1

Chapter 1 Important Safety Instruction

Chapter 1 : Important Safety Instructions

1.1. Safety Precautions

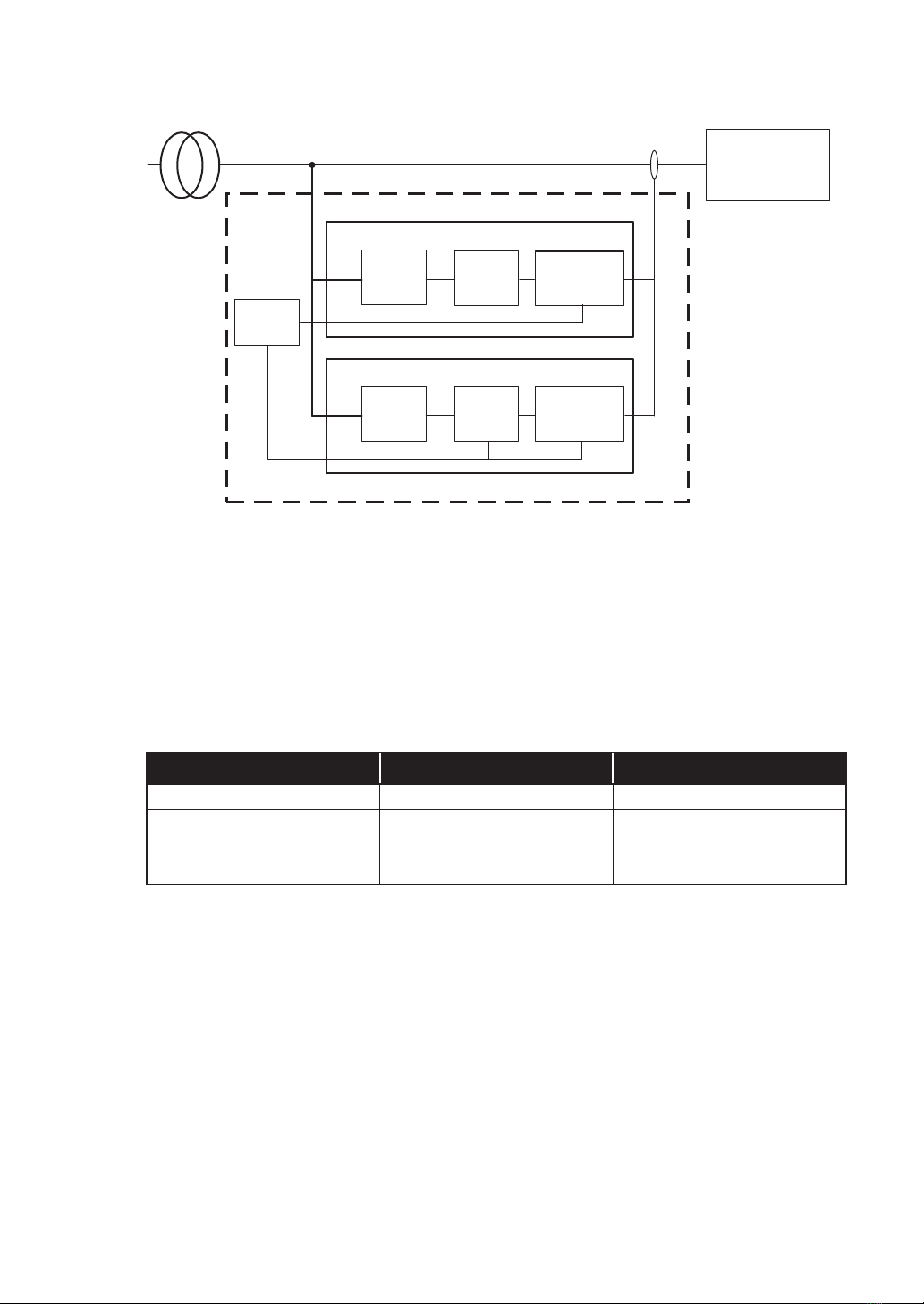

yy The active power lter (‘APF’) shall be connected with a power grid system and in parallel

with harmonic sources (i.e. nonlinear loads) as a means to control harmonics.

yy The APF shall not be exposed to rain or wet conditions, and shall be away from any am-

mable uid, gas or explosives.

yyAdequate space shall be left at the top and bottom of the APF for well ventilation and con-

venient maintenance.

yy To minimize re and electric shock hazards, installation must be conducted by qualied

service personnel in a controllable working environment.

yy To minimize electric shock hazards, all maintenance work must be carried out by qualied

technician. Before maintenance, ensure that all power supply is completely cut off.

yyHigh voltage hazards! It takes over 15 minutes for the DC capacitor to discharge. Please

make sure the device has discharged completely before carrying out any operation.

yyTo minimize electric shock hazards, please read this Manual carefully before switching

the power on, and keep this Manual properly for permanent reference.

yyWhen the APF is used in IT applications, please install an insulation resistance detection

device so that the alarm will go off when a protection earth fault is detected.

1.2. Wiring Warnings

yyTo prevent a possible risk of current leakage, the APF shall be earthed properly.

yyWith regard to wiring, the compensation capacity and the current-carrying capacities of

cables shall be taken into account.

yyThe incoming lines of the APF shall be connected with appropriate protective devices. It is

recommended to provide every module with an over-current protective device with a third-

party certication: rated voltage 400V and rated current 125A. Besides, take the installa-

tion position of the equipment into consideration and choose the protective devices with

adequate breaking capacity.

yy The capacity of the protective device shall t that of the APF.

yyTo prevent scaling caused by high temperature, after the power is cut off, the operating

switch shall be allowed to cool down before being operated again.

yyThe three-phase, four-wire APF is applicable to the power grid system with neutral

grounding.