MS300/MH300 PROFINET Communication Card CMM-PN02

CMM-PN02Operation Manual

1Introduction .......................................................................................................................4

1.1 Introduction to PROFINET IO Communication ....................................................................4

1.2 Features .............................................................................................................................4

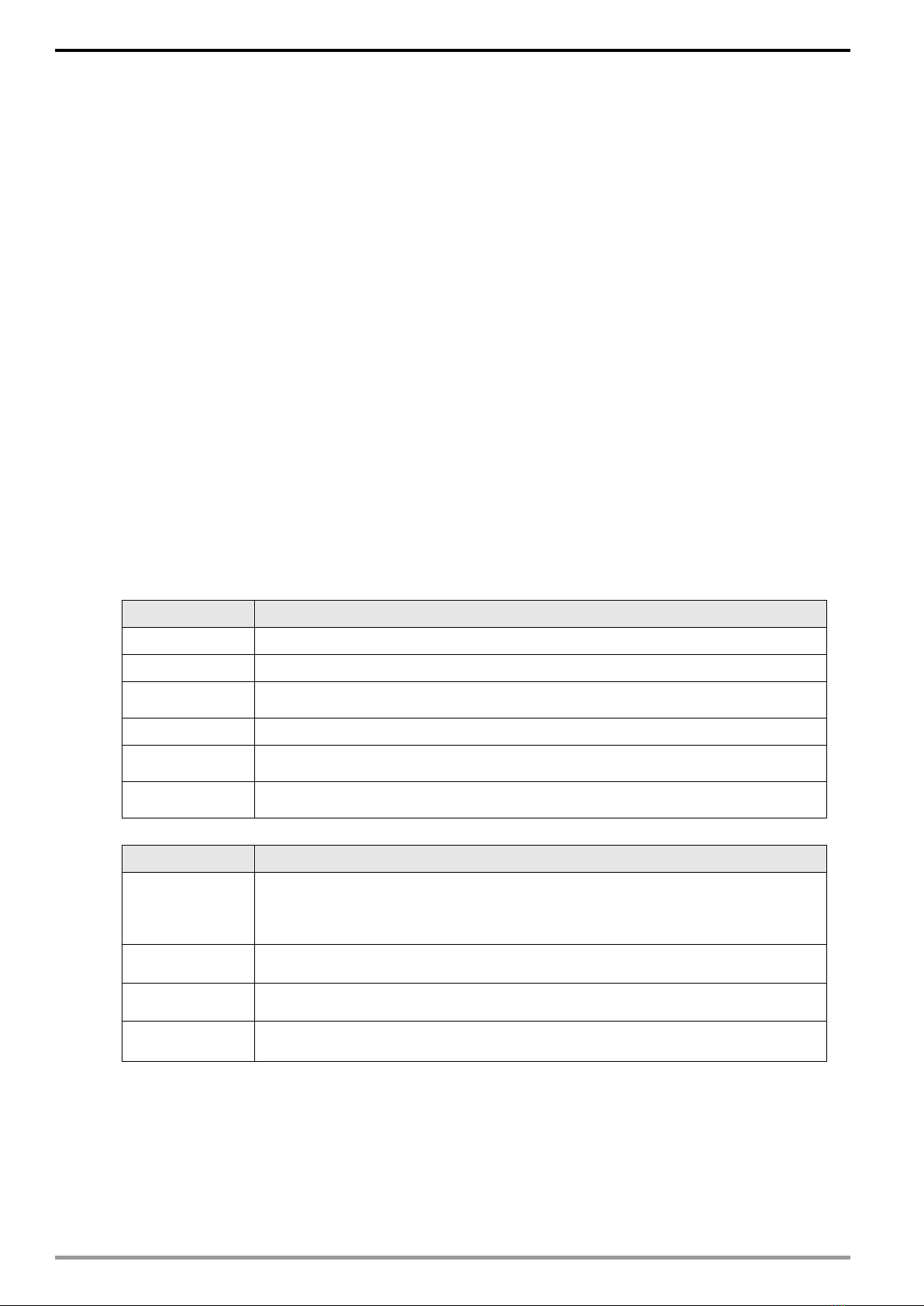

1.3 Network Functions and Specifications.................................................................................4

2Product Appearance and Components ...........................................................................6

