0 : No interface

1 : RS-485

Current Transformer

(CT) Function

(Optional)

None : No CT function (Current transformer is not provided)

T : Current transformer is provided (only DTA7272 series

support this function)

Current Transformer (CT) Function

The Current Transformer (CT) function is used with the alarm output. When using a

current transformer (CT) with the controller, change the corresponding alarm output

mode to mode 13 (alarm output set value is 13), then turn to operation mode and set the

current lower-limit and current upper-limit. You can set current alarm range between 0.5A

~ 30A, display resolution is 0.1A and measure accuracy is +/- 0.5A.

Communication Parameters List

Controller offers a RS-485 port for serial communication.

• Supporting transmission speed: 2400, 4800, 9600, 19200, 38400bps

• Communication protocol: Modbus (ASCII)

• Non-supported formats: 7, N, 1 or 8, O, 2 or 8, E, 2

• Available communication address: 1 to 255, 0 is broadcast address

• Function code: 03H to read the contents of register (Max. 3 words).

06H to write 1 (one) word into register.

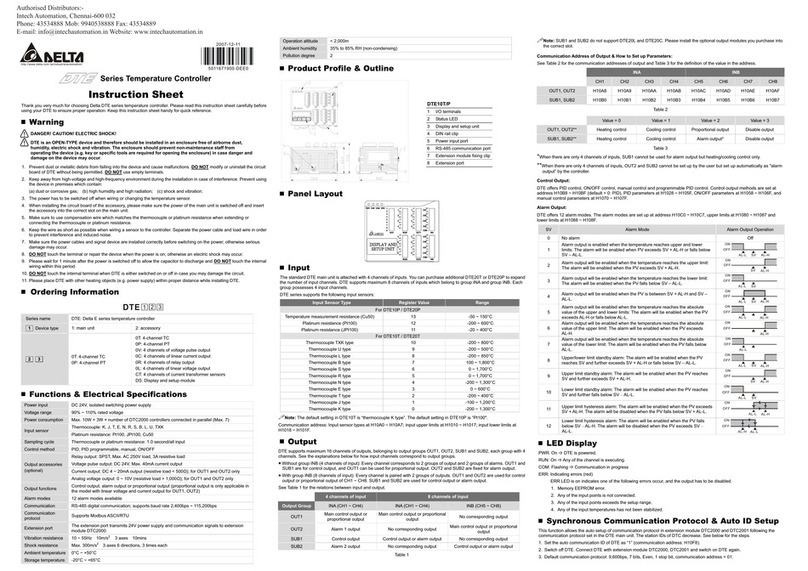

Address Content Explanation

4700H (R) Process value (PV) Measuring unit is 0.1, updated one

time in 0.5 second

4701H Set point (SV) Unit is 0.1, oCor oF

4702H Upper-limit alarm 1

4703H Lower-limit alarm 1

4704H Upper-limit alarm 2

4705H Lower-limit alarm 2

4706H Upper-limit of temperature range The data content should not be

higher than the temperature range

4707H Lower-limit of temperature range The data content should not be

lower than the temperature range

4708H PB Proportional band 0.1 to 999.9, unit is 0.1

4709H Ti Integral time 0 to 9999

470AH Td Derivative time 0 to 9999

470BH Heating/Cooling hysteresis 0 to 9999

470CH~ 470FH Reserved

4710H Input temperature sensor type

Please refer to the contents of the

“Temperature Sensor Type and

Temperature Range” for detail

4711H Control method 0: PID (default), 1: ON/OFF,

2: manual tuning

4712H Heating/Cooling control cycle 1 to 99 second

4713H Proportional control offset error

value 0% to 100%

4714H Temperature regulation value -999~999, unit: 0.1

4715H Alarm 1 type Please refer to the contents of the

“Alarm Outputs” for detail

4716H Alarm 2 type Please refer to the contents of the

“Alarm Outputs” for detail

4717H Temperature unit display selection oC: 1 (default), oF: 0

4718H Heating/Cooling control Selection Heating: 0 (default), Cooling: 1

4719H Control Run/Stop setting Run: 1 (default), Stop:0

471AH Communication write-in selection

Communication write in disabled: 0

(default), Communication write in

enabled: 1

471BH Software version V1.00 indicates 0 x 100

4729H AT Setting OFF: 0 (default), ON:1

Code 0 Normal operation (No error)

Code 1 Initial process

Code 2 Initial status (Temperature is not

stable)

Code 3 Temperature sensor is not

connected

Code 4 Temperature sensor input error

Code 5 Measured temperature value

exceeds the temperature range

Code 6 No Int. error

472BH (R)

