Delta Tau 5XX-603869-XUXX User manual

^3 Programmable Multi-Axis Controller

^4 5XX-603869-XUXX

^5 December 14, 2012

^1 USER MANUAL

^2 Brick Controller

Single Source Machine Control Power // Flexibility // Ease of Use

21314 Lassen Street Chatsworth, CA 91311 // Tel. (818) 998-2095 Fax. (818) 998-7807 // www.deltatau.com

Copyright Information

© 2011 Delta Tau Data Systems, Inc. All rights reserved.

This document is furnished for the customers of Delta Tau Data Systems, Inc. Other uses are

unauthorized without written permission of Delta Tau Data Systems, Inc. Information contained in this

manual may be updated from time-to-time due to product improvements, etc., and may not conform in

every respect to former issues.

To report errors or inconsistencies, call or email:

Delta Tau Data Systems, Inc. Technical Support

Phone: (818) 717-5656

Fax: (818) 998-7807

Email: support@deltatau.com

Web: www.deltatau.com

Operating Conditions

All Delta Tau Data Systems, Inc. motion controller, accessory, and amplifier products contain static

sensitive components that can be damaged by incorrect handling. When installing or handling Delta Tau

Data Systems, Inc. products, avoid contact with highly insulated materials. Only qualified personnel

should be allowed to handle this equipment.

In the case of industrial applications, we expect our products to be protected from hazardous or

conductive materials and/or environments that could cause harm to the controller by damaging

components or causing electrical shorts. When our products are used in an industrial environment, install

them into an industrial electrical cabinet to protect them from excessive or corrosive moisture, abnormal

ambient temperatures, and conductive materials. If Delta Tau Data Systems, Inc. products are directly

exposed to hazardous or conductive materials and/or environments, we cannot guarantee their operation.

Brick Controller User Manual

Safety Instructions

Qualified personnel must transport, assemble, install, and maintain this equipment. Properly qualified

personnel are persons who are familiar with the transport, assembly, installation, and operation of

equipment. The qualified personnel must know and observe the following standards and regulations:

IEC364resp.CENELEC HD 384 or DIN VDE 0100

IEC report 664 or DIN VDE 0110

National regulations for safety and accident prevention or VBG 4

Incorrect handling of products can result in injury and damage to persons and machinery. Strictly adhere

to the installation instructions. Electrical safety is provided through a low-resistance earth connection. It

is vital to ensure that all system components are connected to earth ground.

This product contains components that are sensitive to static electricity and can be damaged by incorrect

handling. Avoid contact with high insulating materials (artificial fabrics, plastic film, etc.). Place the

product on a conductive surface. Discharge any possible static electricity build-up by touching an

unpainted, metal, grounded surface before touching the equipment.

Keep all covers and cabinet doors shut during operation. Be aware that during operation, the product has

electrically charged components and hot surfaces. Control and power cables can carry a high voltage,

even when the motor is not rotating. Never disconnect or connect the product while the power source is

energized to avoid electric arcing.

WARNING

A Warning identifies hazards that could result in personal injury

or death. It precedes the discussion of interest.

Caution

A Caution identifies hazards that could result in equipment damage. It

precedes the discussion of interest.

Note

A Note identifies information critical to the user’s understanding or

use of the equipment. It follows the discussion of interest.

Brick Controller User Manual

REVISION HISTORY

REVISION

DESCRIPTION

DATE

CHANGE

APPROVED

1

MANUAL CREATION

05/02/07

C.P

S.M

2

X15 WATCHDOG DESCRIPTION, P. 10

TB1 CURRENT REQUIREMENTS, P. 11

10/31/08

C.P

S.M

3

ADDED AUXILIARY BOARD INFO IN APPENDIX A

07/24/09

C.P

S.S

4

CORRECTED M5061 ENTRY, P. 27

09/29/09

C.P

M.Y

5

MANUAL REFORMATTING. ADDED MORE TECHNICAL INFO.

E.G. WIRING DIAGRAMS, SPECIAL FEEDBACK ECT…

11/7/11

M.Y

R.N

6

AMPLIFIER CONNECTION WIRING

12/27/11

R.N

R.N

7

GENERAL UPFATES, CORRECTIONS

11/13/12

R.N

R.N

8

- UPDATED PART NUMBER TREE

- UPDATED X9-X12 SECTION

- UPDATED MACRO CONNECTIVITY SECTION

- ADDED SERIAL N0 AND BOARD IDENTIFICATION

- GENERAL FORMATTING, CORRECTIONS, AND UPDATES

12/14/12

R.N

R.N

Brick Controller User Manual

Table Of Contents 5

Table of Contents

INTRODUCTION.....................................................................................................................8

Documentation............................................................................................................................8

Downloadable Turbo PMAC Script.............................................................................................9

SPECIFICATIONS.................................................................................................................10

Part Number..............................................................................................................................10

Options .....................................................................................................................................11

Environmental Specifications....................................................................................................12

RECEIVING AND UNPACKING .........................................................................................13

Use of Equipment .....................................................................................................................13

MOUNTING ...........................................................................................................................14

Connector Locations .................................................................................................................15

Mounting Dimensions...............................................................................................................16

CONNECTIONS AND SOFTWARE SETUP.......................................................................17

TB1: 24 VDC Logic Power.......................................................................................................17

+5V ENC PWR (Alternate Encoder Power) ..............................................................................18

Wiring the Alternate (+5V) Encoder Power..........................................................................19

Functionality, Safety Measures.............................................................................................20

X1-X8: Encoder Feedback, Digital A Quad B...........................................................................21

Setting up Quadrature Encoders...........................................................................................23

