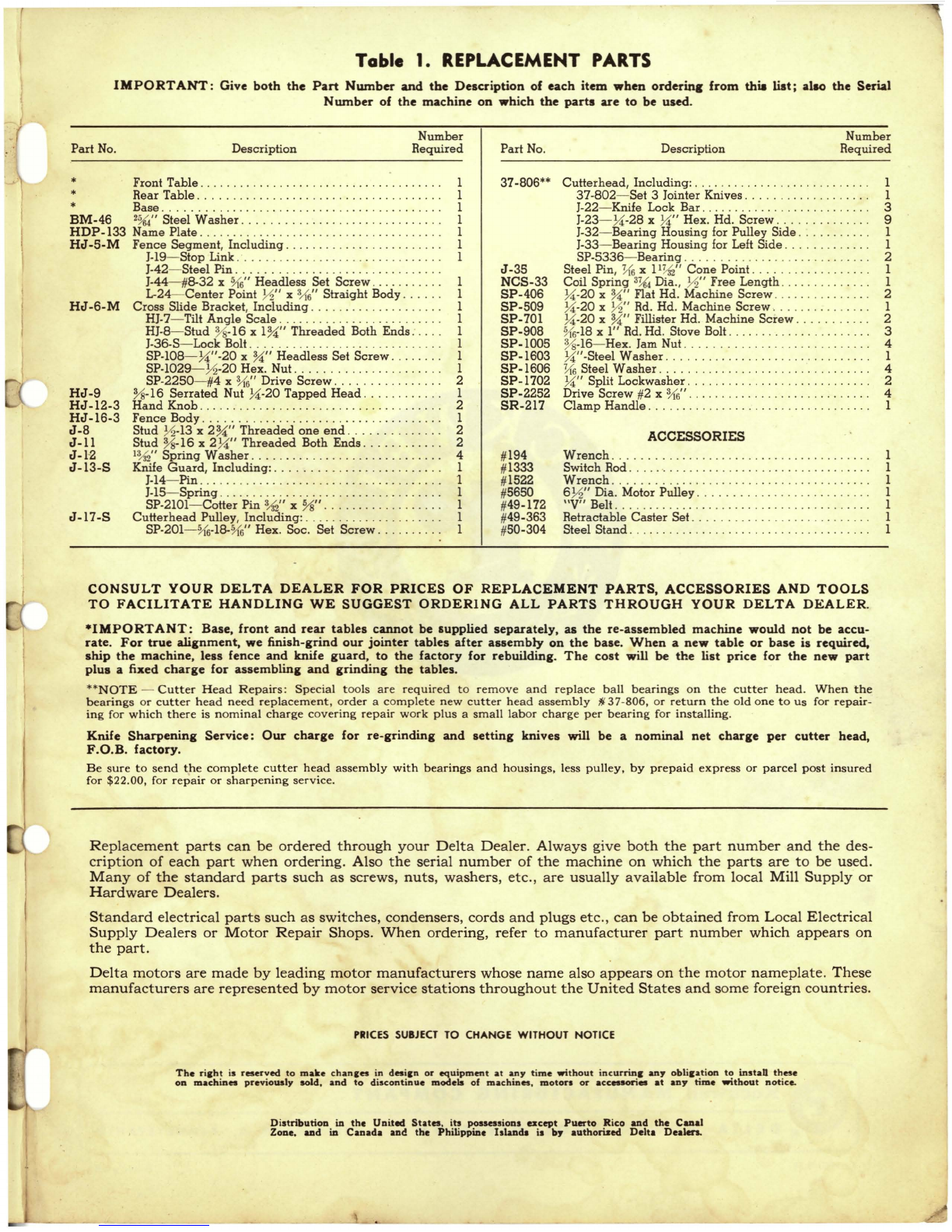

IMPORTANT:

Give

both

the

Part

Number

and

the

Description

of

each

item

when

orderinc

from

thia

list;

allO

the

Serial

Number

of

the

machine

on

which

the

parts

are

to

be used.

Table

1. REPLACEMENT PARTS

1

1

3

9

1

1

2

1

1

2

1

2

3

4

1

4

2

4

1

Number

RequiredDescription

ACCESSORIES

Wrench

.

Switch Rod .

Wrench.

. . . .

..

..

. .

6>-'2"

Dia. Motor Pulley .

"V"

Belt .

Retractable

Caster

Set.

. . . . . . . . . . . . . . . . . .

..

Steel Stand .

Cutter

head,

Including: .

37-802-Set

3Jointer Knives .

J-22-Knife

Lock Bar .

J-23-74:-28

x

74:"

Hex. Hd.

Screw

.

J-32-Bearing

Housing for Pulley Side .

J-33-Bearing

Housing for Left Side .

SP-5336-Bearing

.

Steel Pin,

?1'6

x 11

}f"

Cone

Point. .

Coil

Spring

3~

Dia.,

>-'2"

Free

Length

.

74:-20

x

~"

Flat Hd.

Machine

Screw

.

74:-20

x

>-'2"

Rd. Hd.

Machine

Screw

.

74:-20

x

~"

Fillister Hd.

Machine

Screw

.

Yt6-18

x1" Rd. Hd. Stove Bolt .

%-16-Hex.

Jam Nut .

74:"

-Steel

Washer.

. . . . . . . . . . . . . . " .

