English- 3

General Specifications

Control System SPWM(Sinusoidal Pulse Width Modulation) control (V/f or sensorless vector

control)

Frequency Setting Resolution 0.01Hz

Output Frequency Resolution 0.01Hz

Torque Characteristics Including the auto-torque/auto-slip compensation; starting torque can be 150%

at 3.0Hz

Overload Endurance 150% of rated current for 1 minute

Skip Frequency Three zones, setting range 0.1-600Hz

Accel/Decel Time 0.1 to 600 seconds (2 Independent settings for Accel/Decel time)

Stall Prevention Level Setting 20 to 250% of rated current

DC Brake Operation frequency 0.1-600.0Hz, output 0-100% rated current

Start time 0-60 seconds, stop time 0-60 seconds

Regenerated Brake Torque Approx. 20% (up to 125% possible with optional brake resistor or externally

mounted brake unit, 1-15hp (0.75-11kW) models have brake chopper built-in)

Control Characteristics

V/f Pattern 4-point adjustable V/f pattern

Keypad Setting by

Frequency

Setting External Signal Potentiometer-5kΩ/0.5W, 0 to +10VDC, 4 to 20mA, RS-485 interface; Multi-

function Inputs 3 to 9 (15 steps, Jog, up/down)

Keypad Set by RUNand STOPOperation

Setting

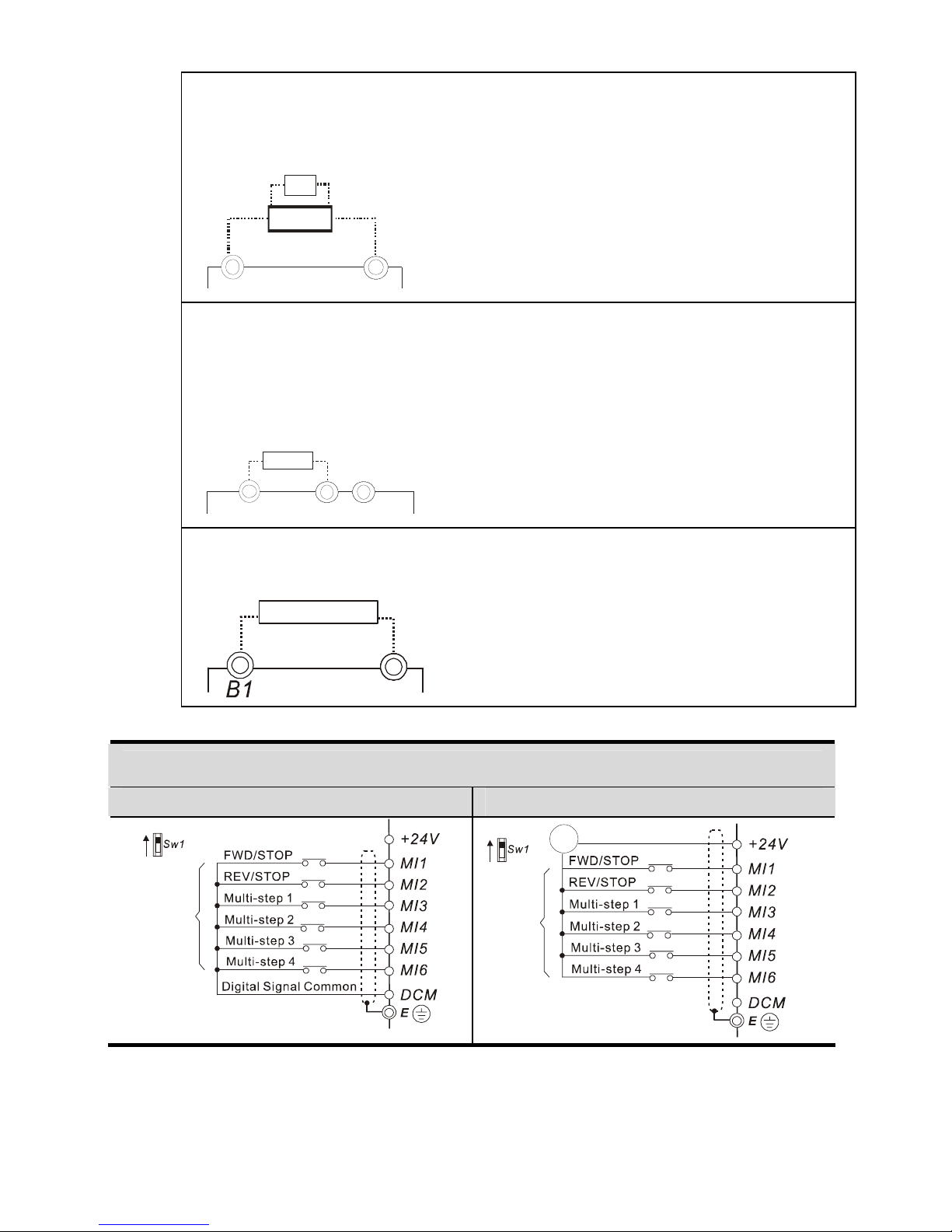

Signal External Signal 2 wires/3 wires ((MI1, MI2, MI3)), JOG operation, RS-485 serial interface