2.1 Exterior Dimensions............................................................................................................6

2.2 Introduction to Each Component.........................................................................................6

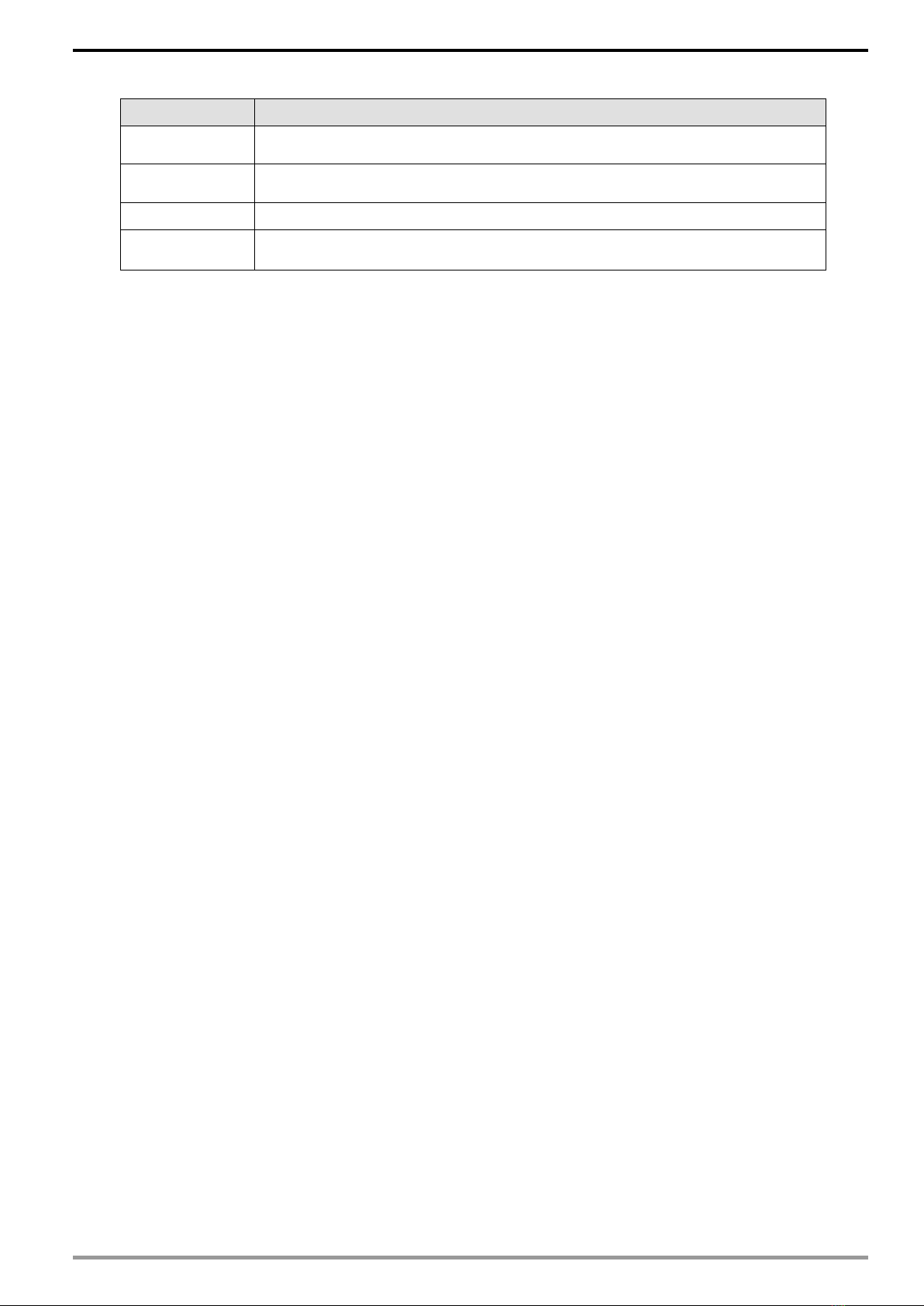

2.3 LED Indicators ....................................................................................................................7

