7

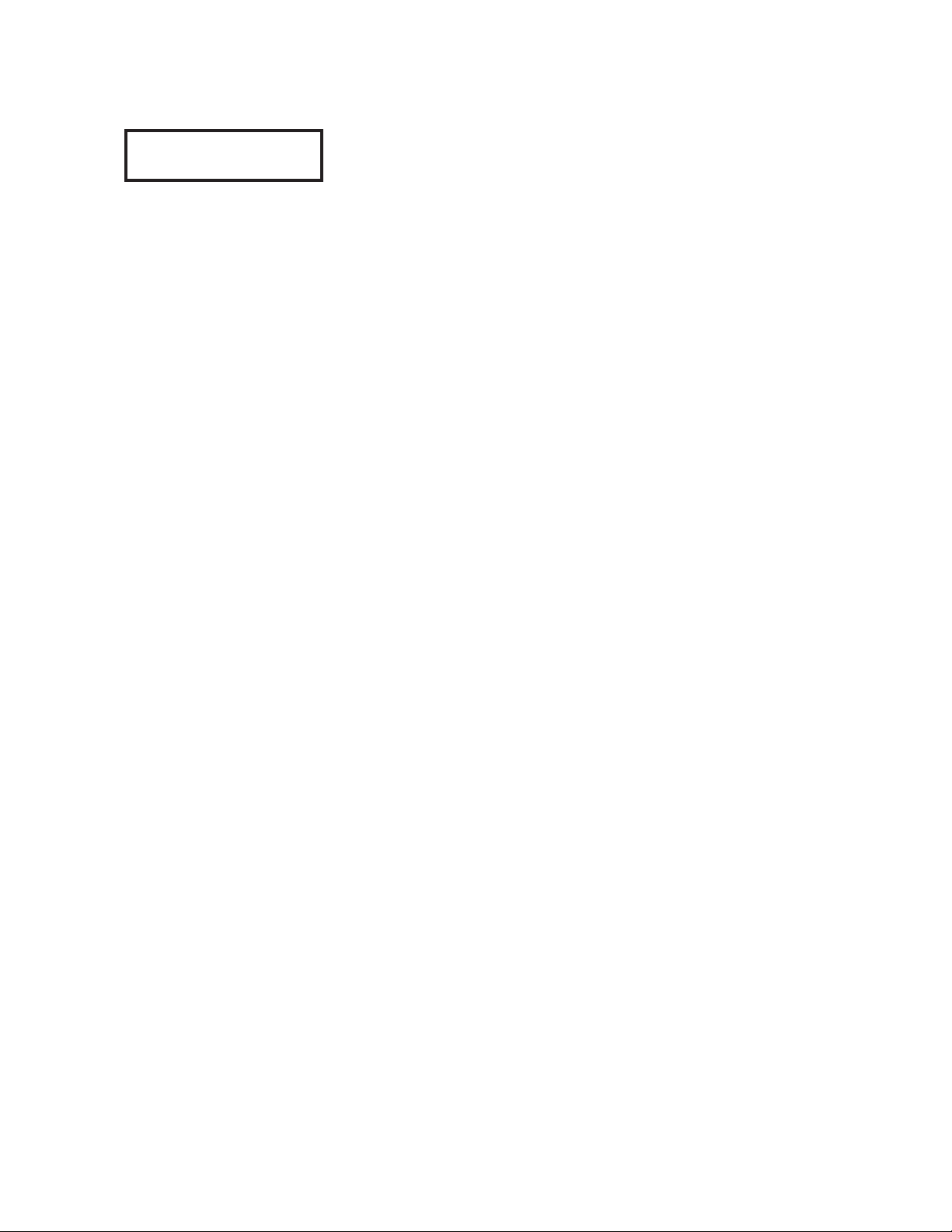

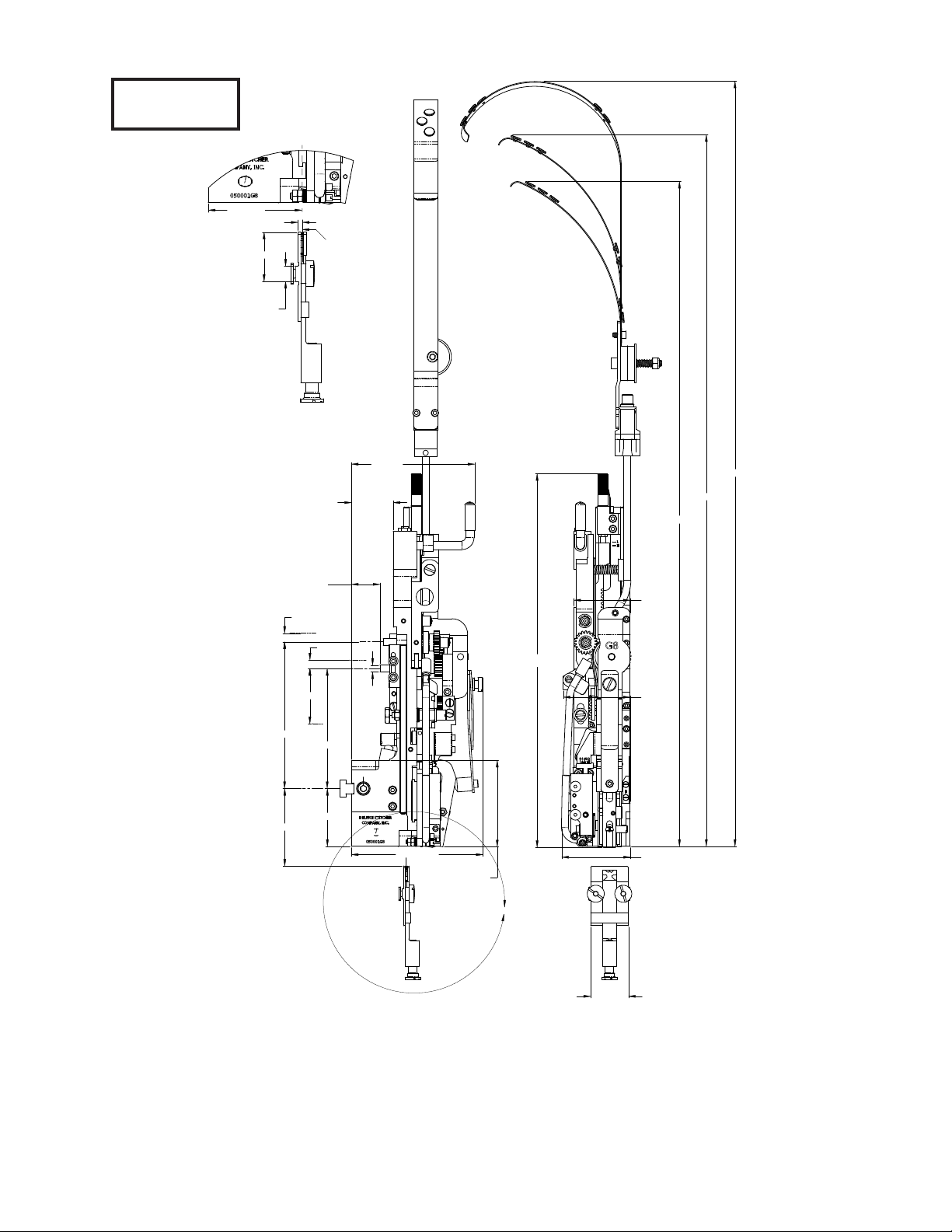

The part number for each Stitcher Head can be used to define the stitcher head itself, in most

cases. The Head’s model type, mounting style, nominal wire size and crown size can all be

determined from the part number.

G8 P HD 24 A 1/2

1/2 = Crown size in inches

A = Mount and Wire Guide Spring Type

24 = Wire Size

HD = Head

P = Original Equipment Manufacturer

G8 = Model type

Part Number Definition

Typical Style Uses:

G8BHD ............................................................. No. 2 and M2 Wire Stitchers

G8MHD .......................................................... No. 17 and M17 Wire Stitchers

G8HD .................................................................Automatic Saddle-Stitchers,

................................................................ Gang-Stitchers, Multibinders and Others

Examples of Replacement Heads for OEM Users*:

AM Graphics / Harris / Heidelberg / Sheridan 455, 562, 690............ G8HD24A

AM Graphics / Harris / Heidelberg / Sheridan 705 ............................ G8HD24A

C.P. Bourg ............................................................................................... G8HD24D

Christensen .............................................................................................. G8HD24A

Horizon SP, SPF ...................................................................................... G8HD24D

Macey Multibinder ................................................................................ G8HD24B

McCain .................................................................................................... G8HD24A

Rosback ................................................................................................... G8HD24B

Boewe 4601 .............................................................................................. G8BOHD241/2

McCain / OmegaBinder.......................................................................... G8HD23A

Harris 855 ................................................................................................ G8HD24-HARRIS

McCain / Sheridan / Harris / Bielomatik, ECH Will \ et.al................ G8HDC24A

Heidelberg ST100, ST270, ST300, ST350............................................. G8HEHD241/2

JMZ&A (Parker) .................................................................................... G8PKHD241/2

Watkiss .................................................................................................... G8WAHD241/2

* These are just a few examples of the replacement heads available for these OEM’s.