(MODBUS), programmable logic controller

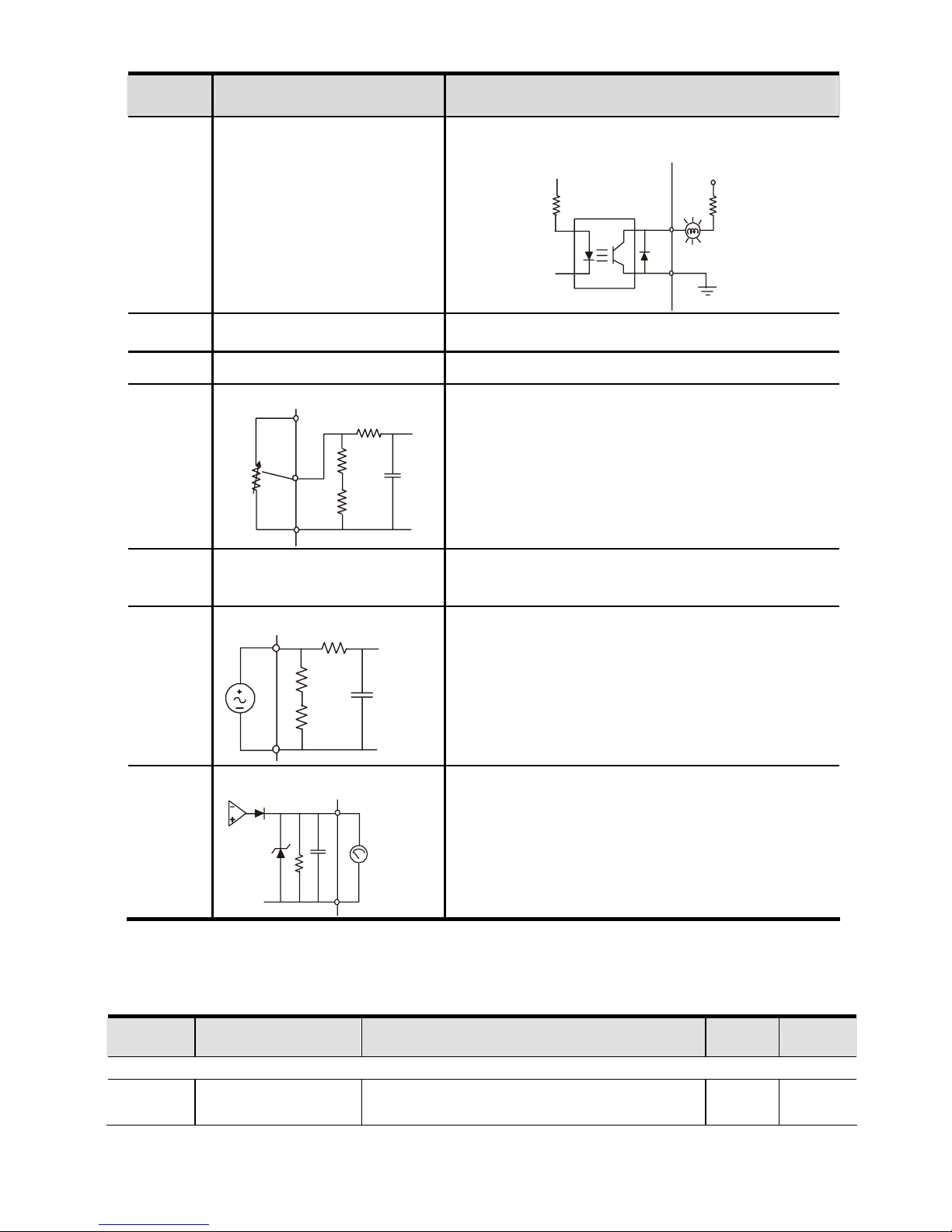

Multi-function Input Signal

Multi-step selection 0 to 15, Jog, accel/decel inhibit, 2 accel/decel switches,

counter, , external Base Block, ACI/AVI selections, driver reset, UP/DOWN key

settings, NPN/PNP input selection

Multi-function Output

Indication

AC drive operating, frequency attained, zero speed, Base Block, fault indication,

overheat alarm, emergency stop and status selections of input terminals

Operating Characteristics

Analog Output Signal Output frequency/current

Alarm Output Contact Contact will be On when drive malfunctions (1 Form C/change-over contact and