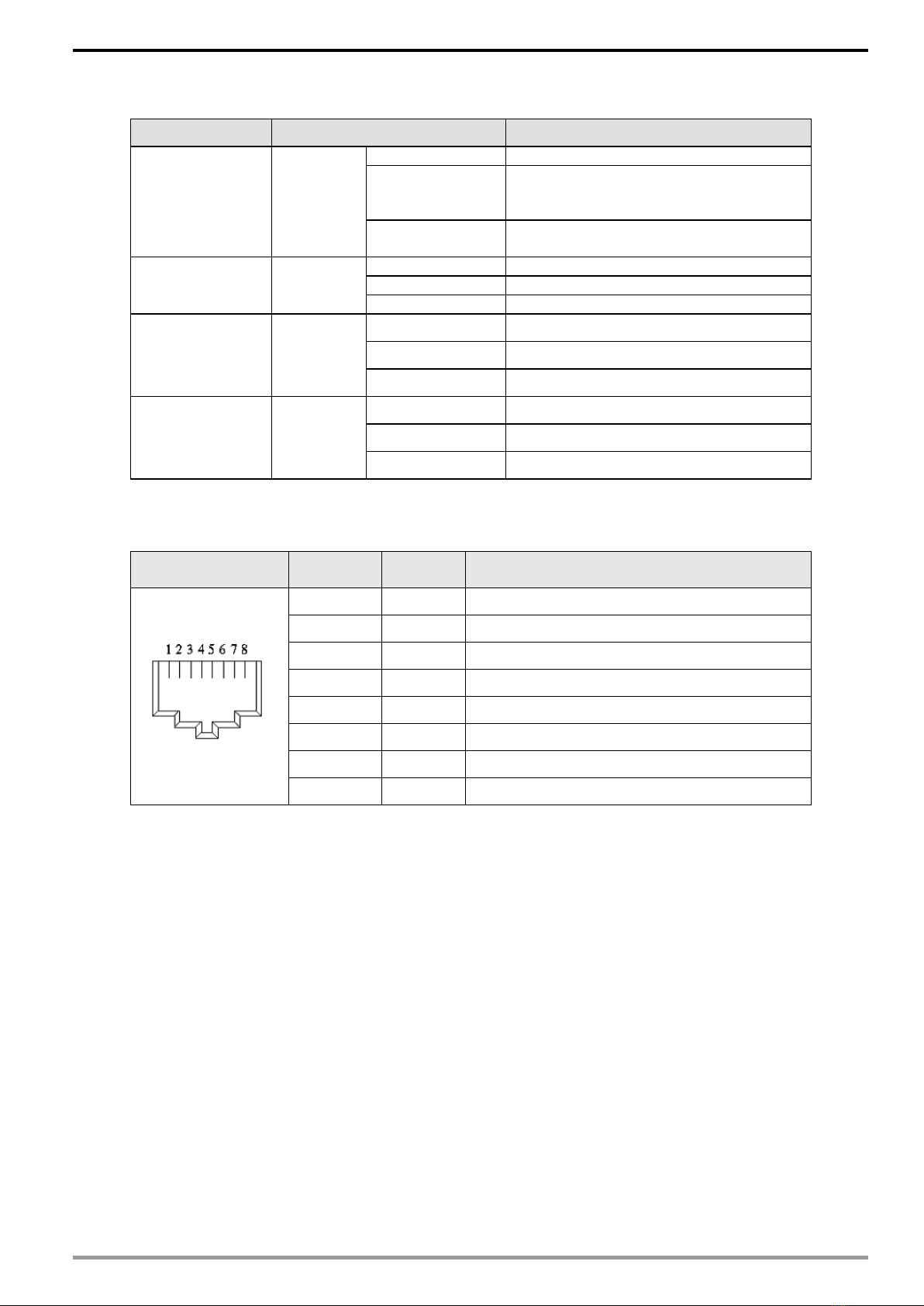

2.4 Definition of RJ45 Pin .........................................................................................................7