Encoder Count Error (Mxx18)..............................................................................................23

Encoder Loss Detection, Quadrature....................................................................................24

Step and Direction PFM Output (To External Stepper Amplifier) .........................................26

X1-X8: Encoder Feedback, Sinusoidal......................................................................................27

Setting up Sinusoidal Encoders.............................................................................................28

Counts per User Units..........................................................................................................29

Encoder Count Error (Mxx18)..............................................................................................30

Encoder Loss Detection, Sinusoidal......................................................................................31

X1-X8: Encoder Feedback, Resolver.........................................................................................32

Setting up Resolvers .............................................................................................................32

Resolver Excitation Magnitude.............................................................................................33

Resolver Excitation Frequency .............................................................................................33

X1-X8: Encoder Feedback, HiperFace ......................................................................................38

Setting up HiperFace On-Going Position .............................................................................39

Setting up HiperFace Absolute Power-On Position...............................................................41

Setting up HiperFace Encoders Example..............................................................................45

Encoder Count Error (Mxx18), HiperFace...........................................................................50

Encoder Loss Detection, HiperFace .....................................................................................50

Brick Controller User Manual

Table Of Contents 6

X1-X8: Encoder Feedback, SSI.................................................................................................52

Configuring SSI....................................................................................................................52

SSI Control Registers Setup Example....................................................................................56

X1-X8: Encoder Feedback, EnDat 2.1/2.2.................................................................................58

Configuring EnDat...............................................................................................................58

EnDat Control Registers Setup Example...............................................................................62

X1-X8: Encoder Feedback, BiSS C/B .......................................................................................64

Configuring BiSS..................................................................................................................64

BiSS Control Registers Setup Example .................................................................................68

Setting up SSI | EnDat | BiSS ....................................................................................................70

Setup Summary.....................................................................................................................71

Technique 1 Example............................................................................................................72

Technique 2 Example............................................................................................................75

Technique 3 Example............................................................................................................79

X1-X8: Encoder Feedback, Yaskawa Sigma II & III .................................................................83

Yaskawa Sigma II 16-Bit Absolute Encoder..........................................................................88

Yaskawa Sigma II 17-Bit Absolute Encoder..........................................................................91

Yaskawa Sigma III 20-Bit Absolute Encoder.........................................................................94

Yaskawa Sigma II 13-Bit Incremental Encoder.....................................................................97

Yaskawa Sigma II 17-Bit Incremental Encoder.....................................................................99

Yaskawa Incremental Encoder Alarm Codes ......................................................................101

Homing with Yaskawa Incremental Encoders .....................................................................102

X9-X10: Analog Inputs/Outputs..............................................................................................103

X11-X12: Analog Inputs/Outputs............................................................................................103

Setting up the Analog (ADC) Inputs....................................................................................104

Setting up the DAC Outputs................................................................................................105

Setting up the General Purpose Relay, Brake......................................................................107

Setting up the External Amplifier Fault Input......................................................................109

X13: USB 2.0 Connector........................................................................................................110

X14: RJ45, Ethernet Connector...............................................................................................110

X15: Watchdog & ABORT (TB2)...........................................................................................111

Wiring the Abort Input........................................................................................................111

Wiring the WatchDog (WD) Output....................................................................................112

J4: Limits, Flags, EQU [Axis 1- 4]..........................................................................................113

J5: Limits, Flags, EQU [Axis 5- 8]..........................................................................................114

Wiring the Limits and Flags ...............................................................................................115

Limits and Flags [Axis 1- 4] Suggested M-Variables..........................................................116

Limits and Flags [Axis 5- 8] Suggested M-Variables..........................................................116

J6: General Purpose Inputs/Outputs.........................................................................................117

J7: Additional General Purpose Inputs/Outputs .......................................................................118

J8: Additional General Purpose Inputs/Outputs .......................................................................119

Brick Controller User Manual

Table Of Contents 7

About the Digital Inputs and Outputs..................................................................................120

Wiring the Digital Inputs and Outputs................................................................................121

General Purpose I/Os (J6) Suggested M-Variables.............................................................122

General Purpose I/Os Additional (J7) Suggested M-Variables............................................122

General Purpose I/Os Additional (J8) Suggested M-Variables............................................123

J9: Handwheel Analog I/O ......................................................................................................124

Setting up the Analog Inputs (J9)........................................................................................125

Setting up the Analog Output (J9).......................................................................................127

Setting up Pulse and Direction Output PFM (J9)................................................................129

Setting up the Handwheel Port (J9) ....................................................................................131

Serial Port (RS232).................................................................................................................132

AMP1-AMP8: Amplifier Connection......................................................................................133

Wiring the DAC Output......................................................................................................134

Wiring the Amplifier Enable and Fault Signals...................................................................135

DRIVE-MOTOR SETUP .....................................................................................................137

Filtered PWM Output (Analog ±10V) .....................................................................................138

Clock Settings, Output Mode, Command Limit....................................................................139

Flag Control, Ixx24............................................................................................................139

I2T Protection: Ixx57, Ixx58...............................................................................................140

Open Loop Test: Encoder/Decode......................................................................................140

Position-Loop PID Gains: Ixx30…Ixx39.............................................................................142

True DAC Output (±10V).......................................................................................................143

Clock Settings, Output Mode ..............................................................................................143

Flag Control, Ixx24............................................................................................................143

I2T Protection: Ixx57, Ixx58...............................................................................................144

Open Loop Test: Encoder/Decode......................................................................................144

Position-Loop PID Gains: Ixx30…Ixx39.............................................................................146

Pulse and Direction Output (PFM) ..........................................................................................147