1 open collector output) for standard type)

Operation Functions

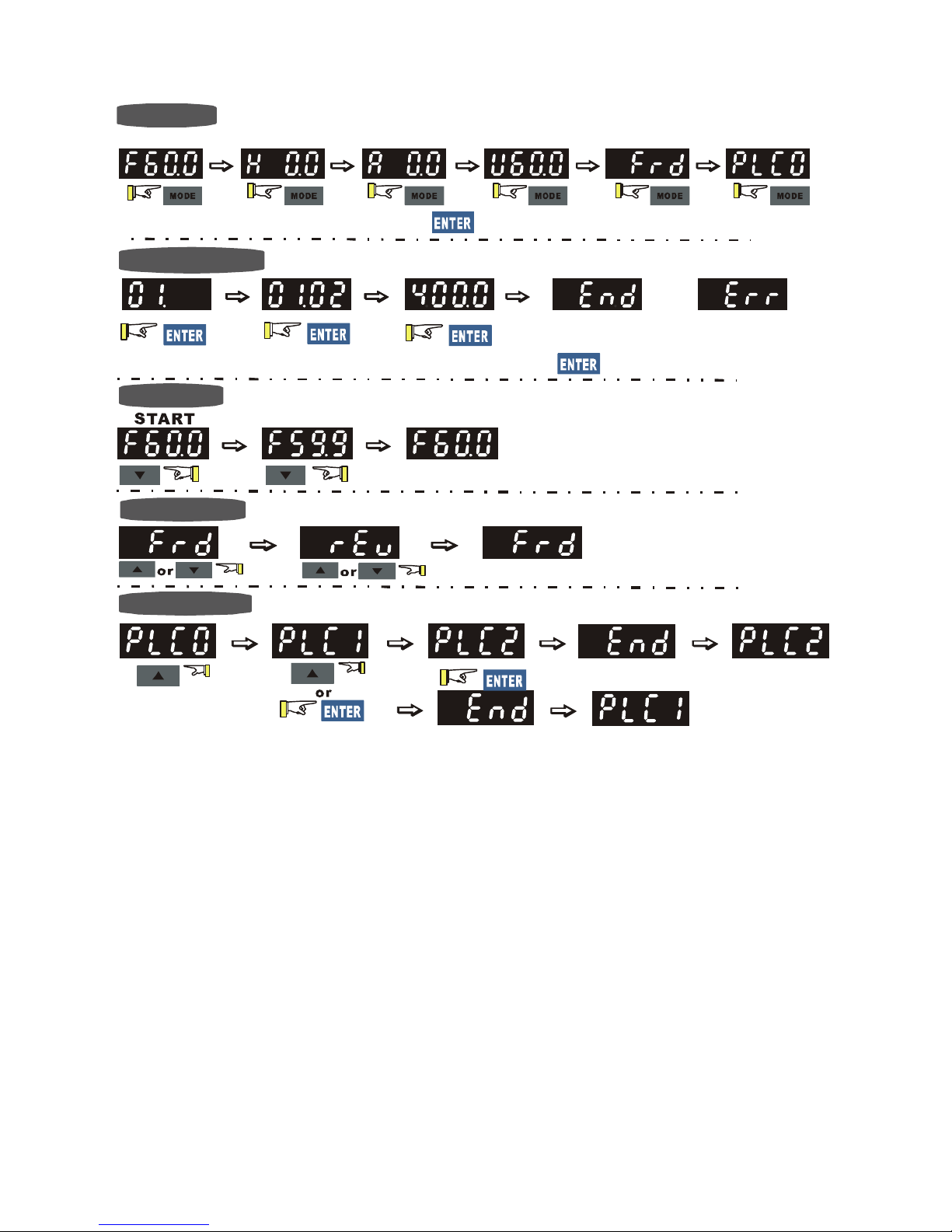

Built-in PLC(NOT for CANopen models), AVR, accel/decel S-Curve, over-

voltage/over-current stall prevention, 5 fault records, reverse inhibition,

momentary power loss restart, DC brake, auto torque/slip compensation, auto

tuning, adjustable carrier frequency, output frequency limits, parameter

lock/reset, vector control, PID control, external counter, MODBUS

communication, abnormal reset, abnormal re-start, power-saving, fan control,

sleep/wake frequency, 1st/2nd frequency source selections, 1st/2nd frequency

source combination, NPN/PNP selection, parameters for motor 0 to motor 3,

DEB and OOB (Out Of Balance Detection)(for washing machine)

Protection Functions Over voltage, over current, under voltage, external fault, overload, ground fault,

overheating, electronic thermal, IGBT short circuit, PTC

Display Keypad (optional)

