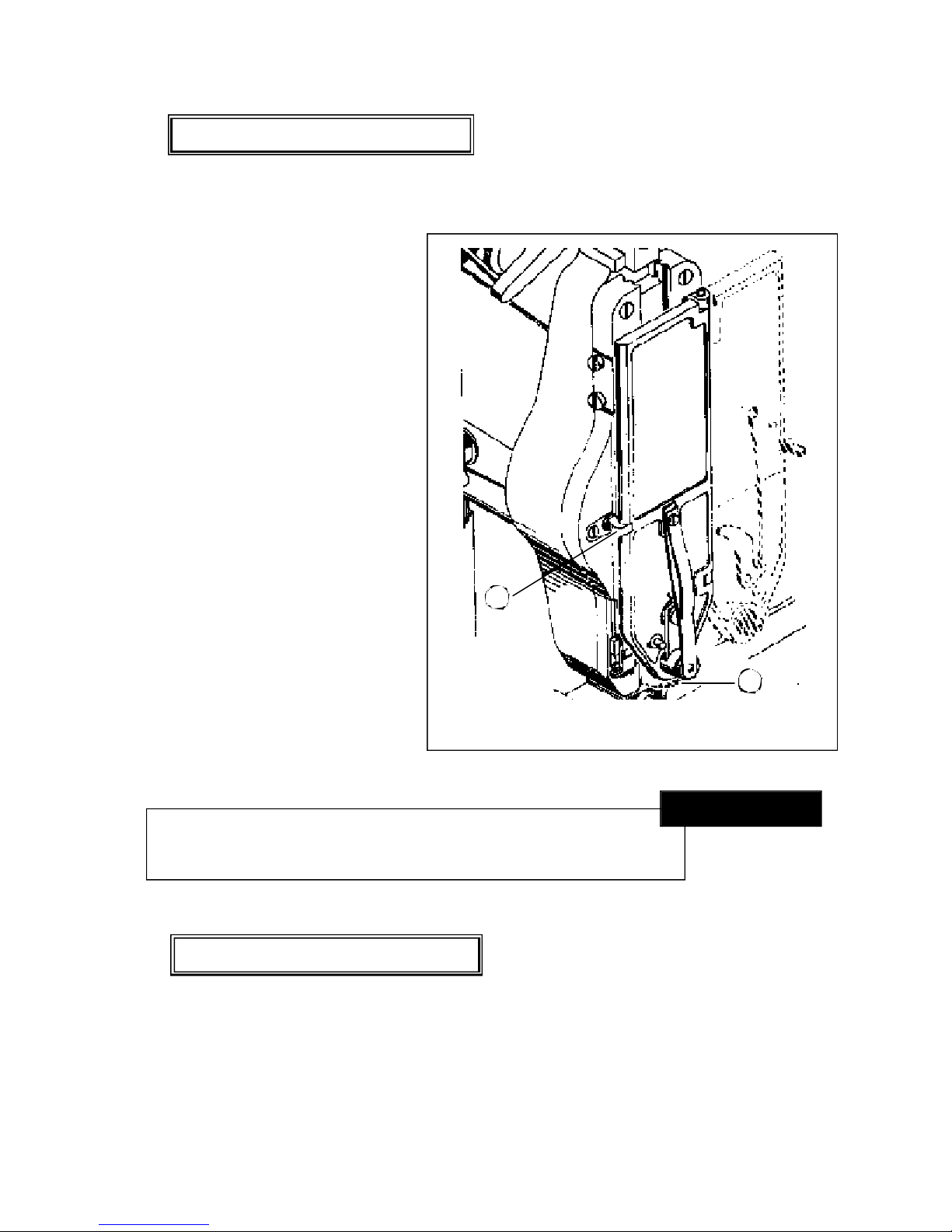

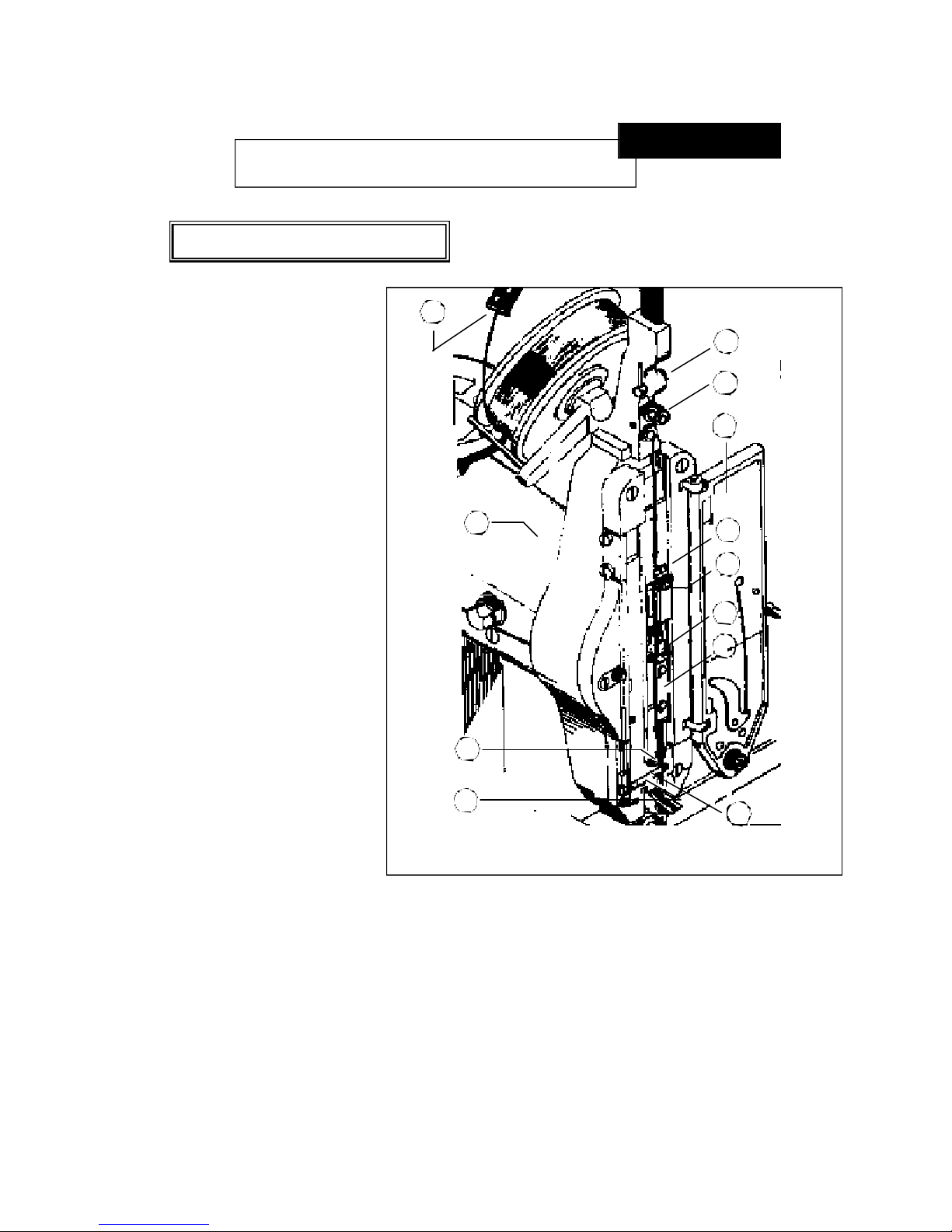

Open the Stitcher Head Door (1).

Pass the wire from the Spool over

the Wire Guide Spring (2),

threading the wire between the

Guide Studs on the Guide Spring

and through the Oiler Felt in the

Retainer (not shown). Thread the

wire between the Rolls of the two

sets of Wire Straighteners (3) and

(4). Pass the end of the wire behind

the Wire Clip (5) and then pull the

wire down until it extends to just

below the Wire Cutter Holder (6).

Push the Wire Holder Slide (7) to

the left. With the Slide held in this

position, lay the wire well back in

the slot (8) in the Wire Cutter Holder

then release the Slide (7) allowing it

to close over and retain the wire in

the slot (8). Slide the Wire Retainer

(9) up, thereby uncovering the

groove in the Wire Guide (10). Lay

the wire in the groove and then slide

the Retainer (9) down securing the

wire in the groove. Turn the

machine over manually until the

wire

automatically falls in place between

the Moveable and Fixed Grips (11) and (12).

The wire is now threaded in the Head. However, before operating the Stitcher under power, turn the

machine over manually a few revolutions and observe that the wire is feeding freely and is being

cut off by the Cutters in the Cutter Holder. Then close the stitcher head door and check that the wire

is feeding in a straight vertical line, as directed in the following paragraph.

8

Wire Threading (Figure 5)

Always disconnect the power supply before

making any adjustments or servicing the stitcher.

rWARNING

!

Figure 5 - Wire Threading

1

4

3

2

5

11

8

76

10

9

12