Code 7 EEPROM Error

4733H CT monitor value Unit is 0.1A

Note: R means “read only” value

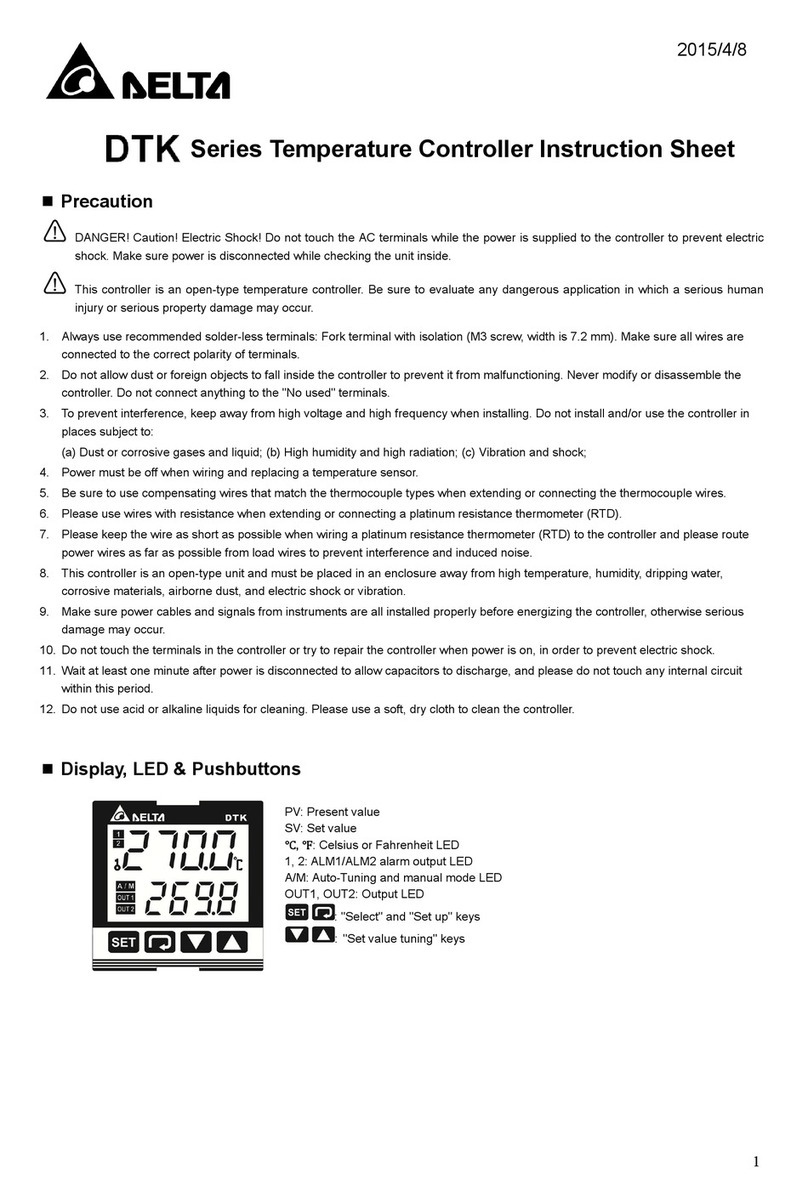

Alarm Outputs

There are up to two groups of alarm outputs and each group allows ten alarm types in

the initial setting mode. The alarm output is activated whenever the process temperature

value (PV) is getting higher or lower than the set point of alarm limit.

Set

Value Alarm Type Alarm Output Operation

0 Alarm function disabled Output OFF

1

Deviation upper- and lower-limit:

This alarm output operates when PV value is

higher than the setting value SV+(AL-H) or lower

than the setting value SV-(AL-L).

ON

OFF

SV-(AL-L) SV SV+(AL-H)

2

Deviation upper-limit:

This alarm output operates when PV value is

higher than the setting value SV+(AL-H).

ON

OFF

SV SV+(AL-H)

3

Deviation lower-limit:

This alarm output operates when PV value is

lower than the setting value SV-(AL-L).

ON

OFF

SV

SV-(AL-L)

4

Reverse deviation upper- and lower-limit:

This alarm output operates when PV value is in

the range of the setting value SV+(AL-H) and SV-

(AL-L).

ON

OFF

SV

SV-(AL-L) SV+(AL-H)

5

Absolute value upper- and lower-limit:

This alarm output operates when PV value is

higher than the setting value AL-H or lower than

setting value AL-L.