6-key, 7-segment LED with 4-digit, 5 status LEDs, master frequency, output

frequency, output current, custom units, parameter values for setup and lock,

faults, RUN, STOP, RESET, FWD/REV, PLC

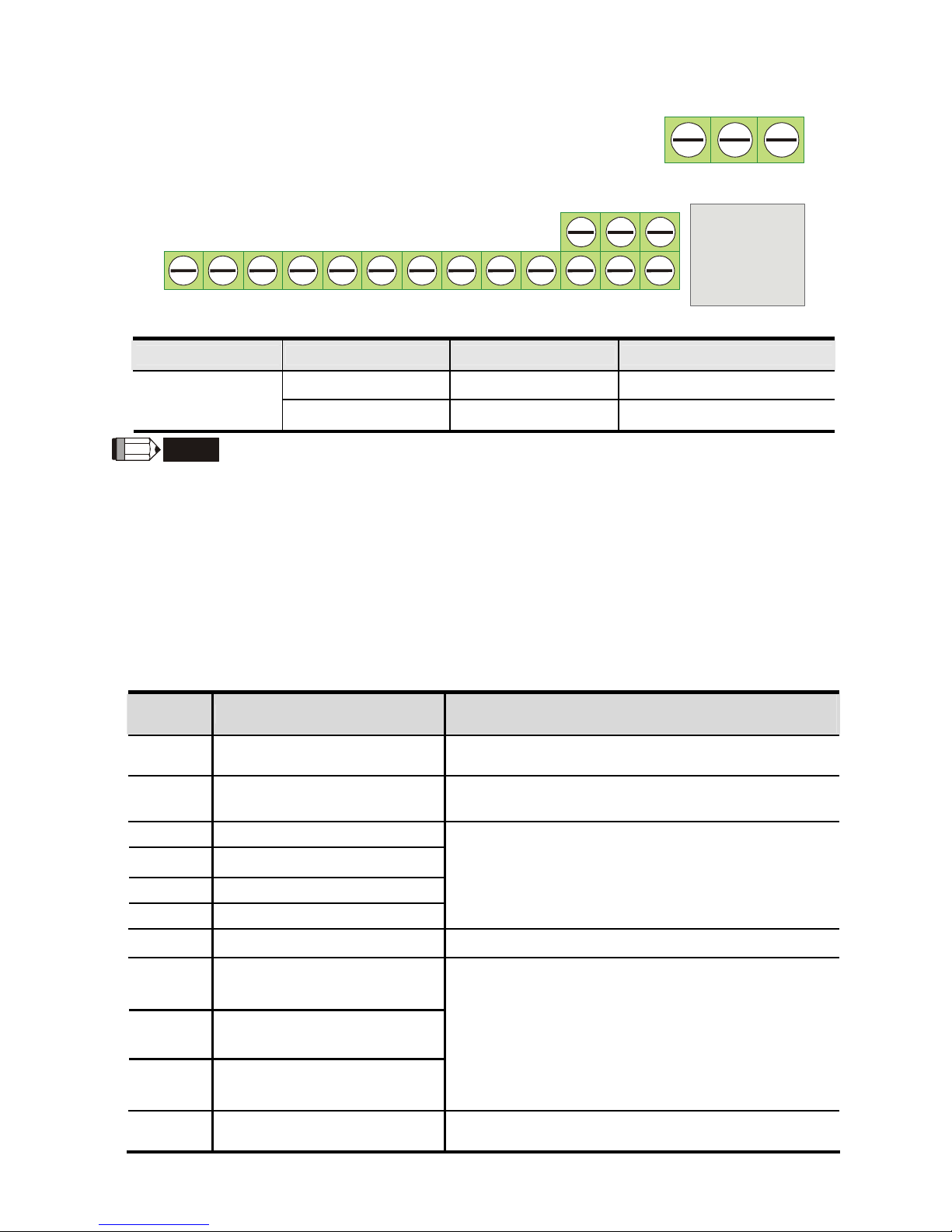

Built-in Brake Chopper

VFD002E11T/21T/23T, VFD004E11T/21T/23T/43T,

VFD007E21T/23T/43T, VFD015E23T/43T, VFD007E11A, VFD015E21A,

VFD022E21A/23A/43A, VFD037E23A/43A VFD007E11C, VFD015E21C,

VFD022E21C/23C/43C, VFD037E23C/43C, VFD055E23A/43A,

VFD075E23A/43A, VFD110E43A, VFD055E23C/43C, VFD075E23C/43C,

VFD110E43C

Built-in EMI Filter For 230V 1-phase and 460V 3-phase models.

Enclosure Rating IP20

Pollution Degree 2

Installation Location Altitude 1,000 m or lower, keep from corrosive gasses, liquid and dust

Enviromental

Conditions

Ambient Temperature -10oC to 50oC (40oC for side-by-side mounting) Non-Condensing and not frozen