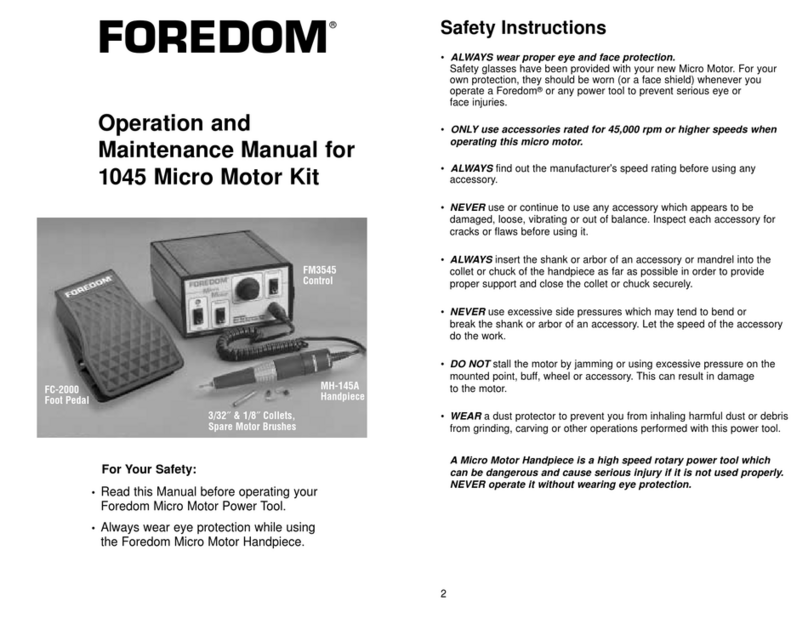

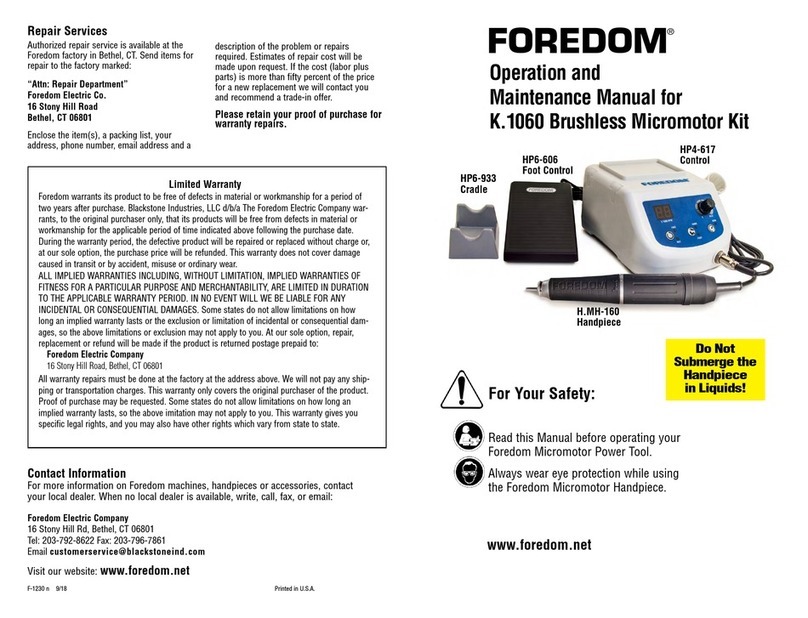

Operation & Maintenance Manual for

K.1050 Brushless Micromotor Kit

with additional Port for connecting a

Brush Type Handpiece

FOREDOM®

For Your Safety:

Read this Manual before operating your

Foredom Micromotor Power Tool.

Always wear eye protection while operating

this Micromotor.

HP4-817

Control

HP4-933

Cradle

HP7-7060

Foot Control

H.MH-150 Brushless Handpiece

For More Information on Foredom machines, handpieces or accessories,

contact your local dealer. When no local dealer is available, write, call or fax:

The Foredom Electric Company

16 Stony Hill Road, Bethel, CT 06801

Visit our website: www.foredom.net for video

descriptions of this product.