PFM Clock Settings Example .............................................................................................147

PFM Setup Example...........................................................................................................148

Writing directly to the PFM register...................................................................................148

Issuing Open-Loop Commands...........................................................................................149

Issuing Closed-Loop Commands.........................................................................................149

MACRO CONNECTIVITY .................................................................................................151

Introduction to MACRO .........................................................................................................151

MACRO Configuration Examples...........................................................................................152

Review: MACRO Nodes and Addressing.............................................................................153

Review: MACRO Auxiliary Commands...............................................................................154

Configuration Example 1: Brick - Brick..................................................................................155

Setting up the Slave ............................................................................................................155

Setting up the Master..........................................................................................................157

Brick Controller User Manual

Table Of Contents 8

Configuration Example 2: Brick - Geo MACRO Drive ...........................................................160

Brick –Brick MACRO I/O Data Transfer ...............................................................................168

Transferring the Digital (Discrete) Input and Outputs ........................................................169

Transferring the X9-X12 Analog Inputs/Outputs.................................................................174

Transferring the J9 Analog Inputs ......................................................................................176

MACRO Limits and Flags, Homing........................................................................................177

Limits and Flags.................................................................................................................177

Homing from Master ..........................................................................................................177

Homing from Slave.............................................................................................................177

MACRO Suggested M-Variables.........................................................................................178

Absolute Position Reporting over MACRO.............................................................................180

TROUBLESHOOTING........................................................................................................181

Serial Number and Board Revisions Identification ..................................................................181

Boot Switch SW (Firmware Reload) –Write-Protect Disable..................................................182

Reloading PMAC firmware.................................................................................................183

Changing IP Address, Gateway IP, Gateway Mask.............................................................185

Enabling ModBus...............................................................................................................186

Reloading Boot and Communication Firmware ..................................................................187

Reset Switch SW (Factory Reset)............................................................................................188

Watchdog Timer .....................................................................................................................188

APPENDIX A........................................................................................................................189

DB- Connector Spacing Specifications....................................................................................189

X1-8: DB-15 Connectors for encoder feedback...................................................................189

X9-12: DB-9 Connectors for Analog I/O.............................................................................189

Screw Lock Size for all DB-connectors...............................................................................189

APPENDIX B........................................................................................................................190

Schematics..............................................................................................................................190

AMP1-AMP8: Amplifier Fault / Amplifier Enable diagrams...............................................190

J6 and J7: General Purpose I/O........................................................................................191

J4: Limit Inputs for Axis 1-4..............................................................................................193

J5: Limit Inputs for Axis 5-8..............................................................................................194

APPENDIX C........................................................................................................................195

Absolute Serial Encoders Limitation with Turbo PMAC .........................................................195

Brick Controller User Manual

Introduction 8

INTRODUCTION

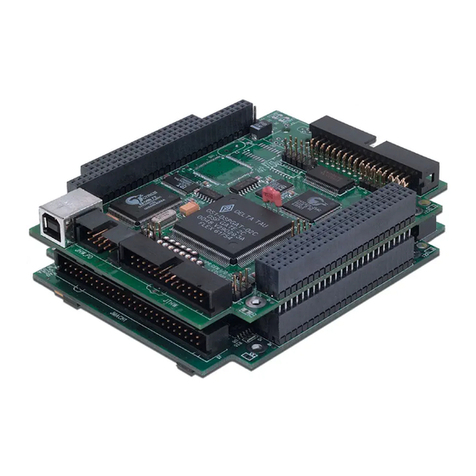

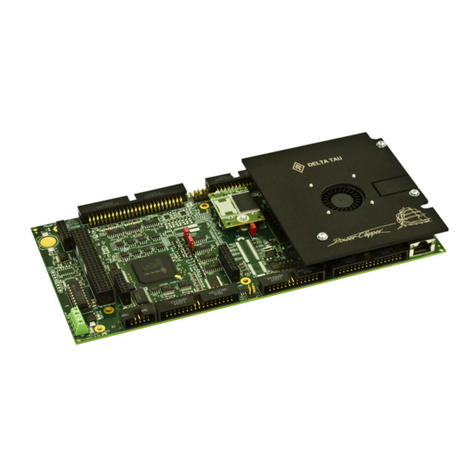

The Brick Motion Controller is a fully scalable automation controller utilizing

the intelligence and capability of its embedded Turbo PMAC2. With the ability

to store motion programs locally and built-in PLC execution, it is

programmable for virtually any kind of automation application. This allows for

complete machine motion and logic control.

The Brick Controller provides 4- or 8- axis of analog ±10V filtered-PWM (12-

bit), dual true-DAC (18-bit), or pulse and direction PFM outputs:

Analog ±10V (12-bit Filtered PWM)

Analog ±10V (18-bit True DAC)

PFM, Pulse and Direction Frequency Modulation

Documentation

In conjunction with this hardware reference manual, the Turbo Software Reference Manual and Turbo

PMAC User Manual are essential for proper use, motor setup, and configuration of the Brick Controller.

It is highly recommended to always refer to the latest revision of the manuals found on Delta Tau’s

website, under Support>documentation>Manuals: Delta Tau Manuals Link

Brick Controller User Manual

Introduction 9

Downloadable Turbo PMAC Script

Caution

Some code examples require the user to input specific information

pertaining to their system hardware. When user information is

required, a commentary ending with –User Input is inserted.

