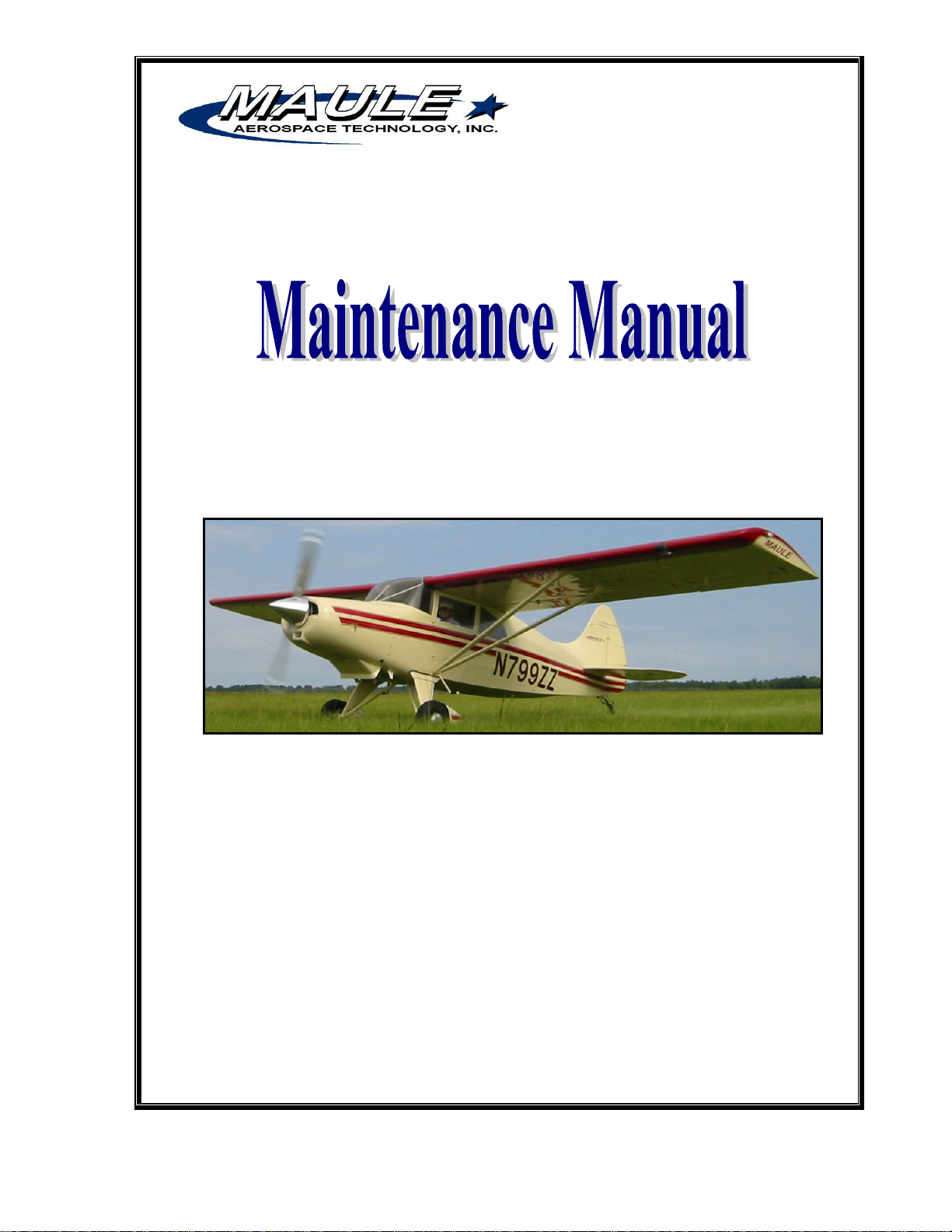

MAULE AEROSPACE TECHNOLOGY, INC.

MAINTENANCE MANUAL

FOR M-4-180V

2

Rev. A

4/13/16

FORWARD

Ahead of you are many hours of flying pleasure. The more you fly your Vintage M-4-

180V the more you will realize that flying this aircraft is a stimulating new sensation that will

never grow old.

The Maule M-4 was designed and built to give you the airplane you have always

wanted. It is fast, comfortable, and easy to fly, yet no light airplane is safer than the Maule

M-4. Its sturdy construction means you will not have to pamper it to enjoy long years of

trouble-free service.

Our dealers and distributors are anxious to serve you and will gladly furnish advice as

to proper servicing methods. You may also address requests for information on any items

not covered in this manual to the Service Department of Maule Air. In correspondence,

please be certain to give complete information on serial number, engine make and model,

etc.

WARRANTY

Maule Air, Inc. warrants each new airplane manufactured by it to be free from defects in

material and workmanship under normal use and service, provided, however, that this

warranty is limited to making good at the Maule factory any part or parts thereof which shall,

within one (1) year after delivery of such airplane to the original purchaser, be returned to

Maule with transportation charges prepaid, and which upon Maule's examination shall

disclose to its satisfaction to have been thus defective; this warranty being expressly in lieu of

all other warranties expressed or implied and all other obligations or liabilities on the part of

Maule, and Maule neither assumes nor authorizes any other person to assume for it any

other liability in connection with the sale of its airplane.

This warranty shall not apply to any airplane which shall have been repaired or altered

outside Maule's factory in any way so as, in Maule's judgment, to affect the airplane’s stability

or reliability, or which airplane has been subject to misuse, negligence or accident.

Certain items of equipment are warranted separately by their manufacturer. The

engine and accessories are warranted by Textron Lycoming, Williamsport, PA. The Hartzell

Propeller is warranted by Hartzell Propeller, Inc., Piqua, OH. Sensenich Propeller is

warranted by Sensenich Propeller Manufacturing Company, Inc., Lititz, PA 17543. Avionics

items are warranted by their manufacturers. Manufacturers of separately warranted item of

equipment request that warranty claims be made through your nearest authorized Distributor

or authorized Service Center. Maule Air will be glad to help you find that facility nearest to

you.