ON

OFF

AL-L AL-H

6

Absolute value upper-limit:

This alarm output operates when PV value is

higher than the setting value AL-H.

ON

OFF

AL-H

7

Absolute value lower-limit:

This alarm output operates when PV value is

lower than the setting value AL-L.

ON

OFF

AL-L

8

Deviation upper- and lower-limit with standby

sequence:

This alarm output operates when PV value

reaches set value (SV value) and the value is

higher than the setting value SV+(AL-H) or lower

than the setting value SV-(AL-L).

ON

OFF

SV

SV-(AL-L) SV+(AL-H)

9

Deviation upper-limit with standby sequence:

This alarm output operates when PV value

reaches set value (SV value) and the reached

value is higher than the setting value SV+(AL-H).

SV+(AL-H)

ON

OFF

SV

10

Deviation lower-limit with standby sequence:

This alarm output operates when PV value

reaches the set value (SV value) and the reached

value is lower than the setting value SV-(AL-L).

SV-(AL-L)

ON

OFF

SV

11

Hysteresis upper limit alarm output: this alarm

output operates if PV value is higher than the

setting value SV+(AL-H). This alarm output is

OFF when PV value is lower than the setting

value SV+(AL-L).

ON

OFF

AL-L

SV AL-H

12

Hysteresis lower limit alarm output: this alarm

output operates if PV value is lower than the

setting value SV-(AL-H). This alarm output is

OFF when PV value is higher than the setting

value SV-(AL-L).

ON

OFF

AL-H AL-L SV

13

CT alarm output:

This alarm operates when the current measured

by transformer (CT) is lower than AL-L or higher

than AL-H (This alarm output is available only for

the controller with current transformer).

ON

OFF

AL-L SV AL-H

Note: AL-H and AL-L include AL1H, AL2H and AL1L, AL2L.

With standby sequence: It means that the alarm output would be temporarily disabled

until the PV value reaches the set value. Then, the alarm output will operate.

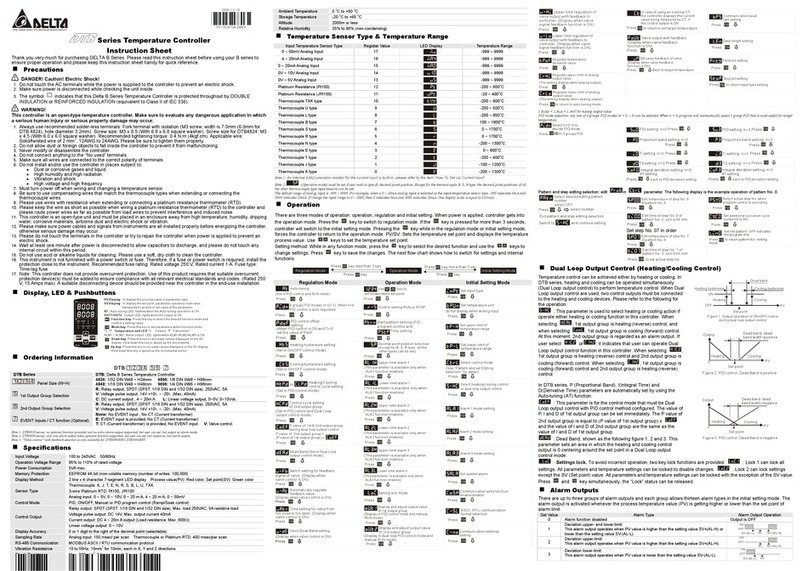

Communication Protocol

Command code to read N words: 03H. The maximum value of N is 3.

For example, in order to read two words from controller 01 (address 01H) at starting data

address 4700H, the command in ASCII mode is:

ASCII mode:

Command message: Response message:

STX ‘:’ STX ‘:’

‘0’ ‘0’ADR1

ADR0 ‘1’

ADR1

ADR0 ‘1’

‘0’ ‘0’CMD1

CMD0 ‘3’

CMD1

CMD0 ‘3’

‘4’ ‘0’

‘7’

Number of data

(count by byte) ‘4’

‘0’ ‘0’

Starting data address

‘0’ ‘1’

‘0’ ‘9’

‘0’

Content of start address

4700H

‘0’

‘0’ ‘0’

Number of data (count

by word)

‘2’ ‘0’

‘B’ ‘0’LRC CHK 1

LRC CHK 0 ‘3’

Content of start address

4701H

‘0’

CR ‘6’END 1

END 0 LF

LRC CHK 1

LRC CHK 0 ‘7’

CR

END 1

END 0 LF

LRC check:

LRC check is the added sum from “Address” to “Data content”. For example, 01H + 03H + 47H

+ 00H + 00H + 02H = 4DH, then take the complementary of 2, B3H.