This manual contains downloadable code samples in Turbo PMAC script. These examples can be copied

and pasted into the editor area in the Pewin32pro2. Care must be taken when using pre-configured Turbo

PMAC code, some information may need to be updated to match hardware and system specific

configurations. Downloadable Turbo PMAC Scripts are enclosed in the following format:

// TURBO PMAC SCRIPT EXAMPLE

P1=0 ; Set P1=0 at download

Open PLC 1 Clear ; Open PLC Buffer 1, clear contents

CMDP"Brick controller Test PLC" ; Send unsolicited response to host port

P1=P1+1 ; Counter using variable P1

Disable PLC 1 ; Disable plc 1

Close ; Close open buffer

Caution

All PLC examples are stated in PLC number 1. It is the user’s

responsibility to arrange their application PLCs’ properly and handle

power-on sequencing for various tasks.

It is the user’s responsibility to use the PLC examples presented in this manual properly. That is,

incorporating the statement code in the application configuration, and handling tasks in a sequential

manner. For example, with serial absolute encoders, setting up the global control registers should be

executed before trying to read absolute position, and absolute phase referencing. Furthermore, other PLC

programs (which would be trying to move motors) should be disabled until these functions are executed.

Caution

Often times, downloadable example codes use suggested M-variables,

it is the user’s responsibility to make sure they are downloaded, or

perform necessary changes to use the intended registers.

Brick Controller User Manual

Specifications 10

SPECIFICATIONS

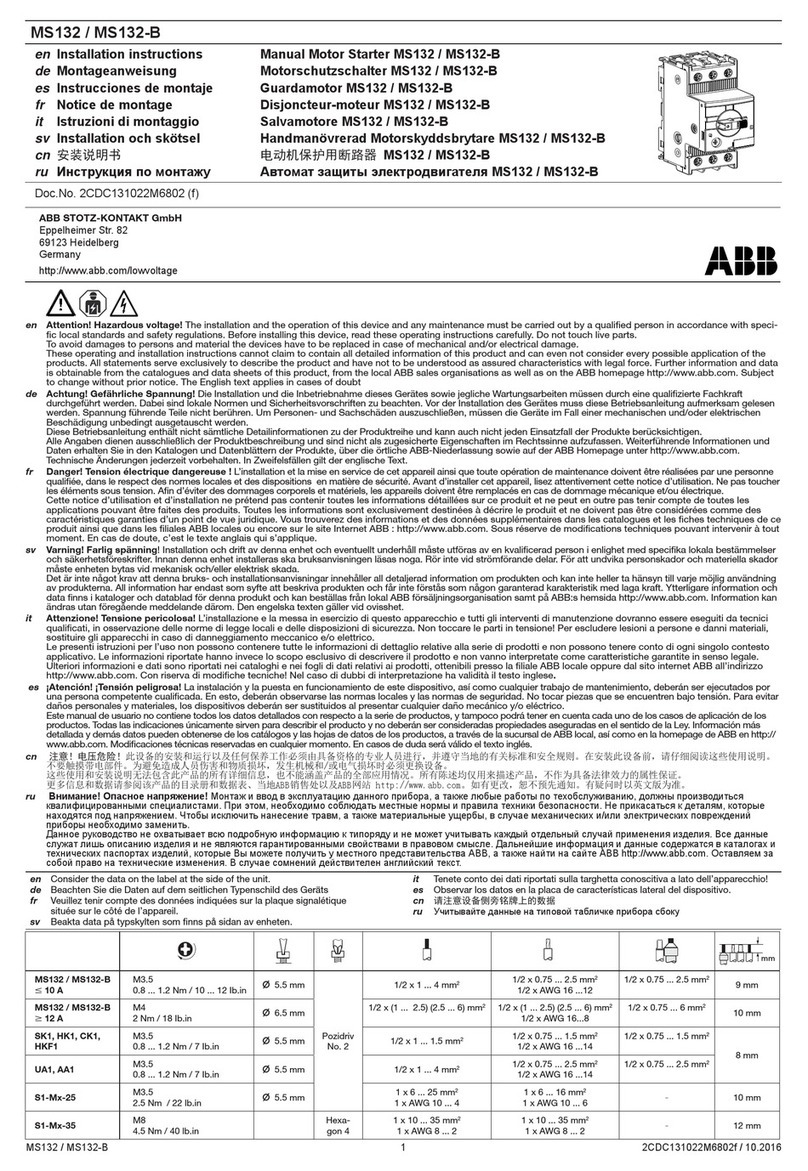

Part Number

BC 0 0000CF

-- - 04 00000

** ** ** **

CPU Options - Turbo PMAC 2 Processor

BCA-BB-CDD-EFG-HHHI0

C0: 80Mhz, 8Kx24 Internal, 256Kx24SRAM, 1MB Flash

(Default)

C3: 80Mhz, 8Kx24 Internal, 1Mx24SRAM, 4MB Flash

F3: 240Mhz, 192Kx24 Internal, 1Mx24SRAM, 4MB Flash

0: No options (Default)

2: Four GPIO Relays (On connectors X9-X12)

3: Two Analog In, two analog Out (On conn. X11-X12) & 4 GPIO Relays (On connectors X9-X12)

4: Four Analog In, four analog Out (On conn. X9-X12) & 4 GPIO Relays (On connectors X9-X12)

7: Two Analog In, 2 analog Out (Conn.X9-X10) & 4 GPIO Relays (On connectors X9-X12)

4

axes

Note: Analog outputs are 12-bit filtered PWM and Analog Inputs are 16-bit.