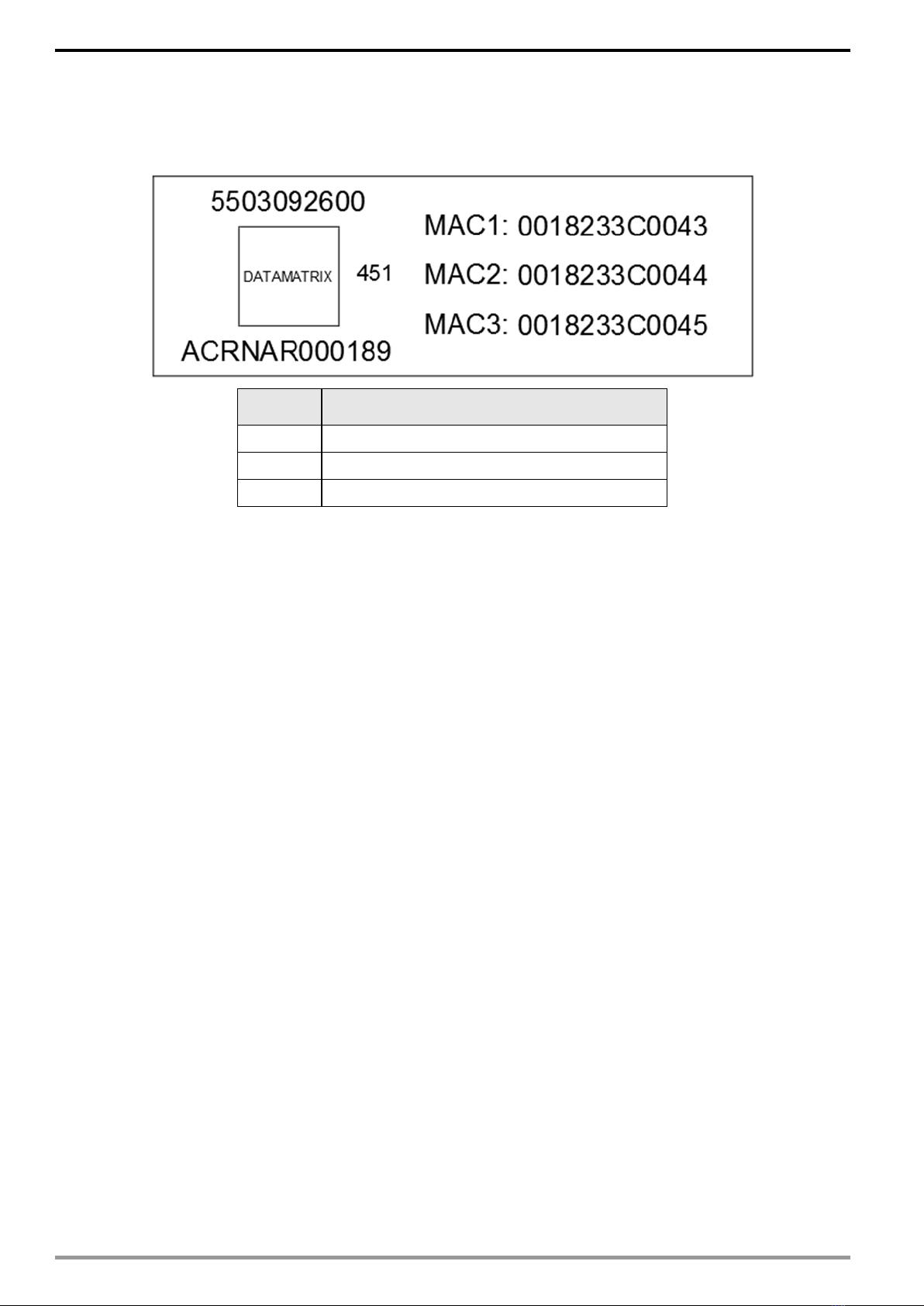

2.5 MAC Address Definition ......................................................................................................8

3Installation and Wiring ......................................................................................................9