Command code to write 1 word: 06H

For example, in order to write 1000 (03E8H) in controller 01 (comm. address 01H) at the

starting data address 4701H, the command in ASCII mode is:

ASCII mode:

Command message: Response message:

STX ‘:’ STX ‘:’

‘0’ ‘0’ADR1

ADR0 ‘1’

ADR1

ADR0 ‘1’

‘0’ ‘0’CMD1

CMD0 ‘6’

CMD1

CMD0 ‘6’

‘4’ ‘4’

‘7’ ‘7’

‘0’ ‘0’

Starting data address

‘1’

Starting data address

‘1’

‘0’ ‘0’

‘3’ ‘3’

Data content

‘E’

Data content

‘E’

‘8’ ‘8’

‘C’ ‘C’LRC CHK 1

LRC CHK 0 ‘6’

LRC CHK 1

LRC CHK 0 ‘6’

CR CREND 1

END 0 LF

END 1

END 0 LF

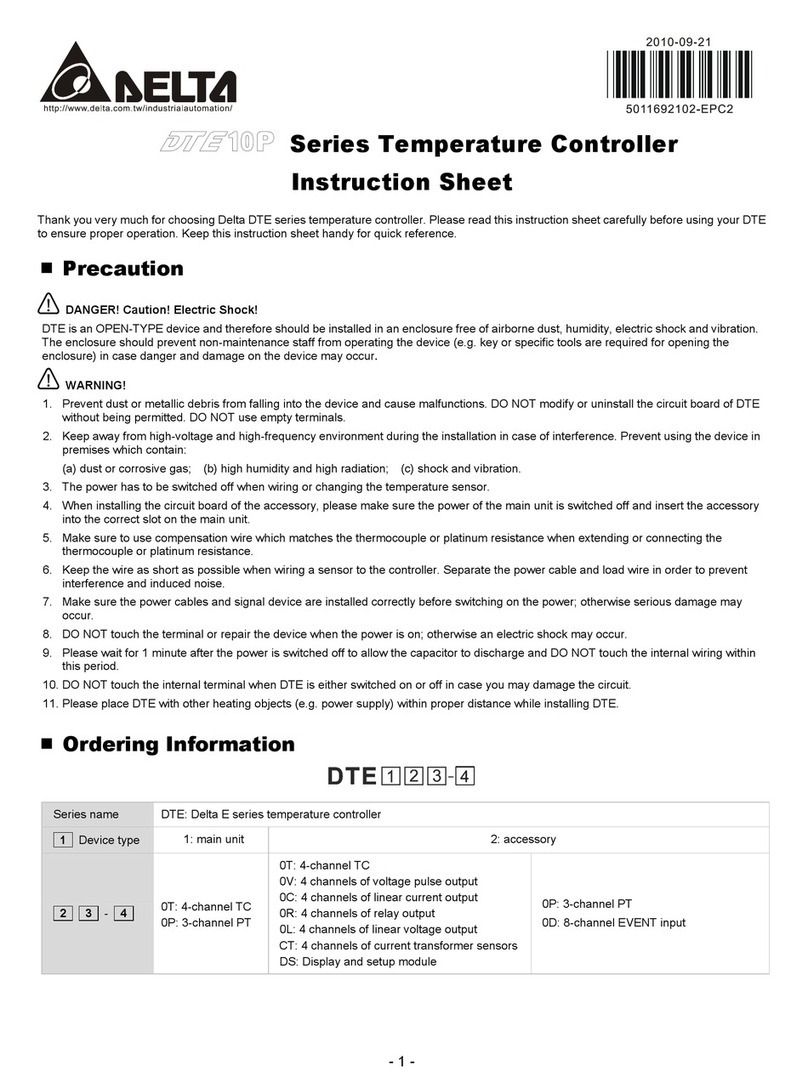

Panel Cutout & External Dimensions

1. Panel wall thickness should range from 1mm to 8mm

2. Provide at least 90 mm clearance around the controller for proper ventilation.

(Dimensions are in millimeter and (inch))

DTA 4848

DTA 4896

DTA9648

DTA7272

DTA9696

Terminals Identification

DTA4848

1

2

5

6

8

7

4

3

9

12

13

14

15

11

10

DC 4~20mA

5A 250Vac

RTD

Tc

14Vdc