Analog I/O Options BCA-BB-CDD-EFG-HHHI0

8

axes

ABCDEFGHI

ABC

DE

F

Brick Controller Model Number Definition

Number of Axes

BCA-BB-CDD-EFG-HHHI0

4:Four Axes (Default)

8: Eight Axes

Axes 1 to 4 Options BCA-BB-CDD-EFG-HHHI0

F: Filtered-PWM analog output on Channels 1-4, 12-bit resolution

(default)

D: Dual true-DAC analog outputs on Channels 1-4, 18-bit resolution

Four primary encoder inputs. No secondary encoders, 4-axis system

Four secondary encoders for a total of 8 encoder inputs

4 Axes (Apply only to BC4-BB-CDD-EFG-HHHI0controller)

Axis 5-8 Feedback Options

Note: For Other Feedback Options See “Special Feedback Options”

12-24V 5V Flags

00 05

02 07

F2 F7

12-24V 5V Flags

-

D2 D7 Filtered-PWM analog output on Channels 5-8, 12-bit resolution

Dual true-DAC analog outputs on Channels 5-8, 18-bit resolution

8 Axes (Apply only to BC8-BB-CDD-EFG-HHHI0controller)

Axis 5-8 Options

Note: Letter must be same as previous letter

Digital I/O Option

BCA-BB-CDD-EFG-HHHI0

0: Digital I/O 16 inputs and 8 outputs, 0.5A, 24VDC (default)

1: Expanded digital I/O additional 16 inputs and 8 outputs, 0.5A, 24VDC

(Total of 32 IN / 16 OUT)

2: Expanded digital I/O additional 32 inputs and 16 outputs, 0.5A, 24VDC

(Total of 48 IN / 24 OUT)

0: No Analog Options available, for this configurations

2: Four GPIO Relays (On connectors X9-X12)

3: Two analog Inputs (On conn. X11-X12) & 4 GPIO Relays (On connectors X9-X12)

4: Four analog Inputs (On conn. X9-X12) & 4 GPIO Relays (On connectors X9-X12)

7: Two analog Inputs (Conn.X9-X10) & Four GPIO Relays (On connectors X9-X12)

Note: For Other Feedback Options See “Special Feedback Options”

Communication Options

BCA-BB-CDD-EFG-HHHI0

USB2 and Eth100 are included

Note: To use PMAC-NC software, DPRAM is required

0xxxxx: No Options, Default

Dxxxxx: DPRAM option, size 8K x 16-bit wide

Mxxxxx: ModBus Ethernet Communication Protocol (Software) option

Sxxxxx: DPRAM and Modbus Options Combined

R00000: RS232 port on 9-pin D-sub Connector*

E00000: DPRAM & RS232 Options Combined*

N00000: RS232 & ModBus Options Combined*

T00000: Modbus, DPRAM & RS232 Combined*

* If any of the “H” or “I” digits is non zero (BCA-BB-CDD-EFG-HHHI0)

then RS232 is included as default. Options R, E, N and T are Incompatible

G

MACRO and Special Feedback Options

MACRO Ring Interface and

8 Single or 4 Differential channel 12-bit

10v range MUXED ADC

BCA-BB-CDD-EFG-HHHI0

-xxx-xxx0x: No MACRO or ADC

-xxx-xxx1x: RJ45 MACRO

-xxx-xxx2x: Fiber Optic MACRO

-xxx-xxx3x: MUXED ADC

-xxx-xxx4x: RJ45 MACRO and MUXED ADC

-xxx-xxx5x: Fiber Optic MACRO and MUXED ADC

I

Special Feedback Number and Type of Channels

BCA-BB-CDD-EFG-HHHI0

000: No Special Feedback Channels

4A0: 4 Sinusoidal Encoder Feedback Channels

4B0: 4 Resolver Feedback Channels

4C1: 4 Serial Encoder Feedback Channels (SSI Protocol)

4C2: 4 Serial Encoder Feedback Channels (Yaskawa Sigma II & III Protocol)

4C3: 4 Serial Encoder Feedback Channels (EnDat 2.2 Protocol)

4C6: 4 Serial Encoder Feedback Channels (BISS-C Protocol)

4D1: 4 Sinusoidal Encoder and Serial Enc. (SSI Protocol)

4D2: 4 Sinusoidal Encoder and Serial Enc. (Yaskawa Sigma II & III Protocol)

4D3: 4 Sinusoidal Encoder and Serial Enc. (EnDat 2.1 / 2.2 Protocol)

4D4: 4 Sinusoidal Encoder and Serial Enc. (HiperFace Protocol)

4D6: 4 Sinusoidal Encoder and Serial Enc. (BISS-C Protocol)

4E1: 4 Resolver Feedback Channels and Serial Enc. (SSI Protocol)

4E2: 4 Resolver Feedback Ch. and Serial Enc. (Yaskawa Sigma II & III Prot.)

4E3: 4 Resolver Feedback Channels and Serial Enc. (EnDat 2.2 Protocol)

4E6: 4 Resolver Feedback Channels and Serial Enc. (BISS-C Protocol)

8A0: 8 Sinusoidal Encoder Feedback Channels

8B0: 8 Resolver Feedback Channels

8C1: 8 Serial Encoder Feedback Channels (SSI Protocol)

8C2: 8 Serial Encoder Feedback Channels (Yaskawa Sigma II & III Protocol)

8C3: 8 Serial Encoder Feedback Channels (EnDat 2.2 Protocol)

8C6: 8 Serial Encoder Feedback Channels (BISS-C Protocol)

8D1: 8 Sinusoidal Encoder and Serial Enc. (SSI Protocol)

8D2: 8 Sinusoidal Encoder and Serial Enc. (Yaskawa Sigma II & III Protocol)

8D3: 8 Sinusoidal Encoder and Serial Enc. (EnDat 2.1 / 2.2 Protocol)

8D4: 8 Sinusoidal Encoder and Serial Enc. (HiperFace Protocol)

8D6: 8 Sinusoidal Encoder and Serial Enc. (BISS-C Protocol)

8E1: 8 Resolver Feedback Channels and Serial Enc. (SSI Protocol)

8E2: 8 Resolver Feedback Ch. and Serial Enc. (Yaskawa Sigma II & III Prot.)

