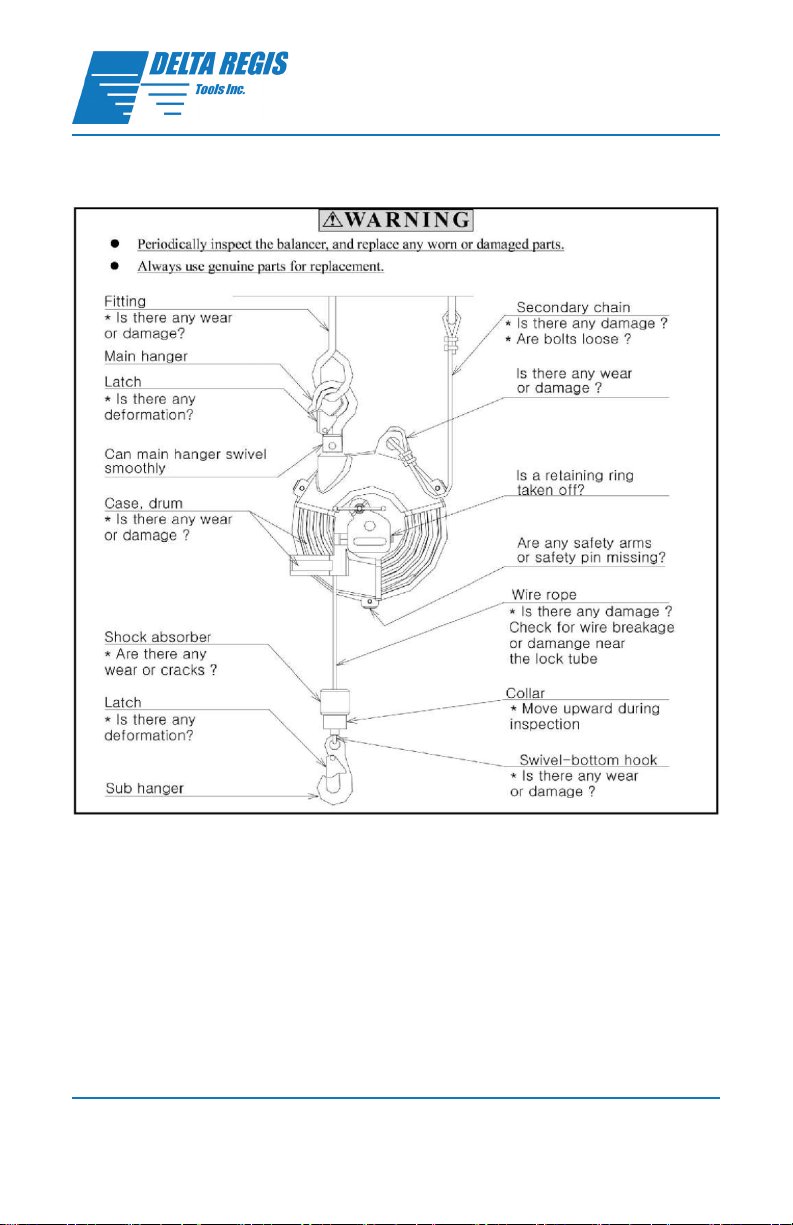

!WARNING

!WARNING