F-1228 n 7/12 Printed in USA

•NEVER cut or exert pressure, toward your hand

or any other part of your body.

•DO NOT wear loose fitting clothing or jewelry.

Loose clothing or jewelry can be come entangled

in the tool. Do not wear items such as neckties,

necklaces, or bracelets when operating power

tools. Secure or tie back long hair.

•NEVER turn on or start the Handpiece while

chuck is in open (unlocked) position. This can

damage the handpiece. Make sure that a bur is

installed and secured in the collet, that the spindle

is NOT locked and that the bur can spin freely.

•Always operate and store it with a bur or other

accessory in the chuck and with the chuck in the

closed position.

•DO NOT operate the handpiece in the presence

of any flammable liquid or gas.

1

Safety Instructions

A Micromotor Handpiece is a high speed

rotary power tool which can be dangerous

and cause serious injury if it is not used

properly. NEVER operate it without

wearing eye protection.

•ALWAYS wear proper eye and

face protection.

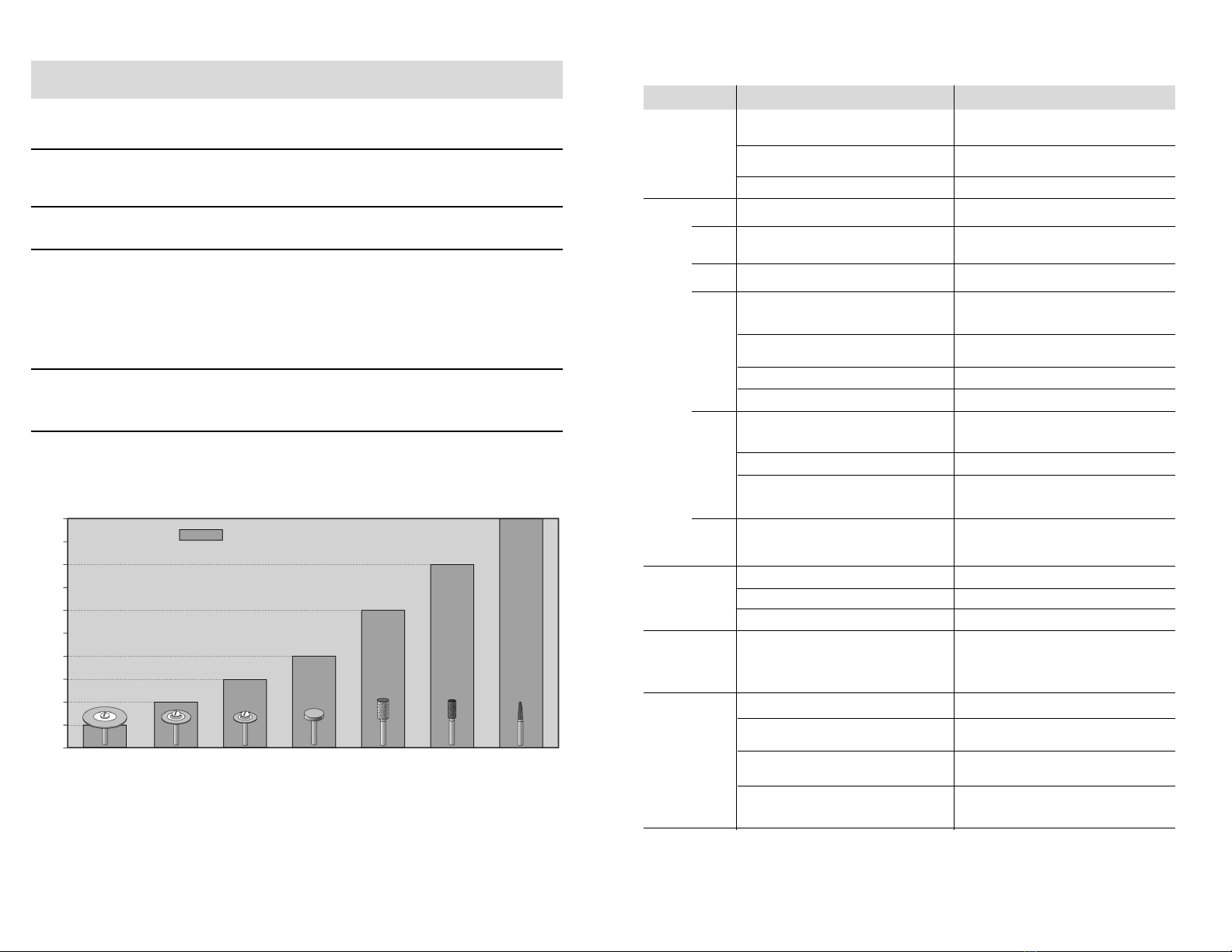

•ONLY use accessories rated for 50,000

rpm or higher speeds when operating

this micromotor. Follow the Allowable

Rotation Speed chart on page 8 of this

manual for safe operation when using

accessories with head diameters of more

than 3/32″(2mm).

•ALWAYS observe the manufacturer's maximum

speed rating when using any accessory.

•NEVER use or continue to use any accessory

which appears to be damaged, loose, vibrating,

bent, or out of balance. Inspect each accessory

for cracks or flaws before use.

•ALWAYS insert the shank or arbor of an acces-

sory or mandrel into the collet or chuck of the

handpiece as far as possible in order to

provide proper support and close the collet or

chuck securely.

•NEVER use excessive side pressures which

may tend to bend or break the shank or arbor of

an accessory. Let the speed of the accessory do

the work.

•DO NOT stall the motor by jamming or using

excessive pressure on the mounted point, buff,

wheel or accessory. This can result in damage to

the motor.

•WEAR a dust protector, mask or respirator to

prevent the inhalation of harmful dust or debris

from grinding, carving or other operations