3.1 Mounting Position of Communication Cards........................................................................9

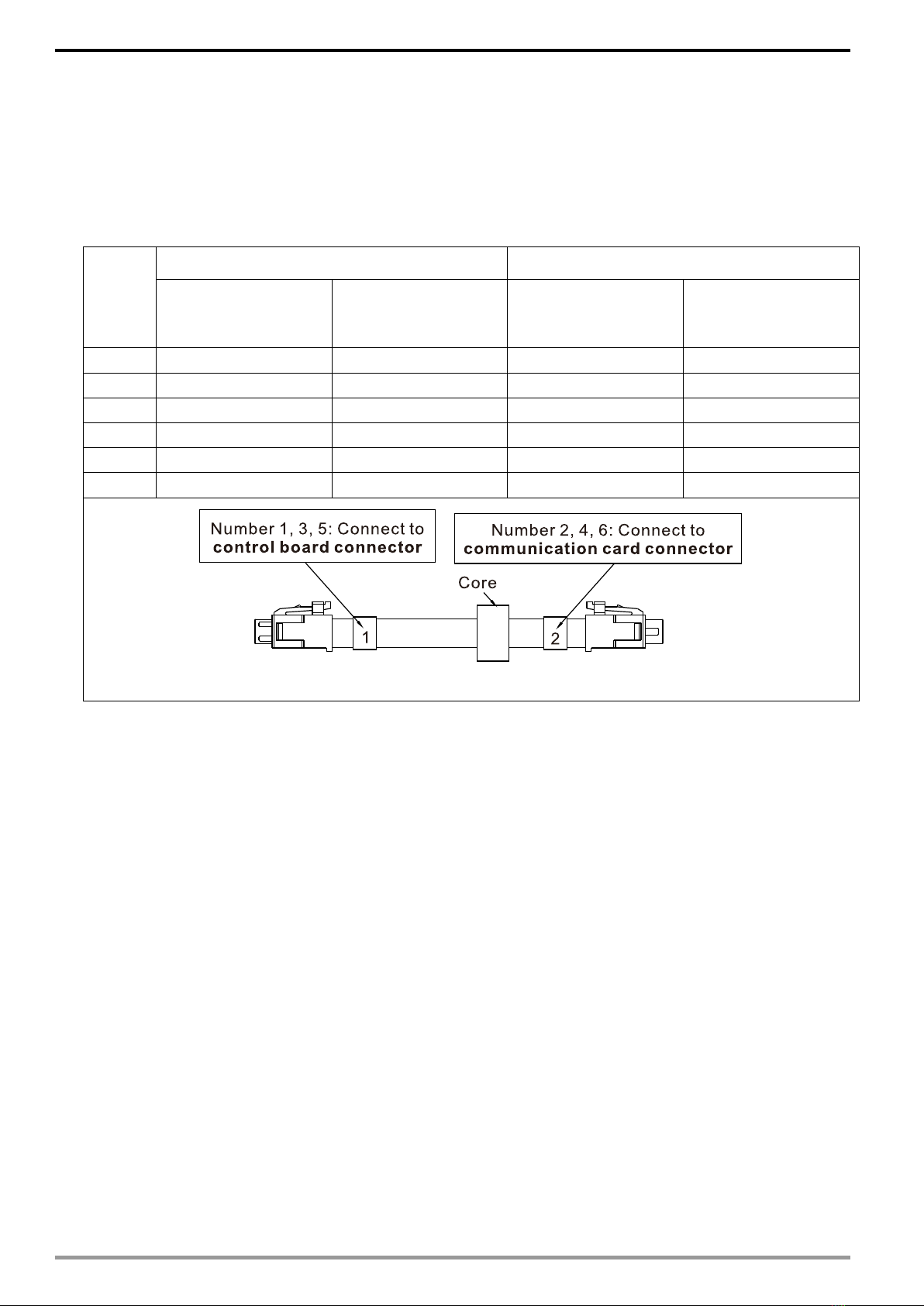

3.2 Communication Cable.......................................................................................................10

3.3 MS300 Installation ............................................................................................................11

3.4 MH300 Installation ............................................................................................................13

3.5 Connecting to the Network................................................................................................16

4MH300/MS300 Drive Settings .........................................................................................17

5PROFINET Communication Profile ................................................................................18

5.1 Profinet comm. card info. (Identification & Maintenance functions (I&M))..........................18

5.2 MS300/MH300 real-time data access method(List of control words and status words) .....19

5.3 Motor Drive Handling when Disconnection........................................................................21

6Connection Configuration to Host Controller...............................................................23

6.1 Basic Configuration...........................................................................................................23

6.2 Speed Mode DEMO (S7-300 + STEP 7) ...........................................................................28

6.3 Speed Mode DEMO (S7-1500 + TIA PORTAL) .................................................................38

6.4 Demonstration of Reading/Writing Synchronous and Asynchronous Parameters

(S7-300 + TIA PORTAL)............................................................................................................48