?1'6

Steel

Washer

.

74:"

Split Lockwasher .

Drive

Screw

#2 x

Vt6"

.

Clamp

Handle

.

Part

No.

#194

#1333

#1522

#5650

#49-172

#49-363

#50-304

J-35

NCS-33

SP-406

SP-509

SP-70l

SP-908

SP-1005

SP-1603

SP-1606

SP-1702

SP-2252

SR-217

37-806**1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

2

1

2

2

4

1

1

1

1

1

1

Number

Required

DescriptionPart

No.

HJ-9

HJ-12-3

HJ-16-3

J-8

J-ll

J-I-2

J-13-S

Front Table .

*Rear Table .

*

Base

.

BM-46

2%4"

Steel

Washer

.

HDP-133

Name Plate .

HJ-5-M

Fence

Segment,

Including

.

J-19-Stop

Link .

J-42-Steel

Pin .

J-44-#8-32

X

Yt6"

Headless

Set

Screw

.

L-24-Center

Point

>-'2"

x

%"

Straight Body .

HJ-6-M

Cross Slide Bracket,

Including

.

HJ-7-Tilt

Angle

Scale

.

HJ-8-Stud

%-16

x

1~"

Threaded

Both Ends .

J-36-S-Lock

Bolt .

SP-108-74:"-20

x

~"

Headless Set

Screw

.

SP-1029->-'2-20 Hex. Nut .

SP-2250-#4

x

%"

Drive

Screw

.

%-16

Serrated

Nut

74:-20

Tapped

Head

.

Hand

Knob.

. .

Fence

Body .

Stud

>-'2-13

x

2~"

Threaded

one

end

.

Stud

%-16

x274:"

Threaded

Both Ends .

1%"

Spring

Washer

.

Knife

Guard,

Including:

.

J-14-Pin

.

J-15-Spring

.

SP-210l-Cotter

Pin

%"

x%" .

Cutterhead

Pulley,

Including:

.

SP-20l-%-I8-Yt6"

Hex. Soc. Set

Screw

.

J-17

-S

CONSULT

YOUR

DELTA

DEALER

FOR

PRICES

OF

REPLACEMENT

PARTS.

ACCESSORIES

AND

TOOLS

TO

FACILITATE

HANDLING

WE

SUGGEST

ORDERING

ALL

PARTS

THROUGH

YOUR

DELTA

DEALER.

*IMPORTANT:

Base.

front

and

rear

tables

cannot

be supplied

separately,

as

the

re-assembled

machine

would

not

be accu-

rate.

For

true

alignment,

we

finish-grind

our

jointer

tables

after

assembly

on

the

base.

When

a

new

table

or

base

is

required.

ship

the

machine,

less

fence

and

knife

guard.

to

the

factory

for

rebuilding.

The

cost

will be

the

list

price

for

the

new

part

plus

afixed

charge

for

assembling

and

grinding

the

tables.

""NOTE

-

Cutter

Head

Repairs:

Special

tools

are

required

to

remove

and

replace

ball

bearings

on

the

cutter

head.

When

the

bearings

or

cutter

head

need

replacement,

order

a

complete

new

cutter

head

assembly

fIi

37-806,

or

return

the

old

one

to

us

for

repair-

ing

for

which

there

is

nominal

charge

covering

repair

work

plus

a

small

labor

charge

per

bearing

for

installing.

Knife

Sharpening

Service:

Our

charge

for

re-grinding

and

setting

knives will be a

nominal

net

charge

per

cutter

head,

F.O.B.

factory.

Be

sure

to

send

the

complete

cutter

head

assembly

with

bearings

and

housings,

less

pulley,

by

prepaid

express

or

parcel

post

insured

for

$22.00,

for

repair

or

sharpening

service.

Replacement

parts

can

be

ordered

through

your

Delta

Dealer.

Always

give

both

the

part

number

and

the

des-

cription

of

each

part

when

ordering.

Also

the

serial

number

of

the

machine

on

which

the

parts

are

to

be

used.

Many

of

the

standard

parts

such

as

screws,

nuts,

washers,

etc.,

are

usually

available

from

local

Mill

Supply

or

Hardware

Dealers.

Standard

electrical

parts

such

as

switches,

condensers,

cords

and

plugs

etc.,

can

be

obtained

from

Local

Electrical

Supply

Dealers

or

Motor

Repair

Shops.

When

ordering,

refer

to

manufacturer

part

number

which

appears

on

the

part.

Delta

motors

are

made

by

leading

motor

manufacturers

whose

name

also

appears

on

the

motor

nameplate.

These

manufacturers

are

represented

by

motor

service

stations

throughout

the

United

States

and

some

foreign

countries.

PRICES

SUBJECT

TO

CHANGE

WITHOUT

NOTICE

The

richt

is

reserved

to

make

chanles

in

de-ieD

or

equipment

at

any

time

without

incurrinl

any

oblilation

to

instan

these

OD

machines

previously

sold.

and

to

discontinue

models

of

machines,

motor.

Of'

accessories

at

any

time

without

notice.

DistributiOD

iD

the

UDited

States.

its

_SiODI

acept

Puerto

Rico

...

d

the

C

....

I

ZODe.

...d

iD

C.Dad.

aDc!

the

PhilippiDe

bl&Dda

il

by

.uthorised

Delt.

Dalen.