8E3: 8 Resolver Feedback Channels and Serial Enc. (EnDat 2.2 Protocol)

8E6: 8 Resolver Feedback Channels and Serial Enc. (BISS-C Protocol)

H

Note: If any of the “H” or “I” digits (BCA-BB-CDD-EFG-HHHI0) are ordered, you will also receive RS-232 comms port, 2 channel "handwheel" port.

Brick Controller User Manual

Specifications 11

Options

CPU Options

C0: 80MHz Turbo PMAC2 CPU (standard)

8Kx24 internal memory, 256Kx24 SRAM , 1MB flash memory

C3: 80MHz Turbo PMAC2 CPU

8Kx24 internal memory, 1Mx24 SRAM, 4M flash memory

F3: 240MHz Turbo PMAC2 CPU

192Kx24 internal memory, 1Mx24 SRAM, 4M flash memory

Encoder Feedback

Digital Quadrature

Sinusoidal

HiperFace

Resolver

SSI

EnDat 2.1 / 2.2

Yaskawa Sigma II / III

BiSS B / C

Panasonic

Tamagawa

Note

Regardless of the encoder feedback option(s) fitted, digital quadrature

encoders can always be utilized. However, Hall sensors cannot be

used with a channel which has been programmed for serial encoding.

Axis Output

18-bit true DAC or 12-bit filtered PWM (default) ±10V analog output

Pulse And Direction (PFM)

Encoder Input

Up to eight encoder inputs, and one handwheel quadrature input

Additional encoder inputs can be obtained through MACRO connectivity

Digital Inputs/Outputs

Up to 48 inputs and 24 outputs (Sinking or Sourcing)

Additional digital I/Os can be obtained through Fieldbus connectivity

Analog Inputs, DAC Outputs, Brakes, and Relays

Up to 4 x 16-bit analog inputs, 8 x 12-bit analog inputs, 4 x brake/ relay outputs , and 5 x 12-bit

filtered PWM (±10V) outputs

Communication

USB 2.0, Ethernet 100 Base T, RS232, DPRAM (required for NC software/applications)

FieldBus Connectivity

MACRO

ModBus

Brick Controller User Manual

Specifications 12

Environmental Specifications

Description

Specifications

Operating Temperature

0 to 45°C

Storage Temperature

-25°C to +70°C

Humidity

10% to 90% non-condensing

Operating Altitude

~3300 Feet (1000 m)

Air Flow Clearances

~3 inches (76.2mm) above and below unit for air flow

Operating Environment

Pollution Degree 2 or equivalent

Brick Controller User Manual

Receiving And Unpacking 13

RECEIVING AND UNPACKING

Delta Tau products are thoroughly tested at the factory and carefully packaged for shipment. When the

Brick Controller is received, there are several things to be done immediately:

Observe the condition of the shipping container and report any damage immediately to the

commercial carrier that delivered the drive.

Remove the Brick Controller from the shipping container and remove all packing materials. Check

all shipping material for connector kits, documentation, or other small pieces of equipment. Be aware

that some connector kits and other equipment pieces may be quite small and can be accidentally

discarded if care is not used when unpacking the equipment. The container and packing materials

may be retained for future shipment.

Verify that the part number of the Brick Controller received is the same as the part number listed on

the purchase order.

Inspect for external physical damage that may have been sustained during shipment and report any

damage immediately to the commercial carrier that delivered the drive.

Electronic components in this product are design-hardened to reduce static sensitivity. However, use

proper procedures when handling the equipment.

If the Brick Controller is to be stored for several weeks before use, be sure that it is stored in a

location that conforms to published storage humidity and temperature specifications.

Use of Equipment

The following restrictions will ensure the proper use of the Brick Controller:

The components built into electrical equipment or machines can be used only as integral components

of such equipment.

The Brick Controller must not be operated on power supply networks without a ground or with an

asymmetrical ground.

If the Brick Controller is used in residential areas, or in business or commercial premises, implement

additional filtering measures.

The Brick Controller may be operated only in a closed switchgear cabinet, taking into account the

ambient conditions defined in the environmental specifications.

Delta Tau guarantees the conformance of the Brick Controllers with the standards for industrial areas

stated in this manual, only if Delta Tau components (cables, controllers, etc.) are used.

Brick Controller User Manual

Mounting 14

MOUNTING

The location of the Brick Controller is important. Installation should be in an area that is protected from

direct sunlight, corrosives, harmful gases or liquids, dust, metallic particles, and other contaminants.

Exposure to these can reduce the operating life and degrade performance of the drive.

Several other factors should be carefully evaluated when selecting a location for installation:

For effective cooling and maintenance, the Brick Controller should be mounted on a smooth, non-

flammable vertical surface.

At least 76 mm (3 inches) top and bottom clearance must be provided for air flow. At least 10

mm (0.4 inches) clearance is required between units (each side).

Temperature, humidity and Vibration specifications should also be taken in account.

Caution

Unit must be installed in an enclosure that meets the environmental IP

rating of the end product (ventilation or cooling may be necessary to

prevent enclosure ambient from exceeding 45° C [113° F]).

The Brick Controller can be mounted with a 3-hole panel mount, two U shape/notches on the bottom and

one pear shaped holes on top.