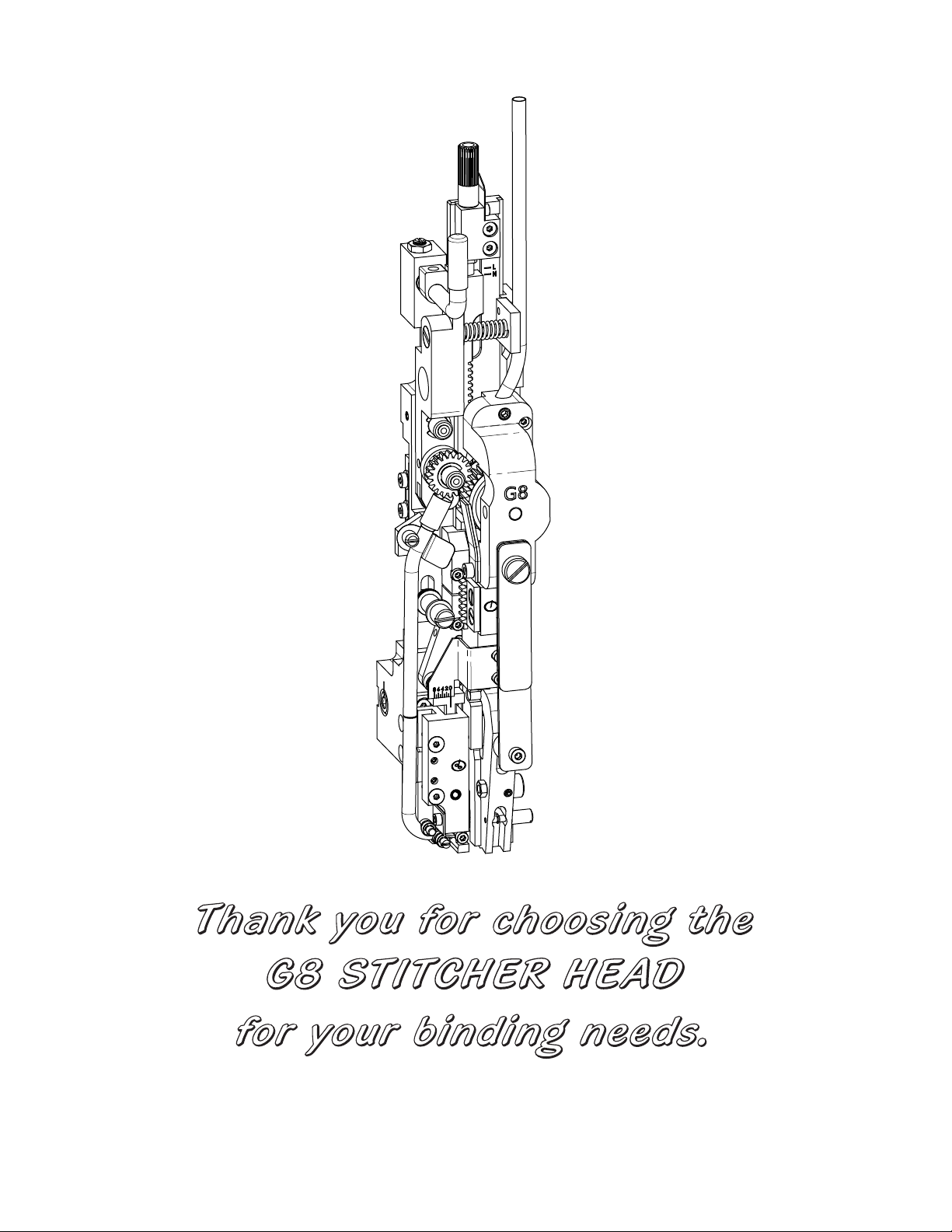

Introduction