performed with this power tool.

•NEVER operate with a damaged power cord.

If the power cord or plug to the handpiece

is damaged, repair or replace immediately.

•USE a dust collector (vacuum system) to pull

sawdust, grinding dust, or other debris

away from the work area and the micromotor

intake vents.

•NEVER wear open shoes or sandals. Use

footwear that is tough enough to protect your

feet from falling tools.

•ALWAYS keep both hands and fingers away

from the cutting edge.

Limited Warranty

Foredom warrants its product to be free of defects in

material or workmanship for a period of two years after

purchase. Blackstone Industries, Inc. d/b/a The Foredom

Electric Company warrants, to the original purchaser only,

that its products will be free from defects in material or

workmanship for the applicable period of time indicated

above following the purchase date. During the warranty

period, the defective product will be repaired or replaced

without charge or, at our sole option, the purchase price

will be refunded. This warranty does not cover damage

caused in transit or by accident, misuse or ordinary wear

ALL IMPLIED WARRANTIES INCLUDING, WITHOUT

LIMITATION, IMPLIED WARRANTIES OF FITNESS FOR A

PARTICULAR PURPOSE AND MERCHANTABILITY, ARE

LIMITED IN DURATION TO THE APPLICABLE WARRANTY

PERIOD. IN NO EVENT WILL WE BE LIABLE FOR ANY

INCIDENTAL OR CONSEQUENTIAL DAMAGES. Some

states do not allow limitations on how long an implied

warranty lasts or the exclusion or limitation of incidental

or consequential damages, so the above limitations or

exclusion may not apply to you.

At our sole option, repair, replacement or refund will be

made if the product is returned postage prepaid to:

The Foredom Electric Company,

16 Stony Hill Road, Bethel, CT 06801

All warranty repairs must be done at the factory at

the address above.We will not pay any shipping or

transportation charges.This warranty only covers the

original purchaser of the product. Proof of purchase may

be requested. Some states do not allow limitations on

how long an implied warranty lasts,so the above

imitation may not apply to you. This warranty gives you

specific legal rights,and you may also have other rights

which vary from state to state.