If multiple Brick Controllers are used, they can be mounted side-by-side, leaving at least a 200 mm

clearance between them. It is extremely important that the airflow is not obstructed by the placement of

conduit tracks or other devices in the enclosure.

If the drive is mounted to a back panel, the back panel should be unpainted and electrically conductive to

allow for reduced electrical noise interference. The back panel should be machined to accept the

mounting bolt pattern.

Brick Controller User Manual

Mounting 15

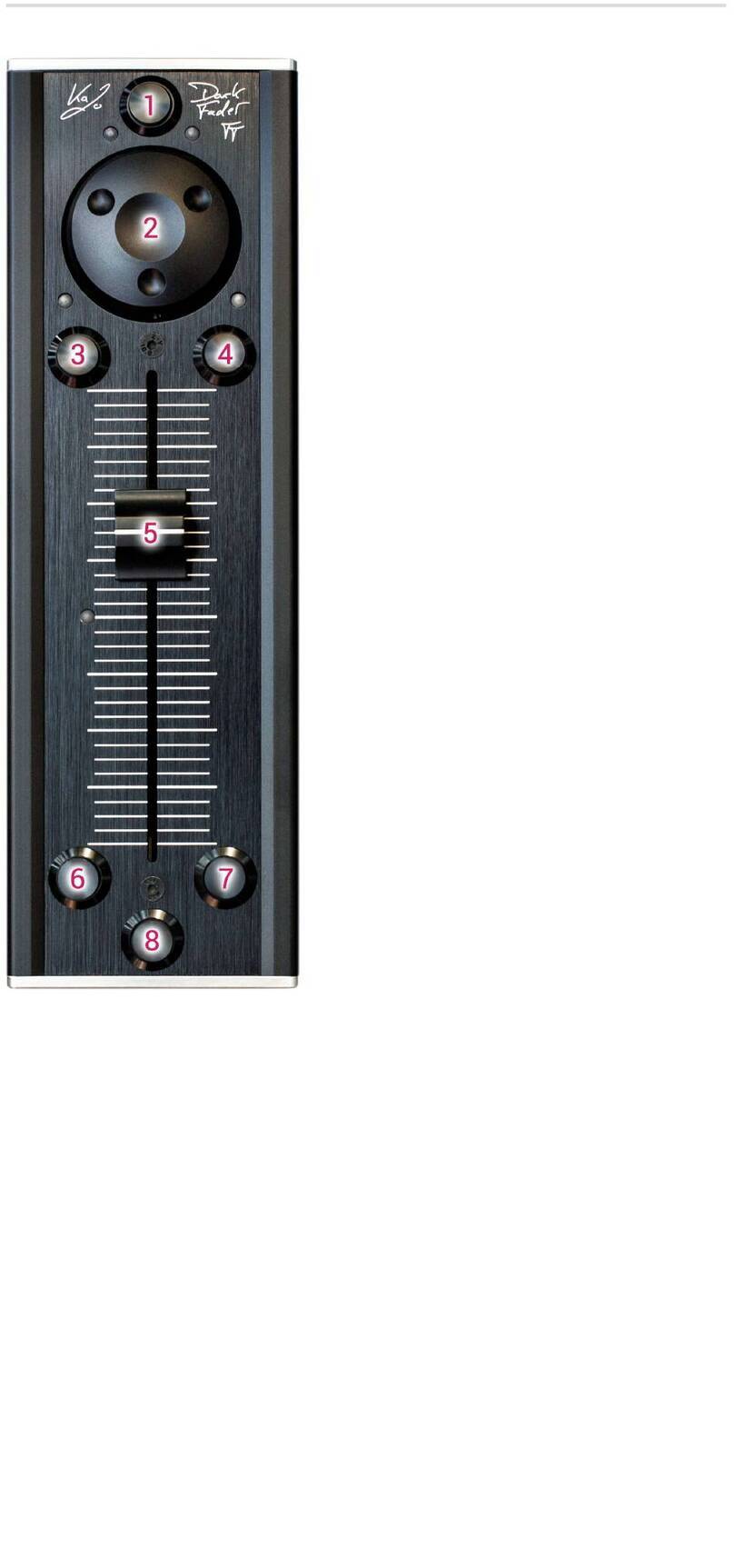

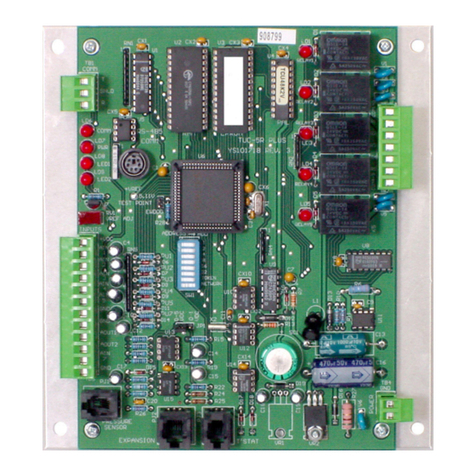

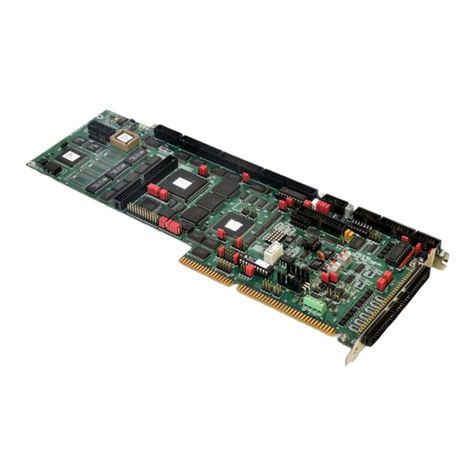

Connector Locations

AMP 7

AMP 8

Analog I/O

Bottom View

24VDC

Logic Power

AMP 1

AMP 2

AMP 5

AMP 6

AMP 3

Alt. Enc. Pwr

Encoder #4

Encoder #3

Encoder #2

Encoder #1

USB

Ethernet

MACRO

Abort & WD

RS232

Analog I/O

Front View

AMP 4

Encoder #5

Encoder #6

Encoder #7

Encoder #8

General

Purpose I/O

Limits

& Flags

Top View

Brick Controller User Manual

Mounting 16

Mounting Dimensions

For both BC4-xx-xxx-xxx-xxxxx and BC8-xx-xxx-xxx-xxxxx:

Width

Depth

Height

3.50 inches (88.90 mm)

7.20 inches (182.88 mm)

15.00 inches (381 mm)

15.00"

(381.00 mm)

2.50"

(63.50 mm)

14.65"

(372.11 mm)

3.50"

(88.90 mm)

13.5"

(342.90 mm)

7.20"

(182.88 mm)

3x M4

Brick Controller User Manual

Connections And Software Setup 17

CONNECTIONS AND SOFTWARE SETUP

WARNING

Installation of electrical control equipment is subject to many

regulations including national, state, local, and industry guidelines

and rules. General recommendations can be stated but it is

important that the installation be carried out in accordance with

all regulations pertaining to the installation.

TB1: 24 VDC Logic Power

This 3-pin Phoenix Terminal Block is used to bring in the 24-Volt DC supply to power up the logic

portion of the Brick Controller.

The 24Volts power supply must be capable of providing 2~4Amps per Brick Controller. If multiple Brick

Controllers are sharing the same 24-Volt power supply, it is highly recommended to wire each one back

to the power supply terminals separately.

This connection can be made using 22 AWG wire directly from a protected power supply.

Pin #

Symbol

Function

Description

Notes

1

+24VDC

Input

Logic power input +

+16~32VDC

2

CHGND

Ground

Chassis ground

Machine Chassis

3

+24VDC RET

Common

Logic power return -

Power Supply Return

Phoenix PCB Edge Connector

Phoenix part #: ZEC 1,5/ 3-ST-5,0 C2 R1,3 (18883051)

Delta Tau part #: 014-188305-001 (For Internal Use)

123

+24 VDC

Power Supply

+24VDC

COM

Brick Controller User Manual

Connections And Software Setup 18

+5V ENC PWR (Alternate Encoder Power)

Typically, feedback devices are powered up through the X1-X8 connectors on the Brick Controller using

the internal +5VDC power supply. In some cases, feedback devices consume power excessively and risk

of surpassing the internal power supply limitation.

This connector provides an alternate mean to power-up the feedback devices (+5V only) if the total

encoder budget exceeds the specified thresholds.

Note

Encoders requiring greater than +5VDC power must be supplied

externally, and NOT through the X1-X8 connectors NOR through this

connector.

B C x - x x - x x x - x x x xxxxx

Add-in Board Options

-

If the Brick Controller is equipped with the add-in board, meaning any of the highlighted part number

digits is a non-zero, then the total +5V encoder power available at X1-X8 is about 1.5 amperes.

If the Brick Controller is not equipped with the add-in board, meaning all the highlighted part number

digits are zeros, then the total +5V encoder power available at X1-X8 is about 2 amperes.

Brick Controller

Total Encoder Power

Available [amps]

Power Per Encoder

(4 Encoders) [mA]

Power Per Encoder

(8 Encoders) [mA]

Without add-in board

1.5

375

188

with add-in board

2

500

250

Caution

The maximum current draw out of a single encoder channel must not

exceed 750 mA.

Brick Controller User Manual

Connections And Software Setup 19

Wiring the Alternate (+5V) Encoder Power

Pin#

Symbol

Description

Note

1

5VEXT

Input

5V from external power supply

2

5VINT

Output

Tie to pin#1 to use internal power supply

3

GND

Common

Mating Connector:

Adam-Tech part number 25CH-E-03

Pins part number 25CTE-R

Crimping tool: Molex EDP #11-01-0208

Caution

Only two of the three available pins should be used at one time. Do

not daisy-chain the internal 5V power supply with an external one.

By default, pins 1-2 are tied together to use the internal power supply. To wire an external power supply,

remove the jumper tying pins 1-2 and connect the external +5V to pin #1, and ground/common to pin#3:

Internal Power Supply

Wiring (Default)

External Power Supply

Wiring

1

2

3

1

2

3

+5V

Gnd

External

Power

Supply

Note

A jumper tying pins 1 and 2 is the default configuration. This is the

configuration with which the Brick Controller is shipped to a

customer.

Note

The controller (PMAC) 5V logic is independent of this scheme, so if

no encoder power is provided the PMAC will remain powered-up

(provided the standard 24 volts is brought in).

Other manuals for 5XX-603869-XUXX

1

Table of contents

Other Delta Tau Controllers manuals

Delta Tau

Delta Tau PBC Series Operating and maintenance manual

Delta Tau

Delta Tau Turbo PMAC Clipper Quick user guide

Delta Tau

Delta Tau ACC-11E User manual

Delta Tau

Delta Tau PMAC2-PC Quick user guide

Delta Tau

Delta Tau PMAC PC User manual

Delta Tau

Delta Tau Universal PMAC Lite Quick user guide

Delta Tau

Delta Tau PMAC2-PC Quick user guide

Delta Tau

Delta Tau PMAC User manual

Delta Tau

Delta Tau PMAC User manual

Delta Tau

Delta Tau PMAC 1.5 Lite Quick user guide